Tyre debeading—removing the steel bead bundles from the rim seat before primary shredding—is a small step that delivers big gains. It protects cutters and rotors from high-tensile bead wire, stabilises feed, reduces unplanned downtime, and unlocks cleaner ferrous recovery. For industrial buyers, the result is a safer plant with lower wear-part consumption, better energy efficiency and higher-value outputs.

What is the tyre bead—and why remove it?

Every pneumatic tyre is reinforced with bead bundles: multiple loops of high-tensile steel wire set in hard rubber around the inner circumference. Their job is to clamp the tyre to the rim under load. Those wires are:

- Hard and springy, capable of chipping knives, hammers and screens.

- Dense and localised, concentrating impact forces when a whole tyre hits a shredder.

- Entangling, liable to wrap around rotors and conveyors.

Debeading extracts these bundles (usually both beads) before the tyre enters the primary shredder.

Operational benefits you can bank on

1) Shields high-value machinery

Removing bead wire significantly reduces:

- Fractured knives/teeth and chipped anvils

- Shock loading of gearboxes and shafts

- Wire “bird-nesting” around rotors

2) Higher throughput and steadier amps

Debeaded casings feed more uniformly, letting you run tighter set-points (gap, screen size, conveyor speed) without nuisance trips.

3) Cleaner, higher-value ferrous

Separated early, bead wire is recovered undiluted by rubber fines, improving bale density and mill yield for your metal offtaker.

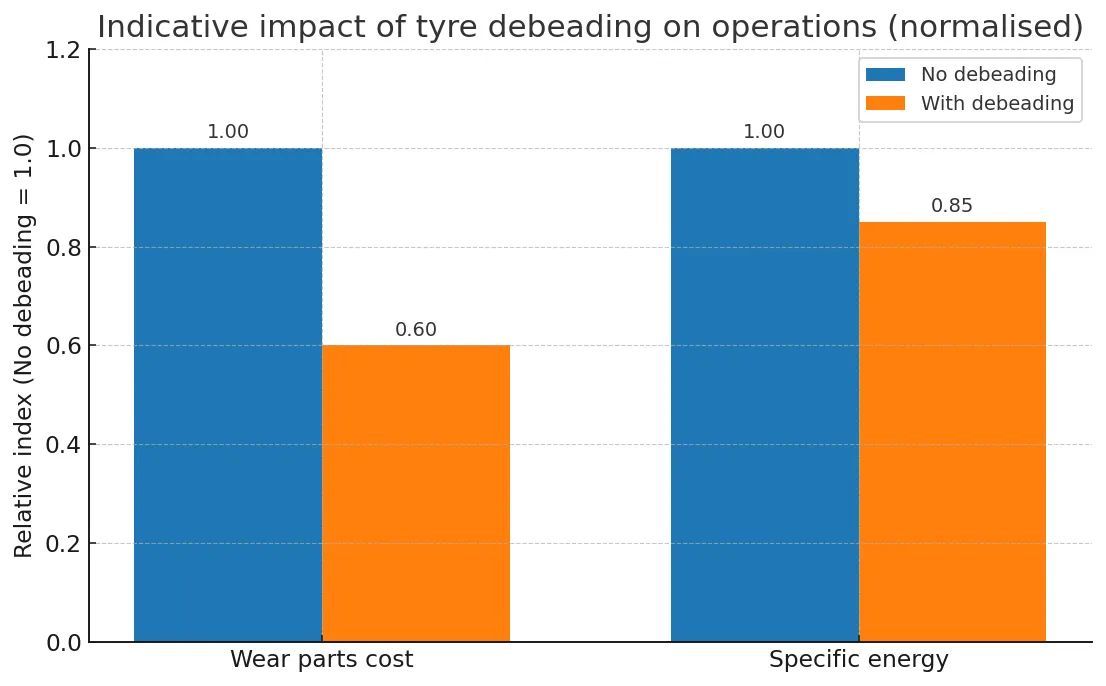

4) Lower OPEX: wear parts and energy

Illustrative model; normalised to “No debeading = 1.0”. Actual results vary by tyre mix, shredder design and operating practice.

5) Safety and housekeeping

Less exposed wire reduces snag hazards, tear-downs for de-wrapping, and manual interventions around live equipment.

Where debeading is essential—and where it’s strategic

- Truck/Bus (TBR) & OTR tyres: Beads are heavy-gauge steel; pre-shred debeading is strongly recommended to avoid catastrophic damage.

- Passenger car tyres (PCR): Many robust primary shredders can accept whole tyres, but plants still debead to cut wear costs, stabilise throughput and maximise clean steel revenue.

- Downstream focus: If you target fine rubber (≤1–3 mm) or mould-ready crumb, upstream debeading simplifies downstream metal removal and quality control.

Debeading technologies (at a glance)

| Technology | How it works | Strengths | Considerations |

|---|---|---|---|

| Mechanical bead pullers (hook & clamp) | Clamp casing, pierce and pull bead in one or multiple bites | Fast cycle times, good for mixed PCR/TBR | Hook and jaw wear; needs accurate centring |

| Hydraulic bead cutters | Shear through the bead area | Handles very rigid beads, OTR friendly | Produces chopped steel; higher power draw |

| Single- vs dual-station | One or both beads removed concurrently | Dual balances takt time with shredder feed | More footprint/controls |

| Manual-assist vs automated | From joystick control to PLC recipe-driven | Higher safety and repeatability when automated | Upfront controls cost |

Specification factors

- Tyre range (PCR, TBR, OTR), diameters and bead hardness

- Required takt time and line balance with your primary shredder

- Power/hydraulic capacity, guarding and interlocks (CE/UKCA)

- Wear-part availability (hooks, blades, grippers) and change-over time

- Steel discharge method (chop, coil, straight pull) and ferrous handling (hopper, conveyor, baler)

How debeading fits in a modern line

Receiving → Inspection → Debeading → Primary Shredding → Ferrous Separation

↓

Steel Bead Bales → Granulation & Cleaning → Rubber ProductsIntegration notes

- Position: Directly upstream of the primary shredder

- Controls: Interlocked safety doors, E-stops, permissives tied to the infeed conveyor

- Materials flow: Clean bead steel to a dedicated bin or baler; debeaded casings onto the shredder feed

Economics and ROI levers

- Wear-part life: Fewer wire strikes = longer knife/hammer, screen and anvil life

- Uptime: Less entanglement → fewer stoppages and restarts

- Energy: Smoother feed and lower peak torque reduce kWh per tonne

- By-product value: Cleaner steel commands better prices and lowers disposal costs for contaminated ferrous

Maintenance and safety best practice

- Inspect hooks/blades for dulling, deformation and cracking; replace on schedule, not failure

- Verify clamping and centring jaw alignment to avoid sidewall tearing

- Monitor hydraulic pressures and temperatures; keep seals and hoses clean

- Train operators on tyre orientation, bead condition recognition and safe clearing procedures

- Enforce strict lock-out/tag-out for all interventions

Energycle: Recycling Machinery’s approach

At Energycle: Recycling Machinery, our debeading solutions are engineered for industrial duty and seamless integration:

- Precision handling: Automatic centring with torque-based pull control to minimise casing damage

- Throughput ready: Dual-station layouts matched to high-volume lines

- Operator safety: Fully guarded cells with interlocked access and optional light curtains

- Connected service: Condition monitoring and remote diagnostics to support uptime

- Line fit: Mechanical and controls interfaces matched to your shredder brand and conveyor geometry

Key takeaways

- Debeading shields critical equipment, stabilises production and improves metal recovery

- It is indispensable for heavy tyres and a profitable choice for many PCR lines

- The right machine selection and integration turn a simple step into a measurable OPEX reduction

FAQs

Is debeading always required?

Not universally—but for TBR/OTR and any line targeting high rubber quality and low wear costs, it is strongly recommended.

Can I retrofit debeading to an existing line?

Yes. Most plants add a guarded debeading cell before the infeed conveyor with minimal civil work.

What happens to the bead wire?

It’s collected separately as clean ferrous, typically baled for efficient transport to steel recyclers.

Talk to our engineers

If you’d like a tailored throughput/wear model based on your tyre mix and shredder, we can build one for you. Speak to Energycle: Recycling Machinery’s engineering team to review integration, controls and ROI for your plant.