PP Woven Bags & Raffia Recycling Line

Built for contaminated woven sacks, raffia tape/yarn, and jumbo bags (FIBC). This line combines high-torque size reduction with intensive washing and drying to deliver clean, dry PP flakes—ready for extrusion and optional peletiranje.

- Designed for PP woven bags, raffia, and FIBC jumbo bags

- Deep cleaning for sand, ink, glue, and organics (hot wash optional)

- Dry output for stable extrusion (typical < 3% residual moisture)

- Typical line capacity: 300–1500 kg/h (configuration dependent)

Why This PP Woven & Raffia Line Works

Practical advantages engineered for real-world woven bag and raffia contamination.

Designed for Heavy Contamination

Built to remove sand, grit, ink, glue, and organics common in woven sacks and raffia.

Stable Downstream Pelletizing

Consistent washing + drying supports stable extrusion and low gel/black-speck risk.

Woven + Raffia Focus

Handles PP woven bags, raffia tape/yarn, jumbo bags (FIBC), and PP non-woven fabrics.

Uso de Recursos Eficiente

Circuito de lavagem otimizado reduz o consumo de água e energia para baixar os custos operacionais.

Design Robusto e de Baixa Manutenção

Componentes industriais construídos para disponibilidade com serviço simplificado e peças de reposição.

Escalável e Personalizável

Layout configurável e capacidades para se adequar ao seu plano de instalação e ao crescimento.

Supported PP Woven & Raffia Feedstocks

Typical incoming materials for this recycling line (share samples for a configuration recommendation).

Bolsas Tejidas de PP

Cement bags, fertilizer sacks, rice bags, and other printed woven sacks.

PP Non-Woven

Non-woven fabric scraps and bags (PP), with optional deeper washing.

PP Raffia (Tape/Yarn)

Raffia strips, tapes, and yarn waste from weaving and packaging operations.

BOPP-Laminated Woven Bags

Laminated woven bags and printed layers (configured based on contamination).

Jumbo Bags (FIBC)

Bulk bags and big bags, including dusty or sand-contaminated material.

Production Scrap

Clean or lightly contaminated woven trims, offcuts, and weaving scrap.

Process Flow (Woven Bags & Raffia)

A typical configuration from size reduction to washing, drying, and optional pelletizing—tuned to your contamination and output targets.

Feeding & Pre-Sorting

Controlled feeding handles loose and bulky materials while reducing foreign contaminants.

Usitnjavanje

High-torque shredding opens woven structures and reduces volume for consistent washing.

Vlažna granulacija

Secondary size reduction with water-assisted cutting improves cleaning efficiency.

Frikcijsko pranje

Removes sand, dust, paper fibers, and loosened ink from PP flakes.

Rinsing & Separation

Rinsing and separation remove heavy contaminants for higher PP purity.

Dewatering & Drying

Mechanical dewatering + thermal drying deliver low-moisture flakes for extrusion.

Pelletizing (Optional)

Convert clean PP flakes into uniform pellets for easy storage and resale.

Key Machines in the PP Woven Bags & Raffia Recycling Line

Transportna traka Tehnički podaci

- Materijal: PVC

- Debljina remena: 0,4 mm

- S uređajem za zatezanje remena i prihvatnim spremnikom

- Largura e Comprimento da Cinta: Prilagođeno na temelju veličine izlaza

- Transportando materiais brutos para o sistema.

Sjeckalica s jednom osovinom Tehnički podaci

- Brzina rotora: 60-100 okretaja u minuti

- Materijal oštrice: Visokočvrsti legirani čelik ili čelik D2

- Komora za rezanje: 400mm x 500mm a 2000mm x 2000mm

- Veličina filtra zaslona: 40mm - 100mm (personalizável)

- Snaga motora: 15-200 kW

- Moer resíduos de diferentes tipos.

- Preparar materiais para reciclagem.

- Minimizar o tamanho dos materiais para facilitar o manuseio.

Vlažni plastični granulator Tehnički podaci

- Brzina rotora: 400-600 okretaja u minuti

- Materijal oštrice: D2 čelik s visokim sadržajem ugljika i kroma

- Raspored rezanja: V-oblik ili rez s dvostrukim škarama

- Veličina filtra zaslona: 10mm - 100mm (personalizável)

- Cortar materiais plásticos em escamas uniformes.

- Pré-lavar e soltar contaminantes.

- Reduzir a formação de poeira em plantas de reciclagem.

Frikcijska podloška Tehnički podaci

- Brzina rotora: 500-600 okretaja u minuti

- Vodovodni sustav: Gornji ulaz, donji izlaz

- Operacija: Stalan

- Metoda čišćenja: Friction High-Speed

- Escovar e limpar materiais plásticos.

- Transportar materiais entre máquinas.

- Remover terra, areia e outros contaminantes.

Plutajući spremnik za odvajanje Tehnički podaci

- Unutarnja širina: 1000mm - 1800mm

- Ukupna dužina: 4 - 7 metros

- Materijal interijera: Nehrđajući čelik tipa 304

- Vanjski okvir: Ugljični čelik

- Motori s lopaticama: 1,5KW × 2 (controle de frequência)

- Base "W" para melhor eficiência.

- Design de duas seções para melhor gestão de contaminação.

- Separação baseada em água para poliolefins (PP/PE).

Vruća perilica Tehnički podaci

- Način rada: Continuo o por lotes (personalizable)

- Sustav grijanja: Ugrađeno grijanje na struju

- Metoda pranja: Topla vodena kupka s kemijskim dodacima

- Prikladni materijali: PP woven bags, raffia, and other contaminated PP plastics

- Eliminación efectiva de aceite, pegamento y contaminantes difíciles.

- Sistema de calentamiento integrado que elimina la necesidad de un calentador externo.

- Uso óptimo de agentes químicos para mejorar la limpieza.

Centrifugalna sušilica Tehnički podaci

- Brzina rotacije: Aprox. 1,000 RPM

- Smanjenje vlage: Hasta aproximadamente 20-30%

- Glavne komponente: Rotor con palas, túnel de malla

- Kućište: Metalni spremnik s vanjskim elektromotorom

- Alta eficiencia con bajo consumo energético.

- Maneja materiales con alto contenido de agua.

- Adecuado para escamas de PET, películas PP/PE y otros reciclados.

Secador de Tubo Térmico Tehnički podaci

- Model: RSJ800

- Snaga puhala: 5,5 kW

- Snaga grijanja: 36 kW

- Promjer cijevi: ⌀159 mm

- Materijal cijevi: Nehrđajući čelik tipa 304

- Proceso de secado continuo.

- Separador ciclónico integrado para la remoción de finos.

- Sistema de deshidratación por aire caliente.

- Diseño escalable (se pueden usar múltiples unidades en serie).

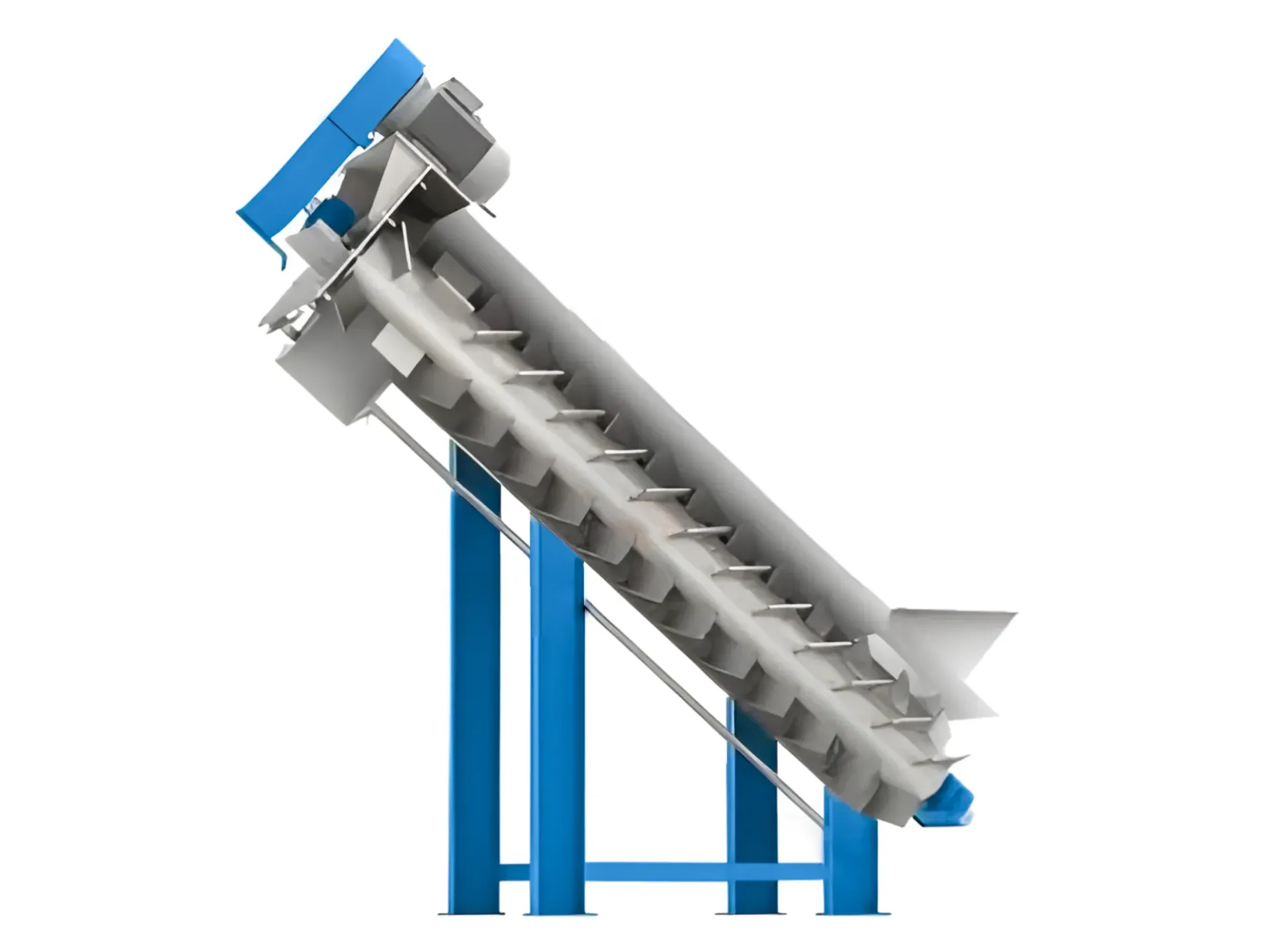

Cjedilo za film Tehnički podaci

- Smanjenje vlage: Reduce la humedad de 10-35% a 1-5%

- Mehanizam: Sustav kompresije vijčanog tipa

- Izlazni kapacitet: 300 kg/h - 1500 kg/h

- Potrošnja energije: 75 kW - 162 kW

- Reduce la humedad de manera eficiente para la granulación.

- Compacts PP flakes into dense agglomerates for easier feeding.

- Mejora la eficiencia general del reciclaje.

Water Ring Pelletizing System (Optional)

- Pellet Type: Water-ring cut, uniform granules

- Typical Inputs: Clean PP flakes from woven bags, raffia, and FIBC scrap

- Prilagodba: Die face, filtration, and automation options

- Stable pelletizing for variable woven-bag feedstock.

- Improved feeding consistency vs. loose flakes.

- Optional filtration upgrades for higher pellet purity.

Qué dicen los clientes

Feedback real de operadores que mejoraron sus líneas de reciclaje con nosotros.

We moved from inconsistent woven-bag flakes to clean, stable PP output. Moisture dropped below 3%, which made extrusion and pelletizing much more reliable.

Installation and training were smooth. Sand and ink removal from printed sacks is far better than our previous setup, and maintenance has been minimal.

Versatile system that handles both raffia and woven sacks reliably. Our downstream efficiency increased noticeably.

Često postavljana pitanja

Respuestas a preguntas comunes para ayudarte a evaluar la mejor solución.

What PP materials can this line process?

It is designed for PP woven sacks, raffia (tape/yarn), jumbo bags (FIBC), and PP non-woven fabrics. We also handle BOPP-laminated woven bags based on contamination level.

What output and moisture level can I expect?

Typical capacity ranges from 300–1500 kg/h. With the full dewatering + thermal drying configuration, residual moisture typically falls below 3%, suitable for stable extrusion and pelletizing.

Do I need hot washing for printed cement bags or oily contamination?

Hot washing is optional and recommended when you need deeper decontamination (ink, oils, glue, heavy organics). We configure the washing loop based on your feedstock and target end-product.

Can this line produce PP pellets directly?

Yes. Add a squeezer and pelletizing module (such as a water ring pelletizing system) to convert washed PP flakes into uniform pellets. Share your requirements and we’ll recommend the best configuration.

Can you customize the layout and automation level?

Yes. We tailor shredding, washing, drying, and optional pelletizing modules to your capacity, contamination level, and plant footprint, with on-site guidance or remote commissioning available.

Solicita tu Propuesta Personalizada

Tell us about your PP woven bags/raffia feedstock, contamination level, capacity goals, and space constraints. We’ll propose a line configuration (with optional pelletizing) that fits your operation.