Einführung

Die Wahl des richtigen Pelletiersystems für Ihre PET-Produktionslinie ist eine wichtige Entscheidung, die Ihre Betriebseffizienz, Produktqualität und langfristigen Kosten erheblich beeinflussen kann. Zu den am häufigsten eingesetzten Methoden gehören Wasserringgranulierung Und wassergekühlte Stranggranulierung. Jedes System hat seine Vorteile und eignet sich für unterschiedliche Produktionsziele und Anlagenbeschränkungen.

Bei Energycle-MaschineWir sind spezialisiert auf die Unterstützung von Herstellern in den USA und Europa bei der Optimierung ihrer Recycling- und Polymerverarbeitungsanlagen. Wenn Sie sich für Systeme für PET-Flakes interessieren, besuchen Sie unsere Einschnecken-Pelletizer für PET-Kunststoffflocken Seite, um mehr über hocheffiziente Einzelschneckenlösungen zu erfahren.

Dieser ausführliche Leitfaden führt Sie durch einen ausgewogenen Vergleich beider Pelletiertechnologien und hilft Ihnen, die beste Lösung für Ihre spezifischen Anforderungen zu finden.

Die Grundlagen der PET-Pelletierung verstehen

Die PET-Pelletierung (Polyethylenterephthalat) ist ein nachgelagerter Prozess in der Kunststoffrecycling- oder Neupolymerproduktionslinie, bei dem geschmolzenes PET in feste Pellets umgewandelt wird. Diese Pellets sind einfacher zu handhaben, zu transportieren und in Herstellungsprozessen wiederzuverwenden.

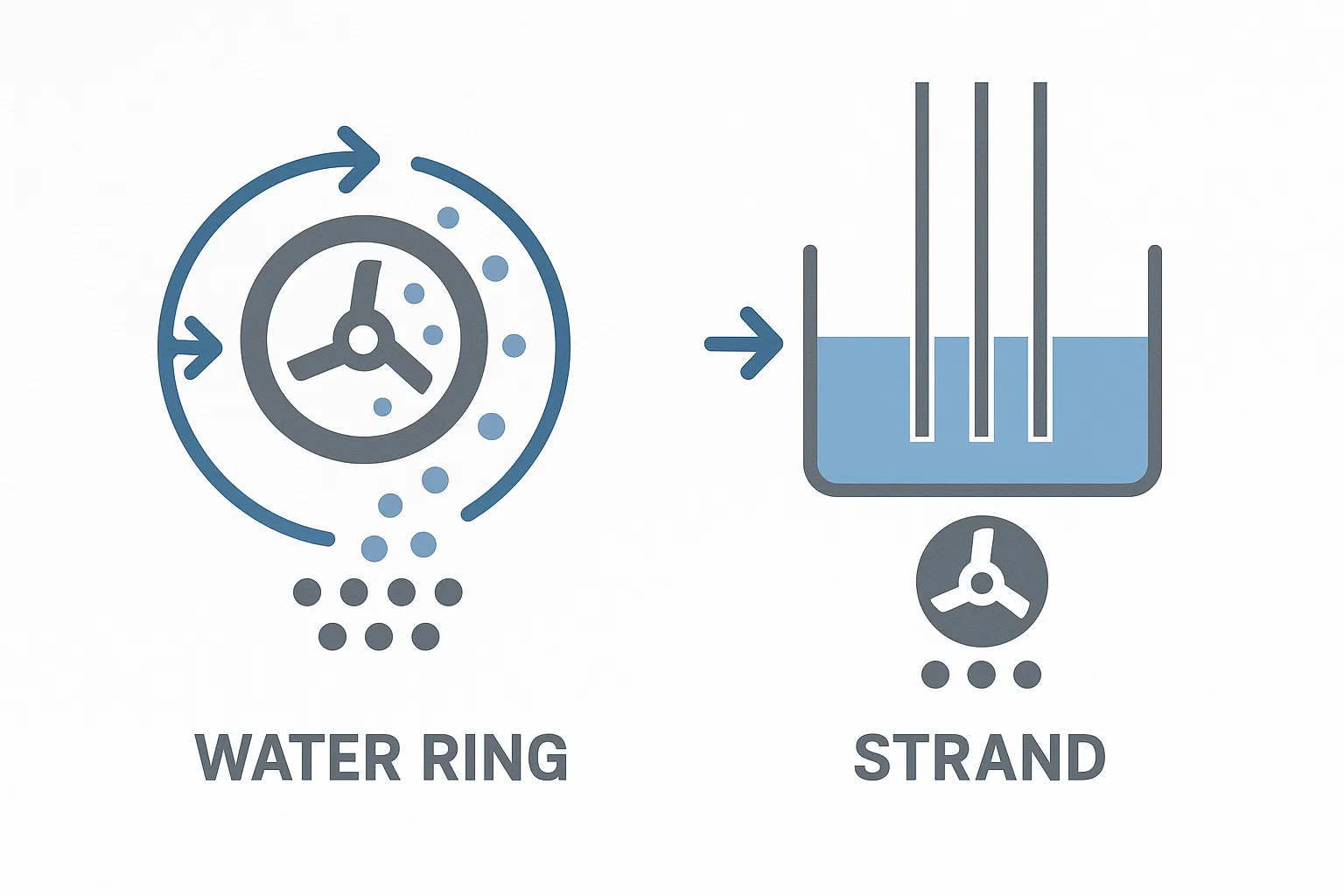

Die beiden vorherrschenden Systeme sind:

- Wasserring-Pelletierung: Geschmolzenes PET wird durch eine Düse extrudiert und sofort von rotierenden Klingen in Pellets geschnitten. Die Pellets werden anschließend in einem zirkulierenden Wasserring gekühlt.

- Wassergekühlte Strangpelletierung: Geschmolzenes PET wird als Endlosstrang extrudiert, in einem Wasserbad abgekühlt und dann in Pellets geschnitten.

Für PET-Flaschenflocken, Energycle-Maschine bietet auch spezialisierte Pelletiersysteme Entwickelt für stabile Leistung und gleichbleibende Pelletqualität.

Stellfläche und Platzbedarf

Wasserring-Pelletierung

Wasserringsysteme sind kompakt und hochintegriert. Sie benötigen weniger Stellfläche und eignen sich daher ideal für Anlagen mit begrenztem Platzangebot. Alle Hauptkomponenten, einschließlich Cutter, Wasserring und Trockner, sind typischerweise als eine Einheit montiert.

Wassergekühlte Strangpelletierung

Strangsysteme benötigen aufgrund der Kühlwasserrinnen und der Strangführung mehr Stellfläche. Dieser Aufbau kann für kleinere Fabriken oder Nachrüstanlagen Einschränkungen mit sich bringen. Er bietet jedoch möglicherweise mehr Flexibilität bei der Handhabung unterschiedlicher Materialviskositäten.

Energycle-Maschine empfiehlt, die Anordnung Ihrer Anlage zu prüfen, um herauszufinden, welches System am besten in Ihren Betriebsablauf passt.

Automatisierung und Benutzerfreundlichkeit

Wasserring-Pelletierung

Wasserringsysteme sind im Allgemeinen stärker automatisiert und erfordern weniger Bedienereingriffe. Der Klingendruck ist oft selbstregulierend und die Pellettrocknung ist integriert, wodurch der Bedarf an manueller Handhabung reduziert wird.

Wassergekühlte Strangpelletierung

Stranggranuliersysteme sind arbeitsintensiver. Bediener müssen auf eine korrekte Strangausrichtung und einen gleichmäßigen Wasserfluss achten. An- und Abfahren erfordern mehr Aufmerksamkeit und Geschick.

Für Hersteller, die ihre Arbeitskosten senken und die Konsistenz verbessern möchten, Energycle-Maschine schlägt vor, die Wasserringpelletierung aufgrund ihrer Automatisierungsvorteile in Betracht zu ziehen.

Pelletform und -qualität

Wasserring-Pelletierung

Produziert abgerundete, gleichmäßige Pellets mit glänzender Oberfläche. Diese eignen sich besonders für anspruchsvolle Anwendungen, bei denen Ästhetik und Fließfähigkeit der Pellets eine wichtige Rolle spielen.

Wassergekühlte Strangpelletierung

Pellets haben typischerweise eine zylindrische Form mit leicht unregelmäßigen Enden. Sie sind zwar für die meisten nachgelagerten Anwendungen noch geeignet, erfüllen jedoch möglicherweise nicht die höchsten ästhetischen oder Verarbeitungsstandards.

Wenn die Einheitlichkeit und das Aussehen der Pellets für Ihre Anwendung entscheidend sind, Energycle-Maschine empfiehlt Wasserringsysteme.

Zusammenfassende Vergleichstabelle

| Besonderheit | Wasserring-Pelletierung | Wassergekühlte Strangpelletierung |

|---|---|---|

| Fußabdruck | Kompakt | Größerer Platzbedarf |

| Automatisierung | Hoch | Mittel bis niedrig |

| Pelletform | Rund, gleichmäßig | Zylindrisch, variabel |

| Wartung | Mäßig | Geringeres Verschleißrisiko |

| Anschaffungskosten | Höher | Untere |

| Betriebskosten | Niedrigere langfristige | Höhere Arbeitskosten |

| Durchsatz | Hoch | Medium |

| Materialflexibilität | Medium | Hoch |

FAQs

F1: Kann ich meine vorhandene PET-Linie mit einem Wasserring-Pelletierer nachrüsten?

Ja, viele von Energycle-MaschineDie Modelle von sind für die Nachrüstung konzipiert, aber Layout- und Extrusionsparameter müssen ausgewertet werden.

F2: Welcher Pelletierer ist für recyceltes PET besser geeignet?

Aufgrund des höheren Durchsatzes und der besseren Trocknungsintegration ist die Wasserring-Pelletierung für recyceltes PET häufig besser geeignet.

F3: Gibt es Hybridsysteme?

Einige Systeme bieten modulare Optionen, die Funktionen beider Pelletierarten kombinieren. Energycle-Maschine kann Sie zu maßgeschneiderten Lösungen beraten.

F4: Wie lange amortisiert sich die Umrüstung auf ein Wasserringsystem normalerweise?

Abhängig von Ihrer Leistung und den Arbeitskosten kann die Amortisationszeit zwischen 1 und 3 Jahren liegen.

Treffen Sie die richtige Wahl für Ihre Produktionslinie

Die Wahl des richtigen Pelletiersystems kann die Zukunft Ihrer PET-Produktionslinie beeinflussen. Energycle-Maschine helfen Ihnen, eine fundierte, zukunftssichere Investition zu tätigen.

Besuchen Sie unsere Einschnecken-Pelletizer für PET-Kunststoffflocken Seite oder kontaktieren Sie uns noch heute, um Ihre Anforderungen zu besprechen.

Fordern Sie ein individuelles Angebot an