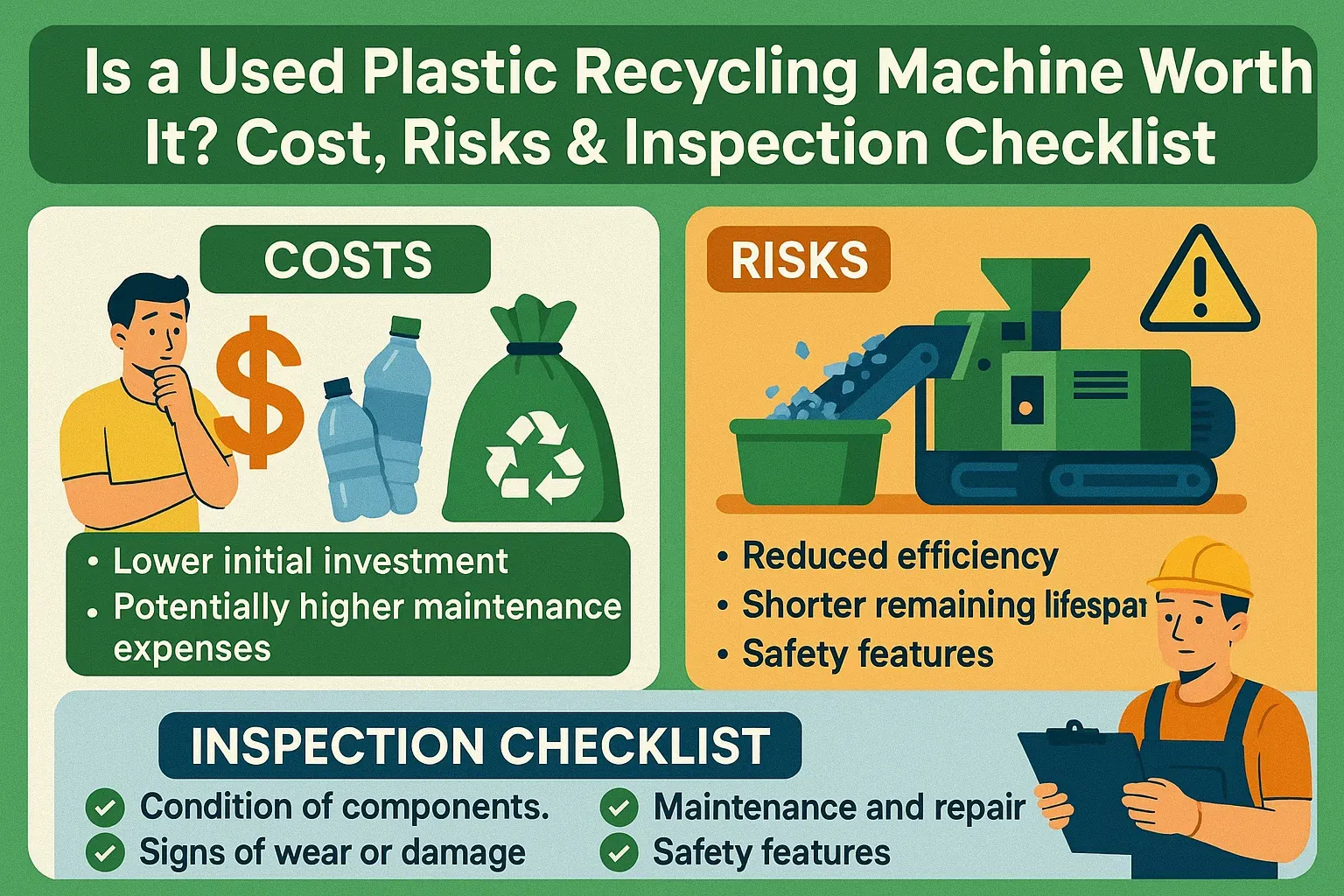

La spinta verso un'economia circolare e la crescente pressione normativa stanno rendendo il riciclaggio della plastica più critico che mai. Per le aziende che desiderano avviare o espandere le proprie attività di riciclaggio della plastica, si pone spesso la questione delle attrezzature: investire in una macchina per il riciclaggio della plastica usata è una mossa finanziaria saggia o una potenziale insidia? Questa guida completa aiuterà gli acquirenti di attrezzature industriali, gli ingegneri e il personale tecnico a districarsi tra le complessità dell'acquisto di macchinari per il riciclaggio della plastica usati, valutandone i costi, comprendendone i rischi e fornendo una checklist di controllo fondamentale.

La spinta globale verso la sostenibilità è innegabile. Poiché le aziende cercano sempre più di ridurre al minimo il proprio impatto ambientale e di conformarsi a normative più severe, la domanda di soluzioni efficienti per il riciclaggio della plastica è in forte crescita. Che siate un operatore esperto nel settore del riciclaggio o un nuovo arrivato che desidera capitalizzare su questo mercato in crescita, i macchinari che sceglierete saranno un pilastro del vostro successo. Sebbene le attrezzature nuove di zecca offrano le tecnologie e le garanzie più recenti, il fascino di un risparmio significativo sui costi rende spesso i macchinari usati un'opzione allettante. Ma è la scelta giusta per la vostra attività?

Il fascino dell'usato: comprendere i potenziali benefici

Il vantaggio più evidente di optare per una macchina per il riciclaggio della plastica usata è il investimento iniziale ridottoQuesto può essere particolarmente interessante per le startup o le aziende con capitale limitato. I risparmi possono variare significativamente, a volte raggiungendo i 50% o più rispetto al prezzo di una nuova unità. Questo capitale liberato può quindi essere allocato ad altre aree critiche dell'azienda, come i costi operativi, il personale o l'approvvigionamento delle materie prime.

Oltre al costo iniziale, altri potenziali vantaggi includono:

- Tempi di consegna più rapidi: I macchinari nuovi spesso richiedono tempi di consegna lunghi a causa della produzione e della spedizione. Un macchinario usato è in genere disponibile molto prima, consentendo di avviare e gestire l'attività di riciclaggio più rapidamente.

- Tecnologia comprovata: Pur non essendo all'avanguardia tecnologica, una macchina usata ha una comprovata esperienza. Potresti trovare modelli con anni di funzionamento affidabile in applicazioni simili, che offrono un certo grado di prevedibilità.

- Potenziale per un ROI più rapido: Un investimento iniziale inferiore può tradursi in un ritorno sull'investimento più rapido, a patto che la macchina funzioni in modo efficiente e affidabile.

Come affrontare le insidie: rischi e considerazioni chiave

Sebbene il risparmio sui costi sia allettante, l'acquisto di macchinari usati per il riciclaggio della plastica non è privo di rischi. Comprendere questi potenziali svantaggi è fondamentale per prendere una decisione consapevole.

1. Cronologia operativa e manutenzione sconosciute:

La più grande incognita delle attrezzature usate è il loro passato. Sono state manutenute meticolosamente secondo le specifiche del produttore o sono state utilizzate a lungo con una manutenzione minima? Una manutenzione inadeguata può portare a un'usura prematura di componenti critici come motori, riduttori, viti, cilindri e lame da taglio.

2. Mancanza di garanzia e supporto:

A differenza delle macchine nuove, le apparecchiature usate in genere non hanno la garanzia del produttore o ne hanno una molto limitata. Ciò significa che eventuali guasti o riparazioni necessarie saranno interamente a vostro carico. Anche l'accesso all'assistenza tecnica del produttore dell'apparecchiatura originale (OEM) potrebbe essere limitato o inesistente.

3. Potenziale di minore efficienza e tecnologia obsoleta:

Le macchine più datate potrebbero non offrire lo stesso livello di efficienza energetica o di produttività dei modelli più recenti. Potrebbero anche non essere dotate di funzionalità di automazione avanzate, capacità di controllo di processo o compatibilità con i moderni sistemi di monitoraggio dei dati. Ciò potrebbe tradursi in costi operativi più elevati e potenzialmente in una produzione di materiale riciclato di qualità inferiore.

4. Difetti nascosti e guasti imminenti:

Un macchinario potrebbe sembrare in buone condizioni di funzionamento a una breve ispezione, ma subito dopo l'acquisto potrebbero emergere problemi nascosti. Questi difetti nascosti possono causare fermi macchina imprevisti e costose riparazioni.

5. Sfide di compatibilità e integrazione:

Integrare una macchina usata nella linea di produzione esistente può presentare delle sfide. Garantire la compatibilità con le apparecchiature a monte e a valle, nonché con l'alimentazione elettrica e l'ingombro della struttura, è essenziale.

6. Disponibilità dei pezzi di ricambio:

Per modelli più vecchi o meno comuni, reperire i pezzi di ricambio può diventare difficile e costoso. I tempi di fermo prolungati dovuti alla mancanza di ricambi possono avere un impatto significativo sulla produzione e sulla redditività.

7. Standard di sicurezza:

I macchinari più vecchi potrebbero non essere conformi agli attuali standard di sicurezza. Le modifiche per soddisfare tali standard potrebbero aumentare il costo complessivo e la complessità dell'acquisizione.

Il ruolo critico di un'ispezione approfondita: la tua checklist pre-acquisto

Un'ispezione meticolosa è la migliore difesa contro l'acquisto di una macchina per il riciclaggio della plastica usata e problematica. Questo processo dovrebbe idealmente coinvolgere personale tecnico esperto o un ispettore terzo qualificato.

Ecco una checklist completa per guidare la tua ispezione:

I. Documentazione e revisione della storia:

- Documenti di acquisto originali: Verificare l'età della macchina e le specifiche originali.

- Registri di assistenza e manutenzione: Questo è fondamentale. Controlla la manutenzione periodica, i cambi d'olio, la sostituzione di componenti e qualsiasi riparazione importante. Le lacune nei registri possono essere un campanello d'allarme.

- Manuali dell'operatore e schemi tecnici: Essenziale per il funzionamento, la risoluzione dei problemi e la manutenzione futura.

- Orari di apertura: Simile al chilometraggio di un'auto, questo dato fornisce un'indicazione di usura.

- Proprietario precedente e domanda: Conoscere come e dove è stata utilizzata la macchina può fornire indicazioni sui potenziali modelli di usura e sulla sua idoneità alle proprie esigenze.

II. Ispezione fisica e meccanica:

- Integrità strutturale complessiva:

- Controllare il telaio per individuare eventuali crepe, piegature o segni di corrosione significativi.

- Controllare l'integrità di tutte le saldature.

- Componenti di elaborazione chiave (varia in base al tipo di macchina, ad esempio trituratore, granulatore, estrusore, pellettizzatore):

- Trituratori/Granulatori:

- Lame/Coltelli: Controllare l'usura, eventuali scheggiature, crepe e la corretta affilatura. Chiedere quando sono state affilate o sostituite l'ultima volta.

- Rotore: Controllare eventuali danni, l'equilibrio e le condizioni dei cuscinetti (prestare attenzione a eventuali rumori insoliti).

- Schermate: Controllare eventuali segni di usura, danni e verificare che la taglia sia corretta.

- Estrusori:

- Vite e canna: Questo è un componente critico e costoso. Informatevi sull'usura (ad esempio, sullo strato di nitrurazione). Un'ispezione visiva potrebbe essere limitata senza smontaggio, ma chiedete informazioni su misurazioni o problemi precedenti.

- Cambio: Controllare eventuali perdite d'olio, rumori insoliti e surriscaldamento. Chiedere informazioni sulla cronologia dei cambi d'olio.

- Fasce riscaldanti e termocoppie: Assicurarsi che funzionino tutti correttamente.

- Cambiafiltro/filtro a fusione: Controllare l'usura e il corretto funzionamento.

- Stendibiancheria (se applicabile):

- Serbatoi e recipienti: Controllare eventuali perdite e corrosione.

- Pompe e agitatori: Controllare eventuali perdite e ascoltare il rumore dei cuscinetti.

- Essiccatori (centrifughi, termici): Controllare l'equilibrio, il funzionamento dell'elemento riscaldante e la presenza di eventuali ostruzioni.

- Pellettizzatori:

- Lame di taglio/rotore: Controllare l'usura e la corretta regolazione.

- Piastra di stampaggio: Controllare eventuali usura e ostruzioni.

- Trituratori/Granulatori:

- Motori e azionamenti:

- Ascoltare eventuali rumori insoliti (ronzio, sfregamento).

- Controllare che non vi sia surriscaldamento.

- Ispezionare i supporti e gli accoppiamenti del motore.

- Verificare che i dati della targhetta corrispondano alle specifiche.

- Sistemi idraulici (se applicabile):

- Controllare eventuali perdite nei tubi flessibili, nei cilindri e nelle pompe.

- Controllare il livello e le condizioni dell'olio (non deve essere torbido o bruciato).

- Testare la funzionalità e la reattività.

- Sistemi pneumatici (se applicabile):

- Controllare eventuali perdite d'aria.

- Ispezionare filtri, regolatori e lubrificatori.

- Componenti per trasportatori e movimentazione materiali:

- Controllare l'usura, la tensione e la tenuta delle cinghie/catene.

- Controllare rulli e cuscinetti.

III. Ispezione del sistema elettrico e di controllo:

- Pannello di controllo:

- Verificare la pulizia e l'organizzazione.

- Controllare le condizioni di interruttori, pulsanti e indicatori.

- Controllare eventuali segni di surriscaldamento dei componenti o di cavi allentati (procedere con cautela e assicurarsi che l'alimentazione sia disattivata per l'ispezione interna).

- Cablaggio: Controllare che i cavi non siano sfilacciati, danneggiati o installati in modo non corretto.

- Caratteristiche di sicurezza:

- Verificare la funzionalità degli arresti di emergenza.

- Controllare i blocchi di sicurezza sulle porte di accesso e sulle protezioni.

- Assicurarsi che tutte le protezioni siano presenti e in buone condizioni.

- PLC e HMI (se applicabile):

- Verificare che l'HMI (interfaccia uomo-macchina) sia reattiva.

- Se possibile, controllare il programma PLC o informarsi sul suo ultimo aggiornamento e su eventuali problemi noti.

IV. Test operativo (se possibile e sicuro):

- Richiedi una dimostrazione: L'ideale sarebbe vedere la macchina funzionare con un materiale simile a quello che si intende lavorare.

- Prestazioni del monitor:

- Prestare attenzione a eventuali rumori insoliti durante il funzionamento.

- Osservare le vibrazioni.

- Controllare eventuali perdite sotto pressione d'esercizio.

- Monitorare l'amperaggio del motore (se possibile) per rilevare eventuali sovraccarichi.

- Valutare la qualità e la coerenza del materiale in uscita.

- Testare tutte le funzioni e le velocità.

V. Considerazioni post-ispezione:

- Costo delle riparazioni/ristrutturazioni: Considerare tutti i problemi identificati e i costi per risolverli.

- Costi di montaggio e trasporto: Possono essere significativi per macchinari di grandi dimensioni.

- Disponibilità di competenze tecniche: Avete personale interno in grado di effettuare la manutenzione e la riparazione di questa specifica macchina oppure dovrete assumere specialisti esterni?

Illustrazione del flusso di lavoro: un tipico processo di riciclaggio della plastica

Conoscere le fasi del riciclaggio della plastica può aiutarti a identificare i tipi specifici di macchinari di cui potresti aver bisogno e a individuare dove un pezzo di attrezzatura usato potrebbe inserirsi nella tua linea.

(Segnaposto per un diagramma/diagramma che illustra un flusso di lavoro comune per il riciclaggio della plastica. In genere include: Raccolta -> Selezione -> Triturazione/Macinazione -> Lavaggio e separazione -> Essiccazione -> Fusione ed estrusione -> Pellettizzazione -> Produzione di nuovi prodotti. Il diagramma evidenzierebbe dove si inseriscono diverse macchine come imballatrici, trituratori, granulatori, linee di lavaggio, estrusori e pellettizzatori.)

Esempio di diagramma del flusso di lavoro:

[Rifiuti plastici grezzi] --> [Selezione manuale/automatica] --> [Pressa (per trasporto/stoccaggio)] | v [Trituratore/Granulatore (Riduzione dimensionale)] --> [Linea di lavaggio (Pulizia e rimozione contaminanti)] | (Lavatrici a frizione, vasche di flottazione, lavatrici a caldo) v [Sistema di essiccazione (Essiccatore centrifugo/termico)] | v [Estrusore (Fusione e omogeneizzazione)] --> [Filtrazione a fusione/Cambio filtro] | v [Pellettizzatore (a filamenti, subacqueo, ad anello d'acqua)] --> [Pellet riciclati] | v [Produzione di nuovi prodotti]

Confronto delle prestazioni: nuovo vs. usato (esempio illustrativo)

Sebbene i numeri specifici varino notevolmente a seconda del tipo, dell'età e delle condizioni della macchina, ecco un confronto illustrativo per evidenziare le potenziali differenze:

| Caratteristica | Nuova macchina per il riciclaggio della plastica (ad esempio, estrusore) | Macchina per il riciclaggio della plastica usata (ad esempio, estrusore - 5 anni) | Note |

| Costo iniziale | Alto | Da medio a basso | Notevoli risparmi iniziali con l'usato. |

| Efficienza energetica | Alta (tecnologia di motore e riscaldamento all'avanguardia) | Da moderato a basso (tecnologia obsoleta) | Può avere un impatto sui costi operativi a lungo termine. |

| Capacità di produzione | In genere più elevato (design ottimizzato) | Potenzialmente inferiore (usura, design obsoleto) | Varia notevolmente in base alle condizioni e al modello specifico. |

| Costi di manutenzione | Basso (inizialmente, in garanzia) | Da moderato ad alto (potenziale di riparazione) | Prevedere un budget per riparazioni impreviste con l'usato. |

| Livello di automazione | Alto (PLC avanzato, monitoraggio remoto) | Da base a moderato | Incide sui costi di manodopera e sul controllo dei processi. |

| Garanzia | Sì (in genere 1-2 anni) | Improbabile o molto limitato | Fattore di rischio importante per le attrezzature usate. |

| Valore di rivendita | Bene | Discreto-basso | Dipende dalle condizioni e dalla domanda del mercato. |

| Tempi di consegna | Settimane a mesi | Giorni a settimane | Avvio più rapido possibile con l'usato. |

Esempio di confronto visivo (grafico a barre concettuale):

Immagina un grafico a barre con due serie di barre (Nuovo vs. Usato) per categorie come:

- Costo iniziale: Barra utilizzata notevolmente più corta.

- Efficienza energetica: Nuovo bar più alto.

- Manutenzione prevista (anno 1-2): Barra usata più alta.

- Caratteristiche tecnologiche: Nuovo bar più alto.

Prendere la decisione giusta: vale la pena usarla? Per te?

In definitiva, la decisione di acquistare una macchina usata per il riciclaggio della plastica dipende da un'attenta valutazione delle circostanze specifiche, della tolleranza al rischio e delle capacità tecniche.

Una macchina usata potrebbe essere una buona soluzione se:

- Il budget è un vincolo fondamentale.

- Puoi contare su una solida competenza tecnica interna per la manutenzione e le riparazioni.

- Ti senti a tuo agio con un livello di rischio più elevato.

- La macchina in questione ha una storia ben documentata e supera un'ispezione approfondita.

- La tecnologia, anche se datata, è adeguata alle vostre esigenze di lavorazione e ai requisiti qualitativi.

- Bisogna tornare operativi al più presto.

Una nuova macchina è probabilmente la scelta migliore se:

- Dai priorità all'affidabilità, alla garanzia e al supporto a lungo termine.

- Per ottenere la massima efficienza, automazione e qualità di output, hai bisogno delle tecnologie più recenti.

- Per le riparazioni complesse disponi di competenze tecniche interne limitate.

- La tua tolleranza al rischio è bassa e la prevedibilità dei costi operativi è fondamentale.

Conclusione: procedere con diligenza

Investire in una macchina per il riciclaggio della plastica usata può effettivamente essere una strategia conveniente, ma richiede un'accurata due diligence, un'attenzione particolare ai dettagli durante l'ispezione e una valutazione realistica dei potenziali rischi. Armandosi di conoscenze, utilizzando una checklist di ispezione completa e soppesando attentamente i pro e i contro in base alle proprie esigenze operative e alla capacità finanziaria, è possibile prendere una decisione consapevole che porterà la vostra impresa di riciclaggio della plastica al successo. Non lasciate che il prezzo iniziale sia l'unico fattore determinante; una macchina apparentemente economica può rapidamente trasformarsi in un onere oneroso se non scelta con saggezza.