A plastic recycling machine is an industrial device (or set of devices) that processes waste plastics and transforms them into reusable raw materials or products. In essence, it takes discarded plastic items – such as packaging, bottles, films, or pipes – and recycles them into forms that can be used again in manufacturing. This typically involves cutting the plastic into smaller pieces, cleaning and drying it, melting it down, and reshaping it into pellets or other usable forms. For companies involved in recycling or manufacturing, these machines are crucial for converting plastic waste into valuable resources while reducing environmental impact.

Modern plastic recycling machines come in various types and configurations, but all share the goal of efficiently reclaiming plastic. They range from stand-alone units to complete integrated lines handling every step of the recycling process. For industrial recycling equipment buyers and professionals, understanding what these machines are – and how they work – is key to making informed purchasing decisions. In this article, we will explore what plastic recycling machines do, the different types available, and how they operate. We will also highlight Energycle – a leading manufacturer of plastic recycling machinery, focusing on the performance, quality, and service they offer through their advanced technology and equipment. By the end, you’ll see why Energycle’s recycling machines are highly regarded in the industry and how they can benefit your operations.

Understanding Plastic Recycling Machines

At its core, a plastic recycling machine is designed to take plastic waste and convert it into a reusable form. This typically means producing clean plastic pellets or flakes that can be fed back into production lines to make new plastic products. Such machines address a critical need in waste management and sustainability by keeping plastics out of landfills and in the circular economy. Companies like Energycle specialise in these technologies, recognising the importance of plastic recycling for environmental protection and resource efficiency. By transforming “waste plastics into valuable renewable materials through advanced technology and innovative solutions”, recycling machines enable businesses to reduce raw material costs and decrease their environmental footprint.

How does a plastic recycling machine achieve this? In practice, it is often not a single machine but a system of coordinated components. Plastic recycling equipment may include shredders or crushers to break down bulky items, washing units to remove contaminants, dryers to eliminate moisture, and extruders or pelletizers to melt and reform the plastic into granules. Each component plays a role in ensuring the output is clean, consistent in quality, and ready for reuse. Importantly, these machines are built for industrial performance – they handle large volumes of plastic, operate continuously or in batches as needed, and are engineered for reliability and efficiency.

From an industrial buyer’s perspective, a quality plastic recycling machine offers three key advantages: high processing performance, durable build quality, and strong after-sales support. High performance means the machine can process significant quantities of plastic quickly and with minimal downtime. Good build quality ensures it can run for long shifts, day after day, without excessive wear or failure. And robust support/service means the manufacturer assists with installation, training, maintenance, and any troubleshooting over the machine’s lifespan. As we’ll see, Energycle emphasizes all three of these aspects – performance, quality, and service – in their plastic recycling machinery offerings.

Types of Plastic Recycling Machines

Plastic recycling isn’t accomplished by a one-size-fits-all machine – it often requires a combination of specialised equipment, each handling a different step of the process. Energycle, for example, produces a range of machines to cover all key stages of plastic recycling. Below are the essential types of plastic recycling machines and what they do (each of these can be part of an integrated recycling line or used individually for specific tasks):

- Shredders and Crushers: These machines are the first line of processing for bulky or rigid plastics. A plastic shredder rips or cuts large plastic items (like drums, crates, pipes, or thick lumps of plastic) into smaller, more manageable pieces. They are built with robust cutting blades and powerful motors to handle tough materials. By reducing size, shredders make subsequent processing easier and more efficient. Some systems combine shredding and crushing functions to achieve finer size reduction in one pass. The output from a shredder is typically irregular chunks or strips of plastic.

- Granulators (Grinding Machines): For a finer and more uniform particle size, plastic granulators (or grinders) are used after shredding. Granulators employ rotating knife blades to cut plastic feedstock into small granules or flakes, usually a few millimetres in size. The result is consistent, small pieces of plastic suitable for washing and melting. Granulators ensure the recycled material is of uniform size, which is important for efficient melting and extrusion later in the process. In industrial recycling lines, granulators can often process a continuous flow of shredded plastic, producing a steady stream of granules.

- Washing and Separation Systems: Plastics, especially post-consumer plastics, often contain contaminants like paper labels, dirt, food residue, or mixed materials. Plastic washing lines are integrated systems designed to thoroughly clean plastic scrap. They typically include conveyor rinsers, high-speed friction washers (which scrub the plastic), float-sink tanks for density separation, and sometimes chemical washing for sticky contaminants. For instance, Energycle offers a Plastic Film Washing Line that “efficiently cleans and prepares plastic film waste for high-quality recycling processes.” There are also washing lines specialised for rigid plastics (like bottles or thicker containers) to ensure the purity of the material before reprocessing. Alongside washing, these systems include separation equipment such as sieves, hydrocyclones, and magnetic separators to remove non-plastic elements (e.g., metals or non-recyclable fragments). Clean plastic output is crucial; it improves the quality of the final recycled pellets and prevents damage to machines downstream.

- Drying Systems: After washing, plastic flakes need to be dried, as excess moisture can interfere with melting and pelletizing. Plastic drying machines remove water from the washed plastic efficiently. Common drying equipment includes centrifugal dryers (which spin flakes to sling off water), thermal dryers that blow hot air through the material, or squeezing dryers that mechanically press water out (often used for films). A well-designed drying system “quickly removes moisture from washed plastics, enhancing recycling efficiency.” By delivering sufficiently dried material, these machines ensure that the extrusion and pelletizing steps can proceed smoothly without steam pockets or hydrolysis issues.

- Extruders and Pelletizers: To actually recycle plastic into a new form, the clean and dried plastic flakes are melted and reformed. This is done by plastic extruder machines, often followed by a pelletizer. An extruder is essentially a long barrel with a screw inside that heats and melts the plastic flakes and forces the molten plastic through a die. In recycling, extruders are used to thoroughly melt and mix the plastic. The output can be strand-like plastic spaghetti if air-cooled, or a molten stream. A plastic pelletizer then cuts this molten plastic into small, uniform pellets as it cools. Pelletizing systems can use methods like water-ring cutting, where the extruded strands are cut into pellets immediately upon exiting the die and cooled in water, or strand pelletizing, where strands are cooled and then chopped. The end product is plastic pellets – typically 3–5 mm in size – which can be bagged and reused as raw material in manufacturing. Energycle’s pelletizing machines, for example, “produce uniform plastic pellets, suitable for various manufacturing applications.” These machines are designed for efficiency and durability, converting waste into high-quality reusable granules. In fact, an Energycle plastic pelletizing line usually includes a compactor (to pre-cut and compact light films), an extruder, an automatic filtering screen changer, a pellet cutting unit, cooling and drying, all working together. Such systems can handle a broad range of plastics (PE, PP, PET, etc.) and offer throughput capacities from a few hundred up to a couple of thousand kilograms per hour – a crucial consideration for industrial buyers looking to match machine capacity with their recycling volume.

- Auxiliary Equipment: In addition to the primary machines above, recycling facilities often employ auxiliary machinery to improve efficiency. This includes conveyors to move material between stages automatically, baling machines to compact plastics (like PET bottles or film scrap) for easier handling before recycling, and storage silos or bins to hold processed material. Energycle, for instance, provides baler machines that “compress plastic waste into dense, compact bales for storage and easy transport.” There are also specialized units like sink-float separation tanks (to separate plastics by density), eddy current separators (to extract metals from shredded plastic streams), and knife sharpeners or spare blade sets for shredders and granulators. Each piece of equipment plays a supporting role to ensure the main recycling line runs smoothly and produces a high-quality output.

It’s worth noting that some machines combine functions – for example, a single-shaft shredder might also act as a coarse granulator, or a cutter-compactor unit can shred, heat, and densify lightweight film in one step before feeding it into an extruder. When planning a recycling system, industrial buyers will often mix and match these machines to suit the specific type of plastic waste they handle (be it PET bottles, PP/PE films, PVC pipes, etc.) and the desired output form. Manufacturers like Energycle offer turnkey recycling lines that integrate all the necessary stages with compatible machinery, ensuring that each part works in tandem with the next.

Modern recycling operations rely on this spectrum of machines to automate and streamline plastic waste processing efficiently. By using the right combination of equipment – shredders for size reduction, washers for cleaning, and extruders/pelletizers for material regeneration – facilities can significantly increase throughput and improve the quality of recycled plastic output. Next, we will look at how these machines actually work together in a typical recycling process.

How Does a Plastic Recycling Machine Work?

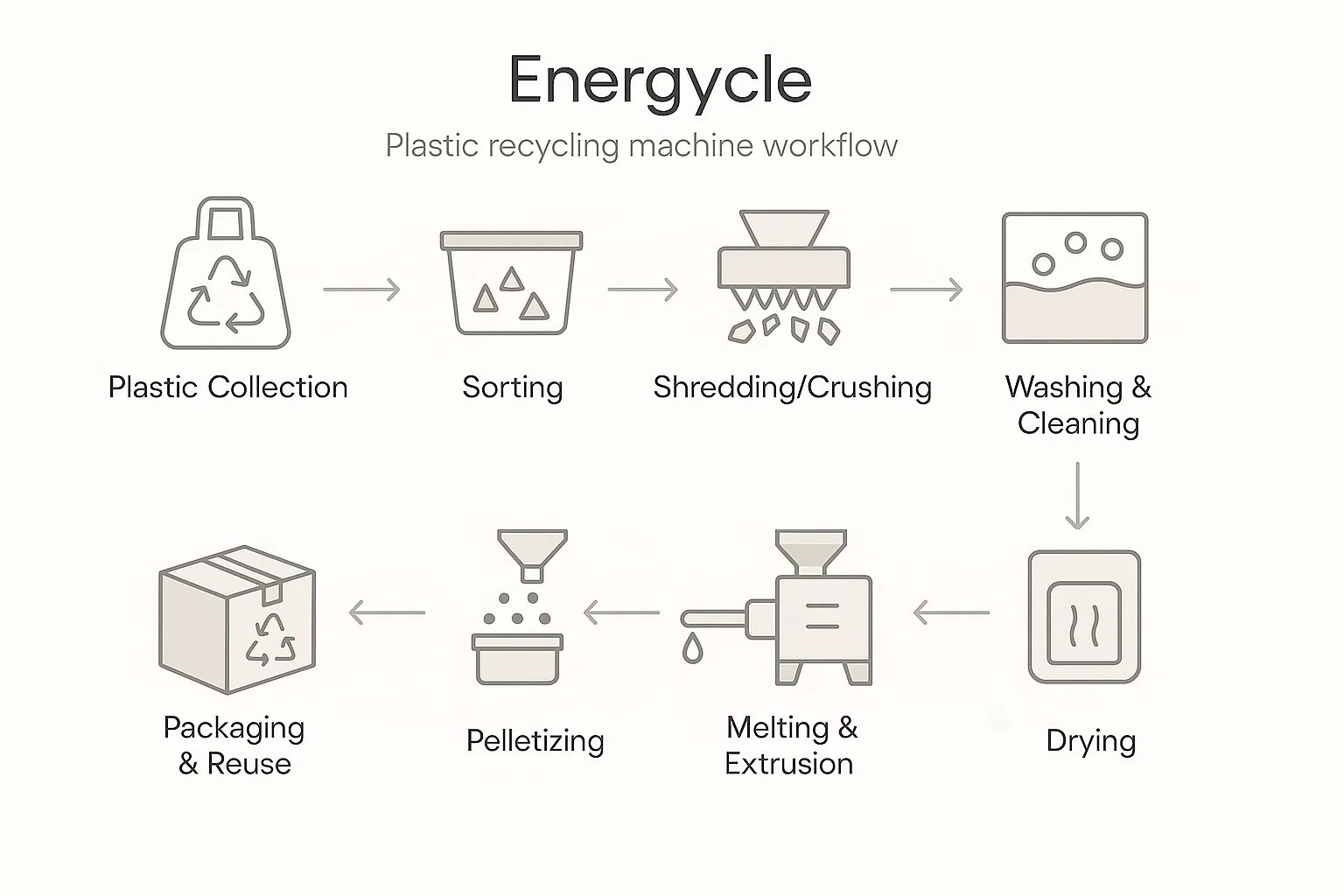

The operation of a plastic recycling machine (or complete recycling line) can be understood as a series of stages. Below is a step-by-step overview of how waste plastic is transformed into recycled material using these machines:

- Collection and Sorting: Before machinery comes into play, the process starts with collecting plastic waste and sorting it by type. Industrial recyclers source plastics from post-consumer waste (like used bottles, packaging films, etc.) or industrial scrap. Sorting is critical – different plastics (PE, PP, PET, PVC, etc.) are usually processed separately because of their different melting points and properties. Any non-plastic contaminants (metal, paper, glass) should be removed at this stage as well, often using manual picking or simple screening machines. Many facilities bale the sorted plastics for compact storage until they are ready to be recycled.

- Shredding/Crushing: The first machine stage involves size reduction. Large pieces of plastic are fed into a shredder or crusher, which cuts them into smaller chunks. For example, whole plastic films, big containers, or thick lumps from production waste would be shredded into strips or flakes a few centimetres in size. This step increases the surface area of the plastic and produces uniformly small pieces that can be washed and further processed. Shredding also liberates composite materials – for instance, separating layers or loosening dirt, making the next cleaning stage more effective. Modern shredders can often handle a few hundred to several thousand kilograms of plastic per hour, depending on their design and motor power.

Illustration: An Energycle industrial plastic shredding and crushing system. The setup includes a large hopper feeding into a green shredder (right), which cuts plastic waste into smaller pieces. A conveyor belt then carries the shredded plastic to the next stage (shown connecting on the left). Such a system is typical in recycling facilities, providing the crucial first step of size reduction before washing and pelletizing.

- Washing and Cleaning: Once shredded, the plastic pieces move through a washing line. In this stage, machines thoroughly wash the plastic to remove dirt, labels, adhesives, and any other contamination. The process may involve multiple sub-steps:

- Pre-wash soaking: In some cases, shredded plastic is first rinsed or soaked in water (sometimes with detergent) to loosen dirt.

- High-friction washing: Machines with rapidly spinning paddles (friction washers) scrub the plastic pieces in water, effectively scouring off residues and breaking apart clumped debris.

- Rinsing and separating: After washing, the material goes through rinse tanks or separation tanks. Here, the difference in density between plastics and contaminants is used: for example, in a float-sink tank, polyolefins like PE or PP will float while heavier materials (or contaminants) sink, allowing separation. Likewise, spinner washers may be used to flush away tiny particles.

- Dry cleaning (if needed): Some systems include an air classifier or zig-zag separator to remove paper labels and fines using air flow.

- Throughout washing, water filtration systems capture and remove dirty particles, keeping the wash water clean and recycling it if possible.

- Drying: After washing, the clean plastic flakes or fragments are wet, so the next step is drying. The material is conveyed into drying equipment such as a centrifugal dryer (which spins the water out), followed by thermal dryers or air drying systems. For thin films, a squeezing dryer may compress and extrude the film into semi-dry spaghetti-like strands, which then are cut into flakes – this both dries and densifies flimsy film. The goal is to reduce moisture to a very low percentage (well below 1%) before melting. Proper drying is important because any leftover moisture can cause issues (e.g. steam bubbles or polymer degradation) in the extrusion phase.

- Melting and Extrusion: Now the clean, dry plastic is ready to be transformed. It is fed into a plastic recycling extruder, where it gets melted. Inside the extruder, an auger screw pushes the plastic through a heated barrel. The plastic transitions from solid to molten liquid. If different types of plastic are present, they might also get blended. At this stage, many recycling extruders incorporate filtration: the molten plastic is forced through a fine mesh screen (or a series of screens) to filter out any remaining solids or contaminants (e.g., bits of paper, unmelted polymer, or metals). Energycle’s extruders often feature automatic screen changers to maintain continuous operation even as filters get clogged and are swapped out, ensuring the melt stays clean without stopping production. The output of the extruder is a continuous stream of molten plastic, typically pushed out through a round die.

- Pelletizing: As the molten plastic exits the extruder, it’s cut into small pellets – the final product of most plastic recycling machines. There are a couple of common pelletizing methods:

- Water-ring pelletizing: The molten plastic emerges from the extruder die holes and is immediately cut by rotating blades into pellets, all inside a closed chamber. Water flows through this chamber, carrying the freshly cut hot pellets away and cooling them simultaneously. The pellets then go through a dewatering dryer to remove water and are collected.

- Strand pelletizing: The molten plastic comes out of the extruder as long strands (like spaghetti) which fall into a water bath to cool, then are fed into a cutter that chops them into pellets of the desired length.

- In both methods, the result is small cylindrical or lens-shaped pellets. These pellets are dried (if water-cooled) and then screened to remove any oversized pieces or fines.

The end result of an effective plastic recycling process: on the left, shredded plastic flakes ready to be melted; on the right, recycled plastic pellets produced by the recycling machine. These high-quality pellets can be used as raw material for new plastic products. The image highlights how recycling machinery transforms waste plastic into a valuable, reusable form, turning discarded scraps into uniform pellets that manufacturers can feed into plastic moulding or extrusion equipment.

- Packaging and Reuse: Finally, the recycled pellets are typically cooled completely, dried, and then packed into bags or silos. They are now a marketable product, often called repro pellets or regranulate. Plastic product manufacturers can buy these recycled pellets to use in place of (or blended with) virgin plastic. For instance, a company making plastic bottles might use a percentage of recycled PET pellets in their production. Because the recycling machine has produced clean and consistent material, it can often be used in high proportions without significantly compromising product quality, all while reducing material costs and environmental impact.

Throughout this workflow, it’s crucial that each machine in the line works in harmony. Automation systems usually coordinate the timing and flow (for example, conveyors feeding the shredder, then automatically transferring material to washers, and so on). Many modern recycling lines have centralised control panels, so an operator can monitor the entire process, adjust speeds, and ensure everything is running optimally.

Furthermore, quality control checkpoints are sometimes added: e.g., sampling pellets for lab testing, or installing metal detectors and automatic shut-offs to protect the extruder. The end-to-end process described above can be customised depending on the input material. For example, recycling a PET bottle may involve additional steps like removing labels and caps (which are different plastic) earlier in the process, or a chemical washing step to eliminate sticky adhesives. But in all cases, the general principle of a plastic recycling machine (or system) remains: take sorted plastic waste, clean it, melt it, and reform it into a usable raw material.

Energycle’s Technology and Product Advantages

When investing in a plastic recycling machine, industrial buyers look for equipment that delivers superior performance, efficiency, and longevity. This is where Energycle’s technology stands out. Energycle is known in the industry for its focus on advanced engineering and innovative solutions in plastic recycling equipment. With over 20 years of experience in this field, Energycle has developed machinery that not only handles the recycling process end-to-end but also does so with impressive efficiency and reliability.

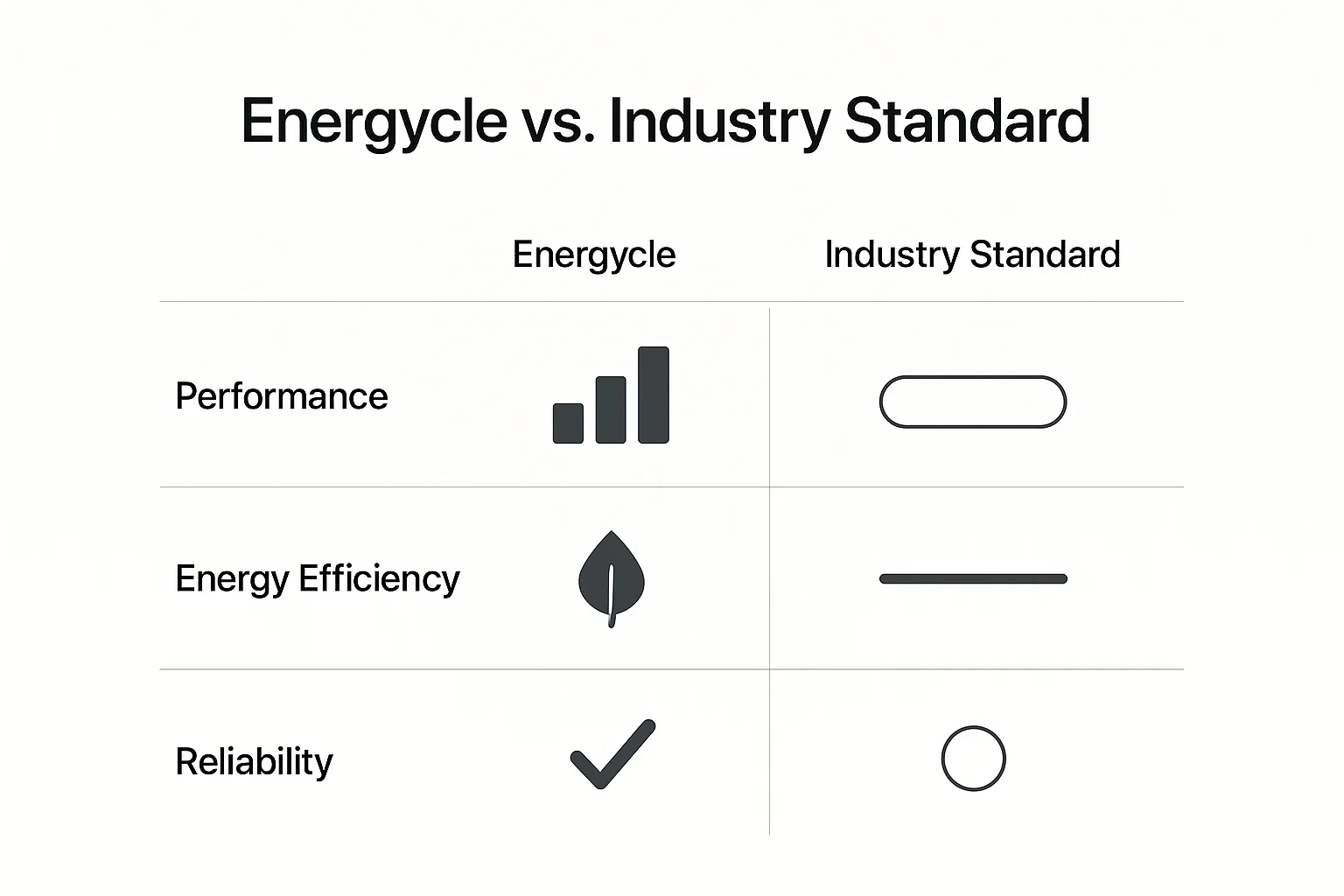

High performance is a hallmark of Energycle’s machines. Their product line covers all key recycling processes – from crushing and washing to dewatering and pelletizing – and each machine is designed for “excellent performance, low energy consumption, and stable operation.” In practical terms, this means Energycle machines can process large volumes of plastic with relatively lower power usage, saving operating costs while maintaining consistent output. For example, Energycle’s pelletizing systems integrate efficient extruders and cutting technology to maximise throughput (hundreds of kilograms per hour or more) without sacrificing pellet quality. The equipment is optimised to minimise bottlenecks; if one part of the line runs faster, the other components are tuned to handle that capacity, ensuring a smooth flow from start to finish.

Another advantage is the quality of engineering and build. Energycle utilises high-grade materials and precise manufacturing for its machinery. All their machines are CE and ISO9001 certified, reflecting strict quality management and safety compliance. The company’s manufacturing facility spans 50,000 square metres and employs over 300 staff, including top-tier engineers dedicated to R&D. This scale and expertise allow Energycle to incorporate the latest technology into their designs – whether it’s improved cutter designs for shredders, more effective washing mechanisms, or smarter control systems for their extruders. The result is machinery that is robust and built to last in demanding industrial environments.

Energycle also excels in specialised recycling solutions. A notable focus area is their PE film recycling technology. Thin, flexible plastics like LDPE films (e.g., plastic bags, packaging wrap) are notoriously challenging to recycle due to their tendency to contaminate and their low bulk density. Energycle has developed advanced film washing and squeezing lines (often called film squeezer or film compactor systems) that efficiently wash and dry films, turning floppy film waste into pellets with high throughput. Similarly, they offer targeted solutions for PET bottle recycling, rigid plastics (like PP crates or HDPE pipes), and even more unique streams like EPS foam or textile plastic blends. This specialised approach means buyers can find equipment tailored to their specific plastic waste stream, rather than a generic one-size-fits-all machine.

Energy efficiency is another key advantage. Reducing energy consumption not only lowers operating cost but also aligns with buyers’ sustainability goals. Energycle’s modern drive systems (using high-efficiency motors and intelligent motor controls) and process optimisations (like recycling hot air in dryers or using friction heat in compaction to assist melting) contribute to lower energy use per kilogram of plastic processed. In fact, advanced recycling machines in general can significantly cut the energy and carbon footprint of recycling operations by streamlining the process. Energycle’s designs take this further by fine-tuning each component for optimal power usage without compromising on output.

Moreover, Energycle’s machines are known for operational stability. Stable operation refers to the machine running smoothly with minimal vibration, consistent processing parameters, and little downtime. Features like automatic feeders, continuous melt filtering, and protective systems (for example, auto-stop if a jam or overload is detected) all contribute to uptime and protect the machinery. Buyers can have confidence that an Energycle recycling line will not be frequently halted by breakdowns or process upsets; instead, it will maintain steady production, which is crucial for meeting output targets and ROI expectations.

To illustrate the product advantages, consider an Energycle plastic pelletizing line specification – it might include a conveyor, a cutter-compactor (which pre-shreds and compresses material), a twin-screw or single-screw extruder (depending on material), a degassing unit (to remove any gases or moisture during melting), an automatic screen changer (for filtering impurities without stopping), a water-ring pelletizer, and a centrifugal dryer for pellets. All these components are integrated and synchronised. The technical parameters could list processing capacity (say 500 kg/h for a mid-size line), compatibility with multiple polymers (PE, PP, etc.), and pellet size adjustability. For an industrial buyer, seeing these numbers alongside Energycle’s reputation for build quality provides confidence that the machinery will meet their needs now and as their recycling volume grows.

Finally, Energycle’s long presence in the market and global reach speak to their credibility. They have over two decades of expertise, with their high-quality recycling lines exported to more than 50 countries worldwide. This track record indicates not only trust from a broad customer base but also the company’s experience in complying with various international standards and customer requirements. Whether it’s a custom modification to handle a unique material or ensuring spare parts availability across continents, Energycle’s experience and scale make it a dependable partner for recycling machinery.

Performance, Quality, and Reliability in Energycle Machines

When choosing a plastic recycling machine, performance and quality are paramount considerations for professionals, and these are areas where Energycle consistently earns praise. Users of Energycle’s equipment often highlight how well these machines perform under real-world industrial conditions. High throughput, low downtime, and excellent output quality are commonly reported benefits.

Energycle’s machines are engineered to deliver high processing performance. This means they can handle large volumes of plastic waste continuously and efficiently. For instance, one recycling plant manager noted that their Energycle machine “consistently delivered high output with minimal downtime”, even when processing a significant volume of post-consumer plastics daily. This kind of performance is crucial – minimal downtime implies the machine seldom needs to stop for maintenance or issues, so production keeps flowing. The ability to maintain a high output rate ensures that strict production targets or recycling quotas can be met without requiring multiple parallel machines (saving on capital costs).

Another aspect of performance is versatility. Energycle equipment is designed to handle various plastic types and forms – from soft films to hard, bulky plastics. Customers have successfully processed a “wide range of plastics” with these machines while getting consistently good results. Whether it’s PP, PE, or even more challenging materials, the machinery’s robustness and smart design (like appropriate blade configurations or adaptable process settings) allow it to cope with different materials without excessive wear or loss of efficiency.

Moving to quality and reliability: Energycle machines boast a robust build quality that underpins their reliability. One customer described the build as “robust” and appreciated that the controls were “user-friendly” for operators. Sturdy construction (using high-grade steel, proper alignment of moving parts, quality motors, and gearboxes) means the machines can run continuously in an industrial environment without premature failures. In fact, a recycler who had been using an Energycle machine for over a year in a demanding setting reported being “very impressed with its durability” and “low maintenance requirements.” They noted that the machine “held up exceptionally well” in continuous operation, and routine maintenance was “simple and quick,” which minimised disruption to their production schedule. This highlights that not only are breakdowns rare, but also the scheduled maintenance (like blade changes, filter cleaning, lubrication) can be done efficiently, reducing overall downtime.

The quality of output from Energycle’s recycling machines is another strong point. Recycled plastic is only as good as the machine that processes it – poor-quality recycling can lead to contaminants or inconsistent material that is unusable for making new products. However, Energycle’s systems “consistently produce high-quality recycled material,” as one user attested. This reflects effective washing and filtration in the process, as well as precise control over melting and pelletizing conditions. The resulting pellets or flakes are uniform and clean, suitable for feeding into manufacturing equipment. High output quality translates to higher value of the recycled product and better suitability for demanding applications (for example, using recycled pellets in film extrusion or injection molding without issues).

Furthermore, the combination of performance and quality yields long-term reliability and return on investment. A satisfied buyer mentioned that the “initial investment was justified by the long-term reliability and performance” of their Energycle machine. Essentially, the machine paid for itself by operating dependably over time and delivering the throughput and quality promised. Reliability in this context means the machine’s performance doesn’t degrade quickly – it remains efficient over years of use, which is crucial for industrial asset investments. Knowing that a recycling machine will last and perform well for the long haul reduces risk for buyers and can significantly lower the cost per tonne of plastic processed (since capital and maintenance costs are spread out over more output).

To ensure this level of performance and quality, Energycle places a strong emphasis on testing and quality control during manufacturing. Their R&D and QC teams presumably run each machine through trials – sometimes with customers’ sample materials – to verify it meets specifications before delivery. This diligence, combined with the use of certified components and a deep expertise in recycling, results in machines that consistently meet the high expectations of industry professionals.

In summary, Energycle’s plastic recycling machines stand out for:

- High throughput and efficiency – achieving more output with less energy and downtime.

- Durable construction – industrial-grade build that withstands heavy use.

- Reliable operation – machines run smoothly with minimal interruptions and easy maintenance.

- Excellent output quality – producing recycled plastic that is clean and uniform, ready for reuse.

- Versatility – capable of processing various plastic types and forms effectively.

These qualities give recycling businesses the confidence that investing in Energycle equipment will enhance their operations, not only in immediate performance gains but also in sustainable, long-term productivity.

Service and Support: Energycle’s Commitment

Beyond the machines themselves, one of the defining features of Energycle as a supplier is its commitment to customer service and support. Purchasing industrial recycling equipment is a significant investment, and its success often depends on the support behind it – from correct installation and commissioning to training operators and maintaining the machinery. Energycle recognises this and has built a reputation for excellent customer service and post-sales support.

When a buyer chooses Energycle, they are not just getting a machine; they are gaining a partner in setting up or improving their recycling process. Energycle’s team provides comprehensive, full-spectrum support, starting from the initial inquiry all the way through to after-sales assistance. This typically includes:

- Consultation and System Design: Energycle experts work with the client to understand their recycling needs (type of plastic, input capacity, desired output, space constraints, etc.). They can then recommend the appropriate machinery configuration or even custom-design a system. This upfront engineering support ensures the equipment proposed will meet the client’s goals effectively.

- Installation and Commissioning: Once the machinery is built and delivered, Energycle assists with installation. Their technicians can either supervise the installation or handle it completely, ensuring that all components are set up correctly according to specifications. During commissioning (the first run of the machine at the customer’s site), they fine-tune settings and make sure everything runs as intended. This stage often includes integrating the new machine with any existing equipment and running test batches of material.

- Training: A plastic recycling machine is only as effective as the people operating it. Energycle typically provides training for the customer’s staff on how to use the machines safely and optimally. This might cover operating the control systems, adjusting parameters for different materials, routine maintenance tasks, and troubleshooting common issues. Proper training empowers the buyer’s team to get the best performance out of the machinery from day one.

- After-Sales Service: Perhaps most importantly, Energycle offers strong after-sales support. If issues arise during operation or if the customer has questions, Energycle’s support team is known to respond promptly and help resolve problems. This could be remote support (via phone or online) to guide technicians through diagnostics, or on-site visits if needed. Quick and effective support minimises downtime if any hiccup occurs. Furthermore, Energycle keeps a good stock of spare parts and wear parts (like shredder blades, extruder screws, seals, etc.) and can dispatch these quickly to customers, reducing the wait time for replacements.

- Maintenance and Upgrades: Energycle might offer maintenance contracts or scheduled service visits to keep the machines in top condition. Preventive maintenance performed by experts can extend the life of the equipment and prevent problems. Additionally, as technology evolves, Energycle can sometimes retrofit older machines with upgrades (for example, a more advanced control panel or an improved washing module), allowing customers to benefit from new developments without needing a whole new line.

Energycle’s dedication to service is evident from their company ethos. They emphasise unparalleled customer service and post-sales support, which has helped garner global recognition and a loyal customer base. In practical terms, buyers have peace of mind knowing that the manufacturer stands behind the product. For instance, one client testimonial highlighted that “the customer support from Energycle has been excellent, promptly addressing any questions” during their machine’s operation. This kind of responsive support is invaluable when an industrial machine is at the heart of your operation – any unplanned downtime can be costly, so having the supplier on standby to assist quickly is a major advantage.

Energycle also provides comprehensive documentation and guidance. From detailed user manuals (noted as very helpful by customers) to maintenance guides and troubleshooting checklists, the company ensures that operators have the information they need at their fingertips. Clear documentation and readily available technical support contribute to smoother daily operations and faster problem resolution.

Lastly, Energycle’s service extends to project consulting for those setting up new recycling plants. They can share best practices on plant layout (how to position machines for optimal flow), utilities requirements (water treatment for washing lines, electrical load planning), and even advice on obtaining quality certifications for recycled output. This holistic approach – treating the supply of a recycling machine as a collaborative project rather than a simple sale – reinforces Energycle’s role as a partner in the customer’s success.

In summary, Energycle’s commitment to service includes end-to-end support (from design to after-care), quick and effective customer service responses, thorough training and documentation, and a willingness to go the extra mile to ensure their machines deliver value over the long term. For industrial professionals and recycling businesses, this level of support can make all the difference in achieving a smooth, efficient recycling operation.

Conclusion: Energycle – A Leader in Plastic Recycling Machinery

A plastic recycling machine is more than just a piece of industrial equipment – it is the linchpin of turning plastic waste into a resource, enabling a circular economy in plastics. In this article, we explored what these machines are and how they work: from the shredders that kick-start the process by cutting down waste, to the washers that cleanse it, and the extruders that give it new life as pellets. We also delved into the various types of recycling machinery and the integrated process that converts discarded plastics into valuable raw materials ready for reuse.

For businesses and professionals looking to invest in recycling equipment, key considerations include performance (throughput and efficiency), output quality, machine durability, and the level of support provided by the manufacturer. This is where Energycle shines as a leading provider of plastic recycling machines. With decades of experience and a proven track record globally, Energycle offers machinery that embodies high performance, robust quality, and innovative technology. Their machines have been praised for operating with high efficiency (e.g., high output with low downtime) and yielding excellent recycled plastic quality, all while being energy-efficient and reliable in continuous use.

Energycle’s commitment to quality and service further sets them apart. Every machine is backed by a team that provides comprehensive support, from the initial planning of a recycling line to prompt after-sales service whenever it’s needed. This means that when you choose Energycle’s equipment, you’re not only getting top-of-the-line machinery but also the assurance of partnership and expertise to help you succeed in your recycling projects. It’s a combination that reinforces Energycle’s credibility and technical leadership in the recycling machinery industry.

In a time when plastic waste management and sustainable manufacturing are more important than ever, investing in a reliable plastic recycling machine is a smart move for many companies. Whether you operate a large-scale recycling facility or an in-house recycling programme for your manufacturing plant, the right machinery can dramatically improve your efficiency and product quality, while also benefiting the planet by reducing waste. Energycle’s range of plastic recycling machines – from shredders and washing lines to advanced pelletizing systems – provides solutions for virtually every recycling need, all designed with performance and longevity in mind.

For industrial recycling equipment buyers and professionals seeking a trusted solution, exploring Energycle’s offerings is a worthwhile step. With their focus on cutting-edge technology, product excellence, and customer-centric service, Energycle has established itself as a go-to source for plastic recycling machines that deliver on their promises.

To learn more about specific recycling solutions, you can visit Energycle’s official website. For example, check out their Plastic Film Washing Line for handling PE films, or explore the Plastic Pelletizers page to see how their pelletizing machines convert waste to high-quality pellets. Energycle’s website also features detailed information on various recycling equipment and a direct line to request quotes or consultations. By leveraging Energycle’s expertise and equipment, businesses can confidently enhance their plastic recycling capabilities, turning waste challenges into opportunities and contributing to a more sustainable future.