Stroj na tavení pěny EPS

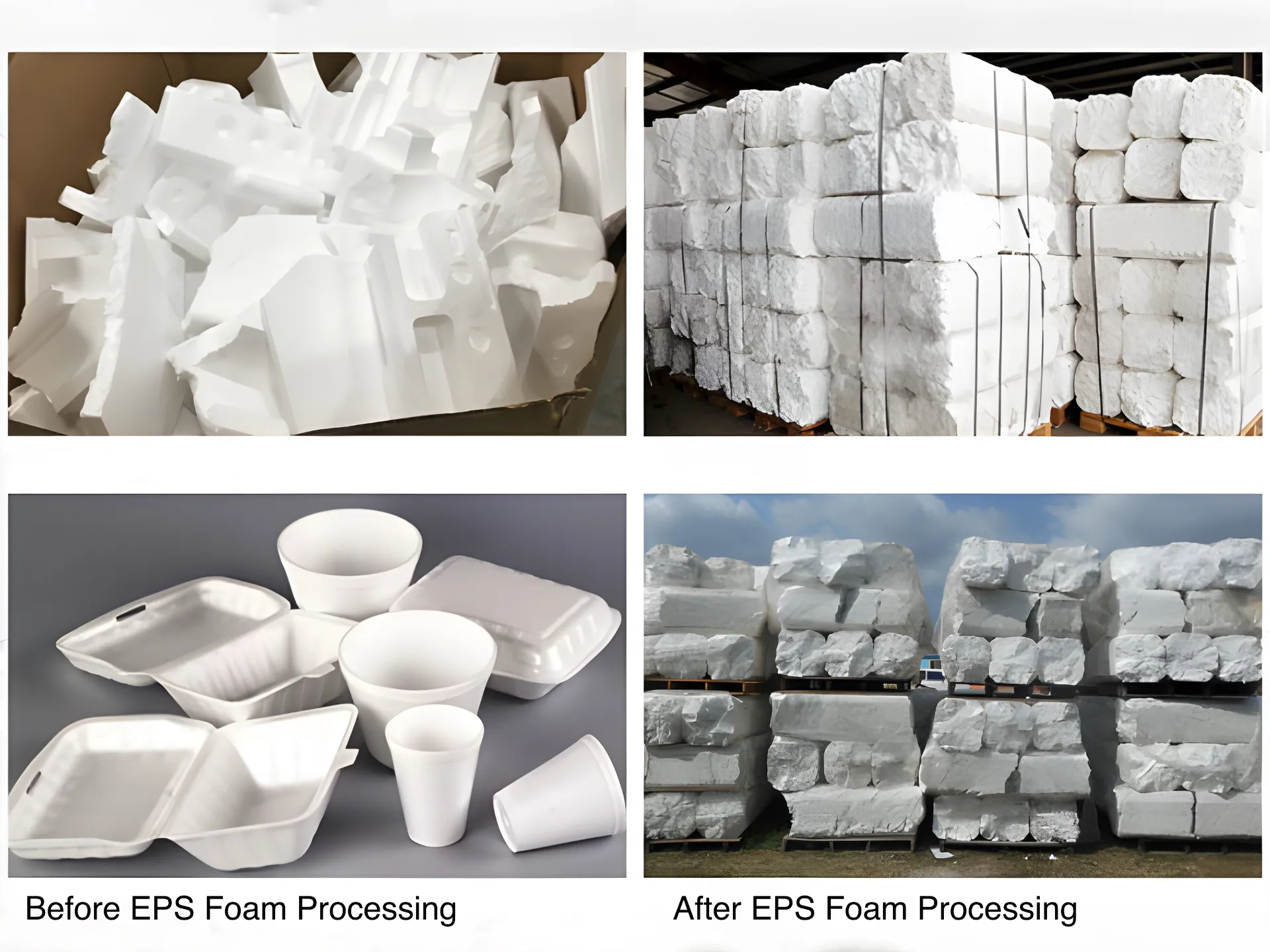

Proměňte objemnou EPS pěnu na husté a cenné ingoty s naší pokročilou technologií tavení. Dosáhněte zmenšení objemu až v poměru 90:1, což zjednoduší skladování a přepravu a vytvoří znovu použitelný zdroj.

Klíčové výhody našeho stroje na tavení EPS pěny

Výjimečné zhuštění

Dosahuje vynikajícího poměru redukce objemu až 90:1, čímž drasticky šetří úložný prostor (až 90%).

Vytváří cenné zdroje

Transformuje odpadní pěnu na husté ingoty nebo bloky, což je cenná komodita pro různá recyklační odvětví.

Energeticky úsporný provoz

Navrženo pro optimální využití energie s automatickým systémem regulace teploty pro efektivní tavení.

Kompaktní půdorys

Díky kompaktnímu designu je vhodný pro zařízení s omezeným prostorem a zároveň pro manipulaci s velkým objemem pěny.

Ochrana životního prostředí

Efektivně snižuje množství odpadu, minimalizuje znečištění životního prostředí a podporuje cirkulární ekonomiku.

Přesná regulace teploty

Automatický systém udržuje optimální podmínky tavení a zajišťuje rovnoměrné tavení bez poškození recyklovatelných vlastností.

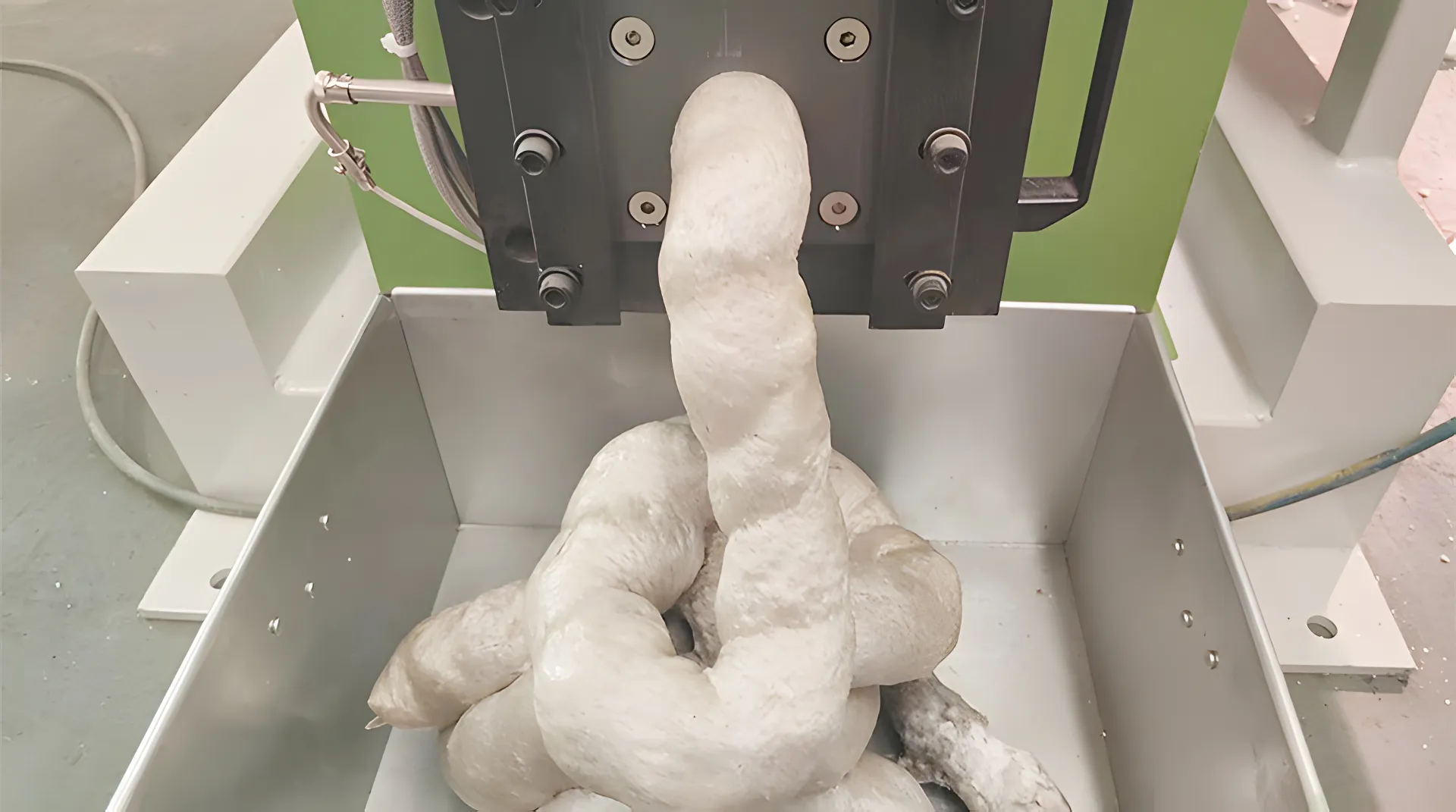

Princip fungování: Z odpadní pěny na husté ingoty

Náš tavicí stroj na EPS pěnu využívá systematický proces k efektivní přeměně sypké pěny na vysoce zhuštěný a snadno ovladatelný materiál.

Krmení a drcení

Odpadní pěna se přivádí do stroje, kde ji dvouhřídelový drticí systém rozdrtí na menší kousky pro efektivní zpracování.

Ohřev a tavení

Drcená pěna vstupuje do vysokoteplotního ohřívacího válce. Rotující šnek ji posouvá a taví ji za řízeného tepla.

Extruze

Roztavená pěna se extruduje jako husté, pevné ingoty nebo bloky, které se výrazně snáze manipulují, skladují a přepravují.

Vypouštění a sběr

Zhutněné bloky se vykládají a jsou připraveny ke sběru a další recyklaci, čímž se ušetří až 901 TP3T skladovacího prostoru.

Technické specifikace

| Parametr | GL-HM100 | GL-HM200 | GL-HM400 |

|---|---|---|---|

| Průměr šroubu | Φ100mm | Φ180–120 mm | Φ180–120 mm |

| Délka šroubu | 1050 mm | 2500 mm | 2500 mm |

| Rychlost šroubu | 150 ot./min | 110 ot./min | 110 ot./min |

| Výstup | 40–50 kg/h | 80–120 kg/h | 180–200 kg/h |

| Velikost ok síta | 40mm | 50mm | 50mm |

| Interval extruzního tlaku | 300 minut | 386 minut | 366 minut |

| Výkon motoru | 5,5 kW | 15 kW | 22 kW |

| Topný výkon | 4 kW | 10 kW | 14 kW |

| Výkon drticího stroje | 1,5 kW | 2,2 + 2,2 kW | 2,2 + 2,2 + 2,2 + 2,2 kW |

| Počet drtičů | 9 sad | 9 + 10 sad | 9 + 10 + 9 + 10 sad |

| Rychlost drtiče | 110 ot/min | 110 mm | 110 mm |

| Rozměry | 1410×1085×1600 mm | 2030 × 1400 × 2050 mm | 3400×1880×2550 mm |

| Hmotnost | 1000 kg | 1800 kg | 2500 kg |

Stroj na tavení EPS pěny v akci

Sledujte, jak náš stroj pracuje:

Galerie produktů

Záruka a profesionální instalace

Každý recyklační stroj obsahuje 1letá omezená záruka, což vám zajistí klid a spolehlivost vaší investice.

Poskytujeme komplexní instalační službyNaši zkušení technici mohou navštívit vaše pracoviště, aby vám pomohli s kompletním procesem nastavení a zajistili tak rychlé a správné uvedení vašeho stroje do provozu.

Opatření pro pravidelné údržbářské čety a provozní konzultanti lze také použít k podpoře vašich probíhajících operací recyklace pěny.

Zeptejte se nyní na nejnovější ceny a dodací lhůty

Chcete-li získat nejnovější ceny a dodací lhůty pro naše tavicí stroje na EPS pěnu, zašlete nám prosím zprávu pomocí níže uvedeného formuláře. Náš tým se vám obratem ozve.

Často kladené otázky (FAQ)

Pro jaké typy pěny je tavicí stroj EPS primárně určen?

Tento stroj je primárně určen pro EPS (expandovaný polystyren), pěnu, která se běžně vyskytuje v obalových materiálech, nádobách na potraviny a izolačních deskách. I když je optimalizován pro EPS, poraďte se s námi ohledně jeho vhodnosti pro jiné typy pěn.

Jakého je typického zmenšení objemu dosaženého procesem tavení?

Tavicí stroj na EPS pěnu dokáže dosáhnout pozoruhodného poměru redukce objemu až 90:1, čímž přemění objemnou pěnu na husté a snadno ovladatelné ingoty.

Jak automatická regulace teploty prospívá procesu tavení?

Automatický systém regulace teploty zajišťuje, že se pěna taví při optimálních a konzistentních teplotách. Tím se zabraňuje přehřátí (které může poškodit recyklovatelné vlastnosti plastu a produkovat nadměrné množství výparů) a nedostatečnému přehřátí (které má za následek neefektivní tavení), což vede k rovnoměrným, vysoce kvalitním ingotům a energetické účinnosti.

Jaké jsou výstupní kapacity dostupných modelů?

Nabízíme různé modely s různou výstupní kapacitou: GL-HM100 (40–50 kg/h), GL-HM200 (80–120 kg/h) a GL-HM400 (180–200 kg/h). Podrobné srovnání naleznete v naší tabulce technických specifikací.

Jaký druh poprodejní podpory je poskytován?

Každý stroj je dodáván s omezenou zárukou 1 rok. Nabízíme také instalační služby na místě prováděné našimi techniky. Dále je možné domluvit si pravidelnou údržbu a provozní poradenství, abychom zajistili bezproblémový a efektivní dlouhodobý provoz.

Investice do tavicího stroje na EPS pěnu je významným krokem k efektivnímu nakládání s odpady a udržitelným postupům. Nejenže řeší problém objemného pěnového odpadu, ale také jej přeměňuje na cenný zdroj, což prospívá jak vašemu provozu, tak životnímu prostředí.