Solve Your Plastic Film Moisture Problem

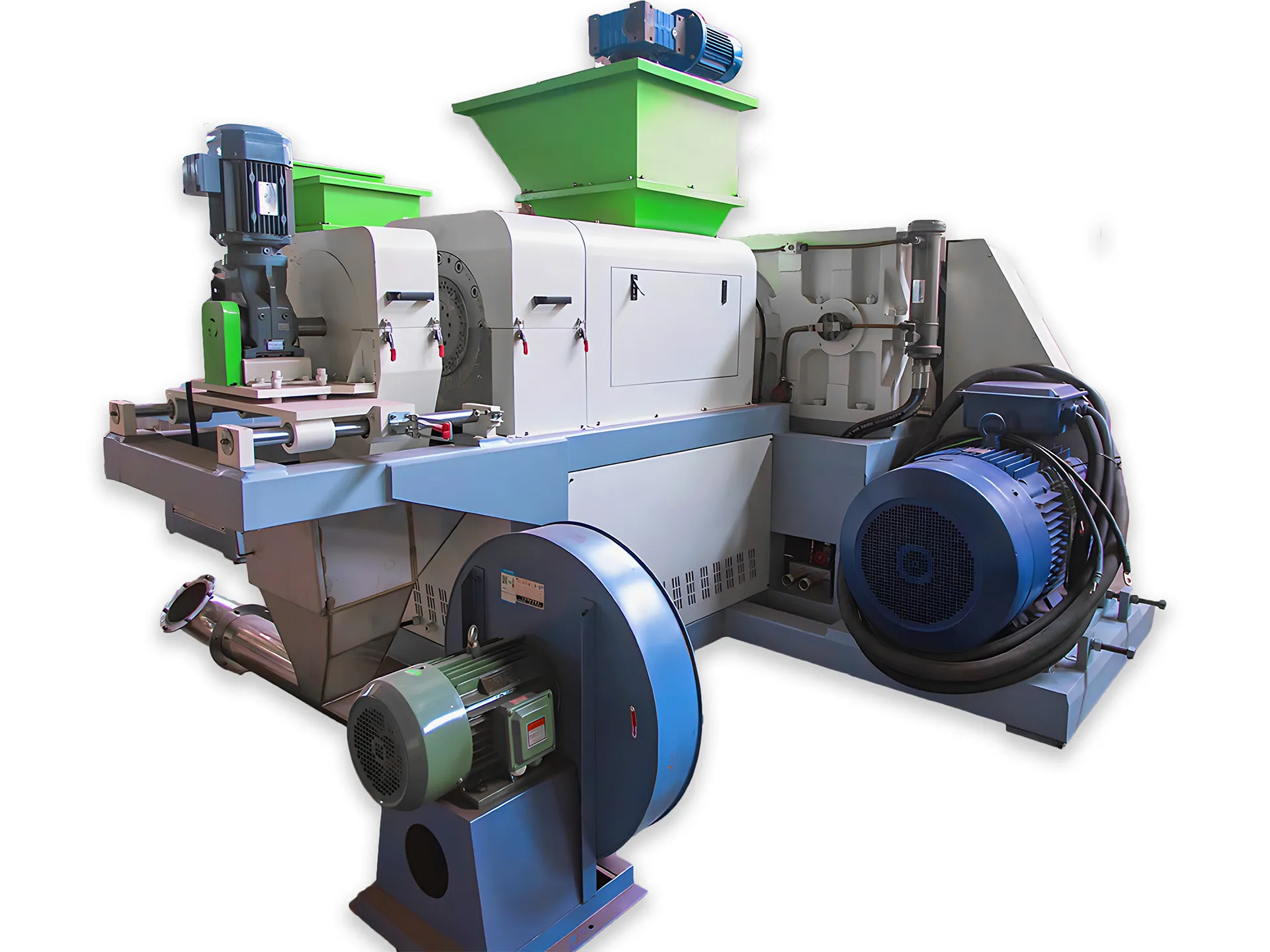

High moisture content in washed PE film and PP woven bags leads to inconsistent feeding, reduced output, and lower pellet quality. Our Plastic Film Squeezer Dryer is the definitive solution, engineered to transform wet, bulky film into dense, dry material ready for high-efficiency pelletizing.

The Ultimate Upgrade for Your Recycling Line

Drastic Moisture Removal

Reduces water content from as high as 40% down to an industry-leading **1-5%**, far surpassing traditional centrifugal or hot air dryers.

Increase Extruder Output

The dense, compacted material ensures smooth, stable feeding into your pelletizer, eliminating bridging and boosting your overall production capacity.

Improve Pellet Quality

Consistent, dry input material results in higher quality, more uniform recycled pellets with fewer voids, increasing their market value.

Seamless Integration, Maximum Efficiency

Our Squeezer Dryer is designed to be the powerful link between your washing line and extruder, creating a seamless and highly productive workflow.

Technical Specifications

| Model | Screw Diameter | Screw Material | Motor Power | Heating Power | Capacity |

|---|---|---|---|---|---|

| ERCG250 | 250mm | 38CrMoAlA Nitride | 90kw | 15kw | 200-300kg/h |

| ERCG300 | 300mm | 38CrMoAlA Nitride | 110-132kw | 22kw | 300-400kg/h |

| ERCG320 | 320mm | 38CrMoAlA Nitride | 160-185kw | 30kw | 500-600kg/h |

| ERCG350 | 350mm | 38CrMoAlA Nitride | 200-220kw | 36kw | 700-800kg/h |

Machine in Focus

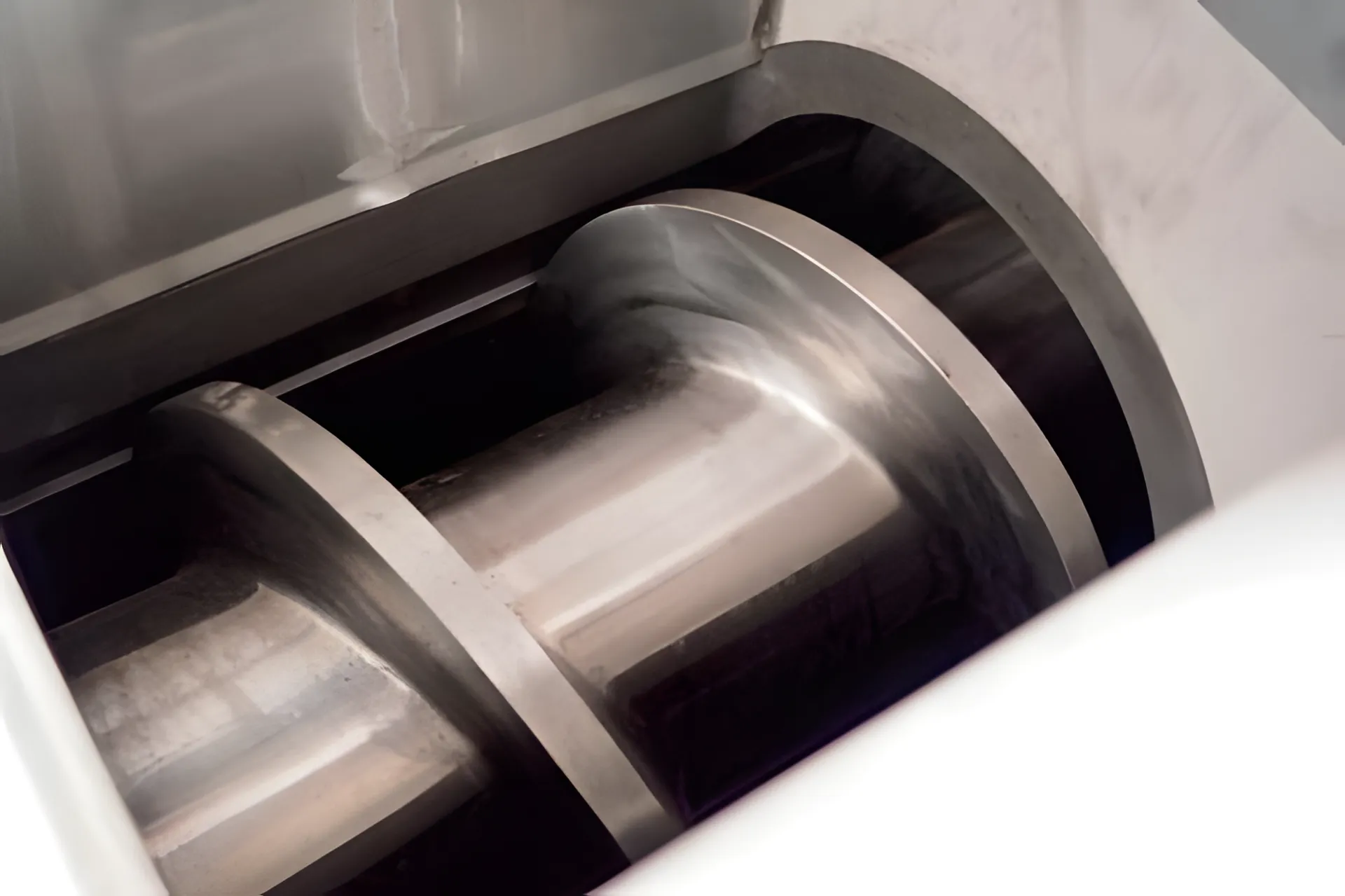

High-Durability Squeezing Screw

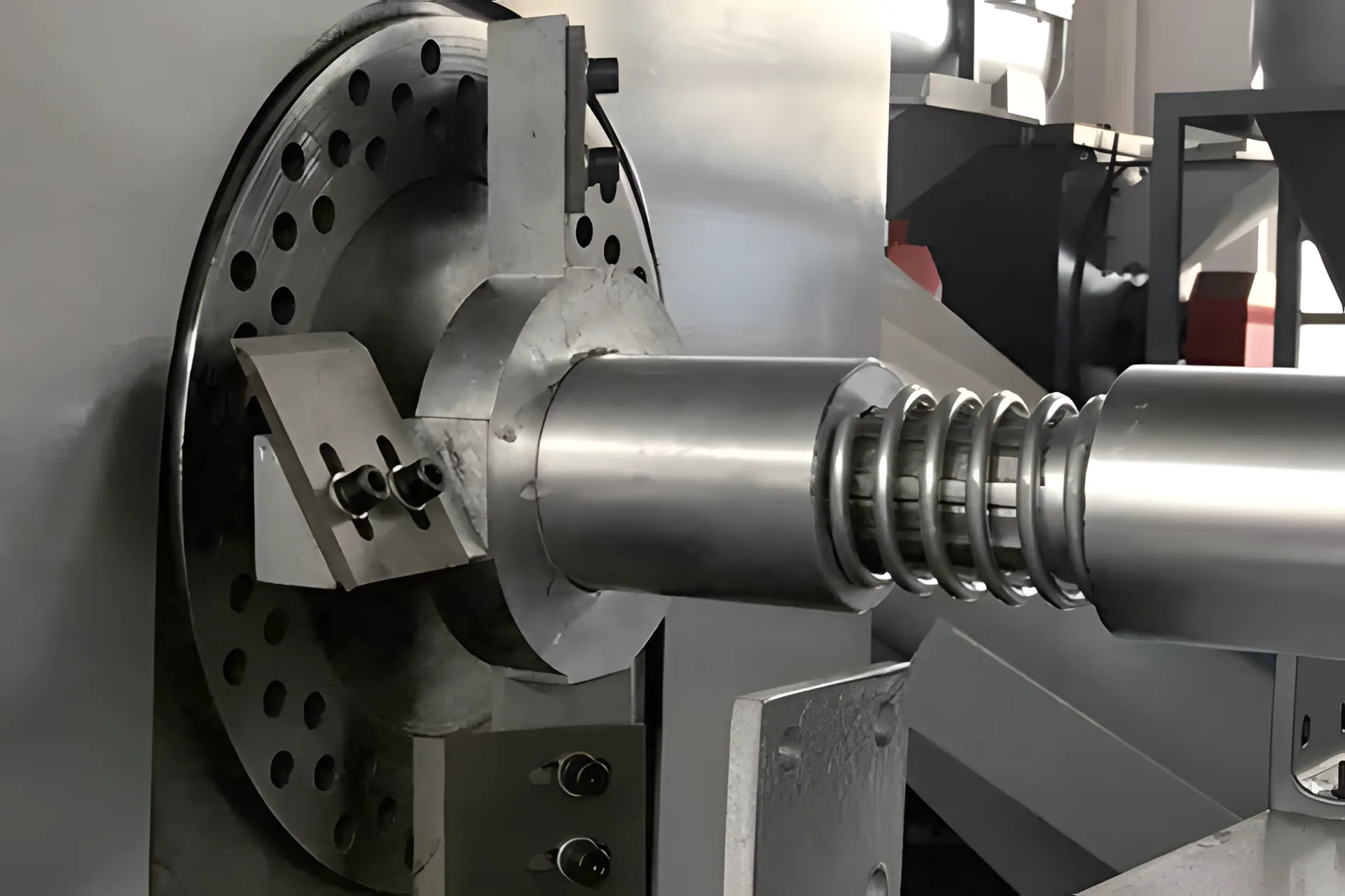

Precision Cutting Head

Final High-Quality Granules

See It In Action

Frequently Asked Questions

What makes this squeezer different from a centrifugal or hot air dryer?

A squeezer uses mechanical pressure and friction to remove water and densify the film, achieving much lower moisture levels (1-5%) and preparing the material for the extruder. Centrifugal and hot air dryers use high speed and heat, which are often less effective and more energy-intensive for thin films.

What specific types of plastic film can this machine process?

It is ideal for soft plastics like washed PE film (LDPE, LLDPE), PP woven bags, agricultural films, and PP jumbo bags. It is not designed for rigid plastics like PET bottles or HDPE containers.

Will this machine damage or degrade my plastic material?

No. It generates low heat through friction, which is just enough to densify the material without causing thermal degradation. This process preserves the intrinsic quality and integrity of the plastic for high-quality recycling.

What are the main maintenance requirements?

Maintenance is straightforward. The primary wear parts are the screw and barrel, which are made from highly durable, nitrided steel for a long service life. Regular inspection and lubrication as per the manual are the key requirements.

Can this machine be customized for my specific capacity needs?

Absolutely. We offer several models with different capacities, from 200kg/h up to 800kg/h. We can consult with you to determine the best model to perfectly match your washing line’s output and your production goals.

Revolutionize Your Film Recycling Process

Ready to boost efficiency, improve pellet quality, and lower your costs? Contact us today for the latest prices and to find the perfect squeezer dryer model for your operation.

[…] Plastic Film Squeezer&Densifier System […]

[…] Plastic Film Squeezer&Densifier System […]

[…] Plastic Film Squeezer&Densifier System […]

[…] Plastic Film Squeezer&Densifier System […]