Recycling News

A Manufacturer's Guide to In-House Plastic Recycling Machines

An in-house plastic recycling machine is a strategic asset that transforms your production waste from a liability into a valuable resource. For plastic manufacturers dealing with volatile raw material prices and increasing environmental regulations, processing post-industrial scrap on-site is no longer a niche practice but a core component of efficient and profitable operation. This guide explains the financial, operational, and market advantages of integrating a recycling system directly into your workflow.

Ignoring production scrap means discarding valuable polymers and paying for their disposal. By recycling in-house, you gain direct control over your material supply chain, reduce operational costs, and enhance your product quality. Let's explore how this process works and the tangible benefits it delivers.

Understanding Post-Industrial Recycling (PIR)

Post-industrial recycling, or PIR, is the process of reclaiming plastic scrap generated during manufacturing before it ever leaves the facility. This is distinct from post-consumer recycling (PCR), which deals with products that have been used by consumers and discarded. PIR materials are cleaner, more uniform, and have a known composition, making them ideal for high-quality recycling.

Common Types of Recyclable In-House Plastics

Nearly every plastic manufacturing process generates recyclable scrap. With the right plastic recycling machine, you can efficiently reprocess these materials back into high-grade pellets. Examples include:

- Film and Sheet Extrusion: Edge trims, roll scraps, and non-conforming startup materials from HDPE, LDPE, LLDPE, PP, and BOPP production.

- Injection Molding: Sprues, runners, rejected parts, and purge materials from PP, HDPE, ABS, and PS processes.

- Blow Molding: Flash, tails, and defective containers from HDPE and PP bottle manufacturing.

- Bag Conversion: Punch-outs from T-shirt bags, handle scraps, and misprinted bag material.

- Woven Products: Off-cuts from PP woven bags and non-woven fabric production.

Because you have complete knowledge of the material's origin, additives, and properties, the resulting recycled pellets are highly consistent and can be reintroduced into your primary production lines with confidence.

The Financial Case for an On-Site Plastic Recycling Machine

Investing in an in-house plastic recycling machine delivers clear and measurable financial returns. It directly addresses several major cost centers in manufacturing while opening up new opportunities for revenue.

1. Drastically Reduce Raw Material Expenditures

The most significant financial benefit is the reduced reliance on virgin polymers. Plastic resin prices are subject to market volatility tied to global oil prices and supply chain disruptions. Every kilogram of scrap you recycle in-house is a kilogram of virgin material you don't have to purchase. This direct substitution lowers your production costs and insulates your business from price shocks. For example, reprocessing your PP scrap can offset the purchase of prime PP resin, leading to substantial savings over a fiscal year.

2. Eliminate Waste Disposal and Third-Party Recycling Costs

Outsourcing your plastic waste management involves multiple expenses. These include:

- Transportation Fees: The cost of shipping scrap to a third-party recycler.

- Service Charges: Fees paid to the recycling company for processing your material.

- Storage Costs: The expense of allocating warehouse space to accumulate enough scrap for a full truckload.

- Disposal Fees: Costs associated with sending non-recyclable or contaminated waste to a landfill.

An in-house system removes these recurring expenses from your budget. The process becomes streamlined: scrap is collected from the production floor and processed immediately, saving time, space, and money.

3. Generate a New Revenue Stream

If your facility generates more scrap than you can re-use in your own products, you can sell the high-quality recycled pellets on the open market. There is strong demand for consistent, clean post-industrial resin. According to reports from industry analysts, the market for recycled plastics is growing, driven by corporate sustainability goals and government mandates. By selling your surplus pellets, you can turn what was once a waste product into a profitable secondary business line.

Gain Full Control Over Material Quality and Consistency

When you send scrap to an external recycler, you lose control. The returned pellets may be a blend of materials from various sources, leading to inconsistencies in melt flow index (MFI), color, and mechanical properties. This variability can compromise your final product quality.

Unmatched Material Purity and Predictability

Recycling your own scrap in-house ensures you know exactly what is going into your production line. You control the entire process, from scrap collection to pelletizing. This guarantees that the recycled material is 100% compatible with your virgin resin, maintaining the strict quality standards your customers expect. For applications requiring precise specifications, such as technical films or precision-molded parts, this level of control is essential.

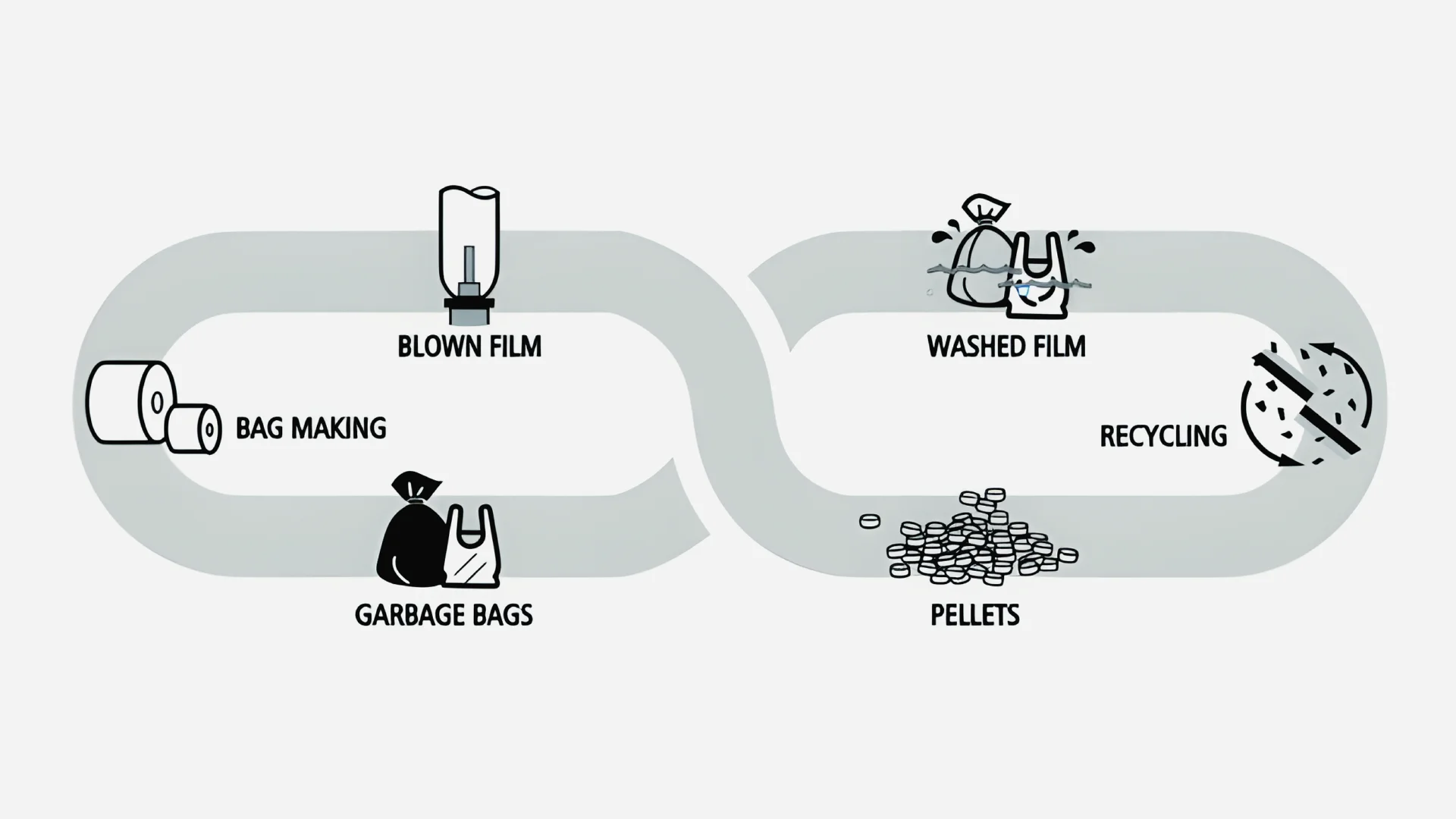

Create a Closed-Loop Production System

An in-house plastic recycling machine facilitates a true closed-loop system. Defective products or production scrap can be immediately reprocessed and fed back into the same production run. This rapid feedback loop improves overall material efficiency and minimizes waste. It transforms your manufacturing facility into a more self-sufficient and resourceful operation, a key principle of the circular economy.

Meet Regulatory Requirements and Enhance Your Brand Image

Globally, governments and consumers are demanding greater environmental responsibility from manufacturers. Integrating in-house recycling is a powerful way to meet these expectations and build a stronger, more sustainable brand.

Comply with Recycled Content Mandates

Many regions, including the European Union and states like California, have enacted legislation requiring products to contain a minimum percentage of recycled material. For example, the EU's Single-Use Plastics Directive sets targets for recycled content in beverage bottles. Having your own source of high-quality post-industrial recycled pellets makes it simpler and more cost-effective to meet these legal obligations and access environmentally-conscious markets.

Strengthen Your Environmental, Social, and Governance (ESG) Profile

A commitment to recycling boosts your company's ESG credentials, which is increasingly important to investors, partners, and corporate customers. Demonstrating a tangible reduction in waste and virgin material consumption strengthens your reputation as a responsible manufacturer. This can provide a competitive advantage in a market where sustainability is a key purchasing criterion.

Choosing the Right Plastic Recycling Machine for Your Needs

Selecting the appropriate machine is critical for success. The ideal system depends on your specific materials, volume, and operational goals. At Energycle Machine, we provide a range of solutions tailored to different manufacturing environments.

Key Considerations for Machine Selection:

- Material Type: Is your scrap primarily soft film (LDPE, HDPE) or rigid plastic (injection-molded PP, PS)? The machine's cutter, screw design, and feeding mechanism must match the material.

- Contamination Level: Post-industrial scrap is usually clean, but printed films or slightly dusty materials may require systems with better degassing and filtration.

- Required Throughput: The machine's capacity (kg/hr) should align with the volume of scrap your facility generates to ensure an efficient workflow.

- Footprint and Integration: Consider the available space in your facility and how the machine will fit into your existing production layout.

Our team at Energycle Machine can help you assess your needs and recommend the perfect plastic recycling machine to maximize your return on investment. We offer systems designed for simplicity, reliability, and producing the highest quality pellets.

Frequently Asked Questions (FAQ)

What is the typical ROI on a plastic recycling machine?

The return on investment (ROI) for a plastic recycling machine is typically very strong, often within 12 to 24 months. The exact timeframe depends on the volume of scrap you process, the cost of virgin resin you are offsetting, and the savings from eliminated disposal fees. High-volume producers often see a faster return.

Can I recycle printed or multi-layer films?

Yes, many modern recycling machines are equipped with advanced features to handle these materials. Double-venting degassing systems help remove inks and moisture, while high-performance screen changers and filters can remove impurities, resulting in clean, usable pellets.

How much labor is required to operate an in-house recycling system?

Modern recycling machines are designed for high levels of automation. A single operator can typically manage the machine's operation, from feeding the scrap material into the hopper to bagging the finished pellets. The user-friendly controls and autom

Meeting Europe’s Circular Economy Mandate with 220V Plastic Recycling Machines

The landscape of plastic use and waste management in Europe is undergoing a seismic shift. Driven by ambitious legislation like the Circular Economy Action Plan and the Packaging and Packaging Waste Regulation (PPWR), businesses are no longer simply encouraged to recycle—they are required to. With mandates for minimum recycled content in new products, such as at least 25% in PET bottles by 2025, the demand for high-quality, traceable recycled polymers has skyrocketed.

For many small to medium-sized enterprises (SMEs), plastic manufacturers, and innovative startups, this presents both a challenge and a significant opportunity. The challenge lies in accessing the means to process plastic waste effectively. The opportunity is to turn a costly waste stream into a valuable resource, securing a competitive edge in a market that rewards sustainability. This is where accessible, efficient technology becomes critical. The 220V plastic recycling machine, particularly suited for facilities without heavy industrial infrastructure, emerges as a strategic asset for navigating this new economic reality.

The Strategic Advantage of In-House, 220V Recycling

Traditionally, industrial recycling machinery has been the domain of large-scale waste processors, requiring substantial capital investment and three-phase power infrastructure. However, a decentralized approach using smaller, more adaptable equipment offers compelling benefits for a wider range of European businesses.

Overcoming the Power Barrier

The most significant advantage of a 220V machine is its compatibility with standard single-phase electrical supplies common in workshops, smaller industrial units, and laboratories across Europe. This eliminates the need for costly and complex installation of a three-phase power system, making advanced recycling technology accessible to businesses that were previously excluded.

Maximizing Floor Space

Factory and workshop space is a premium asset. Compact recycling machines are designed with a minimal footprint, allowing them to be integrated directly into existing production lines or set up in dedicated corners of a facility. This proximity enables a seamless workflow, processing production scrap, rejected parts, or post-consumer waste on-site, right where it is generated.

Transforming Costs into Revenue

Disposing of plastic waste incurs escalating landfill and transportation fees. By processing this material in-house, businesses can drastically cut these operational expenditures. Furthermore, the recycled plastic pellets or flakes become a valuable commodity. This feedstock can be sold to other manufacturers or, more profitably, reintroduced into your own production lines, reducing the need to purchase virgin materials and insulating your business from volatile raw material prices.

A Buyer’s Guide: Selecting a Europe-Friendly Recycling Machine

Investing in a plastic recycling machine requires careful consideration of technical specifications and regulatory compliance. For the European market, this means prioritizing safety, reliability, and performance.

CE Marking: The Non-Negotiable Standard

Any machinery sold and operated within the European Union must bear the CE mark. This certifies that the equipment complies with the EU’s stringent health, safety, and environmental protection standards. Key directives for a plastic recycling machine include:

- Machinery Directive (2006/42/EC): This ensures the fundamental safety design of the machine, covering everything from emergency stops to protective guards.

- Low Voltage Directive (LVD) (2014/35/EU): This applies to all electrical equipment operating between 50 and 1000V AC, guaranteeing the safety of the machine's electrical components and protecting operators from electrical hazards.

Choosing a CE-certified machine is not just about legal compliance; it's a guarantee of quality engineering and operational safety.

Essential Features for Peak Performance

When evaluating a 220V recycling machine, look for these key attributes:

- Robust Shredding and Granulating: The heart of the machine lies in its ability to consistently reduce plastic waste to a uniform size. Look for blades crafted from high-hardness alloy steel for durability and longevity.

- Energy-Efficient Motor: An efficient motor not only lowers electricity consumption but also ensures stable, reliable performance without overloading a single-phase circuit.

- Operational Safety and Noise Reduction: Features like a fully enclosed design, sound-dampening materials, and automatic shut-off mechanisms enhance workplace safety and minimize disruption.

- Ease of Maintenance: A well-designed machine allows for straightforward cleaning and quick blade adjustments or replacements, minimizing downtime and keeping your operations running smoothly.

The Energycle Advantage: Your Partner in European Circularity

At Energycle, we understand the unique challenges and opportunities within the European market. Our range of 220V plastic recycling machines is engineered specifically to empower businesses to thrive in the circular economy.

Designed for European Standards

Every Energycle machine is built to meet and exceed CE requirements, ensuring full compliance with the Machinery and Low Voltage Directives. We prioritize safety and reliability, giving you peace of mind and guaranteeing seamless integration into your operations.

Complete, Tailored Solutions

We offer more than just a single machine; we provide comprehensive recycling solutions. From initial shredding and granulation to washing, drying, and pelletizing, our systems are designed to work in harmony. Our team of experts will work with you to configure a setup that fits your specific material, throughput needs, and facility space, ensuring you produce high-purity, process-ready feedstock.

Unwavering Reliability and Global Support

An investment in machinery is an investment in your future. Energycle is committed to proven uptime and provides responsive, knowledgeable after-sales support. From installation and commissioning by certified engineers to a comprehensive 12-month warranty, we stand behind our equipment, ensuring that your downtime is minimal and your productivity is maximized.

Take Control of Your Plastic Waste Stream

The European push for a circular economy is redefining industry standards. For forward-thinking businesses, this is the moment to invest in technology that builds resilience, enhances profitability, and demonstrates a genuine commitment to sustainability. A 220V plastic recycling machine from Energycle is your accessible, powerful tool to achieve these goals.

Don't let plastic waste be a liability. Transform it into your next great asset.

Contact our team of specialists today to discuss your requirements and request a customized quote. Let’s build a more sustainable and profitable future together.

The Ultimate Maintenance Guide for Your Plastic Film Densifier: Preventing Overheating and Blockages

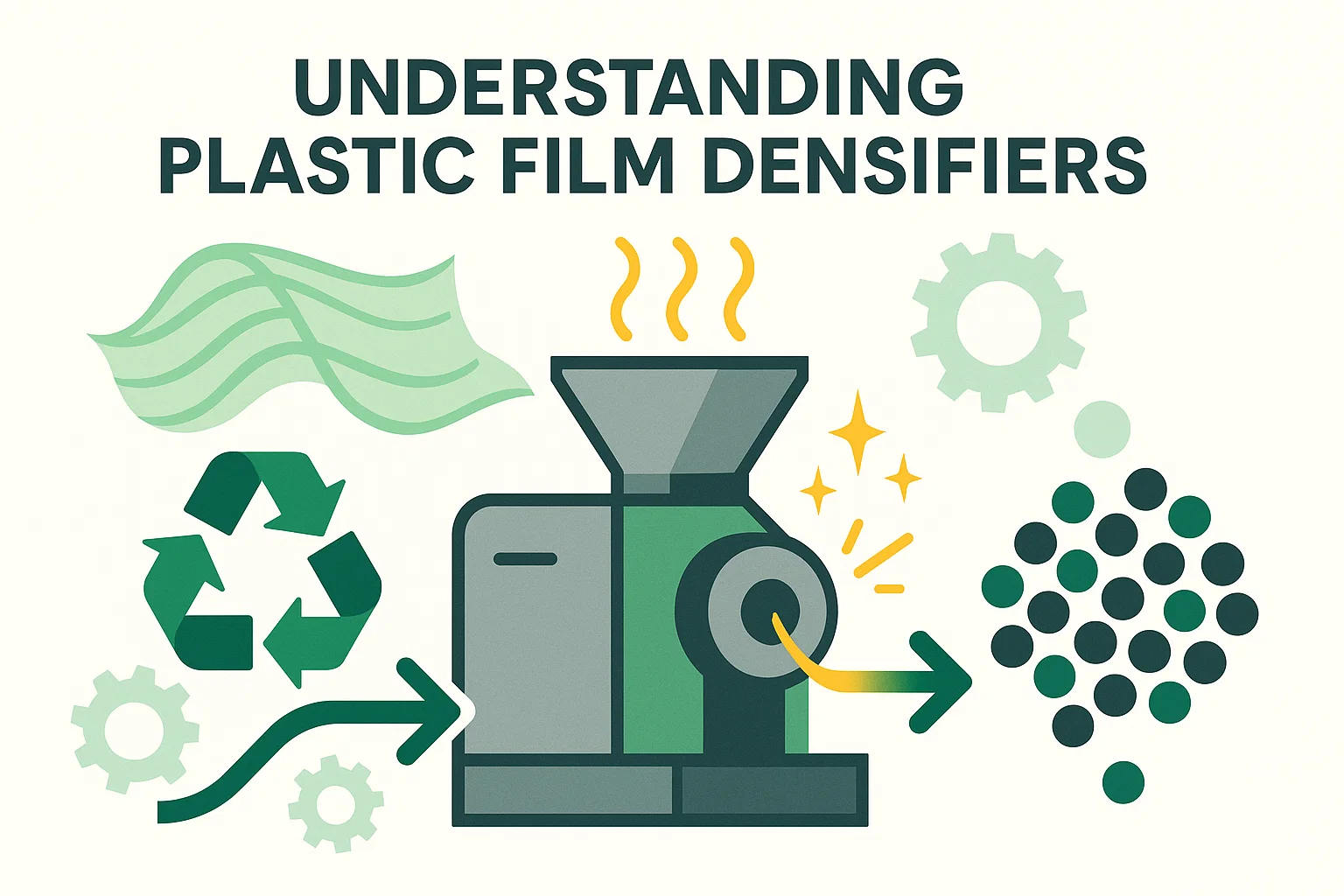

A plastic film squeezer-densifier is the workhorse of a modern recycling line, a powerful machine that operates under immense pressure and controlled heat. When it runs smoothly, it's the key to transforming low-value film waste into profitable, high-density feedstock. But when it’s down, the entire production line grinds to a halt.

The two most common culprits behind unplanned downtime are overheating and material blockages. While they may seem like sudden failures, they are almost always the result of small, overlooked maintenance issues that build up over time.

Preventative maintenance isn't a cost center; it's the single most effective investment you can make in your machine's longevity, performance, and the overall profitability of your operation.

This definitive guide provides a practical, hands-on maintenance schedule and troubleshooting tips drawn from our deep engineering experience at Energycle Machine. Following these steps will help you maximize uptime, ensure consistent output quality, and protect your valuable equipment.

Understanding the "Why": The Root Causes of Overheating and Blockages

Before diving into the "how," it's crucial for operators and maintenance staff to understand why these problems occur.

What Causes Overheating?

A squeezer-densifier is designed to use friction to generate heat, but this must be a controlled process. Overheating occurs when this delicate balance is disrupted.

- Excessive Friction: Worn-out components, especially the screw and barrel, can create uneven surfaces and excessive friction, generating more heat than the system can dissipate.

- Poor Cooling: The cooling systems (air blowers or water jackets) are critical for stabilizing the temperature. Clogged air vents, dirty fan blades, or restricted water flow will inevitably lead to a rise in temperature.

- Material Blockages: A partial or full blockage in the die head forces the motor and screw to work harder, generating a massive amount of friction and heat in a concentrated area.

- Incorrect Operating Parameters: Running the machine at a screw speed that is too high for the specific material can generate heat faster than the plastic can absorb and move it, leading to premature melting and degradation.

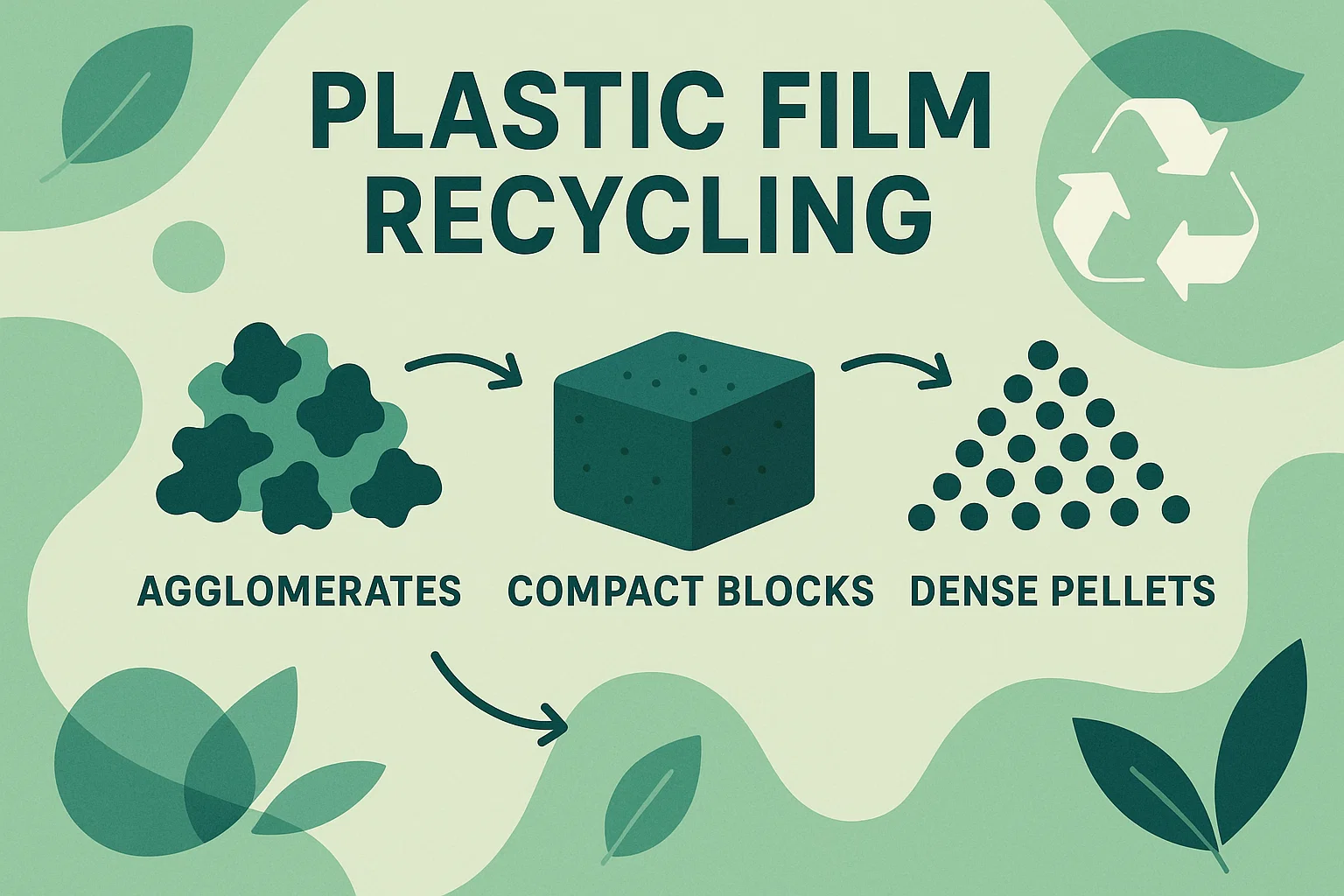

What Causes Blockages?

A blockage, or "bridging," is a traffic jam inside your machine. Material stops flowing smoothly, compacts into a solid mass, and brings the process to a halt.

- Foreign Contaminants: The number one cause. Hard plastics (PET, PVC), metal fragments, wood, or stones that sneak past the washing line can instantly jam the screw or block the die head.

- Dull or Damaged Blades: The rotating blades at the die head are essential for cutting and discharging the densified granules. If they are dull, they will smear the plastic rather than cut it, causing it to build up and clog the exit.

- Inconsistent Feeding: Dumping too much material into the hopper at once can overload the screw, preventing it from moving the material forward effectively and causing a jam at the entry point.

- Premature Melting: If the machine is running too hot (see above), the plastic can become fully molten and sticky far too early in the barrel, adhering to the screw and refusing to move forward.

The Preventive Maintenance Checklist: Daily, Weekly, and Monthly Routines

Consistency is key. Integrating these checks into your standard operating procedures will transform your maintenance from reactive to proactive.

Daily Checks (Performed by the Operator Pre-Shift – 10 Minutes)

- Visual Walk-Around: Look for any loose bolts, hydraulic or oil leaks, and signs of wear on external parts. Check that all safety guards are securely in place.

- Inspect the Die Head and Blades: Before startup (when the machine is cold and locked out), perform a quick visual check of the cutting blades. Is there any plastic residue from the previous run? Are the blades visibly chipped or dull?

- Monitor the Control Panel: During startup and the first 30 minutes of operation, pay close attention to the motor amperage (load) and temperature readings. A gradual increase is normal, but a sudden spike is an early warning sign of a potential blockage. An advanced control system on an Energycle Machine provides precise data to make this monitoring easy.

- Listen to the Machine: Every machine has a normal operating sound. Listen for any new or unusual noises, such as grinding, squealing, or excessive vibration. These are often the first indicators of a mechanical issue.

Weekly Checks (Performed by Maintenance Staff – 1 Hour)

- Thoroughly Clean the Die Head Assembly: This is the most critical weekly task. With the machine safely powered down and cooled, remove the die head cover. Scrape away all plastic residue from the die face, the cutting blades, and the blade holders. A clean cutting surface is essential for preventing blockages.

- Inspect and Clean Dewatering Screens: The perforated screens along the barrel allow water to escape. Over time, they can become clogged with fine plastic particles and contaminants. Use a wire brush and compressed air to ensure they are clear. Clogged screens reduce efficiency and can contribute to overheating.

- Clean the Cooling System: Dust and plastic fines can build up on cooling fan blades, vents, and radiator fins, acting as an insulator. Wipe down fan guards and use compressed air to blow out any accumulated debris to ensure maximum cooling efficiency.

- Check Lubrication Levels: Verify the oil levels in the main gearbox and check any grease points on bearings as specified in your machine's manual. Proper lubrication is vital for preventing friction-related overheating.

Monthly & Quarterly Checks (In-Depth Inspection)

- Blade Sharpness and Wear: Remove the cutting blades and inspect them closely. If they are dull, they must be sharpened or replaced. Running with dull blades dramatically increases energy consumption and is a primary cause of blockages.

- Screw and Barrel Inspection: This is a more involved check. As per your equipment's service interval, you should inspect the screw flights and the inner barrel lining for signs of wear, such as chipping, scoring, or rounding of the flight edges. Significant wear reduces the machine's ability to convey material efficiently.

- Electrical Cabinet Inspection: With all power disconnected, open the main electrical cabinet. Look for loose connections and use a low-pressure air blower to remove any dust buildup, which can cause short circuits or overheating of electrical components.

Troubleshooting Guide: Quick Fixes for Common Scenarios

Even with perfect maintenance, issues can arise. Here’s how to react.

- Scenario 1: Motor Amperage is Spiking Rapidly.

- Likely Cause: A blockage is forming.

- Immediate Action: Immediately stop the infeed conveyor. Allow the machine to process the material already inside. If the amperage drops, you likely had an inconsistent feed. If it remains high, perform an emergency stop, lock out the machine, and inspect the die head for a blockage.

- Scenario 2: Granules Are Clumpy, Discolored, or Smell Burnt.

- Likely Cause: The machine is overheating.

- Immediate Action: Check the temperature reading on the control panel against the setpoint. Verify that the cooling systems are operational (fans are spinning, etc.). You may need to slightly reduce the screw speed or feed rate to bring the temperature back into the optimal range.

- Scenario 3: The Machine is Vibrating Excessively.

- Likely Cause: A foreign object is caught in the screw, or the cutting blades are out of balance or loose.

- Immediate Action: Perform an immediate emergency stop and lock out the machine. Do not restart until you have inspected the die head and, if necessary, the screw chamber for obstructions or damage.

Frequently Asked Questions (FAQ)

1. How often should we replace critical wear parts like blades and screws?

This depends heavily on the type of material you are processing. Abrasive materials like post-consumer film with dirt contamination will cause faster wear than clean, post-industrial scrap. As a general rule, inspect blades monthly and plan for sharpening or replacement quarterly. A screw and barrel, built with high-quality, hardened metals like those used in a plastic film squeezer-densifier system, can last for years with proper care, but should be inspected annually for wear.

2. Is it okay to use third-party, non-OEM spare parts?

While it can be tempting to save costs, we strongly advise against it for critical components. OEM parts from a manufacturer like Energycle Machine are engineered to exact specifications for fit, material hardness, and balance. Using an improperly balanced blade or a screw with the wrong clearance can lead to poor performance, catastrophic failure, and void your warranty.

3. What is the single most overlooked maintenance task that causes problems?

Cleaning the cooling system. It's an easy and quick task, but it's often forgotten. A layer of dust on a cooling fan or radiator can reduce its efficiency by over 30%, which is more than enough to push a hard-working machine into the overheating zone on a hot day.

Conclusion: Your Partner in Performance

Your plastic film squeezer-densifier is a significant investment designed for high performance. Protecting that investment through a consistent, preventative maintenance program is the most effective way to ensure its reliability and profitability for years to come. By understanding the causes of common failures and dedicating a small amount of time to routine checks, you can prevent costly downtime before it starts.

At Energycle Machine, we see ourselves as more than just an equipment supplier; we are your operational partner. Our machines are designed for durability and ease of maintenance, and our support team is always ready to help you keep them running at peak performance.

Need Expert Maintenance Advice or Genuine Spare Parts?

Don't wait for a breakdown to disrupt your production. If you have questions about maintaining your equipment or need to order certified parts for your Energycle Machine densifier, our team is here to help.

Contact us today to speak with a technical expert or to schedule a system health check for your facility.

Introduction

Choosing the right pelletising system for your PET production line is a crucial decision that can significantly impact your operational efficiency, product quality, and long-term costs. Among the most widely used methods are water ring pelletising and water-cooled strand pelletising. Each system has its advantages and is suited to different production goals and facility constraints.

At Energycle Machine, we specialise in helping manufacturers across the USA and Europe optimise their recycling and polymer processing lines. If you’re exploring systems designed for PET flakes, visit our PET Plastic Flake Single Screw Pelletizer page to learn more about high-efficiency single screw solutions.

This in-depth guide will walk you through a balanced comparison of both pelletising technologies, helping you determine the best fit for your specific needs.

Understanding the Basics of PET Pelletising

PET (polyethylene terephthalate) pelletising is a downstream process in the plastic recycling or virgin polymer production line where molten PET is converted into solid pellets. These pellets are easier to handle, transport, and reuse in manufacturing processes.

The two dominant systems are:

- Water Ring Pelletising: Molten PET is extruded through a die and cut immediately into pellets by rotating blades. The pellets are then cooled in a circulating water ring.

- Water-Cooled Strand Pelletising: Molten PET is extruded as continuous strands, cooled in a water bath, and then cut into pellets.

For PET bottle flakes, Energycle Machine also offers specialised pelletising systems engineered for stable output and consistent pellet quality.

Footprint and Space Requirements

Water Ring Pelletising

Water ring systems are compact and highly integrated. They occupy less floor space, making them ideal for facilities where space is a premium. All major components, including the cutter, water ring, and dryer, are typically assembled as one unit.

Water-Cooled Strand Pelletising

Strand systems require longer floor space due to the cooling water troughs and strand layout. This setup can pose limitations for smaller factories or retrofit installations. However, it may offer more flexibility in handling different material viscosities.

Energycle Machine recommends assessing your plant layout to understand which system fits best into your operational footprint.

Automation and User-Friendliness

Water Ring Pelletising

Water ring systems are generally more automated and require less operator intervention. Blade pressure is often self-adjusting, and pellet drying is integrated, reducing the need for manual handling.

Water-Cooled Strand Pelletising

Strand pelletising systems are more labour-intensive. Operators must ensure proper strand alignment and consistent water flow. Start-up and shutdown require more attention and skill.

For manufacturers aiming to reduce labour costs and improve consistency, Energycle Machine suggests considering water ring pelletising for its automation benefits.

Pellet Shape and Quality

Water Ring Pelletising

Produces rounded, uniform pellets with a glossy finish. These are especially beneficial for high-end applications where pellet aesthetics and flowability matter.

Water-Cooled Strand Pelletising

Pellets are typically cylindrical with slightly irregular ends. While still functional for most downstream uses, they may not meet premium aesthetic or processing standards.

If pellet uniformity and appearance are critical to your application, Energycle Machine recommends water ring systems.

Summary Comparison Table

| Feature | Water Ring Pelletising | Water-Cooled Strand Pelletising |

|---|---|---|

| Footprint | Compact | Larger space needed |

| Automation | High | Medium to low |

| Pellet Shape | Round, uniform | Cylindrical, variable |

| Maintenance | Moderate | Lower wear risk |

| Initial Cost | Higher | Lower |

| Operating Cost | Lower long-term | Higher labour cost |

| Throughput | High | Medium |

| Material Flexibility | Medium | High |

FAQs

Q1: Can I retrofit a water ring pelletiser to my existing PET line?

Yes, many of Energycle Machine’s models are designed for retrofitting, but layout and extrusion parameters must be evaluated.

Q2: Which pelletiser is more suitable for recycled PET?

Water ring pelletising is often better for recycled PET due to its higher throughput and superior drying integration.

Q3: Are there hybrid systems available?

Some systems offer modular options that combine features of both pelletising types. Energycle Machine can consult on customised solutions.

Q4: What’s the typical payback period for upgrading to a water ring system?

Depending on your output and labour costs, payback can range from 1 to 3 years.

Make the Right Choice for Your Production Line

Choosing the right pelletising system can shape the future of your PET production line. Let Energycle Machine help you make an informed, future-proof investment.

Visit our PET Plastic Flake Single Screw Pelletizer page or contact us today to discuss your needs.

Request a Tailored Quote

Introduction: The Unseen Hero of Your Recycling Line

In the complex and demanding world of industrial plastic recycling, the plastic pelletizer is the final, critical step. It’s the machine that transforms processed plastic flake into uniform, high-value pellets ready for the manufacturing market. Its consistent and reliable operation is directly linked to your plant's profitability and reputation. However, like any piece of high-performance industrial machinery, a pelletizer’s peak performance is not a given; it is the result of diligent, proactive maintenance.

Unexpected downtime, inconsistent pellet quality, and premature component failure are not just operational headaches—they are significant drains on your bottom line. This is where a structured maintenance strategy becomes one of the most valuable investments you can make. At Energycle Machine, we don’t just engineer robust and efficient recycling equipment; we partner with our clients to ensure they achieve maximum return on their investment throughout the machine's entire lifecycle.

This comprehensive guide provides a detailed maintenance checklist, designed for plant managers, maintenance teams, and operators. Following this schedule will help you enhance safety, extend the lifespan of your equipment, and ensure your Plastic Pelletizer consistently delivers the quality output your customers demand.

The Strategic Value of Proactive Maintenance

Before we delve into the checklist, it's crucial to understand why this matters. Moving from a reactive ("fix it when it breaks") to a proactive maintenance culture yields tangible benefits:

- Increased Equipment Lifespan: Regular care prevents minor issues from escalating into catastrophic failures, significantly extending the operational life of your asset.

- Consistent Pellet Quality: Well-maintained blades, dies, and screens produce uniform pellets. Inconsistent size, shape, or the presence of fines can lead to rejected batches and damage your market reputation.

- Enhanced Operational Safety: A properly maintained machine is a safer machine. Regular checks on safety guards, emergency stops, and electrical systems are non-negotiable for protecting your team.

- Reduced Operational Costs: Proactive maintenance minimises costly emergency repairs, reduces energy consumption (e.g., sharp blades require less power), and prevents expensive production stoppages.

- Improved Throughput: An optimised machine runs at its intended capacity without interruption, maximising your output and revenue.

Your Comprehensive Plastic Pelletizer Maintenance Schedule

A successful maintenance programme is built on routine. We have broken down the essential tasks into daily, weekly, and monthly/quarterly schedules to create a manageable and effective workflow.

Diagram: Tiered Maintenance Workflow

To help visualise the schedule, consider this tiered approach:

PLASTIC PELLETIZER MAINTENANCE PROGRAMME

DAILY TASKS (Pre-Startup & Post-Shutdown) - FOUNDATION

- Visual Inspection, Safety Checks, Debris Removal, Cleaning

- Operator-level tasks, minimal tools required

WEEKLY TASKS - ROUTINE OPTIMISATION

- Blade/Cutter Inspection, Bearing Lubrication, Screen Check

- Requires trained personnel, basic hand tools

MONTHLY / QUARTERLY TASKS - DEEP SYSTEM HEALTH CHECK

- Motor & Gearbox Inspection, Hydraulic System Review

- Performed by experienced maintenance technicians

Daily Maintenance Checks: The 15-Minute Rule

These quick checks, performed at the beginning and end of every shift, are your first line of defence against unexpected downtime.

Before Start-Up:

- General Visual Inspection: Walk around the entire pelletizer. Look for any loose bolts, damaged wiring, or signs of fluid leaks (oil or water) on the floor beneath the machine.

- Check Safety Guards: Ensure all safety guards, covers, and panels are securely in place and functioning correctly. Never operate the machine with safety features bypassed.

- Verify Emergency Stops: Physically test the emergency stop buttons to ensure they are accessible and operational.

- Clear the Cutting Chamber & Feed Area: Inspect the feeding hopper and cutting chamber for any residual plastic, foreign objects (like metal contaminants), or debris from the previous run. Starting with a clean chamber prevents contamination and blade damage.

- Check the Cooling System: For water-ring or underwater pelletizers, verify that the water tank has an adequate level and that the water pump is functioning. Ensure filters in the water line are clear.

After Shutdown:

- Thorough Cleaning: This is paramount. Remove all residual plastic from the die head, cutting chamber, and pellet discharge chute. Polymer left to cool and harden can be extremely difficult to remove and can cause significant damage on the next start-up.

- Wipe Down the Machine: Clean the exterior of the machine to remove dust and fines. This not only keeps the work area tidy but makes it easier to spot future leaks.

- Listen and Document: The operator should report any unusual noises, vibrations, or operational issues experienced during the shift to the maintenance team. A simple logbook is an invaluable tool for tracking the machine's health over time.

Weekly Maintenance: Fine-Tuning for Performance

These tasks require a more hands-on approach and are vital for maintaining output quality and mechanical integrity.

- Blade/Cutter Inspection and Adjustment: The heart of your pelletizer is its cutting system.

- Sharpness: Visually inspect the cutting edges of the rotary and stationary blades. Dull blades tear rather than shear the plastic, leading to poor pellet quality (tails, fines) and increased motor strain.

- Clearance: Check the gap between the rotary blades and the die face (or stationary blade). An incorrect gap results in inefficient cutting. Refer to your Energycle Machine manual for precise clearance specifications, as this varies by model and application.

- Security: Ensure all blade-retaining bolts are torqued to the manufacturer’s specification.

- Bearing Lubrication:

- Identify all grease points for the main rotor bearings and other moving components.

- Apply the correct type and amount of high-temperature grease as specified in your equipment manual. Over-greasing can be as harmful as under-greasing, as it can blow out seals and attract contaminants.

- Screen and Die Plate Check:

- Remove and inspect the die plate. Check for any blocked holes, which can cause uneven flow and pressure build-up. Use appropriate tools (a drill press with soft brass bits) to carefully clean any clogged orifices.

- Inspect the screen pack (if used) for any tears or blockages and replace it if necessary.

Monthly and Quarterly Maintenance: A Deep Dive into System Health

These in-depth inspections are designed to preempt major component failure.

- Motor and Drivetrain Inspection (Monthly):

- Drive Belts: Check the tension and condition of the drive belts. Look for signs of cracking, fraying, or glazing. Adjust tension or replace belts as needed.

- Motor: With the machine off and properly locked out, listen for any roughness as you manually turn the motor shaft. Check that cooling fins are free of dust for proper heat dissipation.

- Gearbox Inspection (Monthly):

- Check the oil level in the gearbox sight glass.

- At least quarterly, take a small sample of the gearbox oil. Look for a milky appearance (indicating water contamination) or fine metallic particles (indicating gear wear). Schedule an oil change according to the manufacturer's recommended interval or based on the oil analysis.

- Hydraulic System Check (Quarterly - if applicable):

- For systems with hydraulic screen changers or die plate actuators, inspect all hydraulic hoses for signs of abrasion, cracking, or leaks, especially around fittings.

- Check the hydraulic fluid level and clarity. Replace the hydraulic filter according to the recommended service schedule.

- Electrical Cabinet Inspection (Quarterly):

- Safety First: This must be performed by a qualified electrician with the main power locked out.

- Open the main electrical cabinet and use compressed air to gently blow out any accumulated dust, which can cause short circuits or become a fire hazard.

- Visually inspect terminals and connections for signs of overheating (discolouration) or looseness.

Key Safety Operating Procedures (SOPs)

Maintenance must always be performed safely. Adhere to these core principles:

- Lockout/Tagout (LOTO): Before any maintenance work begins, the machine must be completely de-energised and isolated from its power source. A lock and tag should be applied to prevent accidental start-up.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, cut-resistant gloves (especially when handling blades), and steel-toed boots.

- Follow Manufacturer's Guidelines: Your equipment manual is your most important resource. The robust design of an Energycle Machine pelletizer simplifies many of these processes, but always refer to the specific instructions and specifications provided.

- Never Bypass Safety Interlocks: They are there for your protection. Report any malfunctioning safety features immediately.

Beyond the Machine: Partnering with Energycle Machine

Choosing a plastic pelletizer is a long-term investment. The design and build quality of the machine itself play a significant role in its maintenance profile. At Energycle Machine, we engineer our systems for durability, ease of access to key components, and operational reliability, which inherently simplifies your maintenance workload.

Our commitment extends beyond the factory floor. We provide comprehensive after-sales support, including detailed manuals, responsive technical assistance, and a ready supply of genuine OEM spare parts. Using genuine parts ensures perfect fitment, performance, and longevity, protecting your investment and guaranteeing your machine operates as intended.

Frequently Asked Questions (FAQ)

1. How often should I sharpen or replace my pelletizer blades?

This depends heavily on the type of plastic you are processing and the presence of any abrasive fillers (like glass fibre). For clean LDPE/HDPE, blades may last for several weeks. For abrasive materials, you may need to inspect and sharpen them weekly. The key indicator is pellet quality; once you see an increase in fines or tails, it's time to service the blades.

2. What are the most common warning signs that my pelletizer needs immediate attention?

Look out for a sudden increase in motor amperage (a sign of dull blades or a blockage), unusual or loud noises (indicating bearing or gearbox issues), excessive vibration, or visible leaks of oil or water. Any of these symptoms warrant an immediate and safe shutdown for inspection.

3. Can I use generic or third-party spare parts for my pelletizer?

While it can be tempting to use cheaper, non-OEM parts, we strongly advise against it. Genuine parts from Energycle Machine are manufactured to precise tolerances and material specifications designed for your machine. Ill-fitting parts can cause premature wear on other components, lead to poor performance, and may even void your warranty.

4. Does the type of plastic I process affect the maintenance schedule?

Absolutely. Softer polymers like PE and PP are less demanding on components. Harder, more abrasive materials like glass-filled Nylon (PA) or PC will accelerate the wear on blades, die plates, and barrels. If you frequently switch materials, you should adapt your maintenance frequency accordingly, with more frequent checks when running abrasive polymers.

Conclusion: Your Partner in Pelletizing Excellence

A well-maintained plastic pelletizer is the cornerstone of a profitable recycling operation. By implementing this structured daily, weekly, and monthly checklist, you are not just performing maintenance; you are investing in uptime, quality, and safety.

This proactive approach transforms your maintenance team from firefighters into strategic partners in your plant's success. It ensures your equipment, especially a high-performance system from a trusted partner, delivers a consistent return for years to come.

Ready to enhance your recycling operations with a reliable, high-performance plastic pelletizer designed for ease of maintenance? Contact the Energycle Machine team today for a personalised consultation or to request a quote for our advanced systems.

For any successful recycling operation, the journey from waste to valuable raw material requires precision at every stage. After transforming post-consumer bottles into clean flakes within a high-performance PET bottle recycling system, a critical decision arises: how to process these flakes into their most marketable form. Pelletizing is the answer, but choosing the right technology is paramount.

The two dominant methods in the industry are traditional strand pelletizing and the more advanced underwater pelletizing (UWP). Each offers distinct advantages and presents different operational and financial considerations. This guide provides a head-to-head comparison to help you determine the optimal solution for your rPET operation.

The Workhorse: Understanding Strand Pelletizing

The strand pelletizing process is a robust and widely adopted method. The workflow is linear and visually intuitive:

- Extrusion: Molten rPET is extruded through a die head, forming continuous, spaghetti-like strands.

- Cooling: These strands travel through a water bath or trough to cool and solidify.

- Dewatering: An air knife or suction unit blows off excess water from the surface of the strands.

- Cutting: The cooled, dry strands are fed into a pelletizer, where a high-speed rotor with cutting blades chops them into cylindrical pellets.

The Precision Method: Understanding Underwater Pelletizing (UWP)

Underwater pelletizing is a more integrated and automated process, valued for its precision and consistency.

- Extrusion & Cutting: Molten rPET is extruded through a die plate that is in direct contact with a circulating water system. Rotating blades slice the polymer into pellets at the moment it emerges from the die face, underwater.

- Cooling & Transport: The newly formed, spherical pellets are immediately solidified by the water and transported as a slurry away from the die head.

- Dewatering: The slurry is fed into a centrifugal dryer, which spins at high speed to separate the water from the pellets, resulting in a dry, finished product.

Head-to-Head Comparison: Strand vs. Underwater

Choosing a pelletizing system for rPET requires a careful analysis of several key factors.

1. Pellet Quality & Consistency

- Strand Pelletizing: Produces uniform, cylindrical pellets. However, the process is susceptible to "strand breakage," which can lead to variations in pellet length ("longs") and the generation of dust or "fines." The quality is highly dependent on operator skill during start-up.

- Underwater Pelletizing: Produces highly uniform, spherical, or lenticular (lens-shaped) pellets with minimal variation in size and shape. The immediate cooling process results in very low dust and fines generation. UWP is generally considered to produce a higher, more consistent grade of pellet, which is often demanded by premium applications.

2. Operational Requirements & Complexity

- Strand Pelletizing: The process is more manual, particularly during start-up, which involves an operator manually "threading" the strands from the die head to the pelletizer. Whilst this requires labour, it also makes the system more forgiving of melt viscosity fluctuations and easier for operators to visually troubleshoot.

- Underwater Pelletizing: This is a highly automated, closed-loop system requiring less operator intervention during a run. However, the process is more complex and sensitive. It demands a very stable extrusion process (melt flow, pressure, and temperature) to function correctly. Start-up and maintenance typically require a higher level of technical skill.

3. Initial Investment & Footprint

- Strand Pelletizing: The initial capital investment for a strand pelletizing line is significantly lower than for a UWP system. The equipment is mechanically simpler. However, the footprint can be quite long due to the cooling trough required.

- Underwater Pelletizing: This technology carries a higher initial investment cost, driven by the precision-engineered cutting head, water tempering system, and centrifugal dryer. The overall footprint, however, is often more compact.

4. Best Applications for rPET

- Strand Pelletizing: An excellent, cost-effective choice for general-purpose rPET pellet production, compounding, and applications where minor variations in pellet shape are acceptable. It is a reliable workhorse for operations where minimising initial capital cost is a priority.

- Underwater Pelletizing: The definitive choice for high-end applications that require perfect pellet uniformity for stable processing. This includes injection moulding of parts with complex geometries, automotive components, and compounding high-value engineering plastics where consistency is non-negotiable.

Summary Table

| Feature | Strand Pelletizing | Underwater Pelletizing (UWP) |

| Pellet Shape | Cylindrical | Spherical / Lenticular |

| Pellet Quality | Good to Excellent, potential for fines | Excellent to Premium, highly uniform |

| Complexity | Lower, more manual start-up | Higher, automated, more sensitive |

| Initial Cost | Lower | Higher |

| Footprint | Longer | More Compact |

| Ideal For | General-purpose, cost-sensitive operations | High-end applications, perfect consistency |

Conclusion: Making the Right Choice

The decision between strand and underwater pelletizing is a strategic one. If your business model focuses on producing reliable, cost-effective rPET for a broad market, the lower initial investment and operational simplicity of a strand pelletizing line make it an attractive choice. If your goal is to target premium markets that demand the highest degree of consistency and quality, the superior output and automation of an underwater pelletizing system justify the higher investment.

Ultimately, the success of either pelletizing method depends on the quality of the input material. A clean, dry, and consistent flake, produced by a robust PET plastic washing line, is fundamental to achieving a high-quality final pellet.

At Energycle, we can help you analyse your specific requirements to determine the best value-added processing solution for your recycled materials. Contact our technical team to discuss your project.