Potražnja za recikliranim PVC-om (rPVC) usko je povezana s građevinskim i industrijskim proizvodima: prozorima, profilima, cijevima, podovima i drugim trajnim primjenama. Ova tržišta cijene rPVC kada zadovoljava dosljedne zahtjeve kvalitete i usklađenosti - posebno u pogledu onečišćenja i povijesti aditiva.

Ovaj vodič objašnjava što potiče potražnju za rPVC-om, koje primjene obično koriste kvalitetniji materijal i što recikleri moraju kontrolirati kako bi pristupili tim tržištima.

Brza jela za van

- Građevinski proizvodi su glavni pokretač potražnje jer se PVC široko koristi u dugotrajnim primjenama.

- Primjene veće vrijednosti obično zahtijevaju strožu kontrolu onečišćenja i povijesti aditiva.

- Odabir opreme (pranje, odvajanje, mljevenje) često određuje kojem tržištu realno možete služiti.

Povezani vodiči

- Najvažnija tržišta za strojeve za recikliranje PVC-a (2026.)

- Recikliranje PVC-a i ugljični otisak (što smanjuje emisije)

- Vodič za strojeve za recikliranje PVC-a (mljevenje, granule, prah)

Što potiče potražnju za rPVC-om

1) Obveze održivosti i pritisak nabave

Brendovi, graditelji i javna nabava sve više traže reciklirani sadržaj i dokumentirane performanse materijala. U Europi programi poput VinylPlusa prate napredak i potiču odgovornu kružnu proizvodnju PVC-a.

2) Stabilnost troškova i opskrbe

Neki proizvođači koriste rPVC kako bi smanjili izloženost promjenama cijena djevičanske smole - kada je kvaliteta dosljedna, a opskrba pouzdana.

3) Regulativa i usklađenost

Pravila o aditivima (na primjer, olovo u starom PVC-u) utječu na to gdje i kako se rPVC može koristiti. To potiče bolje sortiranje, dokumentiranje i kontroliranu krajnju upotrebu.

Primjene koje često koriste rPVC

Krajnja tržišta razlikuju se ovisno o regiji i zahtjevima kupaca, ali uobičajene upotrebe uključuju:

- Proizvodi za prozore i profile (često putem višeslojnih/koekstruzijskih pristupa)

- Cijevi i spojnice bez tlaka (gdje standardi i kupci dopuštaju upotrebu rPVC-a)

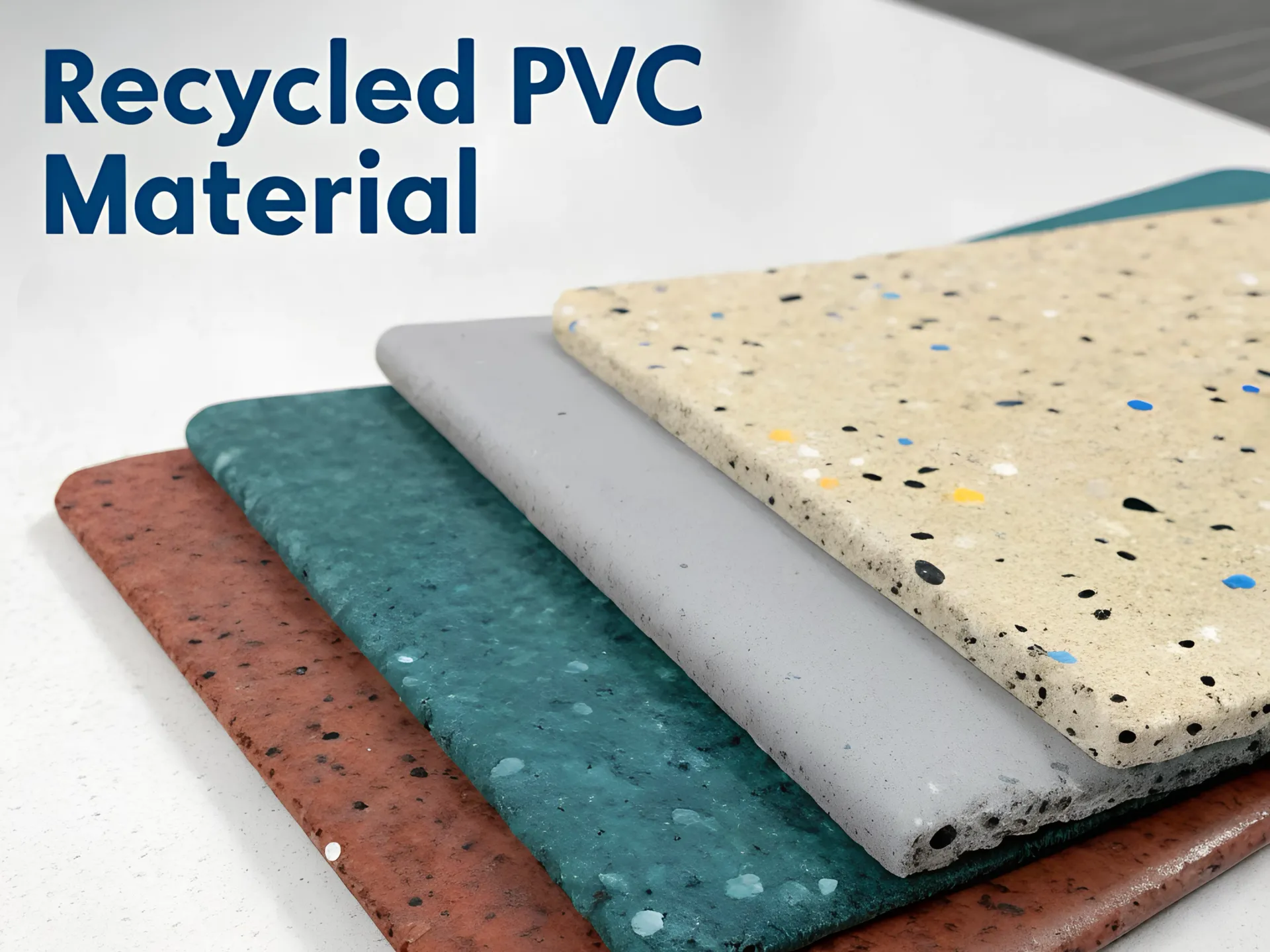

- Podne obloge i proizvodi od ploča (ovisno o formulaciji i granicama kontaminacije)

- Industrijski proizvodi koji može tolerirati rPVC miješanih boja kada su mehanička svojstva zadovoljavajuća

Što recikleri moraju kontrolirati kako bi opsluživali tržišta veće vrijednosti

- identitet polimera i unakrsna kontaminacija (PVC u odnosu na druge polimere)

- kontaminacija metalima i gumom (posebno od sklopova građevinskih proizvoda)

- vlaga i čistoća (ako daljnja obrada uključuje miješanje ili peletiranje)

- povijest i dokumentacija aditiva (stari stabilizatori, ograničene tvari)

Izbor opreme koji pomaže: – Kruto pranje i odvajanje (PP/HDPE/PVC) – Mljevenje/usitnjavanje za praškaste proizvode

Obrasci proizvoda od rPVC-a (i što oni omogućuju)

Različiti kupci žele različite “oblike” recikliranog PVC-a, a oblik često određuje opremu koja vam je potrebna:

- Ponovno mljeveno (grubo): uobičajeno za internu ponovnu upotrebu ili manje stroge aplikacije kada je stream konzistentan.

- Čisti mljeveni materijal / granule (za miješanje): ujednačenije dimenzioniranje i niža kontaminacija; često ima koristi od pranja/odvajanja kada je tok prljav.

- Prašak (za suhe mješavine i profilne proizvode): obično zahtijeva stabilnu sirovinu i mljevenje/klasifikaciju (vidi gore navedeni referenci za pulverizator).

Zahtjevi kvalitete koji obično utječu na cijenu

Kupci rPVC-a više vrijednosti obično plaćaju za predvidljivost i manji rizik. Najčešći "pokretači cijena" su:

- Međupolimerna kontaminacija: Miješanje PVC-a i ne-PVC-a te miješani kruti/fleksibilni PVC.

- Vidljiva kontaminacija: metali, gumene brtve, drvo/papir, pijesak.

- Veličina čestica + fine čestice: gusta distribucija nasuprot prašnjavom mljevenom materijalu koji se ponaša nepredvidivo.

- Vlaga: posebno važno ako se tali/ekstrudira nizvodno.

- Konzistentnost boje/izgleda: kritično za profil i vidljive proizvode.

- Povijest aditiva/usklađenosti: naslijeđeni stabilizatori i potrebna dokumentacija za zakonitu krajnju upotrebu.

Jednostavna kontrolna lista za kontrolu kvalitete prije slanja

Ako želite ponovljene narudžbe, izradite kontrolni popis za kratka izdanja: – vizualni pregled (kontaminacija i konzistentnost boje) – brza provjera sitom (veličina čestica i fine čestice) – provjera vlage (kada je relevantno za proces kupca) – identifikacija serije + bilješke o izvoru + paket dokumentacije (posebno za tokove nakon potrošnje)

Preguntas Frecuentes (FAQ)

Koje rPVC primjene obično isplaćuju više?

Primjene koje zahtijevaju dosljednu kvalitetu i dokumentiranu usklađenost (uobičajeno u građevinskim proizvodima) često su skuplje od prodajnih mjesta koja prihvaćaju miješane boje i varijabilno mljeveno gorivo.

Zašto neki kupci zahtijevaju dokumentaciju za reciklirani PVC?

Budući da povijest aditiva može utjecati na zakonitu upotrebu i prihvaćanje proizvoda (posebno za postkonzumerske tokove). Dokumentacija smanjuje rizik za kupca i pomaže u održavanju stabilnosti ponovljenih narudžbi.

Je li pranje rPVC-a uvijek potrebno?

Ne. Čisti postindustrijski tokovi možda ne trebaju pranje. Prljavi ili miješani tokovi često trebaju ako želite kupce veće vrijednosti s strožim ograničenjima kontaminacije.

Koji su najčešći razlozi odbijanja pošiljki rPVC-a?

Vidljiva kontaminacija, problemi s mirisom, nedosljedna veličina čestica i nejasna povijest aditiva/usklađenosti. To se obično može spriječiti uzvodnom kontrolom i kontrolom kvalitete.

Zaključak

Potražnja na tržištu rPVC-a je stvarna, ali nagrađuje tvrtke za recikliranje koje tretiraju rPVC kao specifikacija proizvoda, a ne samo preusmjereni tok otpada. Ako uskladite svoju opremu i kontrolu kvalitete s oblikom koji vaši kupci trebaju (ponovno mljeveno, čiste granule ili prah) te kontrolirate kontaminaciju i dokumentaciju, možete prodavati u stabilnijim i vrijednijim primjenama.