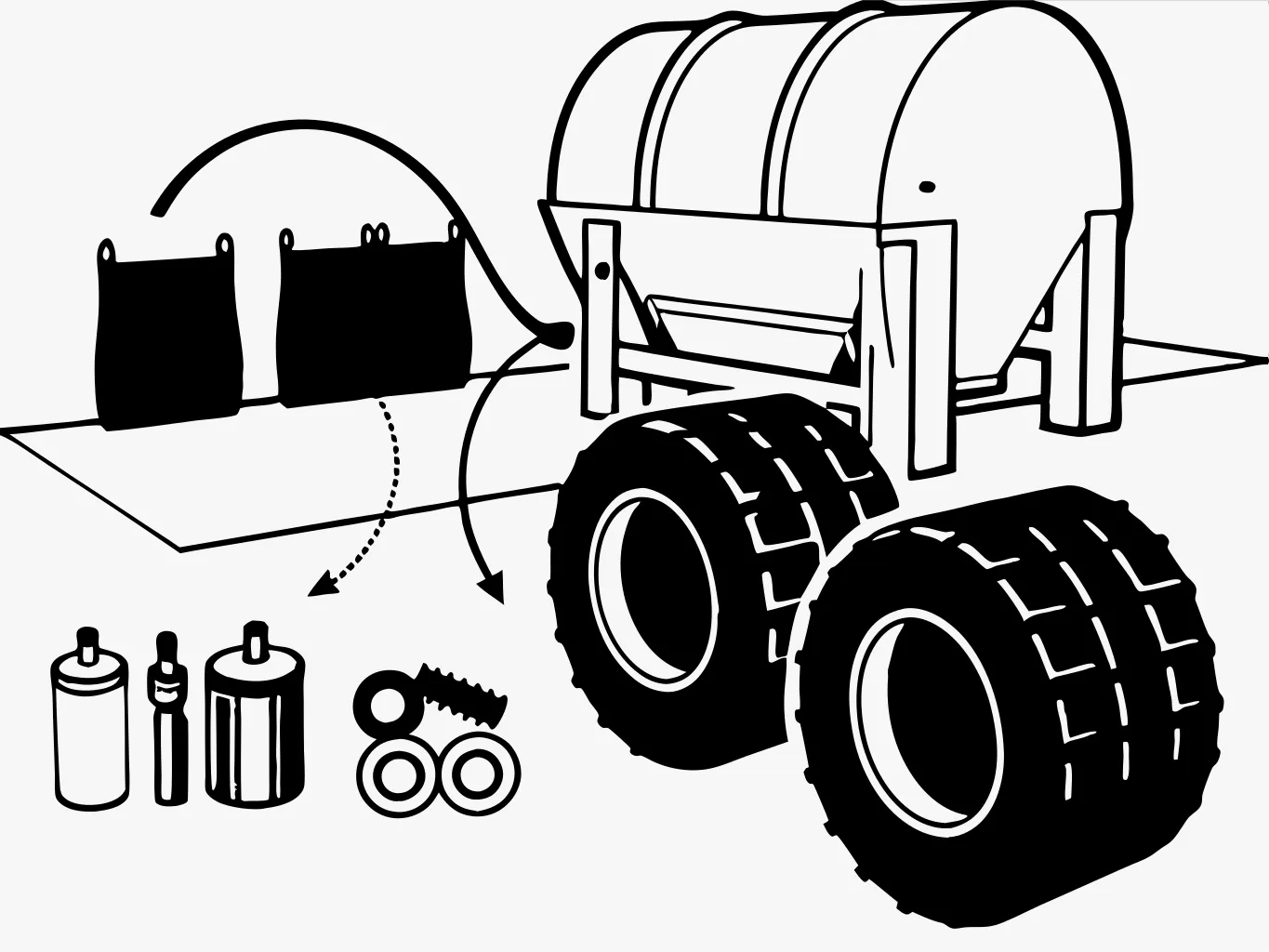

Kako reciklirati velike vreće? Ultimativni vodič za profitabilno recikliranje FIBC kontejnera

Fleksibilni međuspremnici za rasuti teret (FIBC) - često nazvani velike vreće, vreće za rasuti teret ili jumbo vreće - široko se koriste za prijevoz prahova i granula u logistici, poljoprivredi...