Vijesti o recikliranju

U svijetu recikliranja, nije sav otpad jednak. Dok se krute plastike (poput boca i cijevi) lako drobe, Meki materijali - posebno plastične folije i tekstilna vlakna - su notorno teški za obradu.

Omotavaju se oko rotora, zaglavljuju sita i tope se pod trenjem. Ipak, predstavljaju ogroman dio toka otpada.

Da biste ove problematične materijale pretvorili u profit, standardno drobljenje nije dovoljno. Potrebna vam je tehnologija usitnjavanja s velikim okretnim momentom i malom brzinom. Ovaj vodič istražuje kako specijalizirani usitnjivači revolucioniraju oporavak folije i vlakana, pretvarajući potencijalna odlagališta u vrijednu sirovinu.

Izazov: Problem "mekog materijala"

Prije nego što shvatimo rješenje, moramo poštovati izazov.

- Plastične folije (LDPE/LLDPE/PP): Lagan i fleksibilan. U standardnom granulatoru, filmovi imaju tendenciju "plutanja" umjesto da se uvlače, ili još gore, čvrsto se omotavaju oko glavne osovine, uzrokujući zastoje.

- Vlakna (tekstil, tepisi, PP rafija): Iznimno visoka vlačna čvrstoća. Ne lome se lako; trgaju se. Bez prave geometrije rezanja mogu uzrokovati katastrofalna zaglavljivanja i pregaranje motora.

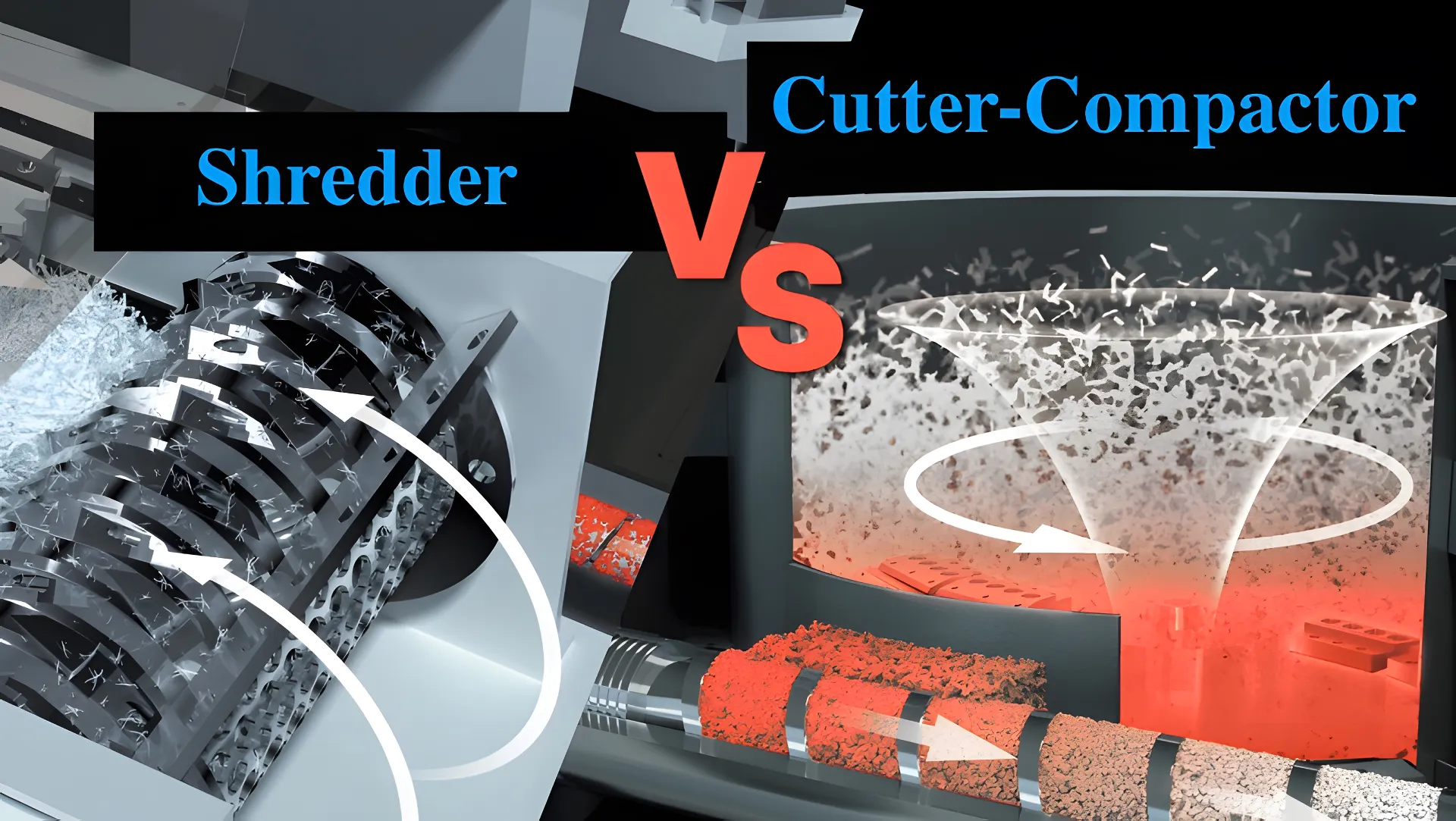

Rješenje: Tehnologija usitnjavanja s jednom osovinom

Industrijski standard za prevladavanje ovih izazova je Sjeckalica s jednom osovinom. Za razliku od granulatora velike brzine, ovi strojevi rade pri nižim brzinama s ogromnim okretnim momentom, koristeći hidraulički cilindar za pritiskivanje materijala na rotor.

1. Revolucioniranje recikliranja vlakana i tekstila

Tekstilni otpad - od stare odjeće do industrijskih tepiha - zahtijeva stroj koji može rezati tvrda sintetička vlakna bez zapetljavanja.

Specijalizirani Uništavač tekstilnog otpada s jednom osovinom je projektiran upravo za tu svrhu.

- Dizajn protiv namotavanja: Noževi rotora su raspoređeni tako da sprječavaju omotavanje dugih vlakana oko osovine.

- Integracija procesa: Razbijanjem rasutog tekstila na jednolične komade, usitnjivač priprema materijal za daljnje procese, osiguravajući nesmetano uvlačenje u Peletizatori plastike bez premošćivanja ili blokiranja grla ekstrudera.

- Smanjenje volumena: Rastresiti tekstil je glomazan i skup za transport. Usitnjavanje značajno povećava gustoću materijala, optimizirajući logistiku.

2. Optimizacija obrade plastične folije

Za poljoprivredne folije, skupljajuću foliju i vrećice nakon upotrebe, usitnjivač djeluje kao ključni "prvi korak" u liniji za pranje.

- Priprema prije pranja: Ne možete učinkovito oprati cijelu balu folije. Usitnjavanje otvara materijal, otkrivajući veću površinu.

- Dubinsko čišćenje: Ovo smanjenje veličine ključno je za sljedeću fazu. Osigurava da voda i mehanička sila mogu učinkovito ukloniti prljavštinu, pijesak i onečišćujuće tvari u sljedećem Frikcijska podloška.

- Zaštitna oprema: Smanjivanjem folije na konzistentnu veličinu (npr. 40-60 mm) sprječavate začepljenje pumpi i transportera dalje niz liniju.

Održivost susreće učinkovitost

Ulaganje u pravi šreder nije samo operativna odluka; to je strategija održivosti.

- Zatvaranje petlje: Učinkovitom obradom teških materijala poput prljave poljoprivredne folije ili odbačenih tepiha, recikleri mogu oporabiti resurse koji su se prije smatrali "preteškima za recikliranje" i poslani na odlagališta.

- Energetska učinkovitost: Moderni šrederi s pametnim sustavima upravljanja (poput automatskog preokretanja pri preopterećenju) troše manje energije po toni u usporedbi sa zastarjelim metodama drobljenja grubom silom.

- Reciklirani materijali više kvalitete: Čist, ujednačen rez dovodi do boljih rezultata pranja i, u konačnici, do recikliranog peleta više kvalitete koji postiže bolju tržišnu cijenu.

Zaključak

Shredderi su čuvari ulaza u postrojenje za recikliranje. Za krute materijale, oni su korisni; za filmovi i vlakna, oni su obavezni.

Bez obzira imate li posla s visokočvrstom PP rafijom ili prljavim poljoprivrednim folijama, razlika između profitabilnog poslovanja i noćne more održavanja često leži u vašem izboru usitnjivača. Korištenjem napredne opreme poput Uništavač tekstilnog otpada s jednom osovinom, osiguravate da vaša linija radi glatko - od početnog rezanja, preko frikcione podloške, pa sve do konačnog peletiranja.

https://www.energycle.com/plastic-shredders/textile-waste-single-shaft-shredder/

Plastični granulatori ključni su dio svakodnevnog rada u postrojenjima za recikliranje, odgovorni za smanjenje plastičnog otpada u jednolične granule za daljnju obradu. Međutim, s vremenom, habanje, kontaminacija i nepravilan rad mogu značajno smanjiti performanse i povećati vrijeme zastoja.

Ovaj vodič se fokusira na praktično održavanje, rješavanje problema i najbolje operativne prakse kako bi se pomoglo postrojenjima za recikliranje da produže vijek trajanja, održe stabilnu proizvodnju i smanje neplanirane zastoje - bez preklapanja s odabirom opreme ili odlukama o kupnji.

Zašto je pravilno održavanje granulatora važno u postrojenjima za recikliranje

U kontinuiranom recikliranju, granulator plastike izložen je različitim materijalima, abrazivnim onečišćujućim tvarima i visokim mehaničkim opterećenjima. Bez strukturirane rutine održavanja, čak i dobro dizajnirani strojevi mogu patiti od preranog trošenja i smanjenja performansi.

Učinkovito održavanje pomaže u:

- Održavajte konzistentnu kvalitetu granula tijekom dugih proizvodnih ciklusa

- Smanjite neočekivane zastoje i hitne popravke

- Produžite radni vijek habajućih komponenti

- Poboljšajte ukupnu učinkovitost i sigurnost postrojenja

Za postrojenja za recikliranje koja posluju s niskim maržama, preventivno održavanje često je isplativije od reaktivnih popravaka.

Osnovni zadaci održavanja plastičnog granulatora

Strukturirani raspored održavanja osigurava stabilan rad u stvarnim uvjetima recikliranja. Sljedeći zadaci preporučuju se za većinu industrijskih okruženja za recikliranje.

Svakodnevno održavanje

- Očistite lijevak i područje za punjenje kako biste spriječili nakupljanje materijala

- Pregledajte komoru za rezanje na ostatke plastike ili onečišćenja

- Provjerite oštrice i sita na rane znakove istrošenosti

- Provjerite mjesta podmazivanja prema radnim satima i opterećenju

Tjedno održavanje

- Očistite zračne filtere kako biste održali pravilno hlađenje i protok zraka

- Provjerite pogonske remene i spojnice na napetost i poravnanje

- Provjerite električne spojeve na labavost ili pregrijavanje

- Uklonite nakupljenu prašinu s vanjskih površina

Mjesečno održavanje

- Provjerite poravnanje rotora i statora u radnim uvjetima

- Pregledajte ležajeve na abnormalnu buku ili porast temperature

- Očistite i podmažite mjenjač ako je potrebno

- Testirajte sigurnosne sustave kao što su zaustavljanja u nuždi i blokade

Godišnji ili planirani remont

- Zamijenite komponente koje se jako troše, kao što su lopatice, sita i ležajevi

- Pregledajte strukturne elemente na umor ili pukotine

- Ponovno provjerite kalibraciju stroja kako biste vratili učinkovitost rezanja

- Pregledajte operativne zapise kako biste identificirali probleme koji se ponavljaju

Rješavanje uobičajenih problema s plastičnim granulatorom

Čak i uz redovito održavanje, problemi u radu mogu se pojaviti. Rana dijagnoza može spriječiti eskalaciju manjih problema.

Granulator se ne pokreće

- Potvrdite stabilno napajanje i ispravan napon

- Pregledajte sigurnosne prekidače i blokade

- Provjerite je li strujni krug za zaustavljanje u nuždi potpuno resetiran

Smanjeni učinak ili protok

- Provjerite oštrinu oštrice i razmak rezanja

- Pregledajte sita na začepljenje ili deformaciju

- Provjerite jesu li veličina ulaznog materijala i brzina protoka konzistentni

Nedosljedna veličina granula

- Pregledajte lopatice i sita na neravnomjerno trošenje

- Potvrdite pravilno poravnanje rotora i statora

- Procijenite konzistentnost ulaznog materijala i razinu kontaminacije

Prekomjerna buka ili vibracije

- Pregledajte ležajeve i točke pričvršćivanja

- Provjerite neravnotežu rotora uzrokovanu neravnomjernim trošenjem

- Provjerite je li stroj ispravno niveliran i usidren

Najbolje operativne prakse za poboljšanje performansi granulatora

Osim rutinskog održavanja, operativna disciplina igra važnu ulogu u dugoročnim performansama.

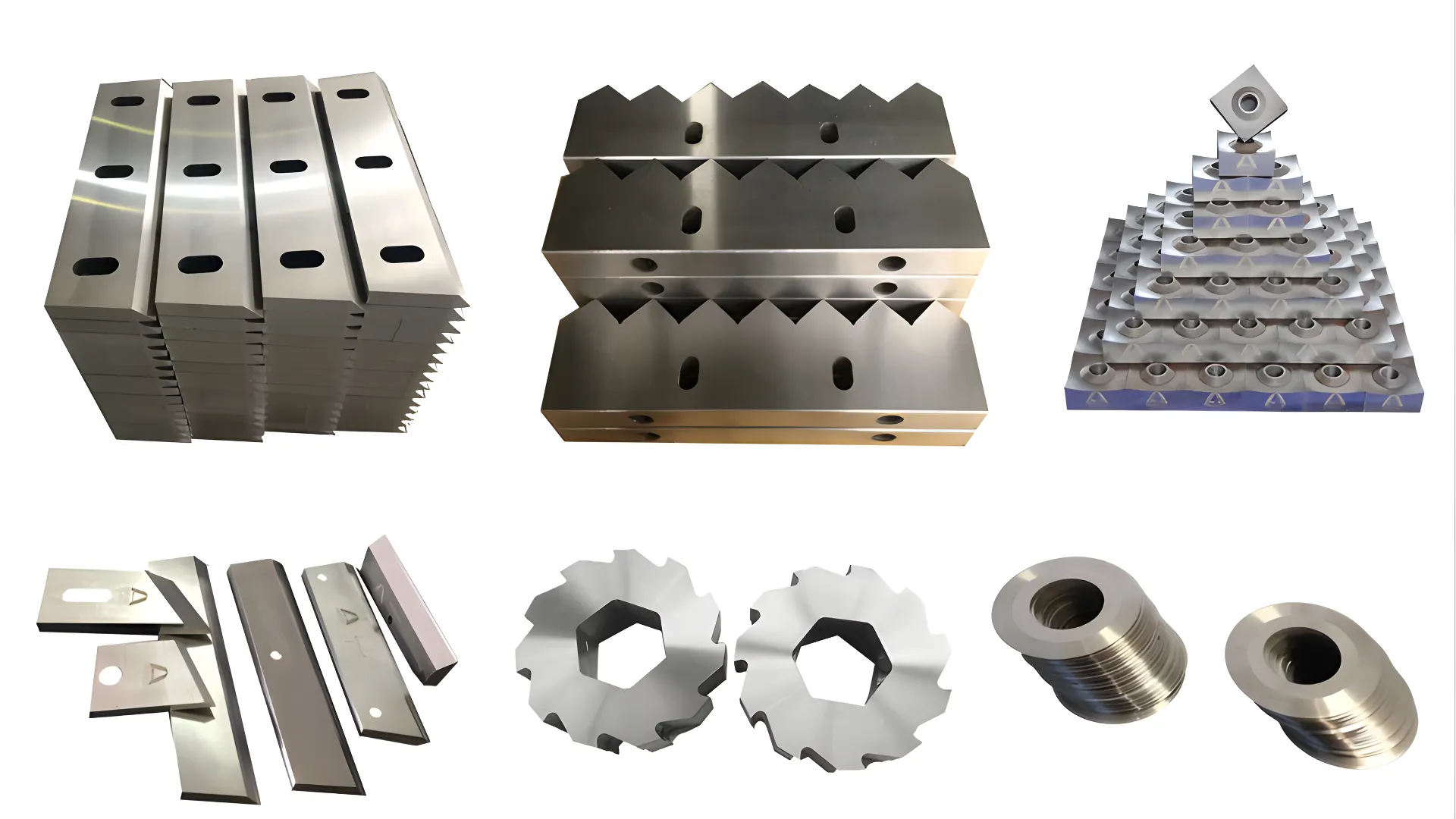

Koristite oštrice i sita prikladne za primjenu

Odabirom reznih komponenti koje odgovaraju vrsti materijala, debljini i tvrdoći smanjuje se potrošnja energije i trošenje.

Održavajte stabilan proces hranjenja

Nagli udari ili nekonzistentno napajanje povećavaju mehaničko naprezanje i ubrzavaju degradaciju oštrice.

Praćenje trendova potrošnje energije

Postupno povećanje potrošnje energije često ukazuje na istrošenost lopatica, začepljenje sita ili probleme s ležajevima prije nego što se pojave vidljivi simptomi.

Primijenite prediktivno održavanje gdje je to moguće

Praćenje stanja, analiza vibracija i praćenje temperature pomažu u ranom prepoznavanju kvarova i smanjenju neplaniranih zastoja.

Kada samo održavanje više nije dovoljno

Održavanje može produžiti vijek trajanja, ali ne može beskonačno kompenzirati ograničenja kapaciteta, strukturni umor ili promjenjive proizvodne zahtjeve.

Ako postrojenje za recikliranje doživi:

- Stalni pad propusnosti

- Povećane vibracije unatoč ponovljenim popravcima

- Strukturno trošenje koje utječe na sigurnost ili pouzdanost

možda je vrijeme za procjenu zamjena opreme ili nadogradnja sustava.

Za postrojenja koja procjenjuju nova rješenja, ovdje možete pregledati naše opcije industrijskih granulatora plastike:

https://www.energycle.com/plastic-granulators/

(Jedna referenca za potrebe procjene; smjernice za održavanje ostaju neovisne o opremi.)

Zaključak

Održavanje granulatora plastike nije samo kontrolna lista - to je operativna strategija koja izravno utječe na produktivnost, sigurnost i kontrolu troškova u postrojenjima za recikliranje. Kombiniranjem preventivnog održavanja, strukturiranog rješavanja problema i discipliniranog rada, recikleri mogu postići pouzdanije performanse i dulji vijek trajanja opreme.

Jasna razlika između operativne smjernice i izbor opreme osigurava bolje donošenje odluka u svakoj fazi procesa recikliranja.

Često postavljana pitanja (FAQ)

Koliko često treba servisirati noževe granulatora?

Servisni intervali ovise o abrazivnosti materijala, stupnju onečišćenja i radnim satima. U industrijskim okruženjima recikliranja, uobičajena je inspekcija svakih 100–300 sati.

Jesu li zamjenski dijelovi prikladni za recikliranje?

Iako zamjenski dijelovi mogu smanjiti kratkoročne troškove, kompatibilnost i trajnost mogu varirati. Neusklađeni dijelovi često dovode do bržeg trošenja i nestabilnog rada.

Kako bi operateri trebali biti obučeni za svakodnevno održavanje?

Operateri bi trebali slijediti dokumentiranu kontrolnu listu koja obuhvaća čišćenje, inspekciju i sigurnosnu provjeru. Praktična obuka i nadzor ključni su za dosljednost.

Što treba učiniti u slučaju iznenadnog kvara?

Sigurno isključite stroj, izolirajte napajanje i sustavno dijagnosticirajte problem. Ponovljeni kvarovi obično ukazuju na dublje mehaničke ili operativne probleme.

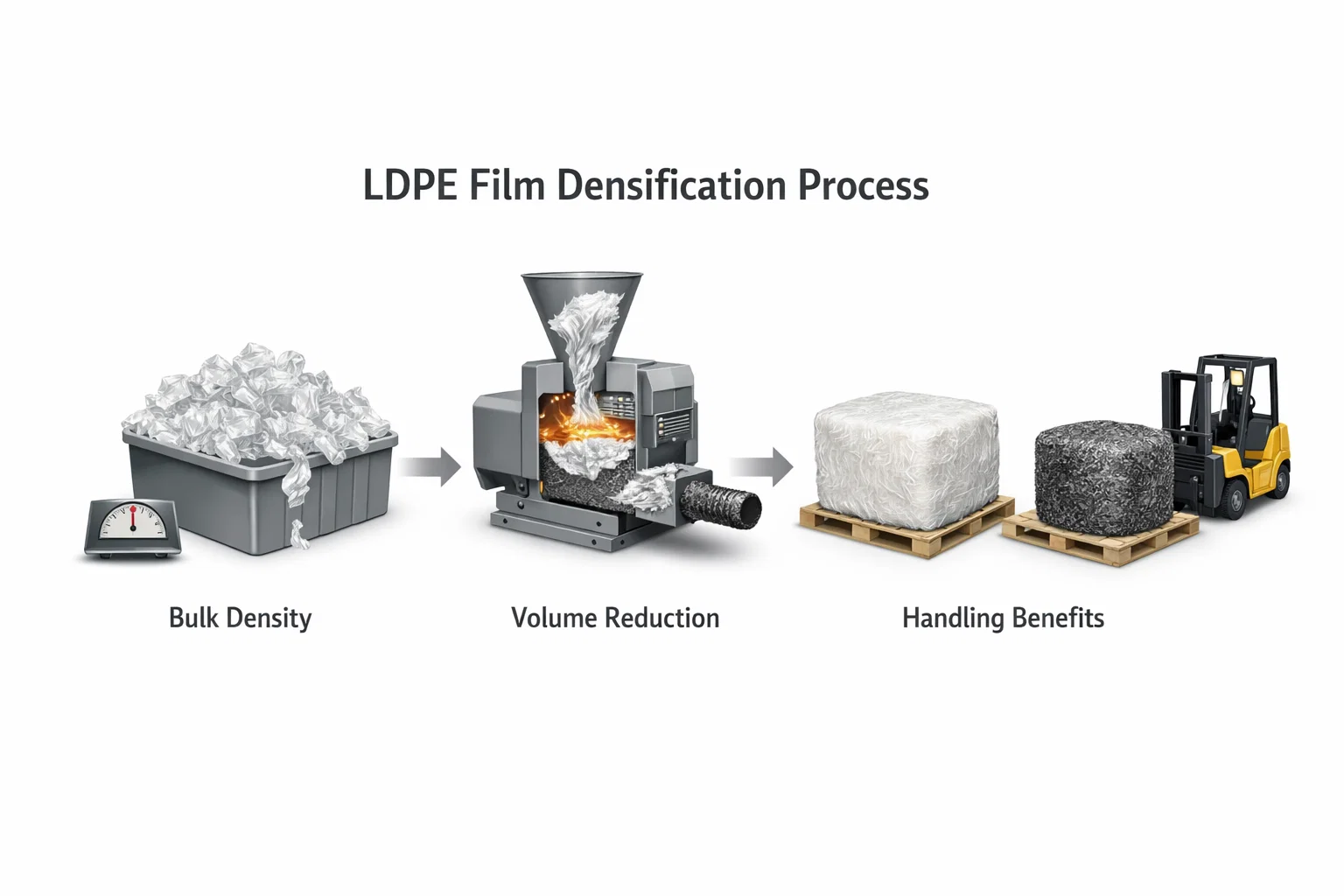

Naše vijčana preša za plastičnu foliju Sustavi (cijedilica/zgušnjavača) prvenstveno su pozicionirani za Europu i Sjevernu Ameriku, gdje se recikleri suočavaju sa zajedničkom stvarnošću: višim troškovima rada, strožim zahtjevima kvalitete i rastućim cijenama energije. Kupci u tim regijama obično daju prednost opremi koja može pružiti:

- Stabilno smanjenje vlage za opranu foliju (za poboljšanje stabilnosti ekstruzije i kvalitete peleta)

- Niži operativni troškovi učinkovitom odvodnjavanjem i korištenjem topline

- Konzistentna propusnost uz minimalnu intervenciju operatera

- Pouzdane performanse na zahtjevnim sirovinama (tiskani film, miješani film, mokri ili kontaminirani film)

Europa (EU/UK): Potražnja je najveća u zemljama sa zrelom infrastrukturom za recikliranje i snažnim ciljevima recikliranja ambalaže - posebno u Njemačkoj, Italiji, Francuskoj, Španjolskoj, Nizozemskoj, Poljskoj i Ujedinjenom Kraljevstvu. Ta tržišta često zahtijevaju strožu kontrolu kontaminacije i vlage kako bi se ispunila očekivanja kvalitete peleta.

Sjeverna Amerika (SAD/Kanada): Mnogi pogoni povećavaju kapacitet kako bi prerađivali više folija nakon potrošnje i komercijalnih/industrijskih folija. Uobičajeni prioriteti uključuju automatizaciju, vrijeme rada i smanjenje potrošnje energije po toni, uz održavanje dosljedne kvalitete peleta za primjene veće vrijednosti.

Što je sustav za prešanje vijkom za plastičnu foliju (stiskalica/zgušnjavač)?

Sustav za vijčanu prešu za plastičnu foliju je mehaničko odvodnjavanje + faza zgušnjavanja koristi se nakon linije za pranje folije. Uklanja slobodnu vodu iz oprane folije pomoću kompresija i smicanje, pretvarajući mokri, pahuljasti film u vrući, zgusnuti izlaz s niskom vlagom koji pouzdanije uvodi u ekstruder i peletizator.

U tipičnoj liniji za proizvodnju folija, vijčana presa se nalazi nakon:

sortiranje → usitnjavanje → pranje → (trenje/ispiranje plutanjem) → mehaničko odvodnjavanje → vijčana preša (cijedilica) → ekstruzija → peletiranje

U usporedbi s osnovnim centrifugama ili jednostavnim valjcima za stiskanje, dobro dizajnirana vijčana preša može pružiti:

- Niža i stabilnija vlažnost

- Vrući, zbijeni izlaz (zgusnuti film)

- Smanjeno zarobljavanje zraka prije ekstruzije

- Bolja stabilnost linije pod varijacijama sirovina u stvarnom svijetu

Zašto kontrola vlage izravno utječe na troškove i kvalitetu peleta

Vlaga nije samo “voda”. Kod recikliranja folija, problemi s vlagom često dolaze u kombinaciji sa:

- ostaci deterdženta, fine onečišćujuće tvari i organski tragovi

- hlapljive tvari tinte (tiskani film)

- neravnomjerno sušenje zbog varijacije debljine filma

- voda zarobljena unutar nabora i višeslojnih struktura

Ako je vlaga nestabilna, ekstruder se mora boriti protiv nje. Rezultat je poznat svakom recikleru folije:

- mjehurići/praznine u peletima

- nestabilan tlak taline

- česte promjene ekrana (kontaminacija + gelovi)

- niža propusnost ili prisilna usporavanja

- veća potrošnja energije po toni

- više otpada i više intervencija operatera

Vijčana preša rješava problem ranije - prije nego što ekstruder postane "sušilica".“

Primarni kupci: Za koga je ovaj sustav namijenjen

Ovaj sustav je dizajniran za postrojenja koja trebaju pretvoriti opranu plastičnu foliju u stabilnu, visokokvalitetnu sirovinu za ekstruziju i peletiranje. Tipični kupci uključuju:

1) Postrojenja za recikliranje plastičnih folija (postpotrošačka i postindustrijska)

- Obrada operatora LDPE/LLDPE folija, stretch folija, folija za pakiranje, vrećice za kupovinu, poljoprivredna folija i miješane fleksibilne plastike

- Postrojenja koja rade cijelu liniju: sortiranje → usitnjavanje → pranje → odvodnjavanje/cijeđenje → ekstruzija → peletiranje

2) Postrojenja za peletiranje / granulaciju

- Proizvođači prelaze s osnovnog odvodnjavanja na bolju kontrolu vlage radi poboljšane stabilnosti taline

- Biljke usmjerene na veća konzistencija peleta, manje mjehurića/šupljina i smanjeni miris uzrokovano preostalom vlagom i hlapljivim tvarima

3) Integratori linija za pranje i EPC/graditelji linija po principu "ključ u ruke"

- Inženjerske tvrtke i integratori koji isporučuju kompletne linije za recikliranje folija i trebaju pouzdanu fazu stiskanja/zgušnjavanja kako bi optimizirali povrat ulaganja cijelog sustava

4) Gospodarenje otpadom i operateri MRF-a koji se šire na recikliranje folija

- Operateri dodaju mogućnosti recikliranja folija kako bi ostvarili veću vrijednost iz fleksibilnih tokova pakiranja

5) Prerađivači i proizvođači plastike s internim recikliranjem

- Tvornice koje recikliraju otpadnu foliju iz vlastite proizvodnje i žele smanjiti troškove zbrinjavanja te poboljšati učinkovitost ponovne obrade

Tipični donositelji odluka

U Europi i Sjevernoj Americi, odluke o kupnji obično se donose na temelju:

- Vlasnici postrojenja / Generalni direktori (ROI i kapacitet)

- Operativni menadžeri (vrijeme rada, osoblje, stabilnost)

- Procesni inženjeri (ciljevi vlage, kvaliteta peleta, integracija linije)

- Voditelji održavanja (upotrebljivost i potrošni dijelovi)

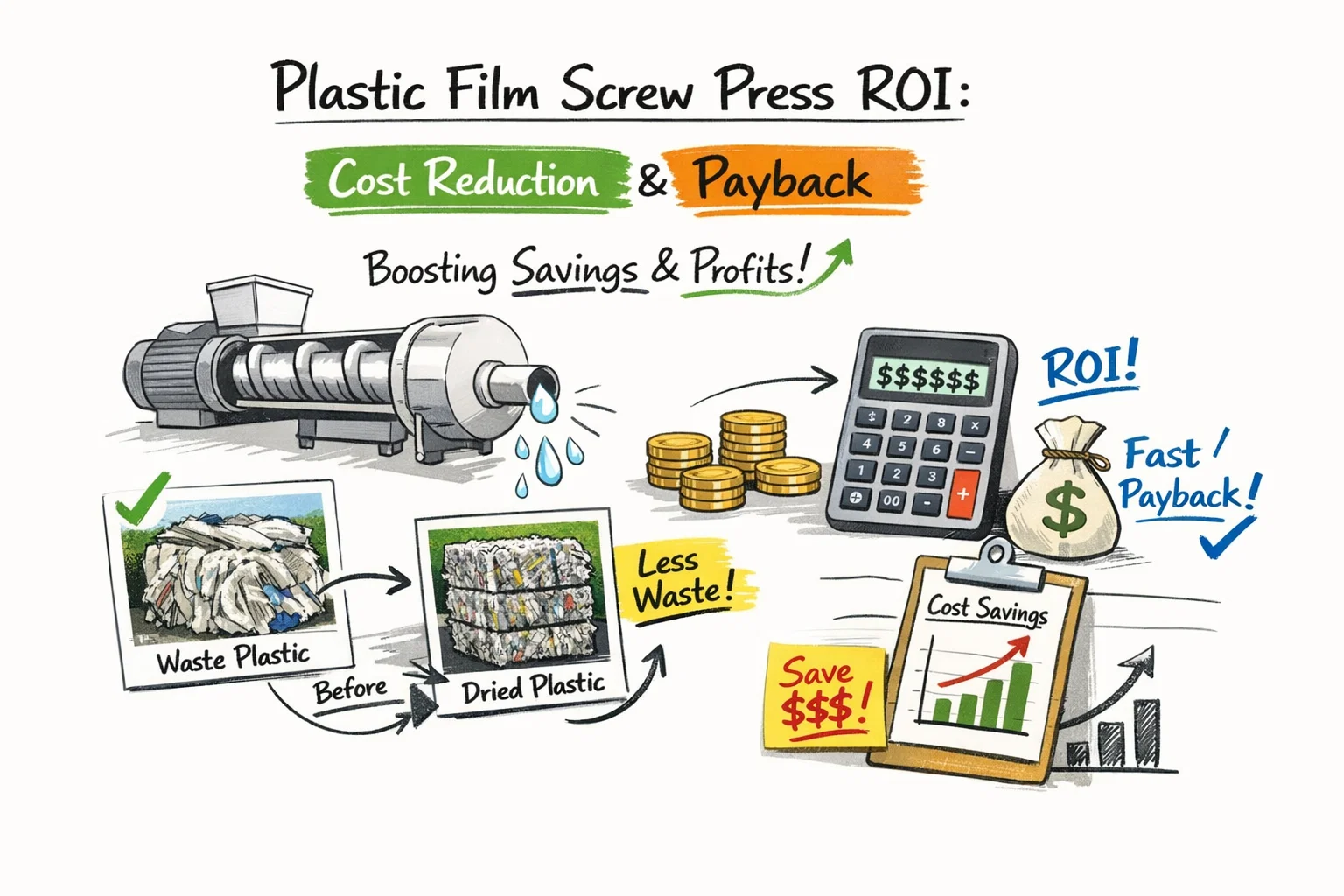

Smanjenje troškova: Gdje vijčana preša ostvaruje pravi povrat ulaganja

Kada postrojenja procjenjuju sustav vijčane preše, najvažnije pitanje nije “kako funkcionira”, već gdje se novac štedi. U stvarnom poslovanju uštede se obično ostvaruju u pet područja:

1) Veća propusnost i manje usporavanja

Mokri film se ponaša nekonzistentno i može preopteretiti dovodne uređaje, uzrokovati stvaranje mostova ili prisiliti ekstruder da radi nižom brzinom. Vijčana preša daje izlaz gusti, topli, konzistentni materijal, što poboljšava hranjenje i stabilizira ekstruziju.

Praktični utjecaj:

- stabilniji tlak taline

- manje zaustavljanja u nuždi

- poboljšano vrijeme rada po smjeni

- lakše održavanje ciljanog učinka

2) Manja potrošnja energije po toni

Ako vlaga uđe u ekstruder, energija se troši na:

- isparavanje vode

- kompenziranje nestabilnosti taline

- jači (i dulji) rad vakuumskih sustava

Mehaničkim uklanjanjem vode (što je općenito jeftinije od termičkog uklanjanja) smanjujete energetsko opterećenje nizvodno.

Što se poboljšava:

- niže kWh/tona za ekstruziju

- manji toplinski šok i manje temperaturnih oscilacija

- smanjena potreba za grijanjem zbog toplijeg zgusnutog sirovinskog materijala

3) Niži troškovi rada kroz smanjenu intervenciju

Mnoge filmske linije oslanjaju se na vještinu operatera kako bi se “borile protiv varijabilnosti”. Vijčana preša smanjuje samu varijabilnost.

Gdje pada radna snaga:

- manje podešavanja postavki dodavača i ekstrudera

- manje isključenja radi čišćenja i rješavanja problema

- manje vremena provedenog u rukovanju pahuljastim, mokrim filmom (ručno odčepljivanje, čišćenje mostova itd.)

4) Bolja kvaliteta peleta (viša prodajna cijena ili širi pristup kupcima)

Vlaga i hlapljive tvari glavni su uzročnici:

- mjehurići u peletama

- nedostaci povezani s mirisima i parom

- loša površinska obrada

- nestabilno ponašanje MFI-ja u nizvodnoj obradi

Bolja kontrola vlage može omogućiti:

- ujednačeniji izgled peleta

- manje pritužbi/povrata kupaca

- pristup primjenama veće vrijednosti (ovisno o sirovini i cjelokupnom dizajnu linije)

5) Smanjeni otpad, zastoji i stres održavanja

Nestabilno mokro hranjenje često se povećava:

- učitavanje i promjena frekvencije paketa zaslona

- prijenos kontaminacije

- trošenje vijaka, grijača i nizvodnih komponenti

- “skriveni zastoji” zbog stalnih mikrozaustavljanja i ciklusa ponovnog pokretanja

Stabilno zgusnuto punjenje smanjuje operativni stres na cijeloj liniji.

Analiza povrata ulaganja: Kako izračunati povrat ulaganja u postrojenju za recikliranje folija

Jednostavan i praktičan model povrata ulaganja uključuje četiri mjerljive stavke:

- Dodatna proizvodnja (tone/godina) od poboljšanog vremena rada i stabilne propusnosti

- Ušteda energije (kWh/tona ili $/tona) zbog manjeg opterećenja sušenjem i stabilne ekstruzije

- Uštede na radu ($/godišnje) zbog smanjenih intervencija i manjeg broja zastoja

- Povećanje kvalitete ($/tona) ako poboljšane pelete postignu bolju cijenu ili šire prihvaćanje od strane kupaca

Formula ROI-a (pojednostavljena)

Godišnja korist = (Dodatne tone × Marža po toni) + Ušteda energije + Ušteda rada + Poboljšanje kvalitete

Razdoblje povrata = Ulaganje u sustav / Godišnja korist

Napomena: “Marža po toni” trebala bi biti vaša stvarna marža (prodajna cijena umanjena za varijabilne troškove), a ne prihod.

Primjer scenarija povrata ulaganja (ilustrativni)

Da bi matematika bila jasnija, evo jednog ilustrativan primjer (brojevi se razlikuju ovisno o postrojenju i regiji):

Uvjeti za biljke:

- Linija za pranje folija koja proizvodi 3.000–6.000 tona godišnje

- Trenutne fluktuacije vlage uzrokuju česta usporavanja i probleme s kvalitetom

Konzervativne pretpostavke o poboljšanju nakon nadogradnje vijčane preše:

- +8% učinkovito poboljšanje vremena rada/propusnosti

- -10% potrošnja energije ekstruzije po toni

- -1 sat/dan smanjenja intervencije (ili ekvivalentno smanjenje troškova)

- smanjeni otpad i ponovna obrada

Čak i uz konzervativne pretpostavke, mnoge elektrane vide povrat ulaganja potaknut:

- više prodajne proizvodnje (tone)

- manje zastoja

- niži ukupni operativni trošak po toni

Ako želite, možemo izgraditi prilagođeni ROI list koristeći vaše stvarne brojke (kapacitet, cijena kWh, stopa rada i stopa otpada) kako bi procjena povrata odgovarala ciljanom tržištu vaše lokacije.

Ključni ciljevi performansi koje kupci traže

Kada kupci u EU/UK-u i Sjevernoj Americi procjenjuju sustave vijčanih preša, obično pitaju:

- Konzistentnost vlage (ne samo prosječna vlažnost)

- Stabilnost protoka pod miješanim filmom i tiskanim filmom

- Trošak potrošnih dijelova i intervali zamjene

- Jednostavnost čišćenja i pristupa za održavanje

- Kompatibilnost integracije s postojećim linijama za pranje i ekstruziju

- Značajke automatizacije (kontrola opterećenja, zaštita od momenta, logika alarma)

Kako se sustav integrira u liniju za pranje i peletiranje

Sustav vijčane preše najučinkovitiji je kada je integriran kao dio stabilnog toka:

- Stabilno punjenje s linije za pranje (konzistentno pranje i mehaničko odvodnjavanje uzvodno)

- Odvodnjavanje + zgušnjavanje vijčanom prešom (mehaničko uklanjanje vode i zbijanje)

- Kontrolirano ispuštanje (gusti, topli izlaz direktno u sustav za dovod ekstrudera)

- Ekstruzija optimizirana za kvalitetu taline, nije prisiljen djelovati kao sušilica

U mnogim nadogradnjama, vijčana preša postaje "stabilizator" koji omogućuje ekstruderu da radi bliže svom predviđenom kapacitetu.

Česta pitanja (FAQ)

P1: Može li vijčana preša rukovati tiskanom folijom i miješanom folijom?

Da. Tiskana folija i miješana folija obično sadrže više hlapljivih tvari i varijacija. Vijčana preša pomaže stabilizacijom vlage i gustoće punjenja, što smanjuje procesne šokove nizvodno.

P2: Zamjenjuje li sušilicu?

U mnogim filmskim linijama, vijčana preša smanjuje ili pojednostavljuje potrebe sušenja. Zamjenjuje li u potpunosti termičko sušenje ovisi o:

- vaša ciljana vlažnost za ekstruziju

- vrsta vaše sirovine i kontaminacija

- dizajn vaše cjelokupne linije

P3: Je li operaterima teško koristiti?

Ne. Većina sustava je izgrađena za jednostavan rad sa:

- kontrola opterećenja i zaštita od momenta

- brisanje alarma i blokada

- stabilan izlaz koji smanjuje ručnu intervenciju

P4: Što je najvažnije za povrat ulaganja - smanjenje vlage ili zgušnjavanje?

Oboje je važno. Smanjenje vlage poboljšava stabilnost taline, dok zgušnjavanje poboljšava dovod i protok. Najbolji povrat ulaganja obično dolazi od kombinacije:

- stabilna vlaga + stabilna gustoća hrane + manje zaustavljanja

Spremni ste smanjiti troškove i poboljšati stabilnost peleta?

Ako vaš pogon prerađuje opranu foliju i borite se s:

- nestabilna ekstruzija

- mjehurići/praznine

- zastoj zbog mokrog hranjenja

- visoki operativni troškovi po toni

Sustav preše s vijcima za plastičnu foliju često je jedan od najbržih načina za poboljšanje povrata ulaganja jer stabilizira najskuplju nizvodnu fazu - ekstruziju i peletiranje.

Kontaktirajte nas s vašom vrstom materijala (LDPE/LLDPE/mješovita folija), ciljanim kapacitetom i trenutnim rasponom vlažnosti. Možemo vam preporučiti pravu konfiguraciju i pomoći vam procijeniti povrat ulaganja na temelju vaših lokalnih troškova električne energije i rada.

Ovaj vodič usmjeren na kupce objašnjava kada se ne smije koristiti drobilica za plastiku, kako odabrati između drobilice i usitnjivača na temelju duljine materijala, realnih pragova kapaciteta i koje opcije za “teške uvjete rada” često nisu potrebne.

Namijenjen stručnjacima za recikliranje, ovaj članak pomaže vam da izbjegnete skupe pogreške i odaberete pravo rješenje za smanjenje veličine za vašu liniju za recikliranje.