Vaš partner za sveobuhvatna rješenja recikliranja

Ingeniería de excelencia se une a la innovación ambiental. Ofrecemos maquinaria de reciclaje de alto rendimiento, confiable por empresas de todo el mundo.

Nuestra Misión y Experticia

Energycle brinda a empresas de todo el mundo la capacidad de transformar flujos de residuos complejos en recursos valiosos y rentables mediante tecnología de reciclaje innovadora.

Nos especializamos en diseñar líneas de reciclaje robustas e integradas, perfectamente adaptadas a sus necesidades, ya sea procesando plásticos rígidos, películas, tejidos, botellas de PET, neumáticos o residuos sólidos municipales.

Con décadas de excelencia en ingeniería, entregamos sistemas llave en mano que maximizan la pureza del material, la eficiencia operativa y su beneficio neto. Somos su socio dedicado desde la concepción hasta la puesta en marcha.

Ključne kompetencije

- Diseño y Integración de Plantas Personalizadas

- Tecnología Avanzada de Lavado y Separación

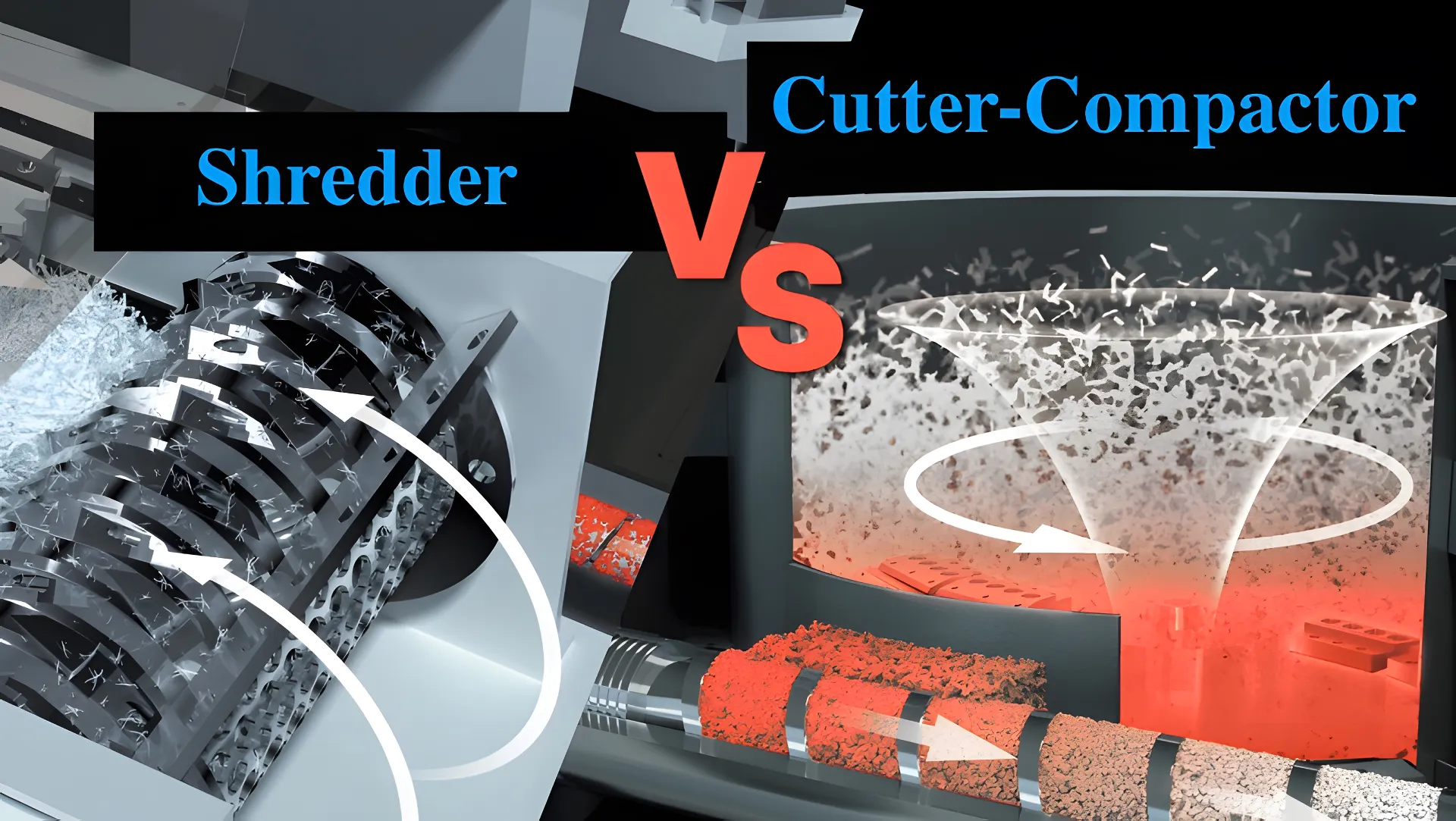

- Trituración y Molienda de Alta Eficiencia

- Sistemas Versátiles de Pelletizado y Granulación

- Potpuni asortiman pomoćne opreme

Portafolio Completo de Productos

Desde equipos independientes hasta sistemas llave en mano, diseñamos soluciones para cada desafío de reciclaje, sin importar el material o la escala.

Apoyo Completo

Nos comprometemos a su éxito en cada etapa de su viaje de reciclaje.

Sveobuhvatne usluge

Apoyo integral desde la consulta inicial hasta la instalación final y más allá.

Posvećeni profesionalci

Trabajando por un futuro sostenible, asegurando que cada proyecto cumpla con los más altos estándares.

Stručni inženjeri

Ingenieros experimentados aportan años de experiencia y precisión a cada solución.

Podrška 24/7

Estamos aquí las 24 horas, asegurando operaciones suaves y eficientes.

Unapređenje budućnosti recikliranja plastike

Ofrecemos una amplia gama de servicios, incluyendo diseño preliminar, fabricación y soporte postventa integral para asegurar su éxito.

Listo para Transformar Su Operación de Reciclaje?

Ya sea que necesite una máquina única o una línea de procesamiento completa, nuestro equipo de ingeniería está listo para diseñar una solución personalizada que maximice su eficiencia y rentabilidad.

Obtenga Su Cotización Personalizada