Granulateur de bouteilles PET à haute efficacité

Conçu spécifiquement pour le recyclage des bouteilles en PET, transformant efficacement les déchets plastiques en produits broyés purs de grande valeur.

Obtenez un devis personnaliséPourquoi choisir un granulateur PET dédié ?

Les granulateurs standards rencontrent des difficultés avec les propriétés uniques des bouteilles en PET. Notre conception spécialisée surmonte ces difficultés et offre un retour sur investissement supérieur.

Granulateur de bouteilles en PET (le nôtre)

-

Conception spécialisée de rotors et de pales L'angle de coupe en V optimisé traite facilement les bouteilles en PET résistantes, garantissant des flocons uniformes avec un minimum de poussière.

-

Système de gavage Empêche efficacement le « pontage » des bouteilles légères et volumineuses dans la trémie, garantissant une production continue et efficace.

-

Décharge pneumatique et dépoussiérage Extrait rapidement les flocons de PET légers tout en séparant les étiquettes en papier et la poussière, garantissant la pureté du produit final.

Granulateur de plastique standard

-

Lames à usage général Les lames s'usent rapidement et génèrent une chaleur et une poussière excessives lors du traitement du PET, dégradant ainsi la qualité du rebroyé.

-

Alimentation par gravité standard Les bouteilles se bloquent facilement dans la trémie, ce qui nécessite une intervention manuelle et entraîne un débit faible et irrégulier.

-

Décharge par gravité simple Les flocons, la poussière et les fragments d’étiquettes sont mélangés, ce qui augmente le coût et la complexité du lavage et de la séparation en aval.

Le processus en un coup d'œil

Des bouteilles usagées aux flocons purs, chaque étape est méticuleusement conçue pour l’efficacité et la qualité.

1. Alimentation

Les bouteilles PET usagées sont introduites dans la trémie via un convoyeur.

2. Gavage

Pousse les bouteilles volumineuses de manière constante vers la chambre de coupe.

3. Granulation

Les couteaux du rotor et du stator cisaillent les bouteilles en flocons uniformes.

4. Dépistage

Un tamis contrôle la taille des flocons pour plus de cohérence.

5. Collection

Un système de soufflage sépare et collecte les flocons et la poussière.

Fonctionnalités principales

Chaque détail est conçu pour la performance, la durabilité et la facilité d'utilisation.

Conception du rotor en V

Répartit la charge de coupe, réduisant la consommation d'énergie et le bruit pour un fonctionnement fluide et efficace.

Boîtiers de roulements extérieurs

Empêche la poussière et le liquide de contaminer les roulements, prolongeant ainsi la durée de vie et simplifiant la maintenance.

Système d'ouverture hydraulique

Permet à une seule personne d'accéder sans effort à la chambre de coupe pour des changements de lame et un nettoyage sûrs et rapides.

Jeu de lame réglable

L'espace entre les couteaux du rotor et du stator peut être facilement ajusté pour maintenir des performances de coupe optimales à mesure que les lames s'usent.

Spécifications techniques

| Modèle | Puissance du moteur (kW) | Débit (kg/h) | Ouverture d'alimentation (mm) | Taille des flocons (mm) |

|---|---|---|---|---|

| PGP-600 | 22 | 400-600 | 600 x 450 | 12-16 (personnalisable) |

| PGP-800 | 37 | 600-800 | 800 x 500 | 12-16 (personnalisable) |

| PGP-1000 | 55 | 800-1200 | 1000 x 550 | 12-16 (personnalisable) |

| PGP-1200 | 90 | 1200-1500 | 1200 x 600 | 12-16 (personnalisable) |

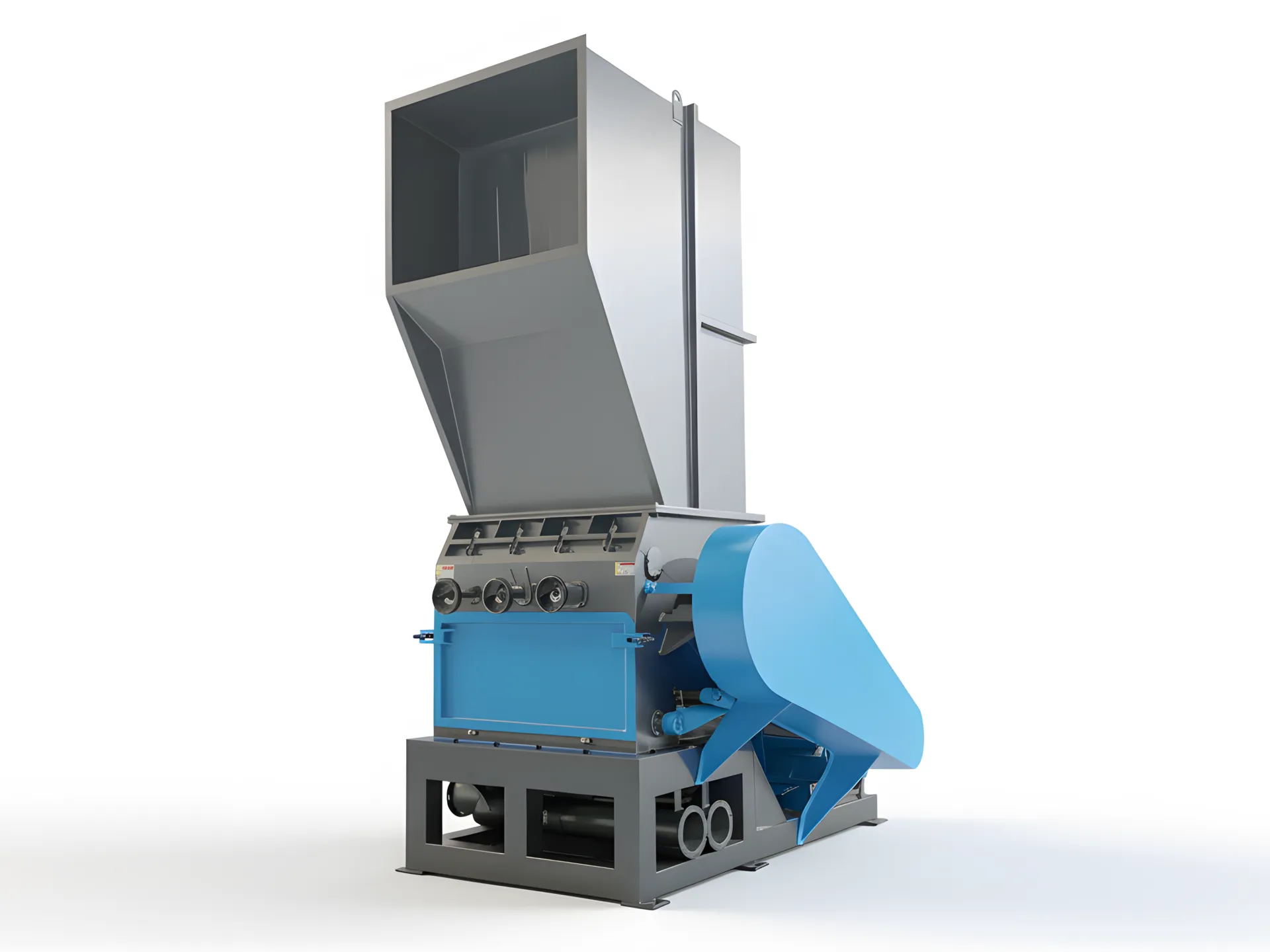

Présentation et vidéo de la machine

Découvrez des photos haute résolution de notre granulateur et regardez-le en action en train de traiter des bouteilles en PET.

Obtenez votre solution de recyclage personnalisée et votre devis

Remplissez le formulaire ci-dessous et nos experts en recyclage vous contacteront dans les 24 heures avec des conseils professionnels et un devis détaillé.

Questions fréquemment posées

Oui. Notre granulateur PET peut traiter des bouteilles avec leurs bouchons en PP/PE et une petite quantité d'étiquettes en papier/PVC. Le système de séparation pneumatique intégré élimine la plupart des fragments d'étiquettes légers après la granulation. Cependant, pour obtenir des paillettes de PET d'une pureté optimale, nous recommandons l'utilisation d'une ligne de lavage et d'un dispositif de retrait d'étiquettes dédiés, intégrés à un système complet.

Absolument pas. Nos machines sont équipées d'un système à vis sans fin hydraulique ou manuel qui permet un accès facile et sécurisé à la chambre de coupe. Les couteaux sont montés en blocs modulaires et, grâce au gabarit de réglage de lame en option, leur démontage, leur affûtage et leur réinstallation sont simples, réduisant ainsi considérablement les temps d'arrêt pour maintenance.

Le modèle idéal dépend de votre débit requis (kg/heure), de la taille maximale de vos bouteilles d'entrée et de vos spécifications concernant la taille finale des flocons. Consultez le tableau des spécifications techniques ci-dessus ou, pour une recommandation personnalisée, contactez nos ingénieurs via le formulaire de demande. Ils vous aideront à choisir le modèle idéal.

Absolument. Nous offrons un service après-vente complet, comprenant des conseils d'installation, la formation des opérateurs et une assistance technique à vie. Nous disposons d'un stock complet de pièces d'usure (comme les lames, les grilles et les roulements) pour vous garantir un remplacement rapide et minimiser les temps d'arrêt potentiels.