Vijesti o recikliranju

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

Aprenda las principales diferencias entre las trituradoras y los molinos de plástico para el reciclaje. Esta guía detalla los principios operativos, los tamaños de salida y las estrategias de decisión de compra, ayudando a los profesionales a elegir el mejor equipo para su flujo de residuos. Descubre detalles personalizados de máquinas y consejos prácticos con Energycle Machine.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

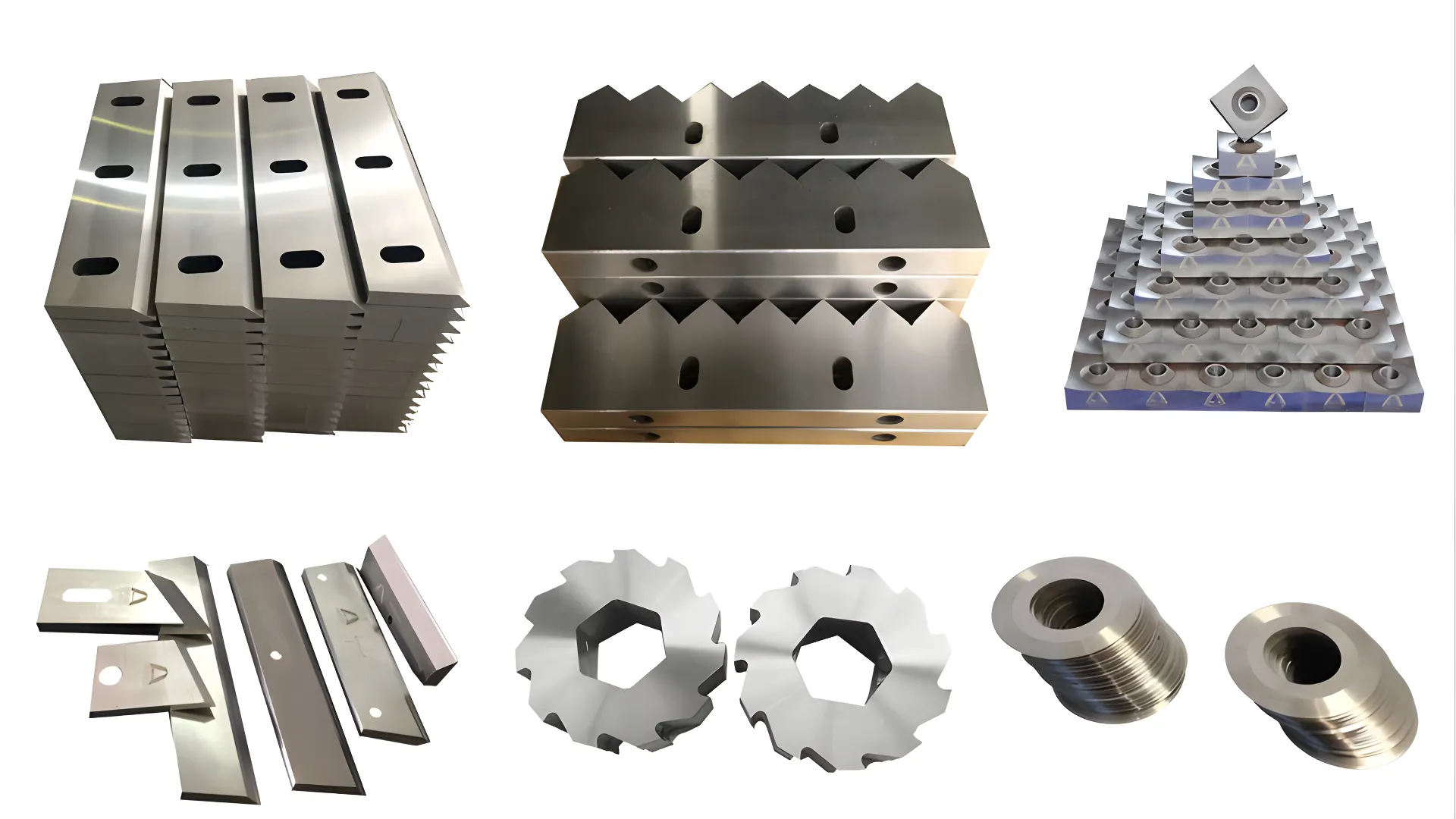

Ovaj članak pruža sveobuhvatan pregled noževa za sjeckanje, s pojedinostima o njihovoj važnosti u procesu usitnjavanja i koracima koji su uključeni u njihovu proizvodnju. Nudi dragocjene uvide u odabir pravih materijala i pridržavanje standarda obrade kako bi se osigurala dugotrajnost i učinkovitost oštrica.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

Otkrijte zašto su čelici D2 i SKD-11, poboljšani volfram-karbidnim premazima, najbolji izbor za izdržljive noževe za usitnjavanje. Ovaj vodič objašnjava ključna svojstva materijala, prednosti otpornosti na habanje i savjete za održavanje koji pomažu inženjerima i kupcima da svoje linije za usitnjavanje održe u radu dulje i efikasnije.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

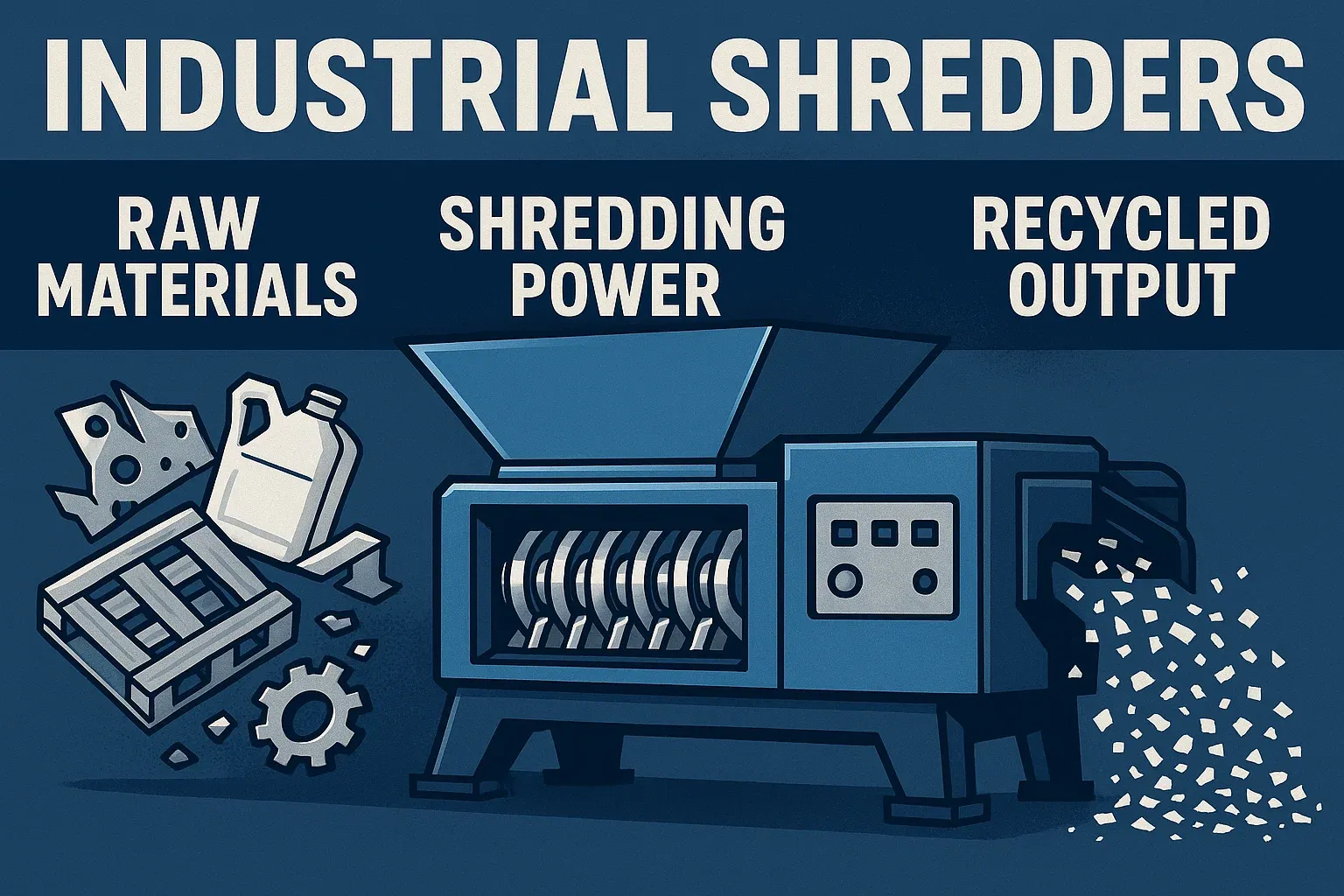

Saznajte više o industrijskim usitnjivačima, njihovim principima rada, različitim vrstama i primjenama u recikliranju i gospodarenju otpadom.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

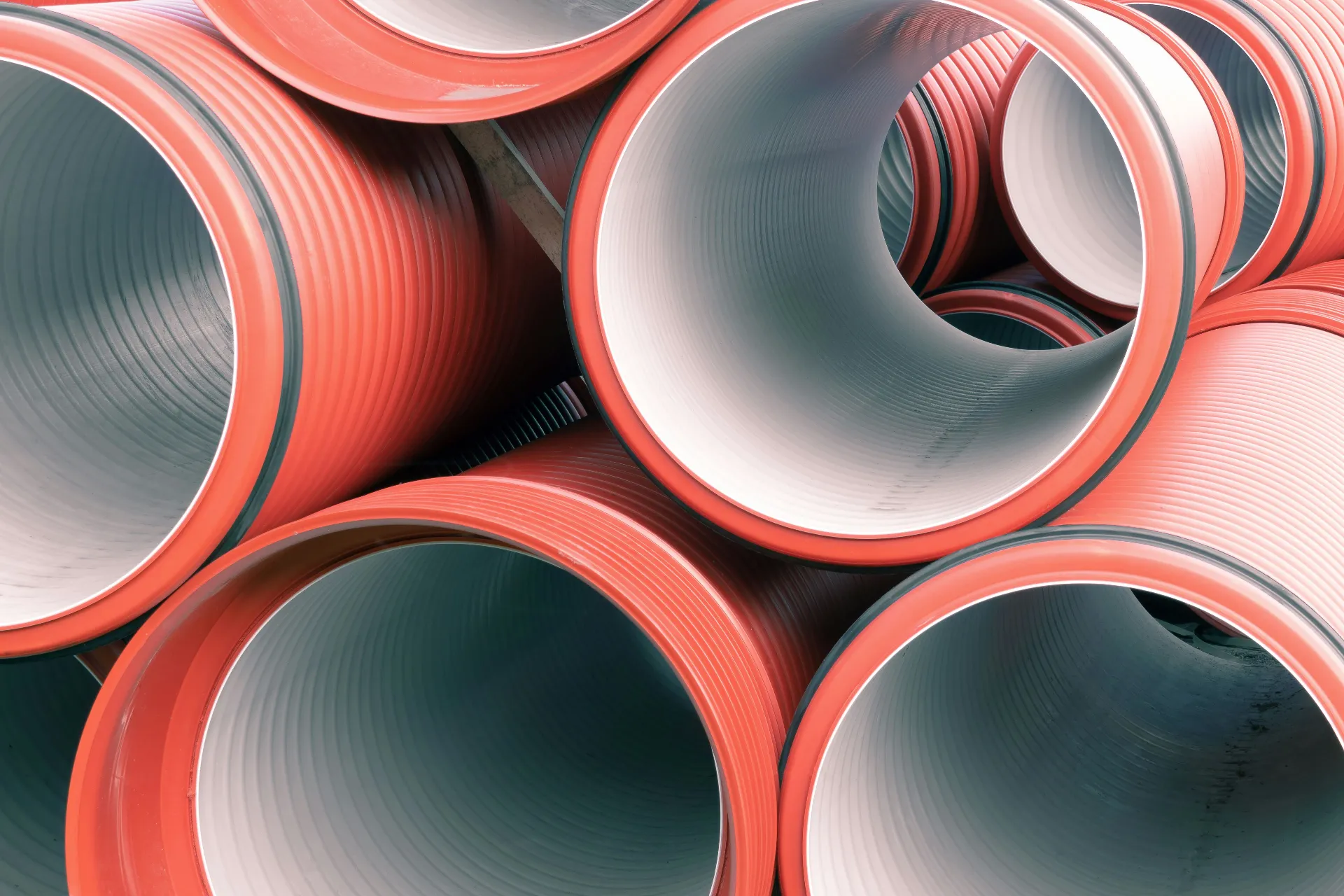

Odabir idealnog rezača za PVC cijevi ključan je za učinkovito gospodarenje plastičnim otpadom i recikliranje. Ovaj vodič objašnjava bitne čimbenike koje treba uzeti u obzir, od snage motora i kvalitete oštrica do kapaciteta, izdržljivosti, sigurnosnih značajki i isplativosti, osiguravajući da odaberete stroj koji zadovoljava vaše specifične operativne potrebe i pruža snažan povrat ulaganja.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

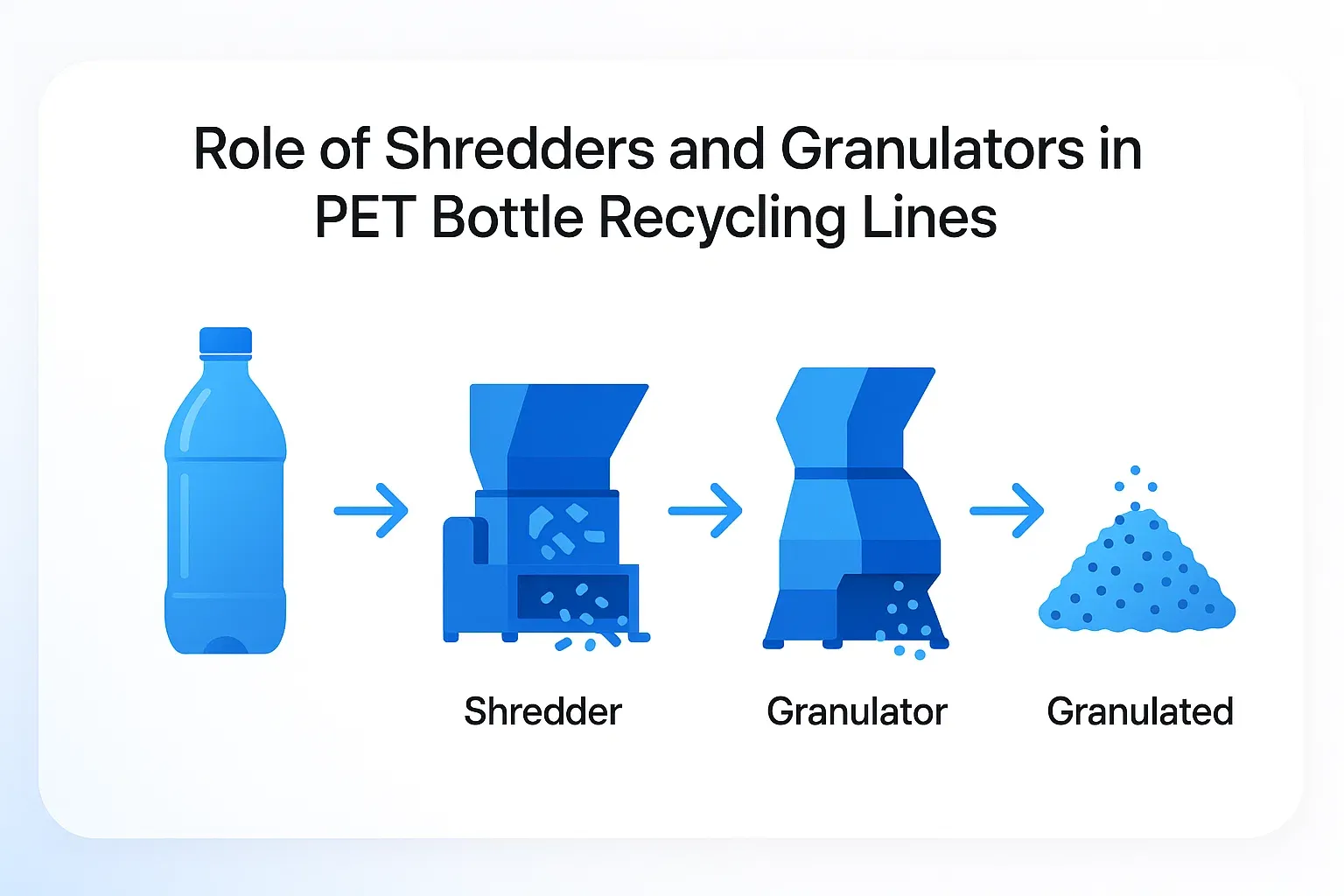

Otključajte učinkovito recikliranje PET boca! Istražite bitne uloge usitnjivača i granulatora u transformaciji otpadnih boca u vrijedne rPET pahuljice. Shvatite njihove razlike, prednosti i kriterije odabira za vašu liniju za recikliranje. Obavezno štivo za stručnjake u industriji.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

Prijevoz šupljih cijevi u centre za recikliranje logistička je noćna mora koja troši gorivo i profit. Mobilni rezač cijevi mijenja pravila igre donoseći industrijsku snagu drobljenja izravno na gradilište. Otkrijte kako usitnjavanje na licu mjesta smanjuje volumen, smanjuje troškove i pojednostavljuje vaše operacije recikliranja plastike uz napredna rješenja tvrtke Energycle.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

Industrijski rezači su ključni strojevi za recikliranje i proizvodne operacije. Ovaj praktični vodič objašnjava kako industrijski rezači rade, glavne vrste rezača, tipične primjene i kako odabrati pravi rezač na temelju materijala, kapaciteta i zahtjeva za daljnju obradu.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

Otkrijte kako se snalaziti u skladu s EU CE i US OSHA standardima za industrijske usitnjivače plastike. Ovaj vodič obuhvaća propise, sigurnosne značajke i praktične savjete za osiguranje sigurnog i učinkovitog rada za inženjere i kupce opreme.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

Uništavači tvrdih diskova nude sigurno rješenje za uništavanje podataka, fizički uništavaju diskove i onemogućuju oporavak. Ovaj članak istražuje prednosti, principe rada i primjene uništavača tvrdog diska.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

Impresivna izdržljivost HDPE cijevi predstavlja jedinstvene izazove za recikliranje. Ovaj vodič istražuje zašto su specijalizirani rezači cijevi ključni za učinkovito razbijanje ovih tvrdih materijala, optimizaciju tijeka recikliranja i doprinos održivijoj budućnosti. Saznajte kako prava oprema čini svu razliku.

Kategorije vodiči za kupnju, Vijesti o recikliranju

Objavljeno na

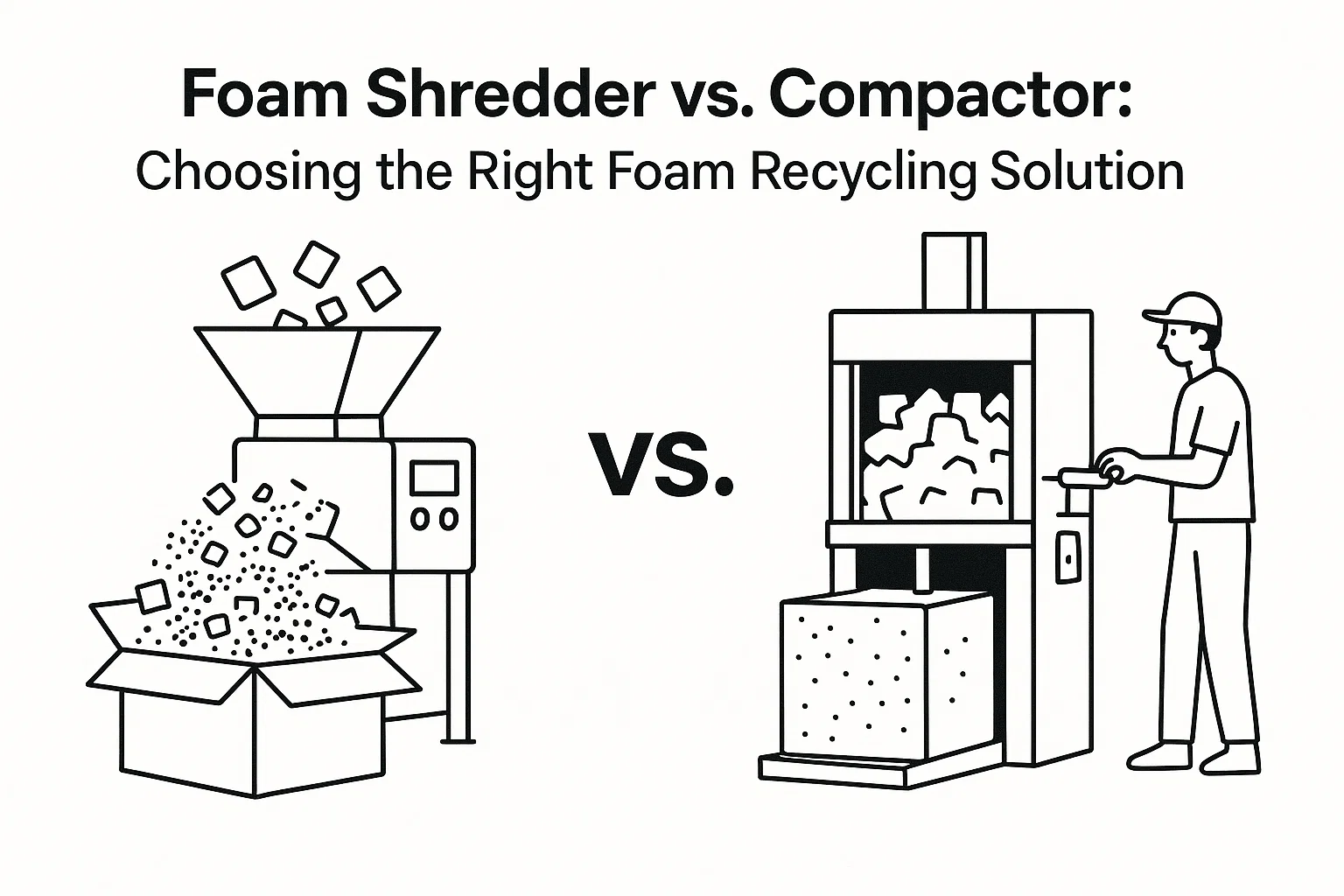

Comprendre les rôles distincts des broyeurs de mousse et des compacteurs dans le recyclage de la mousse. Un broyeur réduit la taille des morceaux pour leur réutilisation en rembourrage, tandis qu'un compacteur réduit considérablement le volume pour le transport et la vente. Ce guide vous aide à choisir la machine adéquate en fonction de vos objectifs d'entreprise, du type de mousse et de la quantité.