Introduction

In an era where plastic waste overwhelms landfills and oceans, the demand for accessible recycling solutions has never been higher. Small-scale operations, from boutique manufacturers to community recycling centers, face the challenge of processing plastic bottles efficiently without investing in bulky, industrial-grade machinery. Enter the small plastic bottle shredder—a compact powerhouse that transforms discarded PET bottles into valuable flakes for reuse. This article dives into the best small plastic bottle shredder equipment available, offering a buyer’s guide to help you select machines that deliver reliability, efficiency, and environmental impact. Whether you’re starting a recycling initiative or optimizing an existing one, understanding these tools can streamline your workflow and align with global sustainability goals.

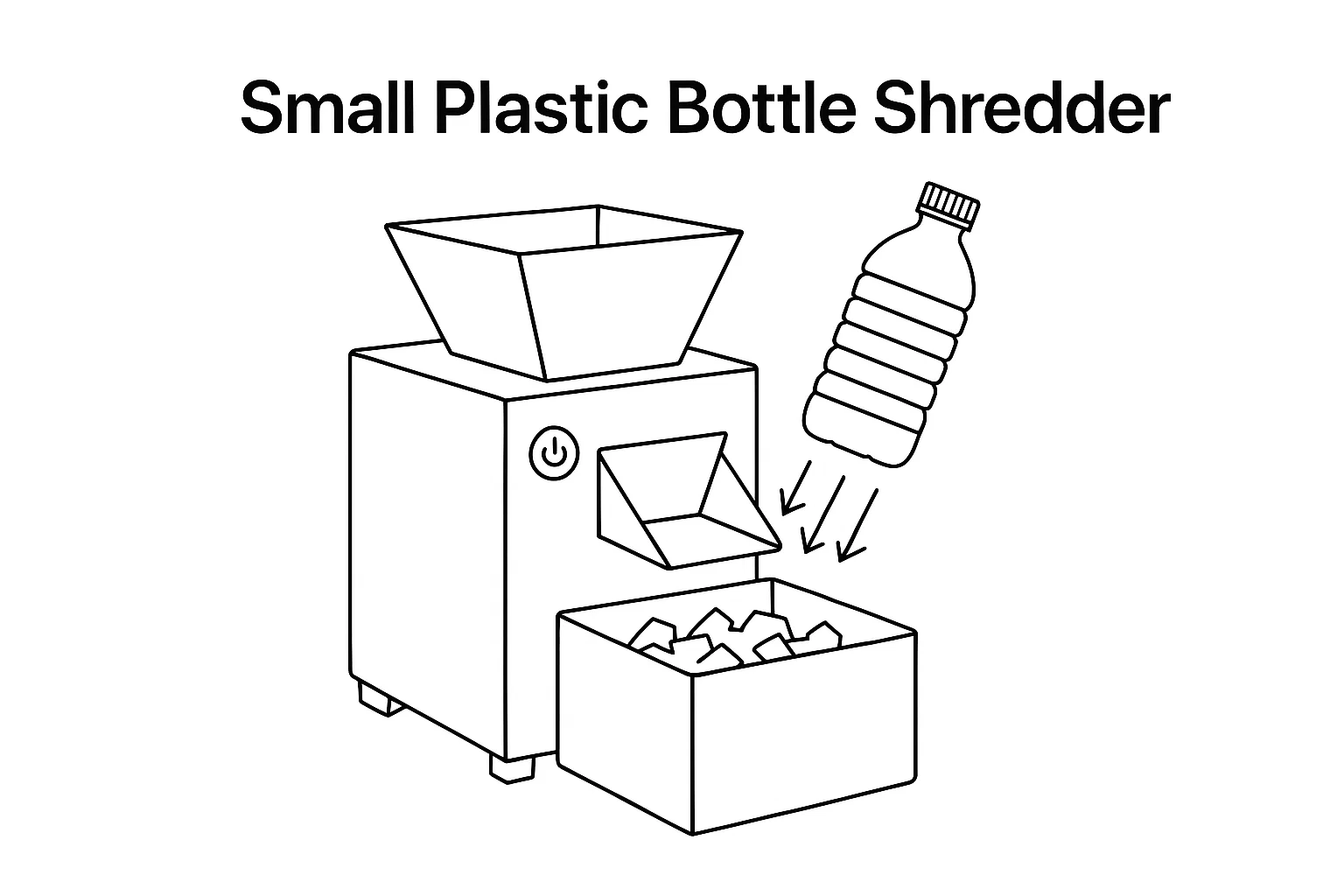

Understanding Small Plastic Bottle Shredders

A small plastic bottle shredder is essentially a mechanical device engineered to break down plastic bottles into smaller, uniform pieces—typically flakes or granules—facilitating easier melting, extrusion, or further processing. Unlike larger industrial models, these units are designed for limited space and moderate throughput, making them perfect for startups, educational facilities, or small manufacturers handling up to 50-200 kg of material per hour.

The core mechanism involves rotating blades or rotors that shear plastic against fixed counters, often powered by electric motors ranging from 1-5 kW. Modern designs incorporate safety features like overload protection and emergency stops, ensuring operator safety in compact environments. From a technical standpoint, blade configuration—such as single-shaft versus double-shaft—plays a pivotal role. Single-shaft shredders excel in precision cutting for clean flakes, while double-shaft options provide robustness for tougher, contaminated bottles.

Industry trends show a shift toward energy-efficient models, with many incorporating variable frequency drives (VFDs) to adjust speed based on load, reducing power consumption by up to 30%. As of 2025, regulations like the EU’s Plastic Packaging Directive and U.S. EPA guidelines are pushing businesses toward verifiable recycling metrics, making these shredders not just tools, but compliance assets.

Key Features to Look for in a Small Plastic Bottle Shredder

Selecting the right small plastic bottle shredder requires balancing performance, durability, and usability. Here’s a breakdown of essential features every buyer should prioritize:

Compact Design and Portability

Space is a premium in small-scale setups. Opt for models with footprints under 2 square meters and weights below 200 kg for easy relocation. For instance, desktop variants offer plug-and-play convenience, ideal for labs or offices. Energycle’s lineup emphasizes modular frames, allowing seamless integration into existing workflows without major renovations.

High-Efficiency Shredding Blades

Blade quality determines output consistency. Look for hardened steel or alloy blades with adjustable spacing to handle varying bottle sizes—from 250ml to 2L. Anti-wear coatings extend lifespan to over 10,000 hours, minimizing downtime. A good shredder should achieve particle sizes of 10-20mm, optimizing downstream processes like washing or pelletizing.

Energy and Noise Optimization

Prospective buyers often overlook operational costs, but modern shredders address this with low-decibel enclosures (under 70 dB) and eco-mode settings. Energy ratings should align with ENERGY STAR equivalents, ensuring annual savings of 20-40% on electricity bills for intermittent use.

Safety and Maintenance Simplicity

Integrated sensors for blade alignment and material feed prevent jams, while quick-release mechanisms simplify cleaning. User-friendly interfaces, including touchscreens for diagnostics, reduce training time. Always verify certifications like CE or UL for peace of mind.

Throughput and Versatility

Match capacity to your needs: entry-level units process 20-50 kg/hour, while mid-range models hit 100 kg+. Versatility extends to handling HDPE, PP, or mixed plastics, broadening application scopes beyond bottles to caps or films.

By focusing on these features, you invest in equipment that scales with your business, delivering ROI through reduced waste hauling fees and potential revenue from recycled flakes.

Buyer’s Guide: How to Choose the Best Small Plastic Bottle Shredder

Navigating the market for small plastic bottle shredder equipment can feel daunting amid a sea of options. This step-by-step guide streamlines your decision-making process, drawing on industry benchmarks and real-world applications.

Assess Your Operational Needs

Start with volume: Estimate daily bottle intake and desired output. For a café recycling program, a 30 kg/hour unit suffices; a small bottling plant might need 150 kg/hour. Factor in space constraints and power availability—most run on standard 220V outlets.

Evaluate Material Compatibility

Not all plastics shred equally. PET bottles dominate, but contamination from labels or residues demands robust pre-sorting. Test samples if possible, or choose models with integrated de-labeling attachments for one-stop efficiency.

Compare Cost vs. Long-Term Value

Upfront costs range from $2,000-$10,000, but prioritize total ownership. Calculate payback periods: A shredder recycling 1 ton/month at $200/ton savings recoups in under a year. Look for warranties exceeding 2 years and local service networks to avoid import delays.

Review Performance Metrics

Seek data on shredding efficiency (kg/kWh) and flake uniformity. Independent tests, like those from the Association of Plastic Recyclers (APR), validate claims. User reviews highlight reliability—aim for 4.5+ stars on platforms like recycling forums.

Consider Sustainability Integration

Top shredders now feature IoT connectivity for tracking carbon footprints, aligning with ESG reporting. Energycle models, for example, include recyclable components, reducing your equipment’s end-of-life impact.

Armed with this guide, you’ll select a small plastic bottle shredder that not only meets current demands but anticipates growth, fostering a resilient recycling operation.

Top Small Plastic Bottle Shredder Models from Energycle

Energycle stands out as a leader in small-scale recycling machinery, blending German engineering precision with cost-effective manufacturing. Our small plastic bottle shredders are tailored for efficiency, backed by a decade of field-tested innovations.

Energycle Mini Desktop Shredder

For ultra-compact needs, the Energycle Mini Desktop Small Shredder redefines accessibility. Measuring just 60x40x50 cm, it shreds up to 20 kg/hour with a 1.5 kW motor, producing uniform 15mm flakes ideal for immediate reuse. Its quiet operation (under 65 dB) suits office environments, and the intuitive controls require minimal setup. Priced affordably, it’s a gateway for hobbyists or pilot programs, boasting 99% uptime in user trials.

Energycle Compact Pro Series

Stepping up, the Compact Pro handles 80-120 kg/hour across single- or double-shaft configurations. Featuring VFD technology, it adapts to load variations, slashing energy use by 25%. Blades are modular for quick swaps, and an optional conveyor feed enhances automation. Clients in beverage packaging report 40% faster processing compared to competitors, with flakes suitable for high-grade rPET production.

Energycle EcoMax for Versatile Applications

The EcoMax targets diverse plastics, processing 150 kg/hour while integrating air classifiers to separate contaminants. Its robust 4 kW drive and stainless-steel construction ensure longevity in humid or dusty settings. With remote monitoring via app, operators gain predictive maintenance alerts, cutting repair costs by 30%. This model excels in community centers, where versatility meets volume.

Each Energycle shredder undergoes rigorous ISO 9001 testing, guaranteeing performance that exceeds industry standards. By choosing our equipment, you gain not just a machine, but a partner in sustainable manufacturing.

Benefits of Investing in Small-Scale Plastic Bottle Shredding Equipment

Adopting a small plastic bottle shredder yields multifaceted advantages, from economic gains to ecological stewardship.

Economically, on-site shredding slashes disposal fees—diverting 500 kg/month could save $500 annually while generating $300 in flake sales. Operationally, compact units free up floor space, enabling leaner facilities. For small businesses, this translates to quicker breakeven points, often within 6-12 months.

Environmentally, these shredders combat the 300 million tons of annual plastic waste by enabling closed-loop recycling. Processed flakes reduce virgin plastic demand, cutting CO2 emissions by up to 70% per ton recycled. Trends like circular economy mandates amplify this, positioning early adopters as industry frontrunners.

From a workforce perspective, user-friendly designs lower injury risks and training barriers, boosting morale. Long-term, scalable shredders support expansion, turning waste management from a cost center into a profit driver.

Industry Trends Shaping Small Plastic Bottle Shredders

The recycling sector evolves rapidly, with small plastic bottle shredders at the forefront. By 2025, AI-enhanced sorting integration is standard, using computer vision to pre-identify bottle types, boosting purity rates to 98%. Biodegradable blade alternatives emerge, though steel remains dominant for durability.

Global supply chains favor localized manufacturing, reducing lead times—Energycle’s U.S.-based assembly exemplifies this. Post-pandemic, hygiene-focused designs with antimicrobial coatings gain traction, addressing contamination concerns in food-grade recycling.

Looking ahead, hybrid solar-powered models promise off-grid viability for remote operations, aligning with net-zero targets. Buyers ignoring these trends risk obsolescence; instead, forward-thinking investments like Energycle’s lineup ensure competitiveness in a $50 billion recycling market.

Maintenance Tips for Optimal Shredder Performance

To maximize your small plastic bottle shredder’s lifespan, adhere to a proactive maintenance regimen. Daily: Clear debris from hoppers and inspect blades for wear. Weekly: Lubricate bearings and calibrate feed rates. Monthly: Perform full disassembly for deep cleaning, using non-abrasive agents to preserve coatings.

Monitor vibration levels via built-in sensors; anomalies signal imbalance, fixable with $50 shim kits. Track throughput logs to predict blade replacements—every 5,000 hours typically. Energycle offers complimentary maintenance kits with purchases, plus 24/7 support hotlines.

Following these steps, expect 95% availability, transforming your investment into a reliable asset.

Conclusion

Small plastic bottle shredders represent a smart, scalable entry into efficient recycling, addressing waste challenges with precision and profitability. From compact desktops to versatile pros, Energycle’s equipment delivers unmatched durability, energy savings, and flake quality, empowering businesses to lead in sustainability. By integrating technical excellence with buyer-focused design, these machines not only process waste but propel your operations forward.

Ready to streamline your recycling? Contact Energycle today for a personalized demo or request a quote on the best small plastic bottle shredder tailored to your needs. Start turning bottles into business value—your sustainable future awaits.