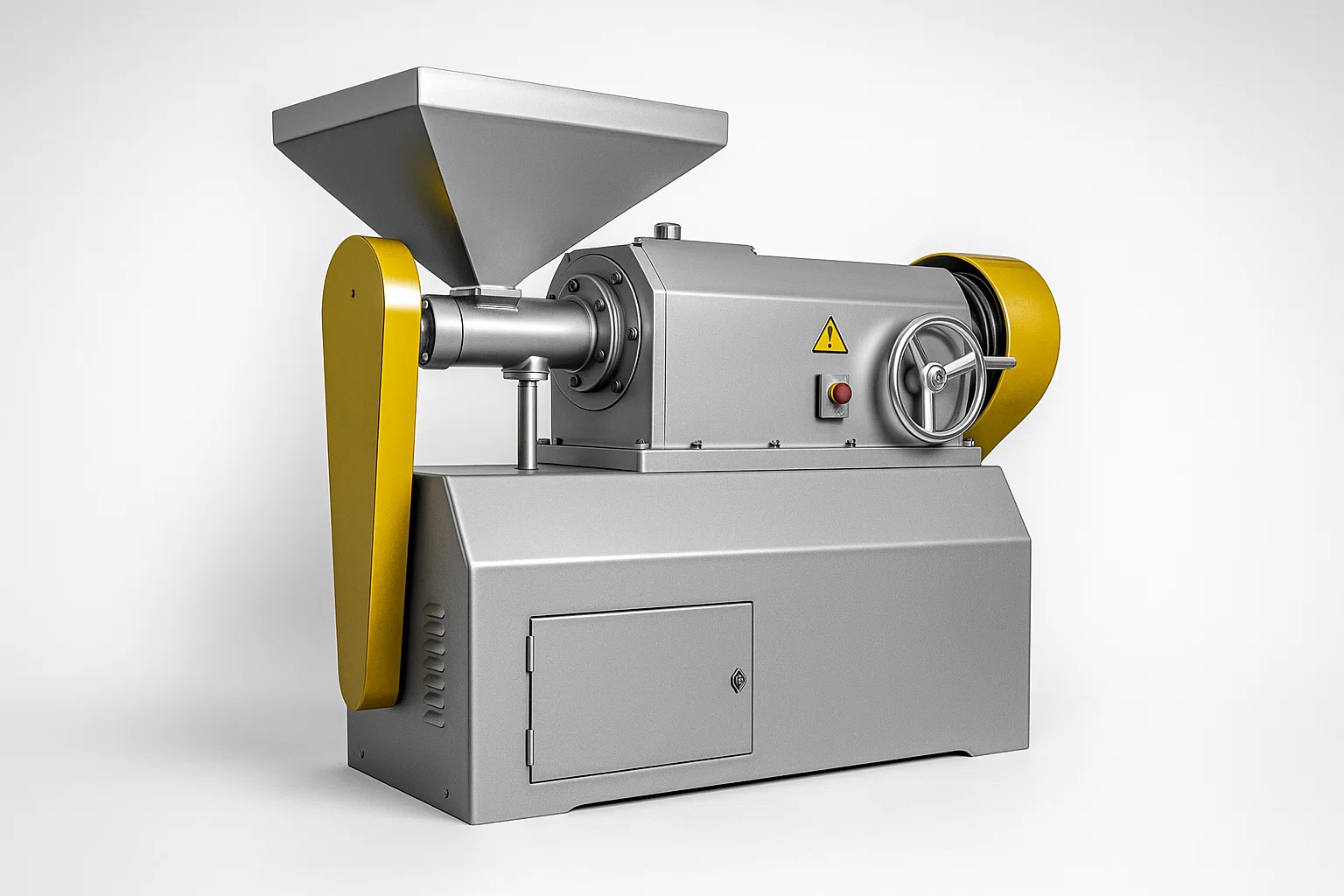

Precision Rubber Pulverizing Grinder

Achieve ultra-fine rubber powder with superior efficiency and consistency for high-value recycling applications.

Request a QuoteHigh Production Efficiency

Engineered for high-capacity output (500-2000kg/h) with consistent and uniform particle quality.

Flexible Operation

Variable-speed controls allow for precise adjustments to handle various materials and meet specific particle size requirements (40-200 mesh).

Eco-Friendly Design

Features an integrated dual-cooling system and dust collection to ensure low energy use and a clean operating environment.

Low Maintenance

Built with robust, precision-engineered components like tungsten carbide grinding discs for reliable, long-term operation.

Advanced Grinding Mechanism

1. Controlled Feeding

Material enters via a variable-frequency feed system for optimal flow.

2. Precision Grinding

High-speed rotating and stationary discs apply mechanical force to reduce particle size.

3. Dual Cooling

An integrated air and water cooling system maintains optimal grinding temperatures.

4. Fine Powder Output

Uniformly-sized fine rubber powder is discharged for collection.

Technical Specifications

| Parameter | Value |

|---|---|

| Production Capacity | 500-2000 kg/h (Material Dependent) |

| Final Particle Size | 40-200 Mesh (Adjustable) |

| Particle Uniformity | >90% within ±5% of target |

| Main Motor Power | 15-30 kW (Process Dependent) |

| Noise Level | < 75 dB(A) @ 1m |

| Grinding Discs | Tungsten Carbide Coated Alloy |

| Cooling System | Air / Water Dual Cooling |

| Control System | PLC Interface with Automated Control |

Core Components

- Heavy-Duty Frame: Robust, vibration-dampening design for maximum stability and longevity.

- High-Performance Motor: IP54 rated main drive motor provides reliable and consistent power.

- Precision Grinding Discs: Expertly engineered discs with tungsten carbide coating ensure fine, uniform grinding and a long service life.

- Variable-Frequency Feed: Allows for precise control over the material input, optimising the grinding process for different materials.

- Integrated Dual Cooling: An air and water cooling system prevents material degradation from heat, ensuring high-quality powder output.

Machine Showcase

Get a Customised Quote

Our technical experts are ready to help you configure the ideal pulverizing system for your specific application. Fill out the form below for a detailed proposal and pricing information.

Frequently Asked Questions

What types of materials can this machine process?

This pulverizing grinder is engineered to process a wide range of materials, including pre-shredded natural rubber, synthetic rubber (like SBR), and various other polymer materials that require fine grinding.

How is the final particle size controlled?

The particle size is precisely controlled by adjusting the gap between the stationary and rotating grinding discs, as well as by managing the feed rate through the variable-speed controller. This allows for an adjustable output from 40 to 200 mesh.

What makes the dual cooling system important?

The high-speed grinding process generates significant heat. The dual air and water cooling system is crucial for maintaining optimal temperatures, which prevents the rubber from melting or degrading, ensuring the quality and consistency of the final powder.