The Essential Role of Plastic Granulators in Modern Recycling

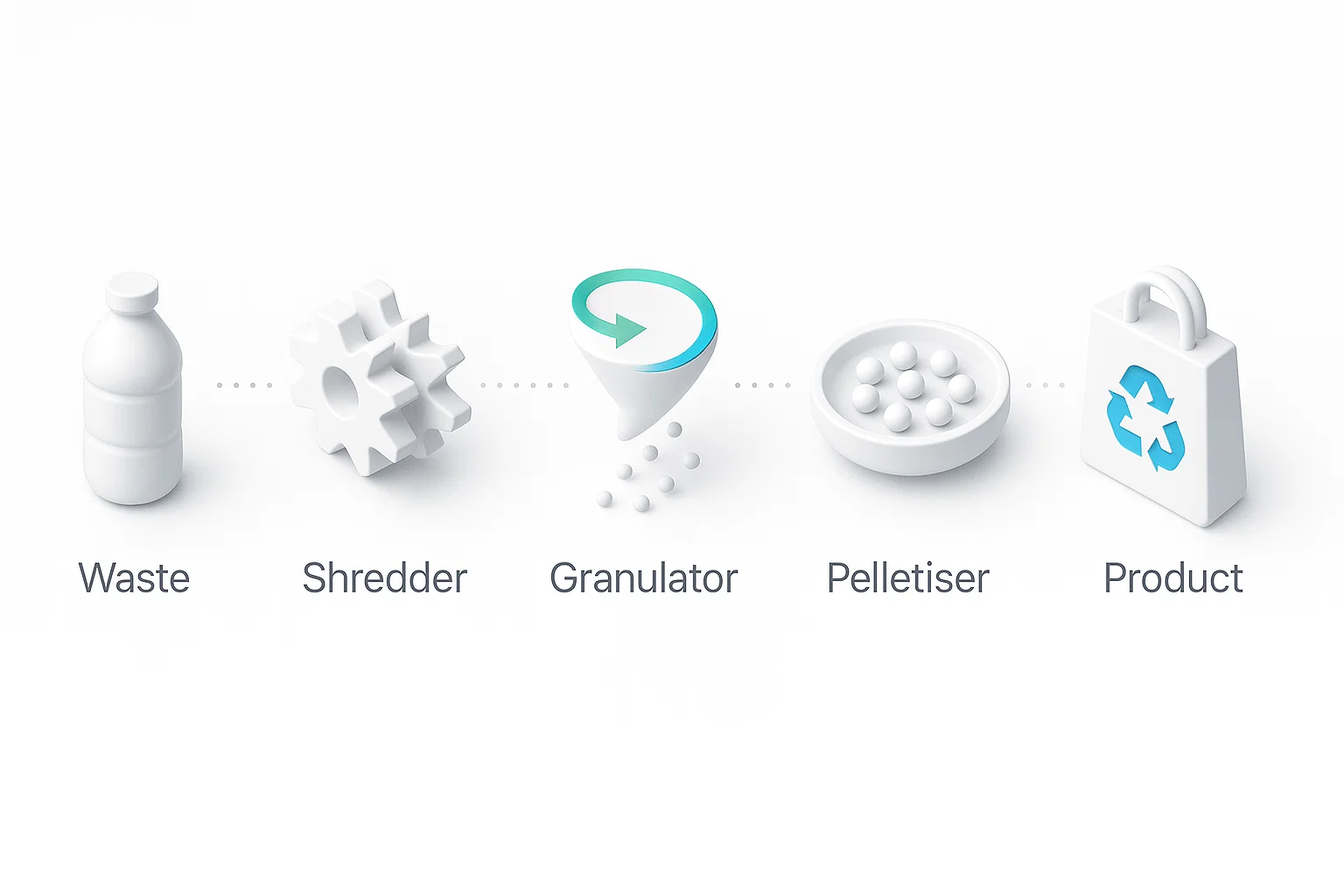

Plastic granulator machines are the lynchpin of any effective plastic recycling system. They work in concert with other specialist machinery to transform bulky plastic waste into a valuable, reusable resource. Understanding their function is key to appreciating the entire recycling journey. Let’s explore how these powerful machines fit into a complete, efficient solution for tackling plastic waste.

Stage 1: Pre-Processing – Preparing Plastic for Granulation

Before a plastic granulator can work its magic, the raw waste material needs to be prepared. This initial stage typically involves a plastic shredder.

Why Shred First? The Shredder vs. Granulator Distinction

It’s a common question: what is the difference between a shredder and a granulator?

- Plastic Shredders: These are low-speed, high-torque machines designed to aggressively tear apart large, heavy, or dense plastic items. Think of them as the primary demolition crew, breaking down items like car bumpers, wheelie bins, pipes, and large plastic purgings into smaller, rougher, and more manageable pieces.

- Plastic Granulators: These are high-speed, low-torque machines that use sharp knives in a scissor-like cutting action. They take the pre-shredded plastic pieces and refine them into small, consistently sized particles known as ‘regrind’ or ‘flakes’.

Using a shredder before the granulator serves two critical purposes:

- Boosts Efficiency: It significantly reduces the strain on the granulator, allowing it to operate much more efficiently.

- Extends Machine Lifespan: It protects the granulator’s precision blades from damage and excessive wear, ensuring a longer operational life.

Stage 2: Granulation – Creating Uniform Plastic Flakes

This is where the plastic granulator machine takes centre stage. Often called plastic crushers, these machines are the heart of the size-reduction process. Inside the cutting chamber, high-speed rotating blades work against stationary bed knives to slice the pre-shredded plastic into uniform flakes.

The size and quality of this regrind are crucial, as they determine the efficiency of the subsequent recycling steps. Our range of Plastic Granulators is engineered to handle a wide variety of plastics, from PET bottles and plastic films to rigid engineering-grade polymers, ensuring a consistent and high-quality output every time.

Stage 3: Cleaning – Purifying the Regrind

Once granulated, the plastic flakes must be thoroughly cleaned. This is a vital step to remove contaminants such as dirt, paper labels, adhesives, and food residue, all of which can compromise the quality of the final recycled material.

High-speed friction washers are typically employed for this task. However, for a more streamlined and efficient process, many modern facilities use wet plastic granulators. These advanced systems introduce water directly into the cutting chamber, offering several key benefits:

- Simultaneous Cleaning: The water washes the plastic as it is being granulated.

- Reduced Friction and Heat: The water acts as a lubricant and coolant, preventing softer plastics from melting and extending the life of the blades.

- Dust Suppression: It significantly minimises dust in the processing environment.

This integrated approach ensures a cleaner, higher-quality regrind, ready for the final transformation.

Stage 4: Further Processing – From Flakes to Pellets

After being washed and dried, the clean plastic flakes move to the final stage of their recycling journey. This typically involves a plastic pelletiser machine. This machine melts the flakes and extrudes them through a die, creating small, uniform pellets (also known as ‘nurdles’).

Why are pellets the preferred form? Their consistent size and shape make them incredibly easy to handle, transport, and, most importantly, feed into manufacturing machinery like injection moulders and extruders. These pellets are the raw material for creating brand-new plastic products, closing the recycling loop.

A Complete Plastic Recycling Solution: How It All Works Together

By integrating shredders, granulators, washing systems, and pelletisers, a seamless and highly effective plastic recycling line is formed. Each machine has a distinct and vital role.

| Machine | Primary Function | Input | Output |

| Plastic Shredder | Coarse size reduction of bulky items | Large plastic parts, bales | Smaller, rough pieces |

| Plastic Granulator | Fine size reduction into uniform particles | Pre-shredded pieces | Small flakes or ‘regrind’ |

| Washing System | Removes contaminants | Dirty plastic flakes | Clean plastic flakes |

| Plastic Pelletiser | Creates new raw material | Clean, dry flakes | Uniform plastic pellets |

This integrated system provides a comprehensive solution capable of handling everything from post-consumer packaging like PET bottles to rigid industrial plastics.

Frequently Asked Questions (FAQs)

Q: Can a granulator handle large plastic parts on its own?

A: While some heavy-duty granulators can handle larger parts, it is generally far more efficient and economical to use a shredder for initial size reduction. This prevents jamming, reduces wear on the granulator, and results in a more consistent final particle size.

Q: What is ‘regrind’?

A: Regrind is the term for the small, recycled plastic particles produced by a granulator. It can be blended with virgin plastic or used on its own to manufacture new products.

Q: Are wet granulators always better?

A: For contaminated post-consumer waste or plastics that are sensitive to heat, wet granulators offer significant advantages in cleaning and efficiency. For clean, in-house industrial scrap, a dry granulator may be perfectly sufficient.

Conclusion: The Cornerstone of the Circular Economy

Plastic granulator machines are far more than just size-reduction equipment; they are fundamental to the success of the circular economy. By working in tandem with shredders, washers, and pelletisers, they provide the critical link that transforms problematic plastic waste into a high-quality, reusable material. This process not only diverts plastic from landfills and oceans but also reduces our reliance on virgin resources, paving the way for a more sustainable future.