PET Plastic Recycling Machine: A Complete Buyer’s Guide

A PET plastic recycling machine represents the heart of any effective plastic recovery operation, converting post-consumer bottles into valuable, recyclable materials. With the increasing global demand for recycled PET (rPET), it is crucial for businesses seeking to enter or expand in this field to understand the technology, process, and economic aspects involved. This guide offers a comprehensive overview of the entire PET recycling process, the specific machinery needed at each stage, and the key factors to consider when making a well-informed investment.

Polyethylene terephthalate (PET) is one of the most widely used plastics, particularly for beverage bottles and food containers, due to its strength, lightweight, and clarity. However, its extensive use also contributes substantially to plastic waste. Recycling PET not only helps mitigate environmental harm but also generates a highly sought-after commodity. According to a report by Grand View Research, the global PET recycling market is expected to continue its robust growth trajectory, driven by sustainability objectives and regulatory pressures.

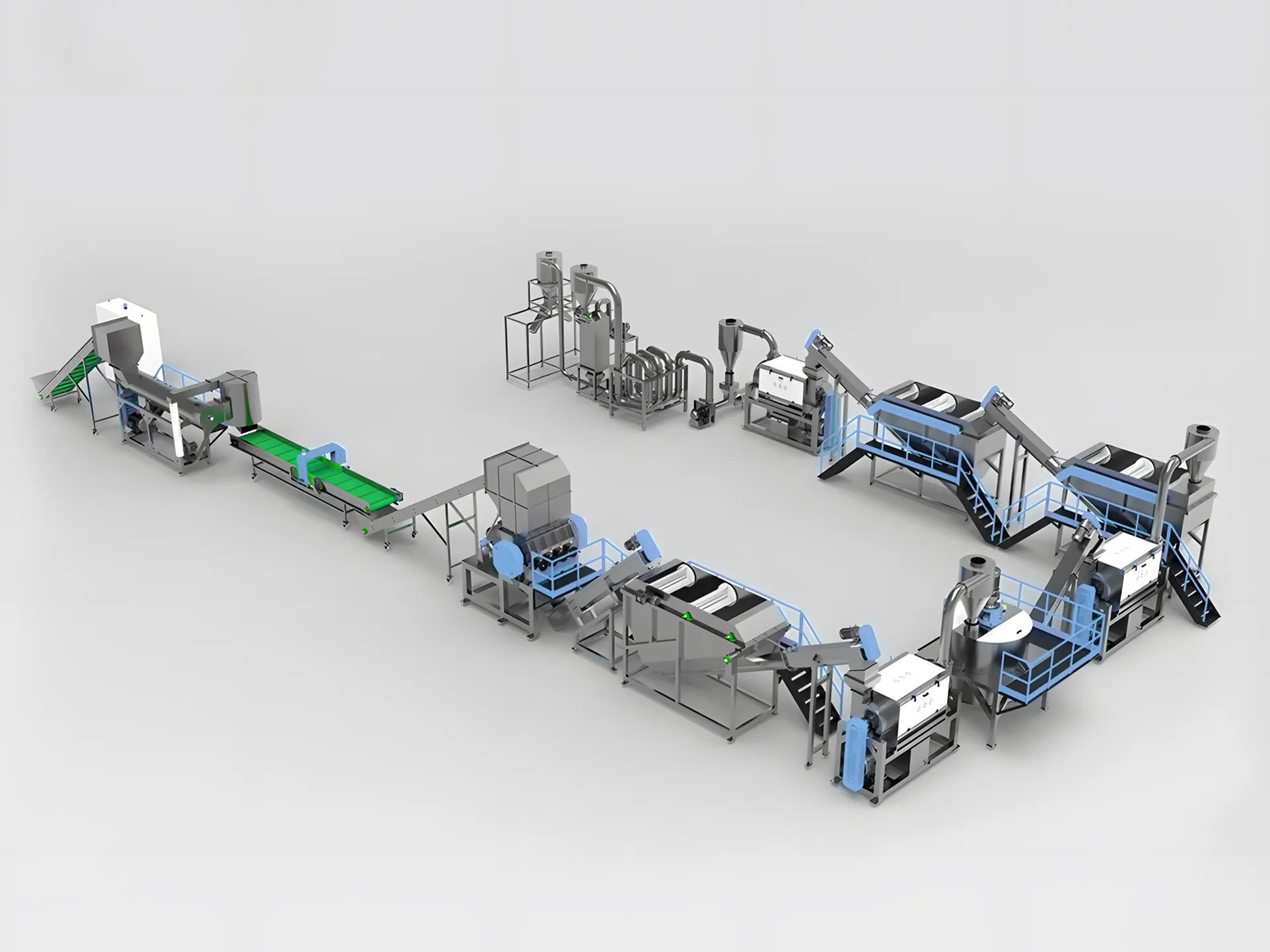

The Step-by-Step PET Recycling Process and Essential Machines

The transformation of a bale of used PET bottles into high-quality rPET flakes or pellets is a multi-step process that requires specialized machinery tailored to each specific task. A complete system is commonly referred to as a PET bottle washing line.

Stage 1: Baling, De-baling, and Sorting

The process commences once used bottles are gathered and compacted into large bales for efficient transportation. The recycling facility’s operations commence at this stage.

- Bale Breaker (De-baler): The initial machine in the line is the Bale Breaker. It dismantles the compressed bales, releasing the bottles and feeding them continuously into the sorting line. This ensures a steady flow of material for the subsequent stages.

- Sorting Systems: This is a critical stage for the removal of contaminants. Contamination from other plastics (such as PVC), metals, paper, and food residue can significantly degrade the quality of the final rPET.

- Manual Sorting Conveyor: Operators stand alongside the conveyor belt to visually inspect and manually remove large contaminants and non-PET materials.

- Trommel zaslon: Drum Sifter:.

- A large rotating drum with apertures of a specific size, which aids in separating finer contaminants like dirt, sand, and loose bottle caps. Optical Sorters:.

Advanced systems utilize near-infrared (NIR) technology to automatically identify and segregate various types of plastics and colors. This is vital for producing high-purity, color-sorted rPET flakes.

Stage 2: Size Reduction – Shredding and Grinding“

After sorting, the entire bottles are broken down into smaller, manageable pieces known as "flakes." Key Machinery: Plastic Shredders and Granulators

- Plastic Shredder: A robust machine designed for the initial reduction of material size. A single-shaft shredder is commonly employed to tear bottles into coarse, smaller fragments. This pre-shredding stage lessens the workload on the granulator.

- Plastic Granulator (or Crusher): The pre-shredded material or whole bottles are introduced into a granulator. This unit employs high-speed rotating blades to cut the plastic into consistent flakes, generally ranging from 10-15mm in size. The flake size is regulated by a screen with defined hole diameters. This operation is frequently carried out wet to pre-wash the material and minimize blade wear.

Stage 3: Intensive Washing and Separation

This phase is arguably the most crucial in determining the final quality of the recycled PET. The objective is to eliminate all surface contaminants, such as adhesives, labels, and residual liquids.

Key Machinery: The Washing Line Components

- Trenje podloške: A high-speed washer equipped with rotating paddles that scrub the flakes against each other and a screen, effectively removing dirt and labels.

- oferece mais do que apenas benefícios ambientais. Apresenta um forte argumento econômico para muitas empresas. This tank operates on the principle of density. It is filled with water, where the denser PET flakes (density ~1.38 g/cm³) settle at the bottom, while the lighter label and cap materials (polypropylene and polyethylene, density ~0.9 g/cm³) float to the surface. <1 g/cm³) plutaju na površinu. Lopatice skidaju plutajuće onečišćujuće tvari, postižući visok stupanj odvajanja.

- Hot Washer: To eliminate persistent glue and oils, the flakes are washed in hot water (approximately 85-95°C) mixed with a caustic soda solution. This process is essential for applications demanding high purity, such as food-grade packaging. The U.S. Food and Drug Administration (FDA) has established specific guidelines for processes that produce post-consumer recycled plastics intended for food contact.

Stage 4: Drying

Before the flakes can be processed further or sold, they must be thoroughly dried. Any residual moisture can lead to defects in the final products.

Key Machinery: Drying Systems

- Centrifugal (Mechanical) Dryer: This machine employs centrifugal force to expel water from the surface of the flakes at high speeds, effectively removing the majority of the moisture swiftly and efficiently.

- Thermal (Hot Air) Dryer: A flow of hot, dry air is directed through the flakes, typically via a zigzag pipeline system. This process eliminates the remaining moisture, reducing the final moisture content to less than 1%.

Stage 5: Pelletizing (Optional but Recommended)

Although high-quality flakes can be sold directly, many manufacturers opt for rPET in pellet form. Pellets are more convenient for handling, transportation, and feeding into production machinery such as injection molders or extruders.

Key Machinery: Plastic Pelletizer

- Ekstruder: Les paillettes propres et sèches sont introduites dans un extrudeur. Un vis tournant fond et homogénéise le plastique, le poussant à travers un système de filtration pour éliminer toute impureté résiduelle.

- Bouche de granulation et coupeuse : Le plastique fondu est forcé à travers une plaque de bouchon, formant des fils ressemblant à des pâtes. Une lame de coupe à haute vitesse coupe ensuite ces fils en petits granulés uniformes, qui sont immédiatement refroidis par de l'eau.

Comment choisir la bonne machine de recyclage PET pour votre entreprise

Le choix de l'équipement dépend de plusieurs facteurs spécifiques à vos objectifs opérationnels. Répondre à ces questions vous aidera à vous et à votre fournisseur d'équipement, comme Rumtoo stroj, à concevoir le système le plus approprié.

1. Analyser votre matière première

La qualité de votre matière première brute (les bouteilles collectées) déterminera la complexité de votre ligne de lavage et de tri.

- Izvor: S'agit-il d'une source propre avec système de dépôt ou de déchets municipaux post-consommateurs ? Les déchets municipaux sont généralement plus contaminés.

- Razina kontaminacije: Des niveaux élevés de saleté, de plastiques non PET et d'autres débris nécessiteront des étapes de tri et de lavage plus robustes, telles que des bassins de flottaison-sink multiples ou un trieur optique avancé.

2. Définir Votre Qualité de Sortie Attendue

L'utilisation finale de votre rPET détermine la pureté requise et, par conséquent, le matériel nécessaire.

- Granulés à Usage Général : Pour des applications telles que le garnissage en fibres ou l'étiquetage, une ligne de lavage standard peut être suffisante.

- Pellets de Bouteille à Bouteille (Grade Alimentaire) : C'est le produit le plus valorisé. Il nécessite un processus de lavage approfondi, y compris un lavage à chaud en profondeur, et souvent un système de granulation avec un filtrage avancé. Comme l'a noté l Agence de Protection de l'Environnement des États-Unis (EPA), le recyclage des plastiques conserve les ressources naturelles et l'énergie. Dépasser la qualité alimentaire maximise ce bénéfice.

3. Déterminer la Capacité Nécessaire (Débit)

La capacité est mesurée en kilogrammes ou en livres par heure (kg/h ou lbs/h). Votre choix dépendra de l'échelle de votre entreprise, des matières premières disponibles et de la demande du marché. Les lignes peuvent varier de petites unités (300-500 kg/h) à des opérations industrielles de grande échelle (2 000 kg/h ou plus). Assurez-vous de planifier pour la croissance future.

4. Evaluate Automation, Energy, and Water Consumption

Modern PET plastic recycling machines come with varying degrees of automation.

- Automatizacija: Automated sorting and monitoring systems can cut labor costs and enhance consistency, though they do demand a bigger upfront investment.

- Energy and Water Consumption: Seek out machines equipped with energy-saving motors and closed-loop water recycling systems. Cutting down on water usage not only slashes operational expenses but is also a crucial element of sustainable operations.

High-Value Applications of Recycled PET (rPET)

The output from a PET recycling facility is a versatile raw material with a wide range of uses, contributing to a circular economy.

- Bottle-to-Bottle Production: This is the most circular application, where rPET pellets are utilized to create new beverage bottles and food containers.

- Polyester Staple Fiber (PSF): rPET flakes are melted and spun into fine fibers for use in textiles (clothing, fleeces), carpets, and as filling for pillows and duvets.

- Strapping: High-strength polyester strapping, employed in packaging and logistics, is a significant market for rPET.

- Sheet and Film: rPET can be extruded into sheets for applications such as clamshell containers and packaging trays.

- Building Materials: Recycled PET finds its way into certain construction applications, like insulation materials and plastic lumber.

Partner with Rumtoo Machine for Your Recycling Success

Ulaganje u a PET plastic recycling machine This is an investment in a profitable and sustainable future. The secret to success lies in selecting robust, efficient equipment that aligns with your unique requirements. At Rumtoo Machine, we offer comprehensive, end-to-end solutions for plastic recycling. Our expert team can assist you in designing a facility that aligns with your input materials and desired output quality, guaranteeing a strong return on your investment.

Ready to transform plastic waste into a valuable asset? Kontaktirajte nas danas Contact us to discuss your project, and let us assist you in establishing a thriving recycling operation. Discover our complete range of plastic recycling solutions for more information.