The global push for a circular economy has placed immense pressure on the recycling industry to innovate. Among the most challenging materials to process are post-consumer and post-industrial plastic films, particularly those made from Polyethylene (PE) and Polypropylene (PP). Their low bulk density, high moisture content, and fluffy nature create significant logistical and processing hurdles. For manufacturers and recyclers, overcoming these challenges isn’t just about environmental compliance—it’s about unlocking profitability.

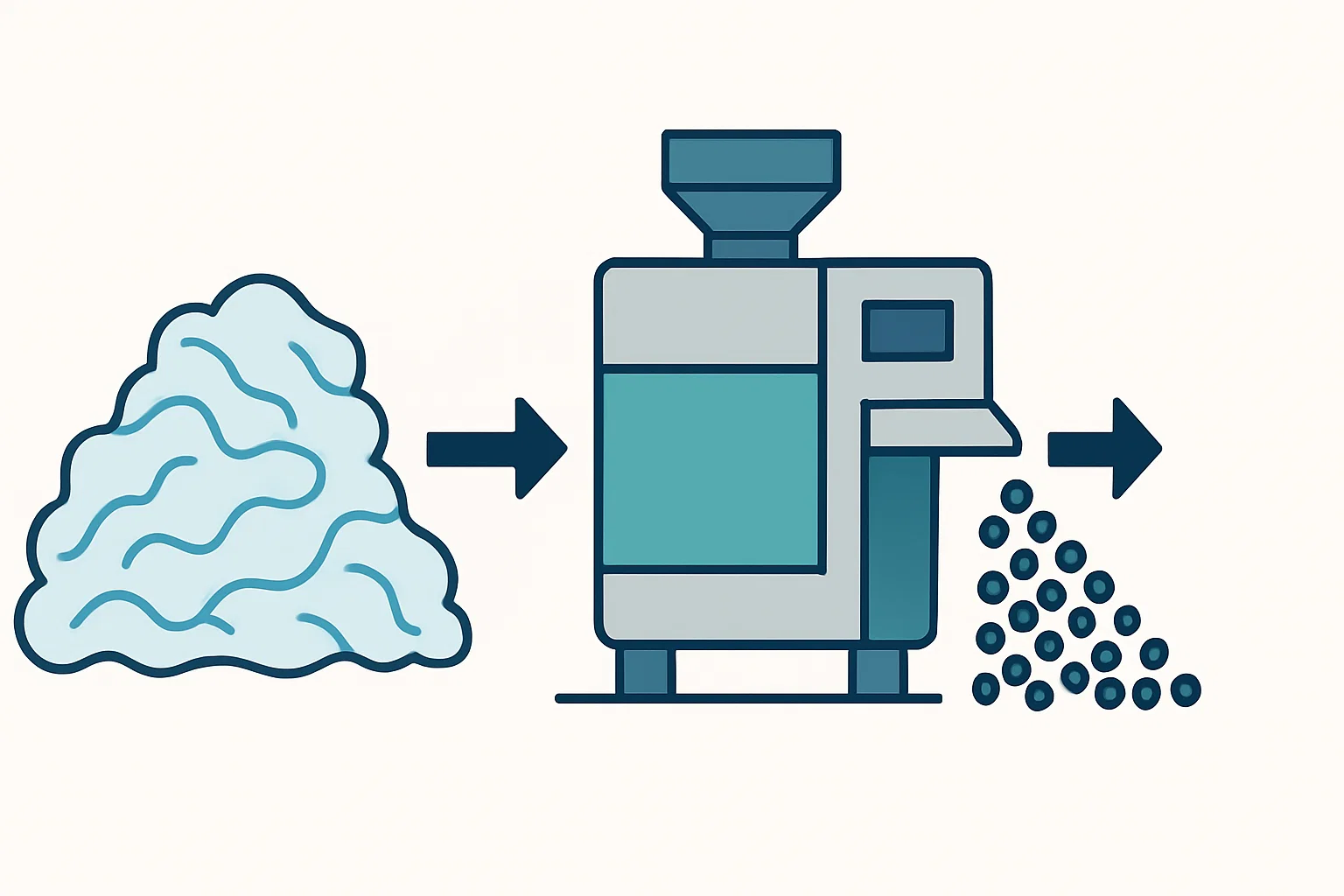

This is where the plastic film squeezer-densifier emerges as a critical piece of technology. This advanced machinery is engineered to be the bridge between a problematic waste stream and a high-value, pellet-ready feedstock.

In this comprehensive guide, we will explore the science and mechanics behind squeezer-densifiers, their tangible benefits for recycling operations, and what to look for when investing in a system. As a leader in recycling innovation, Energycle Machine is committed to providing the insights and equipment necessary to master this process.

The Core Challenge: Why PE/PP Films Are Difficult to Recycle

Before diving into the solution, it’s essential to understand the problem. Thin plastic films, such as LDPE packaging film, LLDPE stretch wrap, agricultural films, and PP woven bags, present a unique set of obstacles:

- High Volume, Low Weight: Unprocessed films are light and “fluffy,” occupying a vast amount of space. This drives up storage and transportation costs, making the logistics of collection and handling economically inefficient.

- Excessive Moisture Content: Most film recycling lines involve a washing stage to remove contaminants like dirt, labels, and organic residue. Post-washing, films can retain a moisture level of 15-30%, which is prohibitive for the next stage—pelletizing.

- Feeding Inconsistencies: Feeding damp, light, and irregularly shaped film scrap directly into a pelletizing extruder is notoriously difficult. It often leads to “bridging” in the hopper, inconsistent melt pressure, and poor-quality final pellets.

- Energy Inefficiency: Attempting to evaporate high levels of moisture within the extruder itself consumes a tremendous amount of energy, drastically reducing throughput and increasing operational costs.

These issues combined can render a film recycling operation unprofitable. A traditional approach using only a centrifugal dryer is often insufficient, leaving behind residual moisture that compromises the entire process.

What Exactly is a Plastic Film Squeezer-Densifier?

A Plastic Film Squeezer-Densifier is a specialized machine designed to aggressively dewater and compact washed PE/PP films into dense, semi-plasticized granules. Unlike a simple mechanical dryer or a baler, it uses a combination of immense mechanical pressure and controlled frictional heat to fundamentally change the material’s physical properties.

The primary function of the machine is to convert a low-density, high-moisture stream of plastic film into a high-density, low-moisture feedstock that is ideal for direct feeding into a pelletizing extruder. The final product resembles popcorn-like, free-flowing agglomerates, which are easy to handle, store, and process.

At Energycle Machine, we design our squeezer-densifiers to be the powerhouse of a modern film washing and recycling line, solving the critical moisture and density problems in a single, efficient step.

The Inner Workings: A Step-by-Step Look at the Energycle Machine Densifying Process

To appreciate the value of a squeezer-densifier, it’s crucial to understand its operational workflow. The process is a sophisticated blend of mechanical engineering and material science.

Step 1: Material Feeding

Washed and shredded plastic film flakes are conveyed from the final rinsing tank of the washing line directly into the hopper of the squeezer-densifier. A consistent feeding rate is crucial for stable operation.

Step 2: High-Pressure Squeezing

The material enters a chamber containing a specially designed high-torque screw. As the screw rotates, it aggressively compacts the film, forcing a significant portion of the free water out through perforated screen plates along the barrel. This initial mechanical dewatering is highly efficient and removes the bulk of the moisture without a large energy input.

Step 3: Frictional Heating and Densification

As the now-compacted material is pushed forward, the intense pressure and friction between the film, the screw, and the barrel walls generate heat. This is the “densification” stage. The temperature rises to the softening point of the plastic (typically 120-140°C for PE). This causes the surface of the plastic flakes to become tacky and semi-molten.

Step 4: Agglomeration and Cutting

At the die head of the machine, the semi-plasticized material is extruded. A set of rotating blades immediately cuts the material into small, uniform granules. The combination of heat and pressure has fused the fluffy film flakes into dense, solid particles.

Step 5: Cooling and Discharge

The hot, newly-formed granules are instantly discharged into a pneumatic conveying system. The rush of cool air rapidly solidifies the granules, preventing them from sticking together and transporting them to a storage silo, ready for the pelletizing stage.

This entire process, expertly managed by an Energycle Machine system, transforms the material’s properties in minutes.

The Tangible Benefits: ROI and Operational Excellence

Investing in a high-quality squeezer-densifier isn’t just an equipment purchase; it’s a strategic upgrade that delivers measurable returns across your operation.

1. Drastic Moisture Reduction (Down to <3%)

This is the most critical benefit. While a centrifugal dryer might leave 10-15% moisture, a squeezer-densifier consistently achieves a final moisture content of less than 3%. This ultra-low moisture level is the gold standard for high-quality pelletizing, eliminating issues like “foaming” and voids in the final pellets.

2. Six-Fold (or More) Increase in Bulk Density

The machine dramatically increases the material’s bulk density from around 30-50 kg/m ³ to over 300-400 kg/m ³. This has two major financial benefits:

- Reduced Storage: You can store significantly more material in the same footprint.

- Lower Transportation Costs: Each truckload can carry more weight, drastically cutting down on shipping expenses.

3. Boosted Pelletizer Throughput and Efficiency

Feeding dense, free-flowing, and pre-heated granules into an extruder is far more efficient than feeding fluffy film. The extruder’s screw can “grab” the material more effectively, leading to:

- Increased Output: Many operators report a 30-50% increase in pelletizer throughput.

- Energy Savings: The extruder doesn’t have to work as hard to melt the plastic or evaporate water, reducing its energy consumption.

- Stable Operation: Consistent feeding eliminates pressure fluctuations, leading to a more stable process and less downtime.

4. Superior Final Pellet Quality

Because the feedstock is dry and consistent, the final recycled pellets are of a much higher quality. They are free from porosity (air bubbles), have a more uniform melt flow index (MFI), and possess better mechanical properties, making them more valuable on the commodity market.

Key Applications Across Industries

The versatility of the plastic film squeezer-densifier makes it an indispensable tool for various recycling sectors in the USA, Europe, and beyond.

- Post-Consumer Film Recycling: Processing materials from municipal collection, such as LDPE packaging films, grocery bags, and bubble wrap.

- Post-Industrial Recycling: Reclaiming in-house scrap from film production, converting clean factory waste directly into reusable pellets.

- Agricultural Film Recycling: Handling heavily soiled materials like greenhouse films and mulch films after they have been through a robust washing line.

- PP Woven Bag Recycling: Densifying shredded polypropylene sacks used for packaging grain, sand, or chemicals, turning a challenging material into a valuable resource.

Choosing the Right System: What to Look for in a Squeezer-Densifier

Not all densifiers are created equal. When selecting a machine for your industrial operation, consider these critical factors:

- Robust Construction and Materials: Look for heavy-duty steel construction and wear-resistant alloys on key components like the screw and barrel. The machine must withstand the immense pressures and abrasive nature of contaminated materials.

- Advanced Control Systems: A reliable PLC with a user-friendly HMI is essential for monitoring and controlling screw speed, temperature, and motor load. Energycle Machine systems incorporate smart controls to automate the process and ensure consistent output quality.

- Energy Efficiency: Modern designs should feature high-efficiency motors and optimized screw geometry to maximize throughput while minimizing energy consumption per kilogram of material processed.

- Ease of Maintenance: Look for features that allow for easy access to the screen, blades, and screw for cleaning and replacement. This minimizes downtime and keeps your operation running smoothly.

- Supplier Expertise and Support: Your equipment provider should be a partner. Choosing an experienced manufacturer like Energycle Machine ensures you receive expert consultation, reliable after-sales support, and a system tailored to your specific material. An advanced plastic film squeezer-densifier system is a significant investment, and partnering with a specialist is key to maximizing its return.

Frequently Asked Questions (FAQ)

1. What is the main difference between a squeezer-densifier and a standard agglomerator?

While both use heat to compact material, their methods differ. An agglomerator is typically a large pot with rotating blades that uses friction to melt and fuse plastic into irregular chunks. A squeezer-densifier is a screw-based extruder that simultaneously provides mechanical squeezing for dewatering and frictional heating for densification, offering much better moisture control and producing more uniform granules.

2. Can the system handle heavily printed or contaminated films?

Yes, but with a caveat. The squeezer-densifier is primarily a dewatering and densifying machine. It is designed to work as part of a complete washing line. For heavily contaminated or printed films, a thorough pre-washing and rinsing process is essential to remove ink and debris before the material enters the densifier. The machine itself is robust enough to handle the physical material.

3. What is the typical operational temperature, and does it degrade the plastic?

The process is carefully controlled to heat the plastic only to its softening point, not its full melting point. This “semi-plasticizing” state is sufficient for agglomeration without causing significant thermal degradation (i.e., breaking of polymer chains). This preserves the material’s integrity, leading to higher-quality final pellets.

4. How does an Energycle Machine squeezer-densifier integrate into an existing recycling line?

Our systems are designed for seamless integration. They can be fed directly from the last rinsing tank of your washing line via a screw or belt conveyor and can discharge the densified granules into a pneumatic system that transports them to a storage silo, ready to feed one or more pelletizers. We work with clients to ensure a perfect fit with their existing infrastructure.

Conclusion: The Strategic Advantage of Densification

In the competitive landscape of plastic recycling, efficiency is paramount. The plastic film squeezer-densifier is no longer a niche piece of equipment but a cornerstone technology for any serious PE/PP film recycling operation. By tackling the fundamental challenges of moisture and density head-on, it streamlines the entire workflow, reduces operational costs, and dramatically improves the quality and value of the final recycled product.

Investing in a robust, high-performance system from a trusted partner like Energycle Machine empowers your facility to turn low-value film waste into a consistently profitable revenue stream, driving your business forward in the circular economy.

Ready to Revolutionize Your Film Recycling Process?

If you’re struggling with high moisture content, inefficient logistics, and underperforming pelletizers, it’s time to explore the transformative power of a squeezer-densifier.

Contact the experts at Energycle Machine today. Our team is ready to discuss your specific material challenges and design a tailored solution that will boost your efficiency and profitability. Request a quote or schedule a consultation to take the next step toward operational excellence.