Industrial Shredders for Recycling

High-efficiency, highly versatile, and built for reliability — engineered to deliver uniform, controllable output across a wide range of materials with stable, low-noise operation.

Shredding Is the First Step of a Complete Recycling Line

A shredder is typically followed by washing, separation, dewatering/drying, and pelletizing. If you’re planning a turnkey project, start with our line-level Recycling Solutions and we’ll configure the right shredder model as part of the full process.

What Is a Plastic Shredder?

Working Principle

A single shaft shredder uses a rotating rotor fitted with cutting knives (moving knives) working against stationary knives (stator/fixed knives). A hydraulic pusher feeds material against the rotor, and a replaceable screen controls the final particle size. This design ensures steady throughput and uniform, controllable output.

At a Glance

- Uniform, controllable size with interchangeable screens

- Wide applicability: films, bags, pipes, profiles, lumps, wood, textiles

- Stable, safe operation with overload protection and low noise/dust

Watch It in Action

Solutions by Material

For Plastic Film & Woven Bags

Pain points: Soft, elastic materials tend to wrap on the rotor, causing blockages and low throughput.

Our solution: Anti-wrap cutter seats and V‑type rotor with optimized knife spacing prevent wrapping; large-diameter rotor and PLC auto‑reverse ensure continuous feeding and higher output.

For Plastic Pipes & Profiles

Pain points: Bulky, thick‑walled parts are hard to grip and feed; risk of stalling.

Our solution: Deep V feed hopper and powerful hydraulic pusher deliver steady bite; high‑torque gearbox and reinforced bearings handle start‑stop loads on thick sections.

For HDPE Lumps & Purgings

Pain points: Dense, impact‑intensive feed can shock the drivetrain and wear knives quickly.

Our solution: Heavy‑duty frame, high‑inertia rotor, wear‑resistant alloy knives, and smart overload/auto‑reverse logic sustain throughput while protecting the gearbox and motor.

For Textile & Carpet

Pain points: High‑tensile strength fibers easily entangle the rotor and jam standard shredders.

Our solution: Unique anti‑wrap protection, close‑tolerance shearing geometry, and wear‑resistant knives ensure clean cutting of fibers without jamming.

Plastic Shredder Applications

Since 2010, Energycle has helped customers shred nearly everything. From office paper to plastics, medical waste, e‑waste and more, we offer proven solutions that deliver a competitive edge.

Key Features & Options

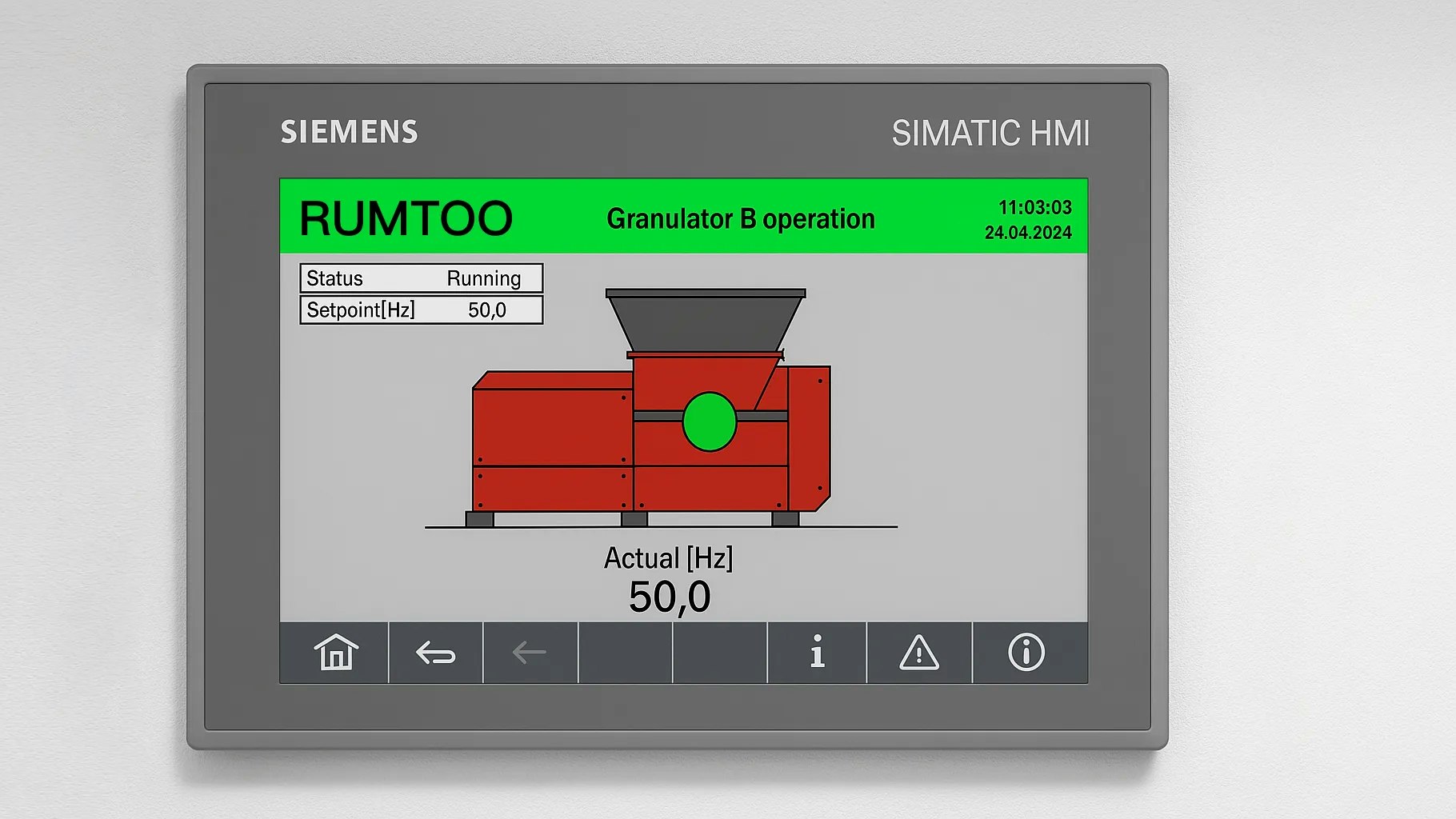

Siemens Motor

Reliable power with high efficiency and strong torque reserve.

Schneider Electrics

Industrial‑grade control components with robust protections.

Alloy Steel Knives

Wear‑resistant, multiple usable edges, easy to replace.

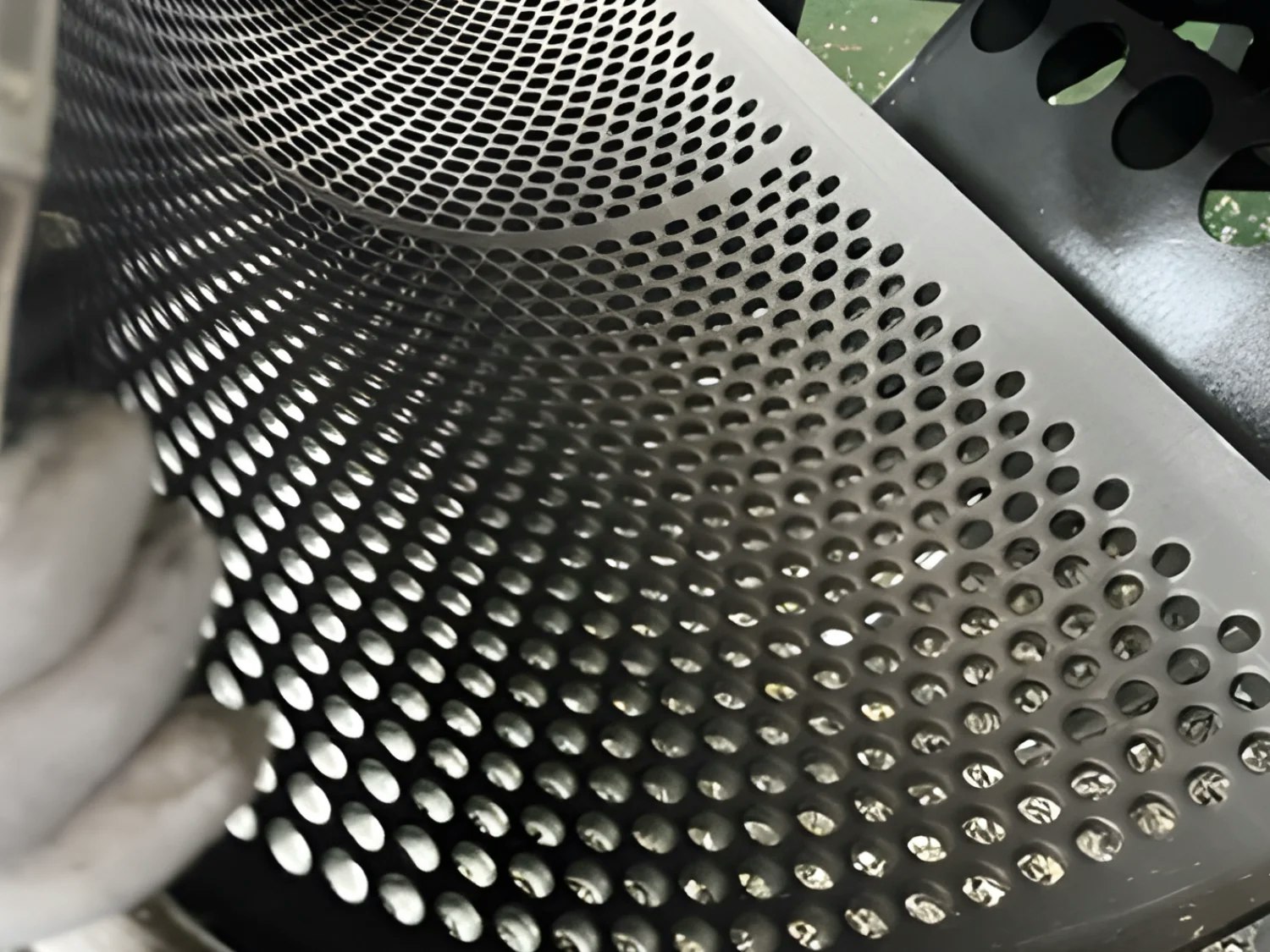

Replaceable Screens

Control output size (typically 20–80 mm) by quick screen swap.

Dust & Noise Control

Sealed housing + optional dust extraction to keep air clean.

Custom Options

Rotor types, feed systems, wear packages, and auto infeed.

Which model suits your needs?

| Specification | R‑S600 | R‑S800 | R‑S1000 |

|---|---|---|---|

| Rotor Ø × Length | 260 × 600 mm | 360 × 800 mm | 450 × 1000 mm |

| Knives (pcs) | 26 | 38 | 50 |

| Main Power | 22 kW | 37 kW | 55 kW |

| Screen | 20–60 mm | 20–80 mm | 20–80 mm |

| Throughput | 300–600 kg/h | 500–900 kg/h | 800–1,200 kg/h |

Note: Capacity varies with material type, density, and screen size. Custom configurations available on request.

Why Choose Us

Proven Installations

Hundreds of field deployments across film, pipe, and lump recycling lines since 2010.

Durable Wear Parts

Alloy knives and wear plates with heat treatment for long service life and easy maintenance.

Controllable Output

Interchangeable screens and PLC logic tune particle size and keep the line running smoothly.

Explore Our Plastic Shredder Lineup

PE/PP Film Shredder

Optimized for films and soft plastics with anti‑wrap cutting and stable feeding.

Rigid Plastic Shredder

Designed for hard plastics, thick profiles, and dense scrap with high‑torque cutting.

HDPE Pipe Shredder

Handles large‑diameter HDPE/PP pipes with stable throughput and efficient feeding.

Extruder Lumps Shredder

High‑torque cutting for purgings, head waste, and dense plastic lumps.

Textile Waste Single Shaft Shredder

Specialized design for carpets, clothing, and high‑fiber waste; prevents wrapping and ensures high output.

Double Shaft Shredder

Double Shaft Shredder with swing arm for stable feeding — low‑speed, high‑torque shredding for bulky plastics and mixed materials.

Integrated Shredder‑Granulator Machine

One‑pass size reduction and granulation with a compact footprint.

General FAQ for Plastic Shredders

How do I select the right shredder model for my specific plastic waste?

- Material Type: Hard plastics (pipes, lumps) vs. soft plastics (films, woven bags).

- Form: Baled, loose, rolls, or production scrap.

- Target Throughput: Required capacity in kg/hr or tons/hr.

- Desired Output Size: Target particle size (e.g., 40mm) determined by the screen.

How much does an industrial plastic shredder cost?

What throughput capacities can your shredding lines achieve?

What types of materials can your industrial shredders process?

What is the manufacturing lead time for a custom order?

Get a Quote

Tell us your materials, screen size, and target throughput. We’ll propose a configuration and budget estimate fast.