V odvětví recyklace plastů je výběr správného stroje zásadní pro optimalizaci efektivity, kvality produktů a provozního úspěchu. Dva běžně diskutované typy zařízení jsou peletizéry a granulátory, ale co je přesně odlišuje? V Energycle, specializujeme se na poskytování nejmodernějších stroje na recyklaci plastů, včetně obou plastové peletizéry a plastové granulátory, přizpůsobený potřebám profesionálů v oblasti průmyslové recyklace, inženýrů a kupujících zařízení. Tento článek zkoumá klíčové rozdíly mezi peletizéry a granulátory, jejich použití a jak vybrat správné zařízení pro vaše recyklační operace.

Pochopení peletizérů a granulátorů: Přehled

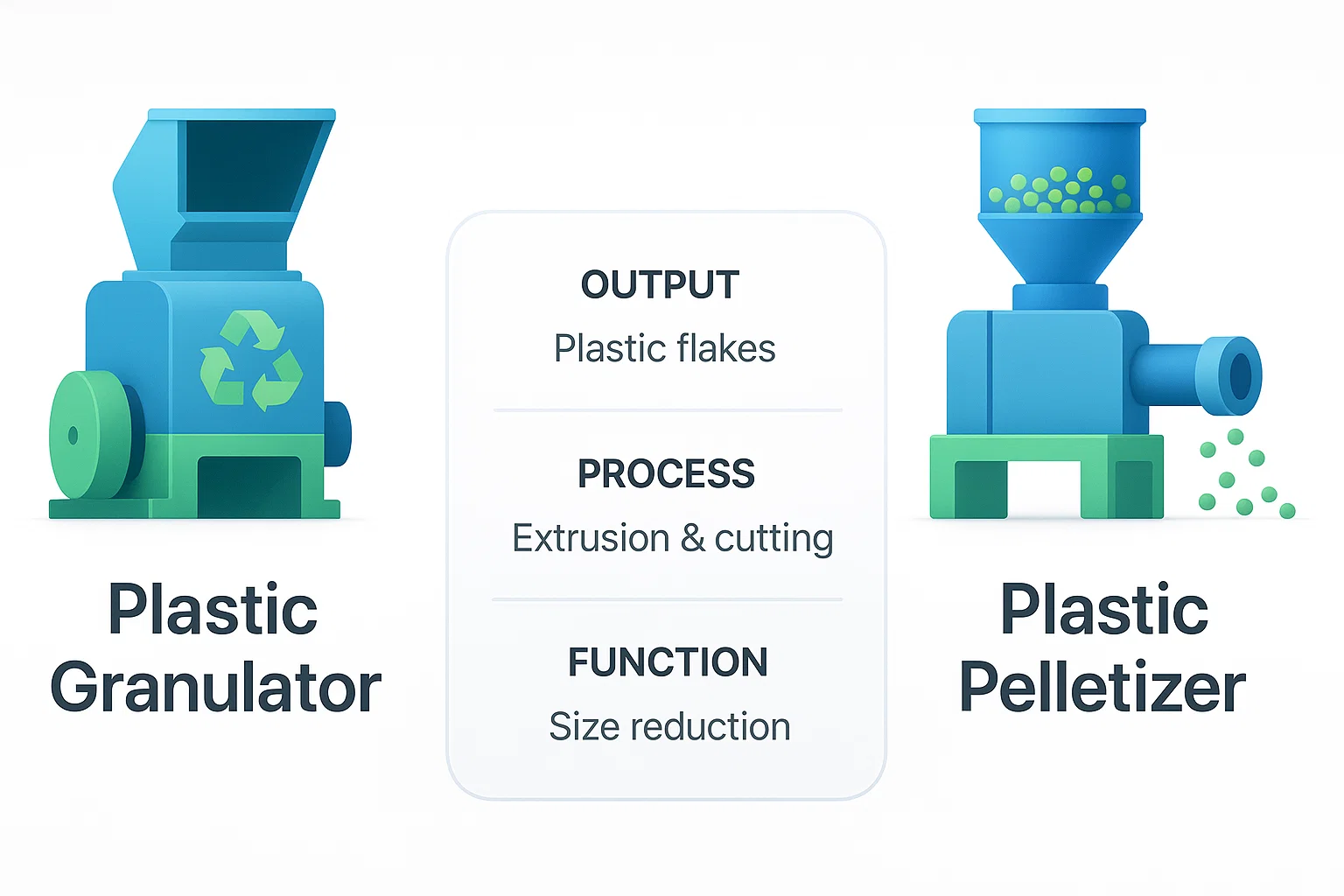

Peletizéry i granulátory hrají zásadní roli při zpracování plastového odpadu, ale v recyklačním postupu slouží jiným účelům. granulátor redukuje plastové materiály na menší, zvládnutelné kousky, zatímco peletizér transformuje tyto kusy na jednotné pelety vhodné pro další výrobu. Pro lepší pochopení pro odborníky z oboru si rozeberme jejich funkce, provedení a použití.

Co je to plastový granulátor?

A plastový granulátor je stroj určený k drcení nebo mletí plastového odpadu na malé, nepravidelné vločky nebo granule, obvykle o velikosti od 2 do 12 mm. Tyto granule jsou často prvním krokem v procesu recyklace a připravují materiály k dalšímu zpracování, jako je extruze nebo peletizace.

- FunkceGranulátory používají ostré nože nebo rotory k řezání plastového odpadu (např. lahví, fólií nebo průmyslového odpadu) na menší kousky.

- VýstupNepravidelně tvarované granule nebo vločky, ideální jako vstupní surovina pro následné procesy.

- AplikacePoužívá se při počátečním zmenšování velikosti široké škály plastů, včetně PET, HDPE, PP a PVC.

- Klíčové vlastnosti:

- Vysokorychlostní řezací systémy pro efektivní dělení materiálu.

- Robustní konstrukce pro práci s odolnými plasty a nečistotami.

- Přizpůsobitelné velikosti sít pro řízení výstupu granulí.

Pro podrobnější informace o našich vysoce výkonných granulátorech navštivte naši Stránka s plastovými granulátory.

Co je to plastový peletizér?

A plastový peletizérna druhou stranu odebírá zpracovaný plastový materiál (často granule z granulátoru) a přeměňuje ho na jednotné válcové pelety. Tyto pelety jsou ve výrobě velmi žádané díky své konzistentní velikosti, tvaru a hustotě, což zajišťuje plynulé podávání do extruderů nebo vstřikovacích lisů.

- FunkcePeletizéry taví a vytlačují plastové granule a tvarují je do jednotných pelet pomocí matrice.

- VýstupKonzistentní, válcovité pelety (obvykle o průměru 2–5 mm).

- AplikacePoužívá se v závěrečných fázích recyklace k výrobě vysoce kvalitních pelet pro výrobu nových plastových výrobků.

- Klíčové vlastnosti:

- Přesná regulace teploty pro konzistentní kvalitu pelet.

- Pokročilé systémy matric pro jednotné tvary pelet.

- Možnosti pro vodou chlazené nebo vzduchem chlazené peletizační systémy.

Prozkoumejte naši řadu špičkových peletizačních řešení na našem Stránka s plastovými peletizéry.

Klíčové rozdíly mezi peletizéry a granulátory

Abychom vám pomohli činit informovaná rozhodnutí o vašich recyklačních operacích, porovnejme peletizéry a granulátory podle několika klíčových faktorů:

| Aspekt | Plastový granulátor | Plastový peletizér |

|---|---|---|

| Účel | Redukce velikosti plastového odpadu na granule/vločky | Tvarování granulí do jednotných pelet |

| Vstupní materiál | Plastový odpad (např. lahve, fólie, zbytky) | Předzpracované granule nebo roztavený plast |

| Výstup | Nepravidelné granule nebo vločky (2–12 mm) | Jednotné válcovité pelety (2–5 mm) |

| Proces | Mechanické řezání nebo broušení | Tavení, vytlačování a řezání |

| Aplikace | Počáteční fáze recyklace | Závěrečná fáze výroby vstupních surovin |

| Složitost vybavení | Jednodušší design, zaměřený na řezání | Složitější, zahrnující zahřívání a extruzi |

Diagram: Pracovní postup recyklace plastů

Pro ilustraci rolí granulátorů a peletizátorů následující diagram znázorňuje typický proces recyklace plastů:

[Plastový odpad] → [Granulátor: Redukce velikosti] → [Granule] → [Peletizer: Tavení a tvarování] → [Rovnoměrné pelety] → [Výroba]Tento pracovní postup ukazuje, jak granulátory a peletizéry spolupracují na přeměně surového plastového odpadu na vysoce kvalitní vstupní surovinu pro nové produkty.

Výběr správného vybavení pro vaše potřeby

Výběr mezi plastový granulátor a peletizér závisí na vašich provozních cílech, typech materiálů a výrobních požadavcích. Zde je několik klíčových aspektů:

- Typ a objem materiálu:

- Granulátory jsou ideální pro zpracování rozmanitého plastového odpadu, včetně tuhých a flexibilních materiálů. Pokud vaše zařízení zpracovává velké objemy směsných plastů, je granulátor nezbytný pro počáteční zmenšení velikosti.

- Peletizéry jsou vhodné pro provozy zaměřené na výrobu vysoce kvalitních, jednotných pelet pro specifické výrobní aplikace.

- Požadavky na konečný produkt:

- Pokud vaši klienti požadují konzistentní, vysoce kvalitní pelety pro extruzi nebo lisování, je peletizér pro splnění těchto standardů zásadní.

- Pro méně přísné aplikace nebo jako mezikrok mohou postačovat granule z granulátoru.

- Integrace se stávajícími systémy:

- Mnoho recyklačních zařízení používá oba stroje postupně. Například naše plastové granulátory efektivně připravovat materiály pro naše plastové peletizéry, čímž je zajištěn bezproblémový proces recyklace.

- Rozpočet a prostor:

- Granulátory jsou obecně méně složité a nákladově efektivnější, což z nich činí dobrý výchozí bod pro menší provozy.

- Peletizéry s pokročilými extruzními systémy mohou vyžadovat vyšší investici, ale pro velkovýrobce poskytují vynikající výkon.

Proč si vybrat stroje na recyklaci plastů od Energycle?

Ve společnosti Energycle chápeme jedinečné potřeby profesionálů a inženýrů v oblasti průmyslové recyklace. Naše plastové granulátory a plastové peletizéry jsou navrženy s využitím nejmodernějších technologií pro maximalizaci efektivity, odolnosti a kvality výstupu. Zde je důvod, proč naše zařízení vyniká:

- Přesné strojírenstvíNaše stroje jsou konstruovány pro zpracování široké škály plastů s minimálními prostoji.

- Řešení na míruNabízíme konfigurace šité na míru, které vyhoví vašim specifickým potřebám recyklace.

- Zaměření na udržitelnostNaše zařízení podporuje principy cirkulární ekonomiky, pomáhá vám snižovat množství odpadu a vytvářet vysoce hodnotné recyklované produkty.

- Odborná podporaNáš tým poskytuje komplexní poradenství, od výběru zařízení až po instalaci a údržbu.

Závěr

Stručně řečeno, rozdíl mezi a plastový granulátor a peletizér spočívá v jejich funkci, výstupu a roli v procesu recyklace. Granulátory jsou nezbytné pro rozmělnění plastového odpadu na zvládnutelné granule, zatímco peletizéry transformují tyto granule na jednotné pelety připravené k výrobě. Pochopením těchto rozdílů můžete činit informovaná rozhodnutí pro optimalizaci vašich recyklačních operací.

Ve společnosti Energycle se zavázali k tomu, že posílíme vaši firmu špičkovými recyklačními stroji. Ať už potřebujete robustní plastový granulátor nebo vysoce přesný plastový peletizér, naše řešení jsou navržena tak, aby přinášela výjimečné výsledky. Kontaktujte nás ještě dnes a proberte s námi své požadavky a zjistěte, jak vám můžeme pomoci s vašimi cíli v oblasti recyklace.