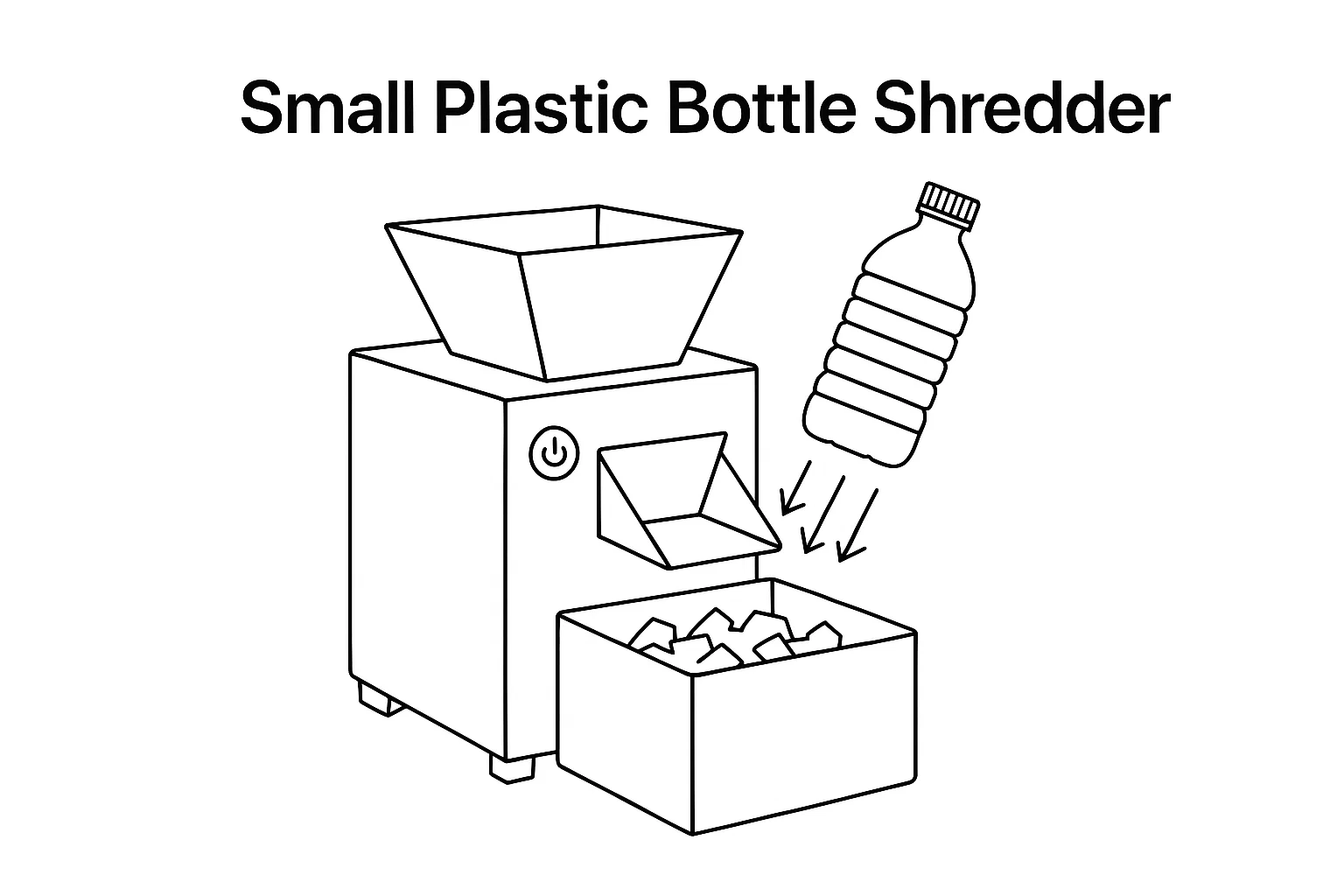

Najbolji mali strojevi za usitnjavanje plastičnih boca optimiziraju prostorna ograničenja bez ugrožavanja učinkovitosti protoka u linijama za recikliranje. Za lokalizirane centre za recikliranje, postrojenja za brizganje i laboratorijske testne linije, odabir pravog usitnjivača uključuje procjenu okretnog momenta motora, geometrije sita i sastava lopatica, a ne samo dimenzija. Ovaj vodič analizira tehničke zahtjeve za kompaktnu opremu za preradu PET-a.

Za postavke koje zauzimaju malo prostora, pogledajte naše mini stolni mali drobilica stranica.

Mehanika malih industrijskih šredera

Mali rezači plastičnih boca obično koriste jedan od dva primarna mehanizma rezanja, ovisno o potrebnoj kvaliteti izlaznog materijala i gustoći protoka.

Sjeckalice s jednom osovinom

Ove jedinice rade s rotorom velike brzine (obično 80–120 okretaja u minuti) uz stacionarni nož. Rad velike brzine omogućuje precizno određivanje veličine čestica putem sita, što ih čini idealnim za proizvodnju ujednačenih pahuljica (10–15 mm) pogodnih za trenutno pranje ili ekstruziju. Međutim, zahtijevaju konzistentne brzine dodavanja kako bi se spriječili skokovi u amperaži motora.

Sjeckalice s dvostrukom osovinom

Karakterizirani malom brzinom i visokim okretnim momentom, strojevi s dvostrukom osovinom koriste dvije suprotno rotirajuće osovine za rezanje i kidanje materijala. Podnose veće razine kontaminacije i manje su skloni zaglavljivanju na bocama s velikim punjenjem. Izlaz su općenito grublje trake, a ne definirane pahuljice, što često zahtijeva sekundarni granulator za konačno dimenzioniranje.

Ključne tehničke specifikacije za odabir

Prilikom nabave malog usitnjivača plastičnih boca, inženjeri obično definiraju radni prozor na temelju sljedećih parametara.

1. Pogonski sustav i ograničenja momenta

Male jedinice (protok <200 kg/h) obično zahtijevaju motore između 3 kW i 7,5 kW. Za obradu PET boca, visoki okretni moment je ključan za probijanje predoblika ili dijelova vrata bez zastoja. Električni pogoni s reduktorima su standardni; hidraulički pogoni su rezervirani za veće pogone zbog troškova.

2. Geometrija komore za rezanje

Veličina komore određuje maksimalnu prihvatljivu dimenziju boce bez premošćivanja. Za standardne boce od 2 l preporučuje se minimalna širina komore za rezanje od 300 mm do 500 mm kako bi se osiguralo učinkovito gravitacijsko punjenje.

3. Veličina zaslona i brzina fluksa

Sito za pražnjenje određuje konačnu veličinu čestica i protok. Manji otvori (npr. 10 mm) proizvode čišće pahuljice, ali povećavaju povratni tlak i stvaranje topline, što može otopiti PET fine čestice. Sito od 12-15 mm nudi ravnotežu između kvalitete pahuljica i protoka za operacije malog opsega.

| Značajka | Sjeckalica s jednom osovinom | Dvostruki šreder (škare) |

|---|---|---|

| Primarno djelovanje | Rezanje / Granuliranje | Šišanje / Drobljenje |

| Izlazni oblik | Ujednačena pahuljica (10-20 mm) | Nepravilne trake (20-50 mm) |

| Snaga motora (mala skala) | 4 kW – 11 kW | 3 kW – 7,5 kW |

| Razina buke | Viša (75-85 dB) | Niže (65-75 dB) |

| Fokus na održavanje | Podešavanje razmaka lopatica, čišćenje sita | Tvrdo navarivanje osovina, ulje za mjenjač |

| Idealna primjena | Konačno dimenzioniranje za liniju za pranje rublja | Smanjenje volumena za transport |

Preporučene konfiguracije opreme

Na temelju zahtjeva obrade PET, HDPE i PP boca, specifične konfiguracije daju optimalne rezultate.

Kompaktni sustavi s jednom osovinom (Energycle Desktop serija)

Dizajnirane za laboratorije ili mikro-reciklažne sustave (<50 kg/h), ove jedinice daju prioritet preciznosti.

* Motor1,5 kW

* Komora: 300 mm x 300 mm

* Materijal oštriceD2 Visokougljični čelik (tvrdoća 58-60 HRC)

* PrimjenaProizvodnja pahuljica ispitne kvalitete za ekstruziju u istraživanju i razvoju.

Srednji industrijski usitnjivači (Energycle Compact Pro)

Pogodno za pilot postrojenja ili recikliranje otpada na kraju linije (80–120 kg/h).

* Pogon4 kW s VFD-om (frekvencijskim pogonom) za mjerenje opterećenja.

* Vrsta rotoraV-Rotor dizajn za centriranje boca i smanjenje trošenja bočnih stijenki.

* SigurnostSenzor nulte brzine blokira se kako bi se spriječilo otvaranje spremnika tijekom rada.

* OtpustPneumatski spoj za usisavanje sprječava nakupljanje prašine.

Održavanje i kontrola onečišćenja

Pouzdanost malih usitnjivača ovisi o strogim protokolima održavanja, posebno s obzirom na abrazivnu prirodu plastike punjene staklom ili papirnatih etiketa.

- Oštrenje oštricaTupe oštrice povećavaju potrošnju energije do 30% i stvaraju fine čestice (prašinu). Rotirajući noževi (kvadratni umeci) omogućuju operaterima da indeksiraju oštrice 4 puta prije zamjene.

- Zaštita ležajaPET fine čestice su abrazivne. Odabirom strojeva s vanjskim ležajevima odvaja se kućište ležaja od komore za rezanje, sprječavajući oštećenje brtve i kontaminaciju mašću.

- Podešavanje razmakaRazmak između rotirajućih i stacionarnih noževa treba održavati na 0,2–0,3 mm za učinkovito rezanje boca s tankim stijenkama.

Preguntas Frecuentes (FAQ)

Kolika je potrebna snaga za šreder od 100 kg/h?

Protok od 100 kg/h za rastresite plastične boce obično zahtijeva snagu motora od 5,5 kW do 7,5 kW (7,5–10 KS) za rješavanje vršnih opterećenja bez zastoja, posebno pri obradi baliranog ili gustog materijala.

Može li mali šreder rukovati kapicama i prstenovima?

Da. Industrijski shredderi s jednom osovinom i čeličnim oštricama D2 ili SKD11 mogu obrađivati PP/PE čepove i prstenove pričvršćene na PET boce. Međutim, nizvodno je potrebno odvajanje (spremnik s plutajućim spremnikom) kako bi se izolirali različiti polimeri.

Koliko često je potrebno mijenjati noževe usitnjivača?

Za čiste PET boce, oštrice od čelika D2 obično traju 300-500 radnih sati prije nego što je potrebno oštrenje. Oštrice s vrhom od karbida mogu produžiti taj interval na 1000+ sati, ali imaju veće troškove zamjene.

Reference

[1] Terminologija i standardi recikliranja plastike — ISO 15270. Terminologija i standardi recikliranja plastike — ISO 15270

[2] “Smanjenje veličine plastike” Priručnik za industrijsko polimerno inženjerstvo. Smanjenje veličine plastike