Dans un secteur du recyclage en pleine expansion, le choix d'une machine de recyclage adaptée est crucial pour traiter efficacement les déchets plastiques. Que vous travailliez dans le recyclage du plastique, la gestion des déchets ou la fabrication, disposer d'un équipement adapté améliore non seulement l'efficacité opérationnelle, mais contribue également à la réalisation des objectifs de développement durable. Cet article propose un guide complet pour aider les acheteurs d'équipements industriels, les ingénieurs et le personnel technique à choisir la machine de recyclage idéale en fonction du type et du volume de déchets plastiques à traiter.

Comprendre les types de déchets plastiques

Avant de choisir votre machine, il est essentiel de comprendre les types de déchets plastiques que vous traitez. Chaque plastique possède des propriétés spécifiques qui influencent son traitement. Voici une liste des types de plastiques courants et de leurs critères de recyclage :

- Polyéthylène (PE) et polypropylène (PP)Ces plastiques sont courants dans les matériaux d'emballage tels que les bouteilles, les sacs et les contenants. Ce sont des thermoplastiques, ce qui signifie qu'ils peuvent être chauffés, remodelés et recyclés plusieurs fois.

- Chlorure de polyvinyle (PVC): Présent dans les tuyaux, les revêtements de sol et les produits médicaux, le PVC est plus rigide et nécessite des machines spécialisées capables de gérer ses propriétés uniques.

- Polyéthylène téréphtalate (PET):Largement utilisé dans les bouteilles et les conteneurs, le PET est hautement recyclable mais nécessite souvent un nettoyage en profondeur pour éliminer les contaminants.

- Polystyrène (PS):Utilisé dans les emballages et les produits jetables, le PS est léger mais peut être difficile à recycler en raison de sa fragilité et de sa tendance à se briser en petits morceaux.

- Plastiques mixtes:Les entreprises sont souvent confrontées à des déchets plastiques mixtes. Cela nécessite des machines capables de traiter plusieurs types de plastique, généralement grâce à une combinaison de systèmes de broyage, de lavage et de tri.

Facteurs clés à prendre en compte lors du choix d'un Machine de recyclage

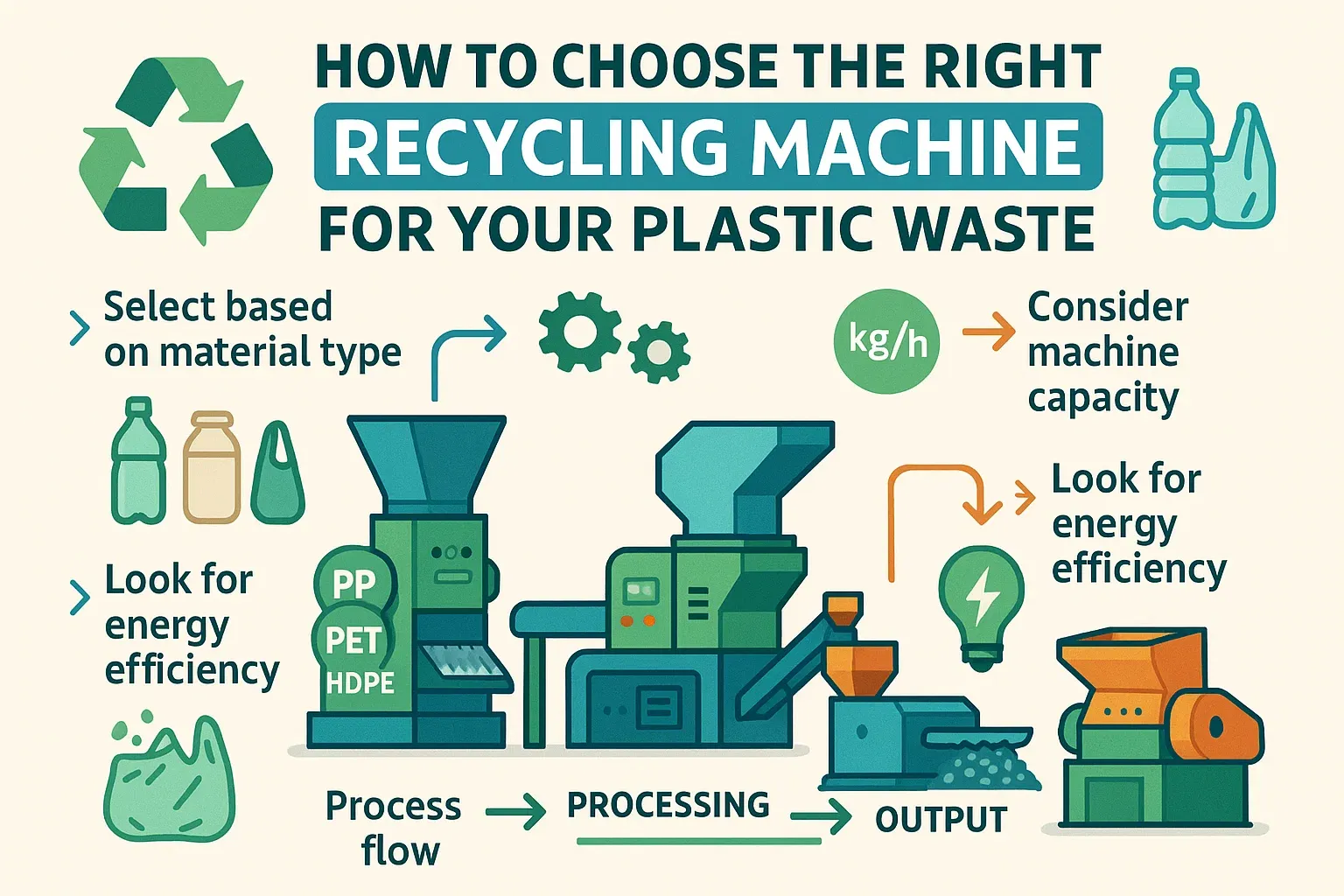

Choisir la bonne machine implique d'évaluer plusieurs facteurs clés en fonction de vos besoins. Examinons les aspects les plus importants à prendre en compte :

1. Type et composition des déchets plastiques

La composition de vos déchets plastiques déterminera le type de machine de recyclage dont vous aurez besoin. Par exemple :

- Plastiques monomatières (comme le PET ou le PEHD) peuvent être traités plus efficacement avec un broyeur ou un granulateur dédié.

- Plastiques mixtes nécessitent un système de recyclage polyvalent capable de trier, de déchiqueter et de laver les matériaux simultanément.

2. Capacité de traitement

La capacité de traitement de la machine doit être adaptée au volume de déchets plastiques que vous traitez. La capacité de traitement des machines varie généralement, allant des systèmes à petite échelle, par lots (idéals pour les faibles volumes), aux machines à grande échelle, à flux continu, adaptées aux volumes plus importants.

3. Efficacité de la machine

Les machines de recyclage varient en termes de consommation d'énergie, de vitesse et de rendement. Évaluez l'efficacité des machines pour vous assurer qu'elles répondent à vos besoins de production sans engendrer de coûts d'exploitation excessifs.

4. Automatisation et intégration

Les fonctions d'automatisation sont de plus en plus importantes pour réduire les coûts de main-d'œuvre et minimiser les erreurs humaines. Les machines intégrables à d'autres systèmes, tels que les unités de tri et de lavage, contribuent à rationaliser le processus de recyclage. Assurez-vous que la machine que vous choisissez offre des options d'automatisation adaptées aux besoins de votre usine.

5. Entretien et durabilité

La fiabilité et la facilité d'entretien d'une machine sont des facteurs clés pour sa performance à long terme. Des machines difficiles à entretenir peuvent entraîner des temps d'arrêt coûteux. Optez pour des équipements conçus pour durer et dotés de fonctionnalités simplifiant la maintenance, comme l'accès sans outil ou des composants modulaires.

Types de machines de recyclage des déchets plastiques

Maintenant que nous comprenons les facteurs qui influencent le choix des machines, explorons les différents types de machines couramment utilisées dans le recyclage du plastique.

1. Broyeurs de plastique

Les broyeurs comptent parmi les machines les plus couramment utilisées pour le traitement des déchets plastiques. Ils découpent le plastique en morceaux plus petits, plus faciles à manipuler et à traiter lors des étapes ultérieures du recyclage.

- Convient pour:Objets en plastique de grande taille, emballages et autres articles qui doivent être décomposés.

- Caractéristiques principales: Modèles à double arbre ou à arbre unique, réglages de lame variables, rendement élevé.

2. Granulateurs de plastique

Les granulateurs sont similaires aux broyeurs, mais sont plus spécialisés dans la réduction du plastique en granulés plus petits et uniformes. Ils sont particulièrement utiles pour les plastiques devant être retraités ou pour préparer les matériaux à l'extrusion.

- Convient pour: Bouteilles en PET, films et autres produits en plastique rigide.

- Caractéristiques principales:Granulométrie variable, fonctionnement économe en énergie.

3. Extrudeuses

Les extrudeuses servent à fondre et à façonner le plastique en nouvelles formes ou granulés. Il s'agit d'une machine essentielle à la création de nouveaux produits plastiques à partir de matériaux recyclés. Elles sont couramment utilisées lors de la dernière étape du recyclage, après le déchiquetage et la granulation du plastique.

- Convient pour:Déchets plastiques à grand volume, produisant des granulés destinés à être réintégrés dans les processus de fabrication.

- Caractéristiques principales:Températures élevées pour la fusion, systèmes d'alimentation à vis et têtes de filière pour la granulation.

4. Systèmes de lavage

Les déchets plastiques contiennent souvent des contaminants tels que des étiquettes, de la saleté ou des huiles. Les systèmes de lavage éliminent ces impuretés pour garantir la qualité du plastique recyclé.

- Convient pour: PET, PEHD et autres plastiques nécessitant un nettoyage en profondeur avant réutilisation.

- Caractéristiques principales:Nettoyeurs haute pression, réservoirs de flottaison et systèmes de séchage.

5. Trieurs et séparateurs

Pour les déchets plastiques mixtes, les trieurs et séparateurs permettent de distinguer les différents types de plastique, améliorant ainsi l'efficacité du processus de recyclage. Ces machines utilisent l'air ou des moyens mécaniques pour séparer les matériaux en fonction de leur densité ou de leur taille.

- Convient pour: Plastiques mixtes, garantissant que les différents types de plastique sont séparés pour un recyclage efficace.

- Caractéristiques principales: Séparateurs en zigzag, classificateurs à air, séparateurs magnétiques.

Comparaison des performances : sélection de machines pour différents types de déchets plastiques

| Type de plastique | Machine appropriée | Caractéristiques principales | Capacité | Efficacité |

|---|---|---|---|---|

| Bouteilles en PET | Broyeur, granulateur, extrudeuse | Matériau propre, rendement élevé, bon écoulement à l'état fondu | 500-3000 kg/h | Haut |

| Conteneurs en PEHD | Broyeur, granulateur, laveur | Nettoyage efficace, granulés uniformes | 500-1500 kg/h | Haut |

| Plastiques mixtes | Déchiqueteuse, trieuse, laveuse | Tri et lavage polyvalents en plusieurs étapes | 500-2000 kg/h | Moyen |

| tuyaux en PVC | Broyeur, granulateur, laveur | Découpe haute puissance et précision pour plastiques rigides | 300-100 kg/h | Moyen |

Conclusion : Choisir la bonne machine de recyclage pour vos déchets plastiques

Choisir le bon machine de recyclage Cela dépend du type de déchets plastiques traités, de la capacité de la machine et de l'efficacité requise pour vos opérations. En prenant en compte des facteurs tels que la composition du plastique, l'automatisation de la machine et la durabilité, vous pouvez garantir une efficacité maximale à votre entreprise tout en maintenant des résultats de recyclage de haute qualité.

À mesure que les technologies de recyclage évoluent, il est important de se tenir informé des dernières innovations susceptibles d'optimiser vos processus de recyclage du plastique. Avec le bon équipement, vous pouvez transformer les déchets en ressources précieuses et contribuer ainsi à un environnement de production plus durable.

Vous recherchez la bonne machine de recyclage ?

Si vous avez besoin d'aide supplémentaire pour sélectionner la meilleure machine de recyclage pour votre exploitation, n'hésitez pas à contacter des experts du domaine qui peuvent vous fournir des conseils et une assistance personnalisés pour vos besoins de recyclage spécifiques.