Pitate se kako još više poboljšati svoj proces recikliranja plastike? Upoznajte se Sustavi za flotaciju otopljenim zrakom (DAF)! Ovo je fantastičan alat u modernom recikliranju, koji nudi super učinkovit i prijazan način obrade otpadnih voda. Vještim uklanjanjem onečišćujućih tvari poput sitnih krutih tvari (TSS), ulja i masti (FOG), masti, pa čak i biokemijske potrošnje kisika (BOD), DAF sustavi pomažu da vaš proces recikliranja bude zeleniji, čišći i isplativiji. Započnimo!

Što je točno flotacija otopljenim zrakom (DAF)?

Zamislite flotaciju otopljenim zrakom (DAF) kao pametan proces pročišćavanja vode. Njena glavna zadaća je bistrenje otpadnih voda uklanjanjem suspendiranih tvari poput ulja, krutih tvari i drugih nečistoća. Kako djeluje? Zrak se otapa u vodi pod tlakom, poput pjene u boci gaziranog pića. Zatim se ta mješavina zraka i vode ispušta u poseban flotacijski spremnik pri normalnom atmosferskom tlaku. Presto! Oslobođeni zrak formira bezbrojne sitne mjehuriće. Ti mjehurići djeluju poput malih podizača, pričvršćujući se na suspendirane čestice i nježno ih podižući na površinu. Ovaj sloj plutajućeg materijala zatim se jednostavno uklanja, ostavljajući za sobom prekrasno čistu vodu, bez onečišćujućih tvari.

Zašto koristiti DAF u recikliranju plastike? To je pametan izbor!

Postrojenja za recikliranje plastike, iako odlično obavljaju svoj posao, prirodno stvaraju otpadne vode. Ta voda može sadržavati mikroplastiku, ulja, ostatke kemikalija i druge ostatke. Ako se ispusti neobrađena, može naštetiti našem okolišu i dovesti do visokih troškova odlaganja. Uvođenje DAF sustava u vaše postrojenje izravno rješava ove ekološke probleme. Osim toga, pomaže vam uštedjeti vodu omogućujući ponovnu upotrebu, što zauzvrat smanjuje operativne troškove. To je obostrano korisna situacija!

Gdje još DAF sustavi blistaju? Ključne primjene:

Iako je DAF zvijezda u recikliranju plastike, njegovi talenti su prepoznati u mnogim industrijama! Evo gdje biste još mogli pronaći ove svestrane sustave na djelu:

- → Tvornice papira: Oporavak vrijednih vlakana i čišćenje otpadnih voda.

- → Tiskanje i bojenje: Odvajanje tvrdokornih boja i pigmenata.

- → Objekti za galvanizaciju: Uklanjanje teških iona teških metala.

- → Industrijska područja (uljna voda): Odvaja ulja i masnoće kao šampion.

- → Kožarnice: Rješavanje problema s masnoćama, dlakama i kemikalijama iz obrade kože.

- → Kemijski pogoni: Pomaže u odvajanju raznih kemijskih onečišćujućih tvari.

- → Prerada hrane: Rješavanje problema s masnoćama, uljima i masnoćama (FOG) kao profesionalac.

- → Postrojenja za biološku obradu: Pomaže u odvajanju biološkog mulja.

- → Obrada površinske vode: Učinkovito uklanjanje algi i drugih prirodnih onečišćujućih tvari.

Kako DAF čini svoju magiju u recikliranju plastike

Dakle, kako DAF sustav konkretno pomaže u postavljanju sustava za recikliranje plastike? Obično uključuje otapanje komprimiranog zraka u ulaznoj otpadnoj vodi. Ova „nabijena“ voda zatim teče u flotacijski spremnik. Kako tlak pada, mikromjehurići se šire i vežu za suspendirane čestice plastike, ulja i druge komadiće. Ove plutajuće nakupine se dižu na površinu, tvoreći sloj mulja. Mehanički strugač zatim nježno uklanja ovaj sloj, ostavljajući vam puno čišću vodu – često spremnu za ponovnu upotrebu natrag u vašoj reciklažnoj liniji!

Stručni savjet: Kako bismo ovaj proces učinili još učinkovitijim, često dodajemo korisne kemikalije poznate kao koagulanti (poput polialuminijevog klorida ili PAC) i flokulanti (poput poliakrilamida ili PAM). Oni djeluju poput magneta, pomažući manjim česticama da se skupe u veće skupine (flokule), što mjehurićima zraka znatno olakšava da ih uhvate i podignu.

Brzi pregled: Tehničke specifikacije DAF sustava

Trebate neke brojke? Evo kratkog pregleda tehničkih detalja za neke uobičajene DAF modele:

| Model | Snaga motora | Protok pumpe | Kapacitet |

|---|---|---|---|

| APW-5 | 2,2 kW | 10 m³/h | 5 m³/h |

| APW-10 | 4,0 kW | 12 m³/h | 10 m³/h |

| APW-20 | 4,0 kW | 16 m³/h | 20 m³/h |

| APW-30 | 5,5 kW | 22 m³/h | 30 m³/h |

Dobre vijesti! CE certifikat je dostupan. Trebate nešto veće ili snažnije? Možemo vam dizajnirati veće modele po narudžbi – samo pitajte!

Nevjerojatne prednosti DAF-a u recikliranju plastike

- Niži troškovi: Uštedite mnogo na računima za vodu i operativnim troškovima pročišćavanjem i recikliranjem vode na licu mjesta.

- Ekološki prvak: Dajte svoj doprinos planetu! DAF sustavi drastično smanjuju ispuštanje onečišćujućih tvari, čineći vaš proces recikliranja mnogo zelenijim.

- Super fleksibilno: Ovi prilagodljivi sustavi mogu se nositi s različitim vrstama otpadnih voda, što ih čini vrijednim alatom u raznim industrijskim okruženjima.

- Vrhunska kvaliteta vode: Nabavite dosljedno čistu vodu koju često možete ponovno koristiti u procesu recikliranja, osiguravajući stalnu opskrbu.

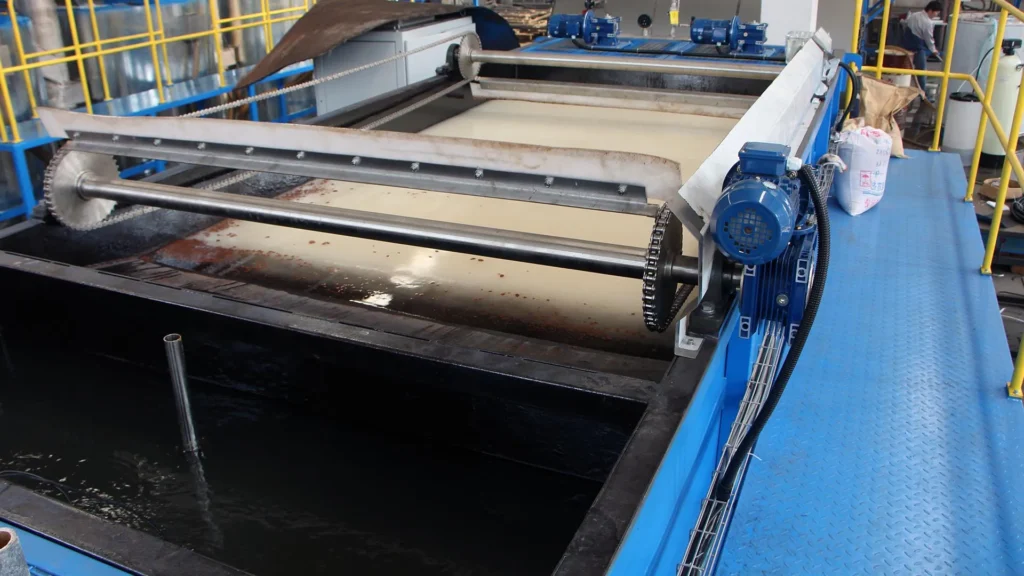

Pogledajte DAF sustave u akciji

Zaključak: Povećajte svoje recikliranje s DAF-om!

Dodavanje sustava flotacije otopljenim zrakom (DAF) vašem postrojenju za recikliranje plastike zaista je pametno ulaganje u održivost i vašu dobit. Pomaže vam da poslujete na ekološki odgovoran način i značajno smanjuje troškove vode učinkovitim pročišćavanjem i recikliranjem otpadnih voda. Sa svojom dokazanom učinkovitošću i svestranošću u različitim industrijama, DAF sustav je vrijedna imovina koju ćete rado imati.

Mir uma: Jamstvo i podrška za instalaciju

Stojimo iza naših strojeva! Svaki DAF sustav dolazi s 1-godišnje ograničeno jamstvo za vaš mir. Trebate li pomoć s postavljanjem? Nudimo usluge instalacije gdje naši iskusni inženjeri mogu doći izravno na vašu lokaciju kako bi vam pomogli da sve nesmetano radi. Također možemo razgovarati o dogovorima za kontinuiranu podršku u održavanju i operativne savjete ako je potrebno. Tu smo da vam pomognemo uspjeti!

Spremni za razgovor? Raspitajte se odmah!

Zanimaju vas najnovije cijene i koliko brzo možete nabaviti DAF sustav za svoj pogon? Samo nam pošaljite poruku putem jednostavnog obrasca u nastavku. Jedva čekamo čuti od vas!