Vertical Cotton Fiber Textile Baler

Streamline logistics and reduce volume with a safety-first, heavy-duty baler designed for cotton, synthetic fibers, non-wovens, yarn scraps, and textile offcuts.

Why Choose This Baler

Engineered for consistent bale density, safe operation, and low maintenance in challenging recycling and packing environments.

Front & Rear Doors

Front and rear opening doors ensure easy and quick strapping for secure, neat bales.

Automatic Bale Eject

An automatic chain bale ejector speeds up unloading, reduces manual labor, and shortens cycle time.

Safety-First Ram

The ram movement stops when the feed gate is open, preventing accidental compression during loading.

Emergency Stop

An independent E-stop immediately halts the system to protect operators and equipment.

Anti-Rebound Gate

Prevents material spring-back during compaction and complies with EU/US safety standards.

Stable Ram Guide

A special guide design avoids platen tilt, ensuring uniform bale density and less wear.

Premium NOK Seals

Japanese NOK hydraulic seals provide long life and reliable performance under pressure.

Leak-Proof Joints

A.M.C. oil pipe joints minimize leakage for cleaner operation and reduced downtime.

Direct Motor-Pump

A direct-coupled motor and pump improve alignment, efficiency, and pump lifespan.

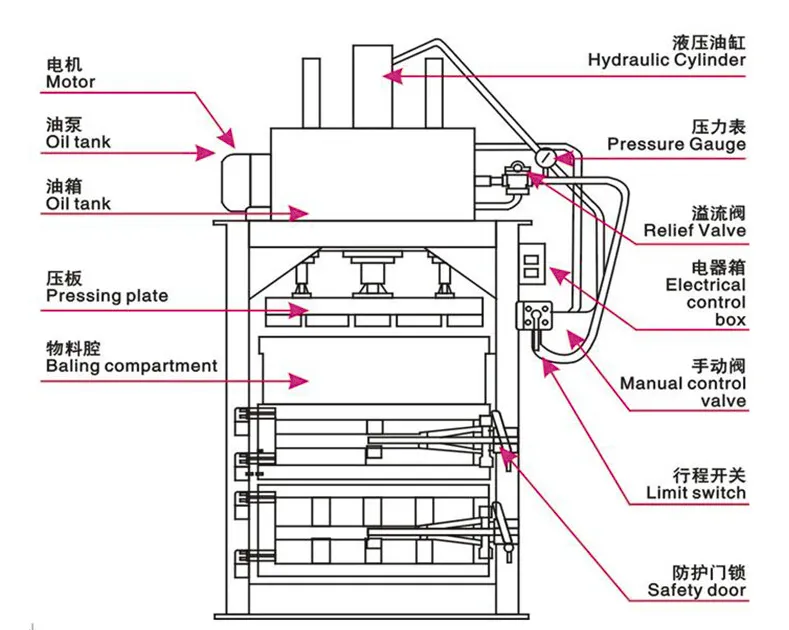

How the Vertical Baler Works

A vertical hydraulic ram compresses loose fiber and textile materials into tight, strapped bales for easy handling.

Load Materials

Feed cotton, synthetic fiber, non-wovens, and textile offcuts into the chamber.

Hydraulic Compaction

The ram compresses materials to the target density with stable guidance and safety interlocks.

Strap the Bale

Use front/rear door access to strap and secure the bale for storage or transport.

Automatic Ejection

The automatic chain ejector releases the bale quickly, readying the chamber for the next load.

Prijave

Ideal for textile recycling plants, fiber packing stations, and production waste consolidation.

Textile & Fiber Recycling

Bales cotton, polyester, viscose, polypropylene fiber, yarn scraps, and rags for efficient transport.

Non-Wovens & Padding

Compacts non-woven rolls, trims, and padding materials into stable, stackable bales.

Mill & Warehouse Use

Perfect for textile mills, rag graders, and logistics centers to reduce storage volume and handling costs.

Tehničke specifikacije

Two typical configurations shown below. We can adjust the chamber, power, and controls to suit your material and throughput.

| Parametar | RTM-1500LF11042 | RTM-1500LF12080 |

|---|---|---|

| Pritisak | 150 tons | 150 tons |

| Otvor za punjenje (D×V) | 1100 × 1400 mm | 1200 × 500 mm |

| Visina komore za baliranje | 2400 mm | 1500 mm |

| Veličina bale (D׊×V) | 1100 × 400 × (400–1000) mm | 1200 × 800 × (400–1000) mm |

| Težina bale | 70–180 kg | 100–250 kg |

| Vlast | 18.5 / 22 kW | 18.5 / 22 kW |

| Težina stroja | 4500 kg | 5000 kg |

| Overall Dimension (L×W×H) | 1800 × 1450 × 1300 mm | 3500 × 1300 × 3500 mm |

Machine Photos

Često postavljana pitanja

Koje materijale može obraditi ova balirka?

Cotton, polyester, PP/PE fiber, non-wovens, yarn scraps, rags, and similar low-density textile materials.

How does the bale eject system operate?

An automatic chain ejector safely and swiftly pushes out the strapped bale, minimizing manual handling.

Koje su sigurnosne značajke uključene?

Safety interlock stops the ram when the gate is open, along with an independent emergency stop and anti-rebound gate structure.

Can the chamber and power be customized?

Absolutely, we customize the chamber size, motor power, and control logic based on your material type, bale size, and throughput requirements.

Jamstvo i montaža

Comes with a 1-year limited warranty. We provide on-site commissioning, operator training, and optional maintenance plans.

Ready to Streamline Textile Baling?

Share your materials, target bale size/weight, and capacity. Our engineers will select the perfect baler for you.