High-Performance Plastic Pelletizing Line

Transform your washed plastic films and flakes into high-quality, uniform pellets. Our all-in-one line is engineered to maximize the value of your recycled materials and boost your profitability.

Pelletizing Starts with Clean, Well-Dried Flakes

Get stable extrusion, cleaner pellets, and fewer rejects

Pellet quality depends heavily on upstream preparation—washing, separation, and efficient dewatering/drying. If you are still selling flakes or need a complete line from shredding to pelletizing, start here: Line-Level Recycling Solutions.

From Low-Value Waste to Premium-Grade Pellets

Produce High-Quality Pellets

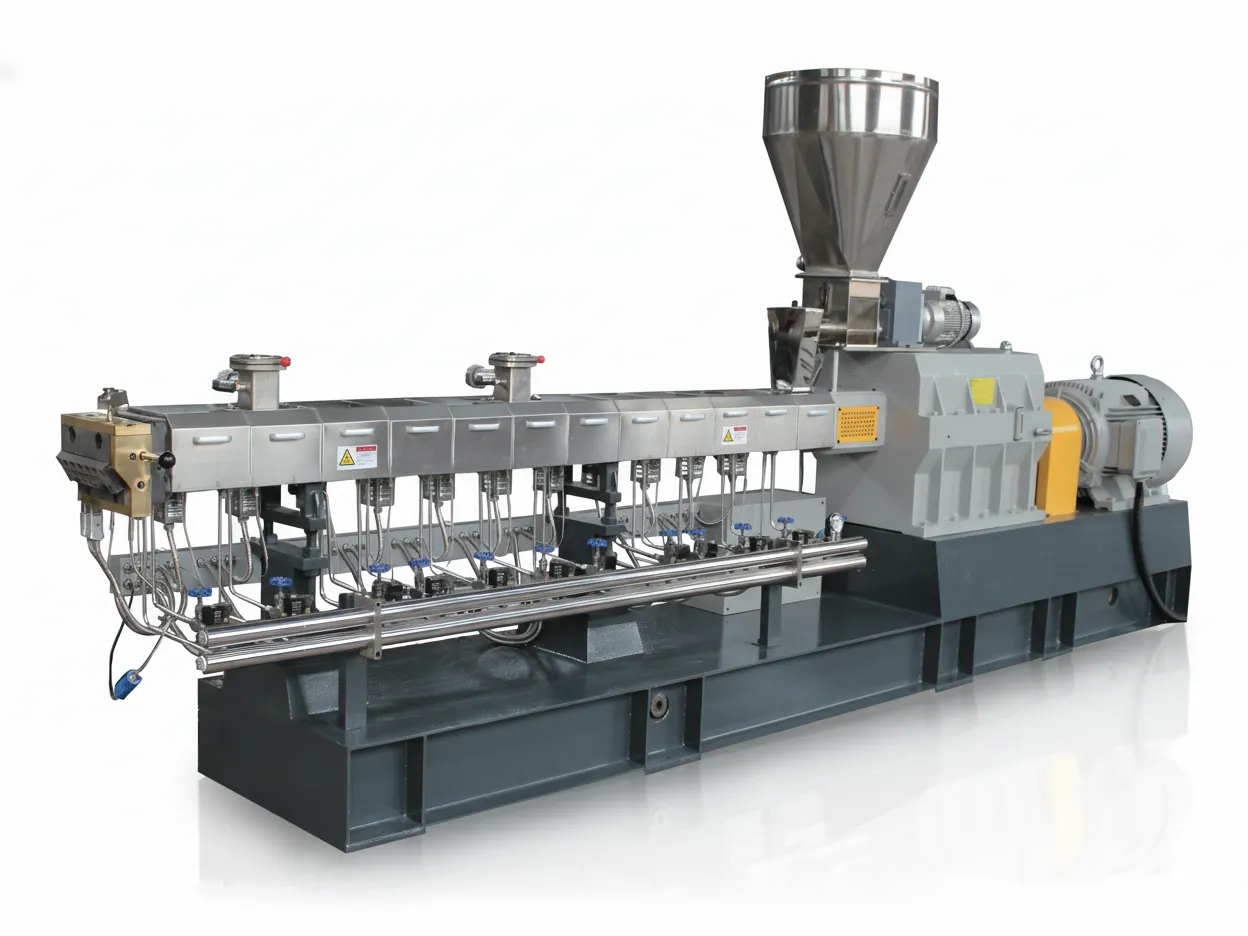

Advanced triple-degassing and filtration systems remove contaminants, producing pure, high-value pellets.

Maximize Material Value

Unlock significantly higher profits by selling uniform, easy-to-handle pellets instead of raw flakes or film.

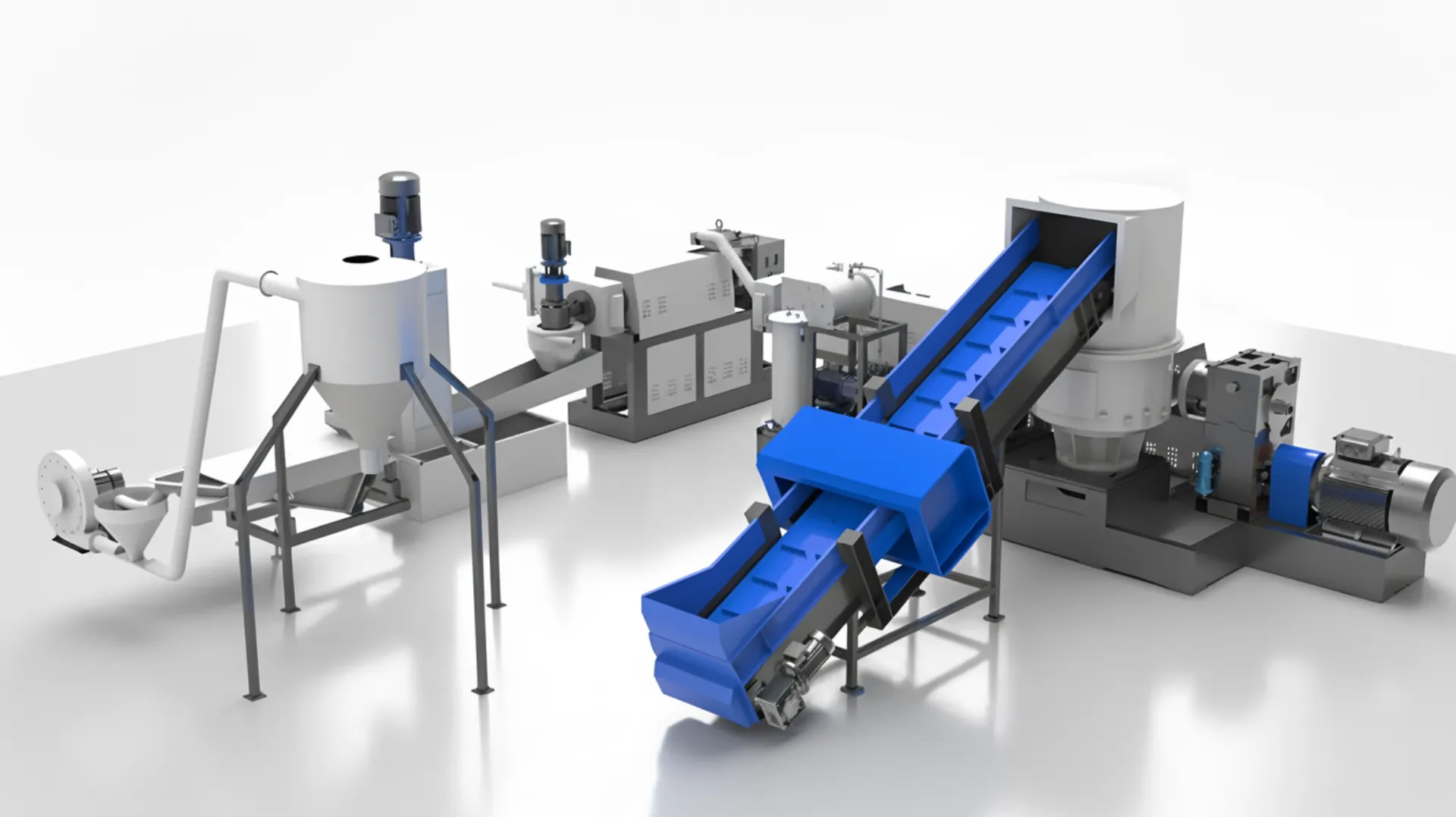

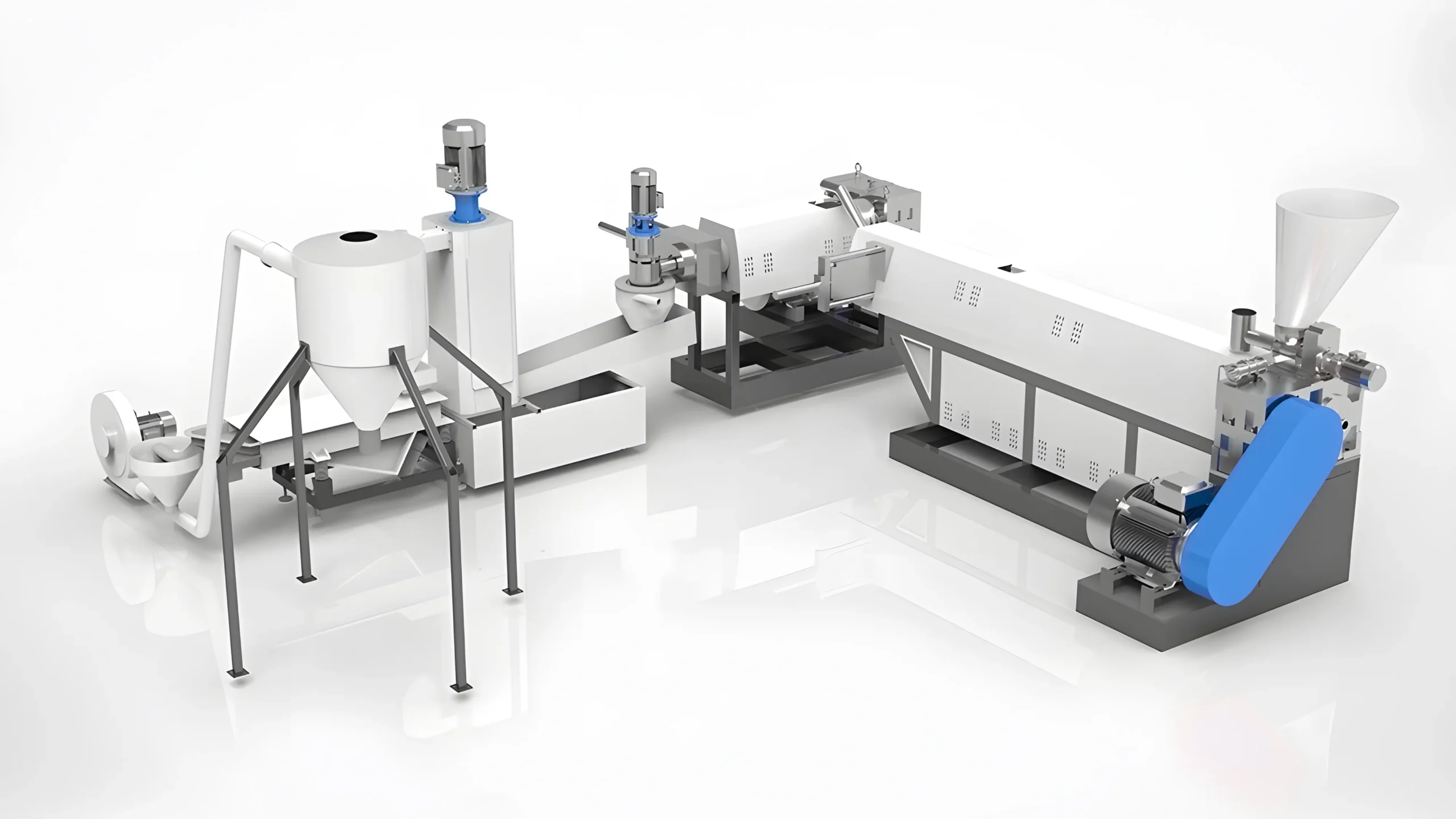

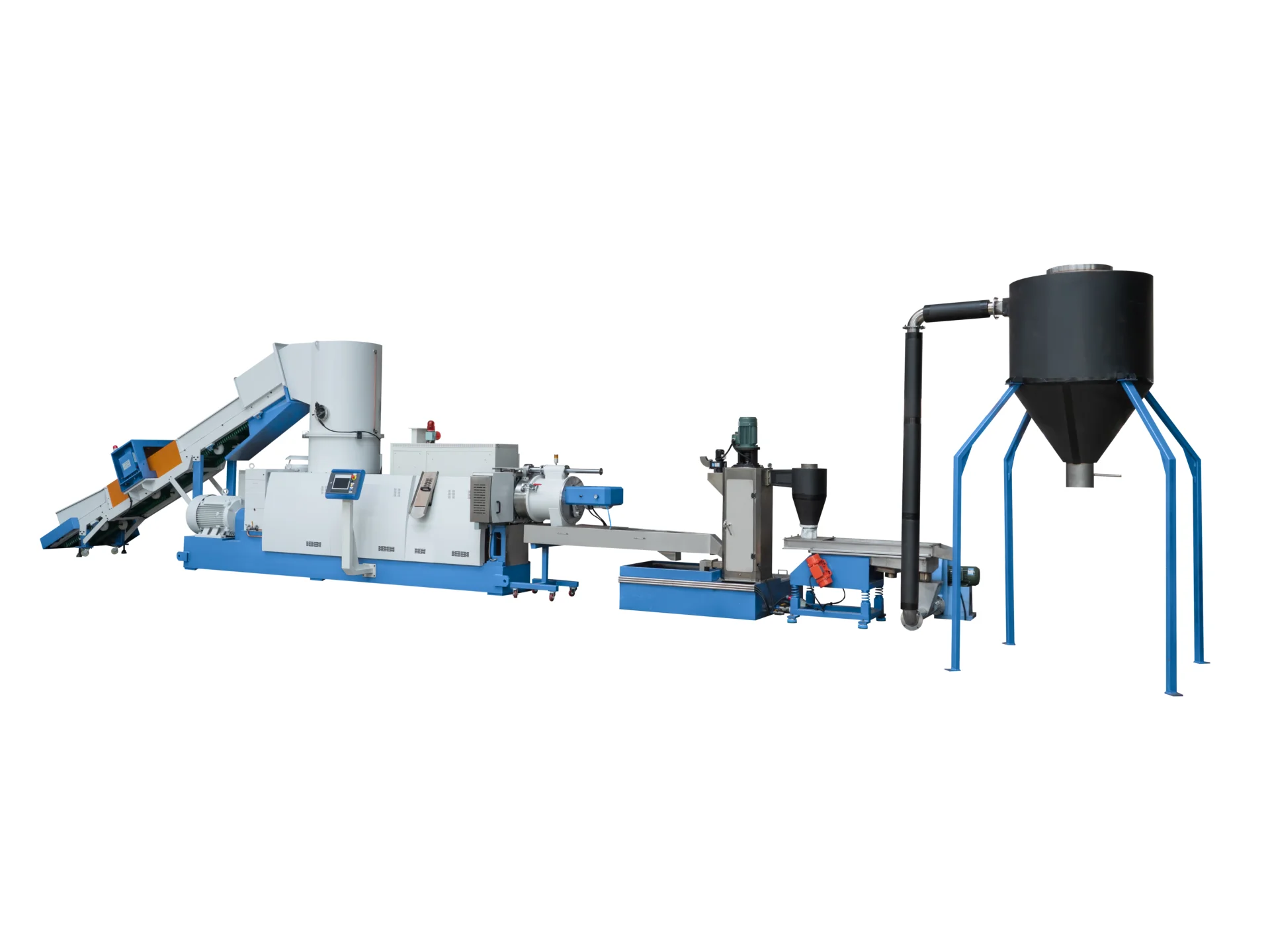

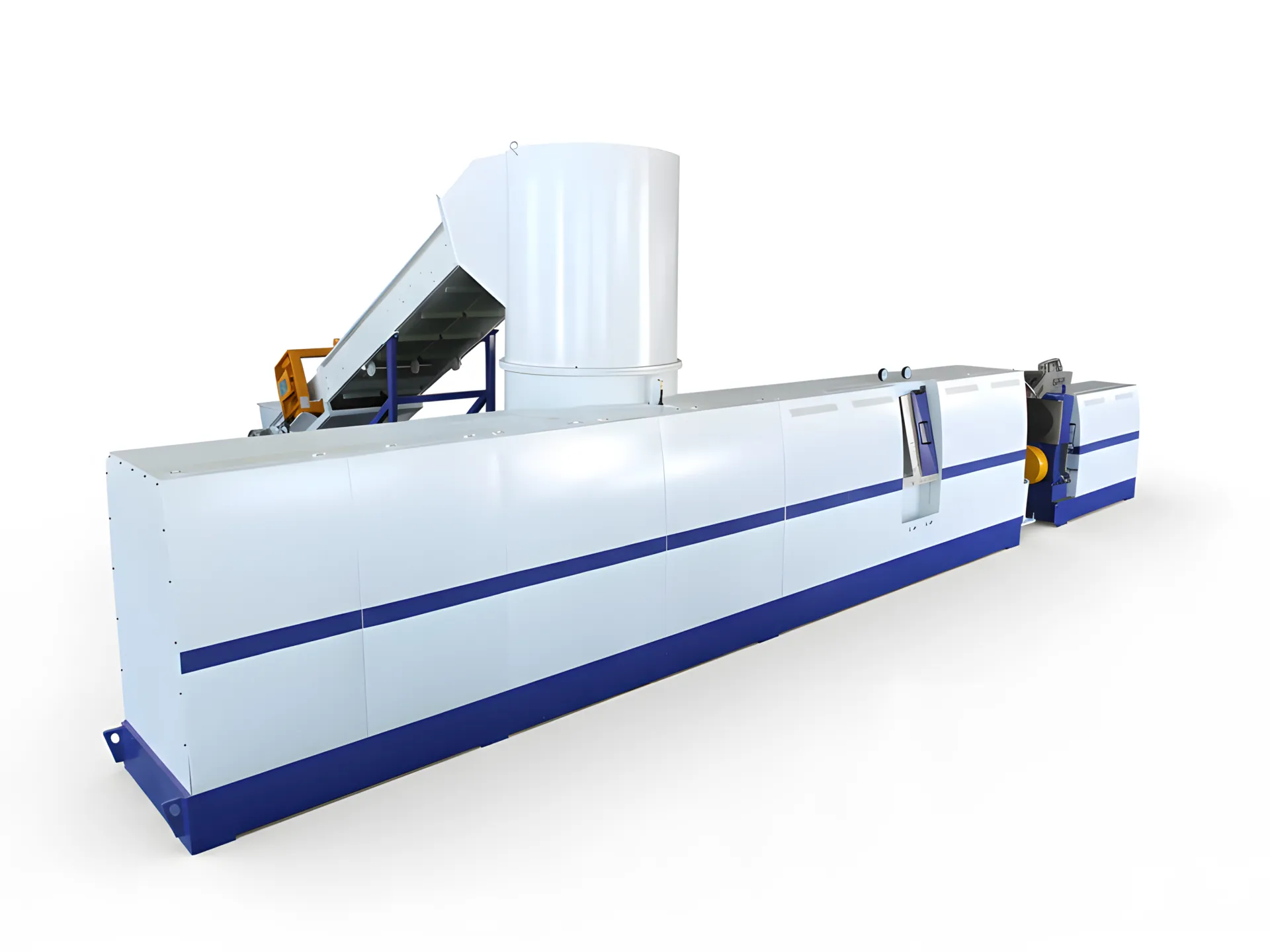

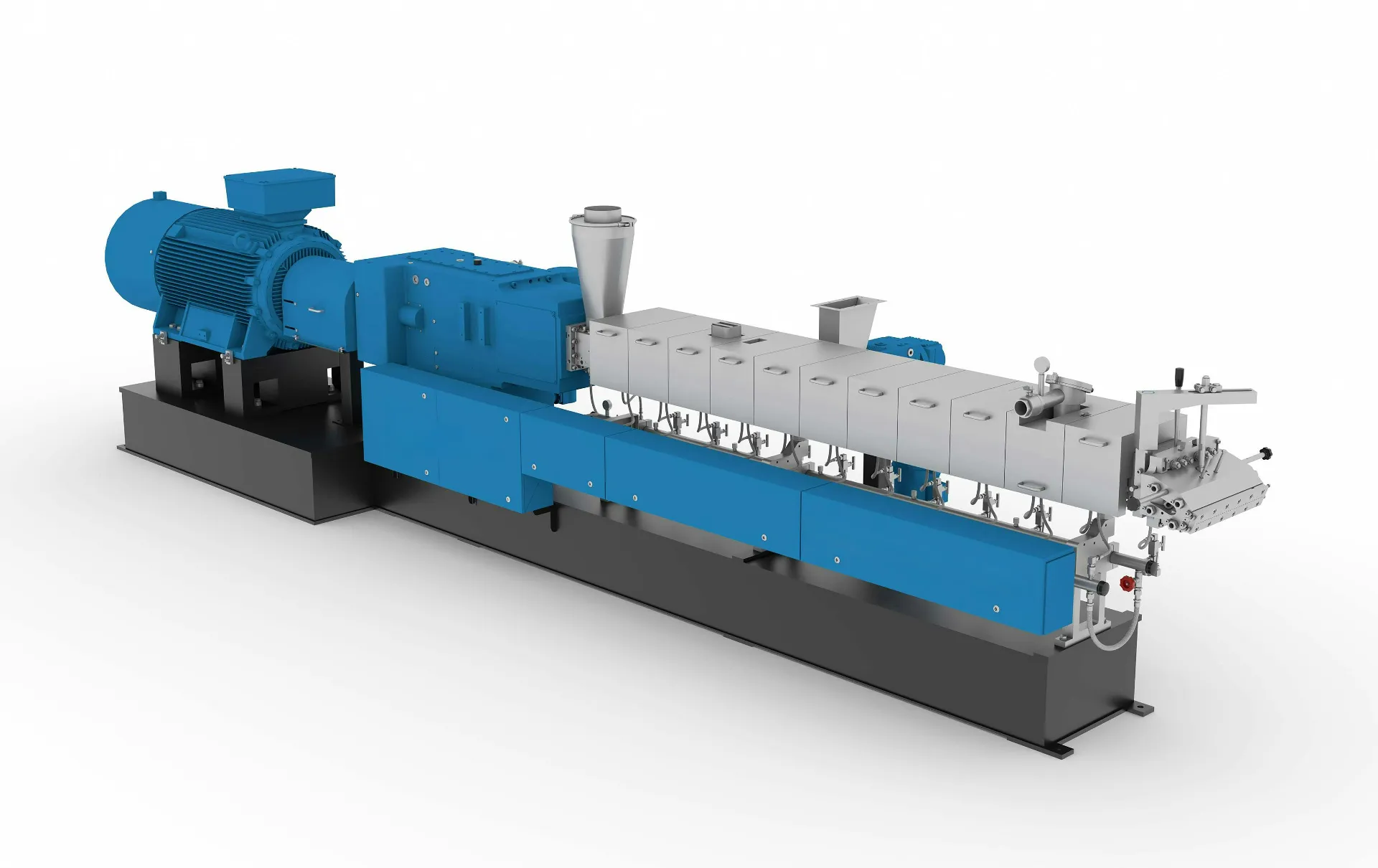

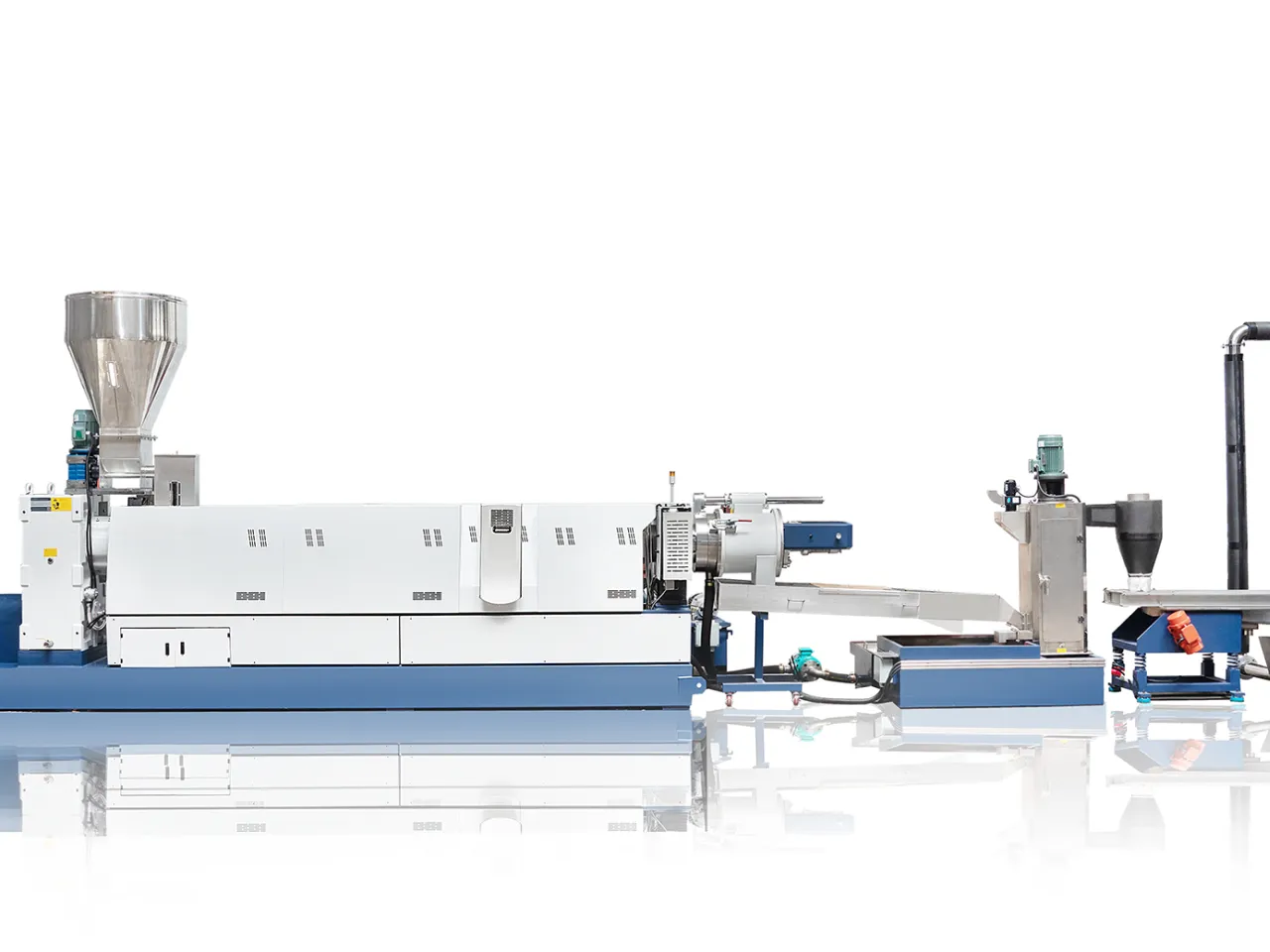

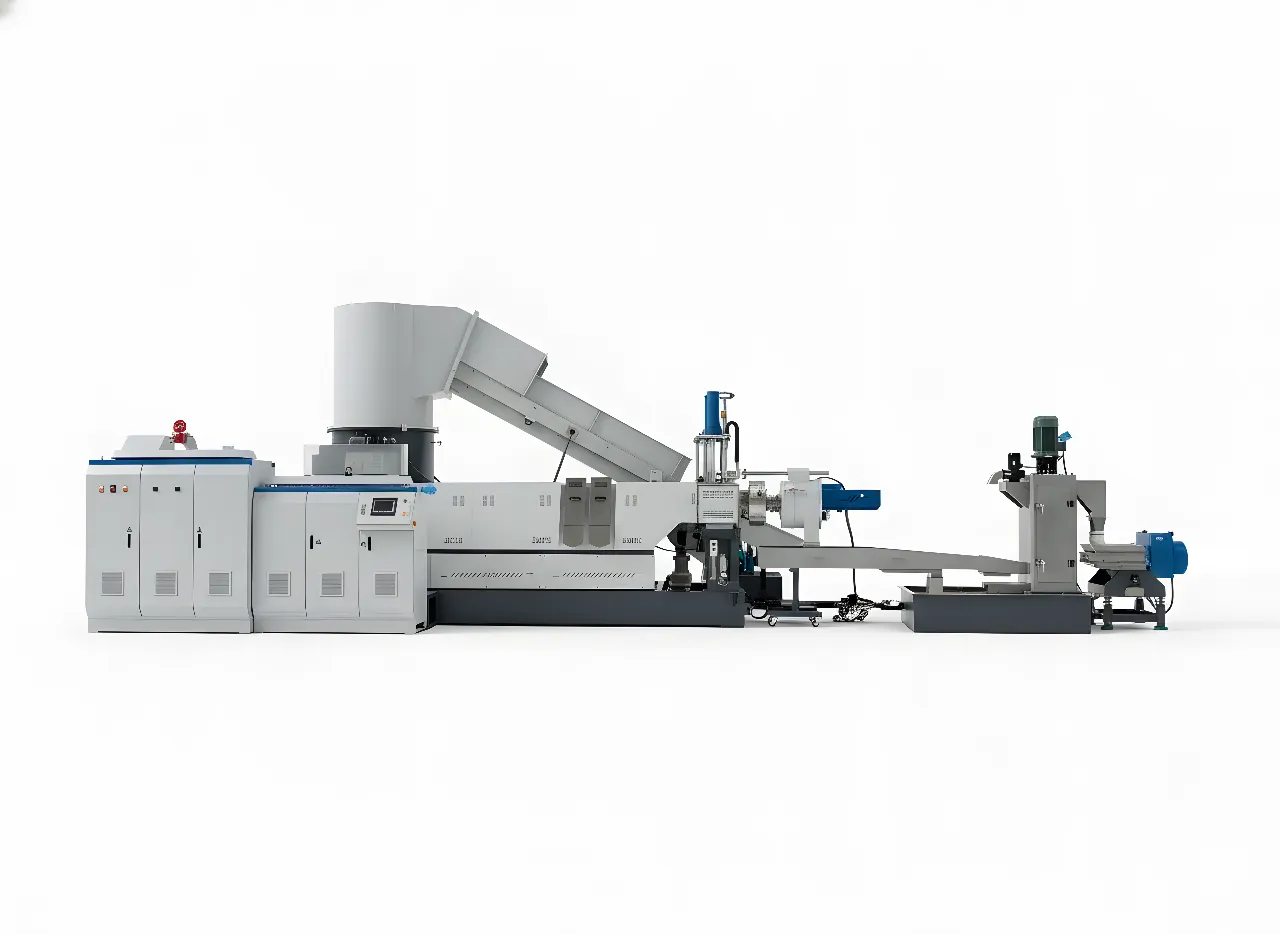

All-in-One Automated System

Our integrated line includes a cutter-compactor, extruder, and pelletizer for a seamless, efficient process.

Overcome the Challenges of Plastic Recycling

Common Recycling Hurdles

- Low market value and high transport costs for bulky, washed plastic flakes and films.

- Inconsistent material quality and contamination (ink, moisture) lead to rejected batches.

- Difficulty processing low-density or heavily printed materials in standard extruders.

The Integrated Pelletizer Solution

- Create dense, valuable pellets that are in high demand and cheaper to transport and handle.

- Advanced degassing and filtering ensures a pure, consistent final product ready for manufacturing.

- An integrated cutter-compactor pre-processes fluffy and printed film for stable, high-output extrusion.

The 4-Step Pelletizing Process

1. Feeding & Compacting

Plastic scrap is fed via conveyor into the cutter-compactor, which cuts, mixes, and densifies the material.

2. Extrusion & Degassing

The material is melted in the extruder, while vacuum degassing zones remove volatiles, ink, and moisture.

3. Filtration & Pelletizing

Molten plastic is filtered for impurities and then cut into uniform pellets by a high-speed water-ring pelletizer.

4. Drying & Storage

The pellets are rapidly dewatered and dried before being pneumatically conveyed to a product silo for storage.

Selling Flakes vs. Selling Pellets

| Factor | Selling Washed Flakes/Film | Selling High-Quality Pellets |

|---|---|---|

| Market Value | Low to Medium | High / Premium |

| Material Handling | Difficult (Bulky, Dusty) | Easy (Dense, Uniform) |

| Buyer Appeal | Limited Market | Broad Market (Ready to use) |

| Profit Margin | Low | Significantly Higher |

See the Complete Line in Operation

Unlock New Manufacturing Possibilities

Film Blowing

Produce high-quality recycled films for use in packaging, agriculture, and construction.

Pipe Extrusion

Create durable, non-pressure pipes, conduits, and profiles from your recycled PE and PP pellets.

Injection Molding

Manufacture a wide range of products like pallets, crates, furniture, and automotive parts.

Technical Specifications

| Processing Capacity | 300 - 2000 kg/h |

|---|---|

| Applicable Materials | HDPE, LDPE, LLDPE, PP, BOPP Film & Flakes |

| Key Components | Cutter-Compactor, Extruder, Degassing System, Pelletizer, Dewaterer |

| Final Pellet Size | 3mm - 5mm (Adjustable) |

| Voltage | Customized to regional standards (e.g., 480V 60Hz, 415V 50Hz) |

Frequently Asked Questions

What is the maximum moisture content for input materials?

Can this line handle heavily printed films?

How is the pellet size controlled?

Is this a complete, turnkey solution?

Can you design a complete line from shredding and washing to pelletizing?

What Our Clients Are Saying

Upgrading from selling flakes to pellets has transformed our business. This line produces exceptionally high-quality pellets that fetch a premium price. The investment paid off much faster than we anticipated.

Recycling Plant Owner

The ability to process our heavily printed post-industrial film waste was a game-changer. The degassing system works flawlessly, and the pellet quality is consistently excellent.

Production Manager

We were impressed by how automated the entire line is. The cutter-compactor handles fluffy film without any issues, and the system runs smoothly with minimal operator oversight. Highly recommended.

Operations Director

Upgrade Your Recycling Operation

Contact our specialists today to configure the right pelletizing line for your material. If you need upstream washing, separation, or drying, see our complete recycling line solutions and we’ll design the full process around your feedstock.