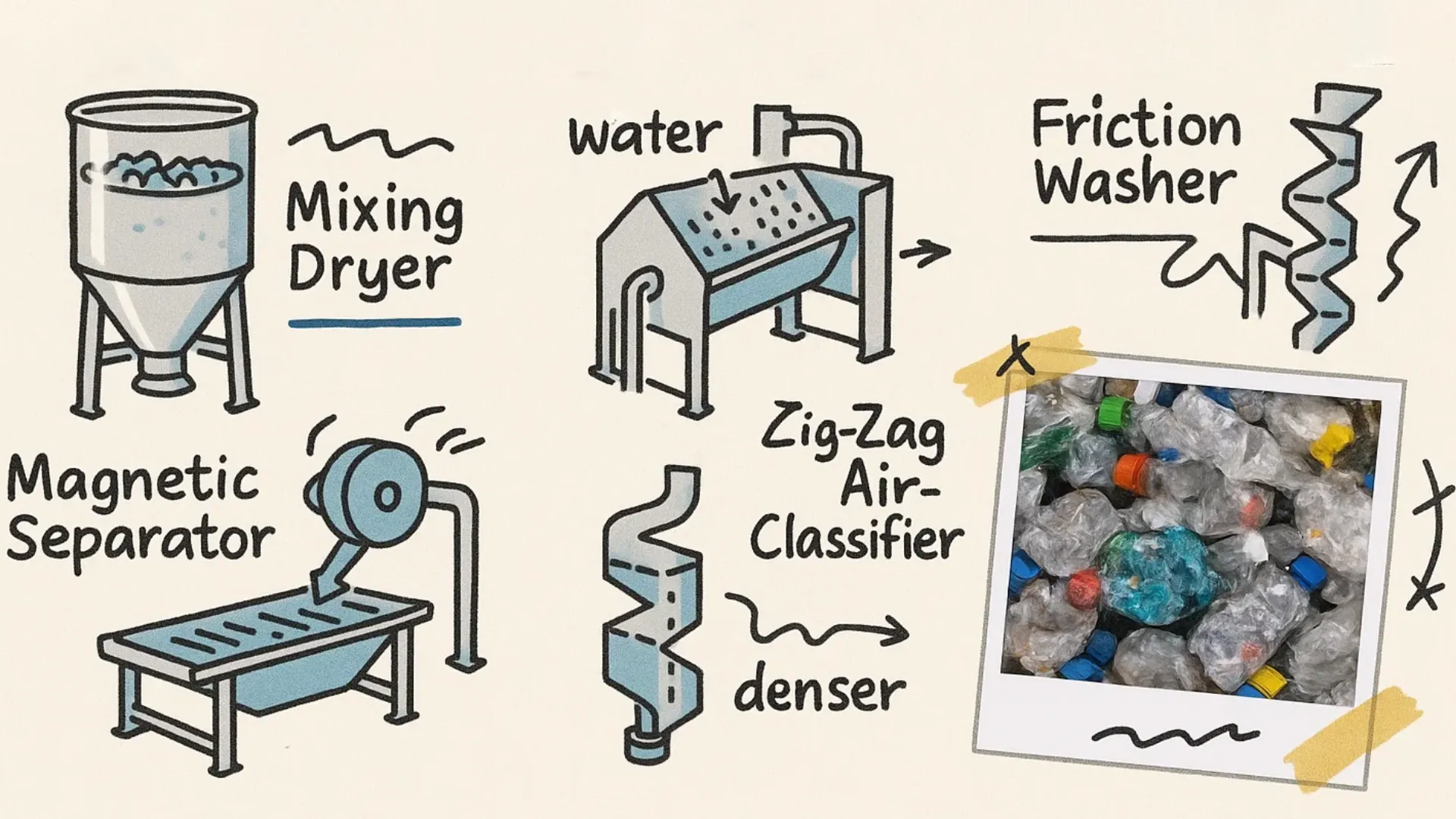

Assistive System Solutions For Plastic Recycling

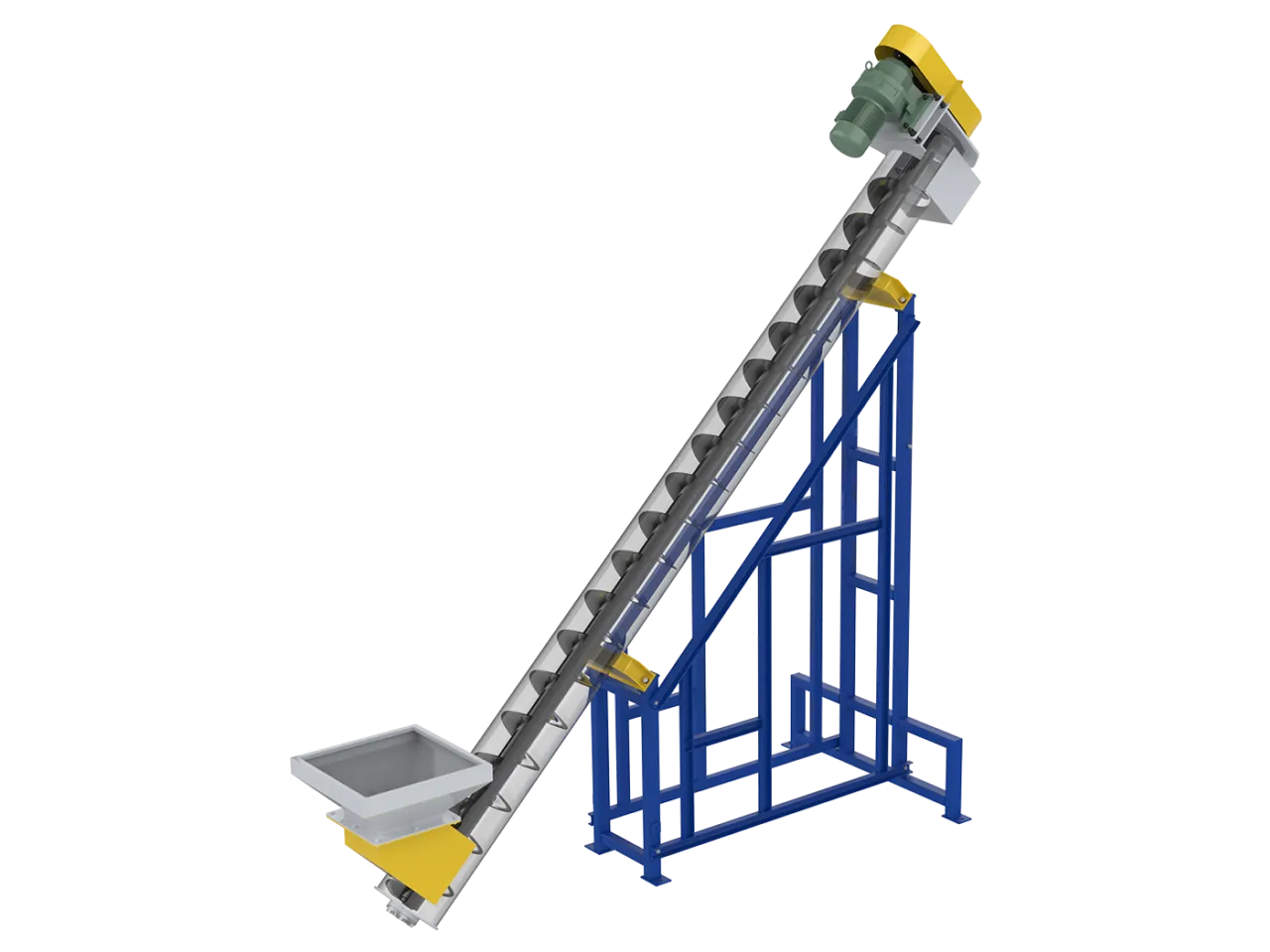

Energycle’s auxiliary equipment — dryers, washers, separators, chillers & more — keep your recycling line running faster, cleaner, and smarter.

Why Add Assistive Systems?

+30 % Throughput

Continuous flow with fewer stoppages.

Up to 99.9 % Purity

Precise separation & cleaning boosts flake value.

‑70 % Labour

Automation cuts manual handling & errors.

Safer Workplace

Enclosed, automated handling of sharp, hot or ferrous hazards.

High‑Speed Friction Washer

1 000 + RPM rotor scrubs flakes clean while saving water — boosts PET & PE purity before rinsing.

Water‑Jet Design

Strategic jets cut consumption by up to 30%.

Models to 2 t/h

Scalable capacities with CE‑marked builds.

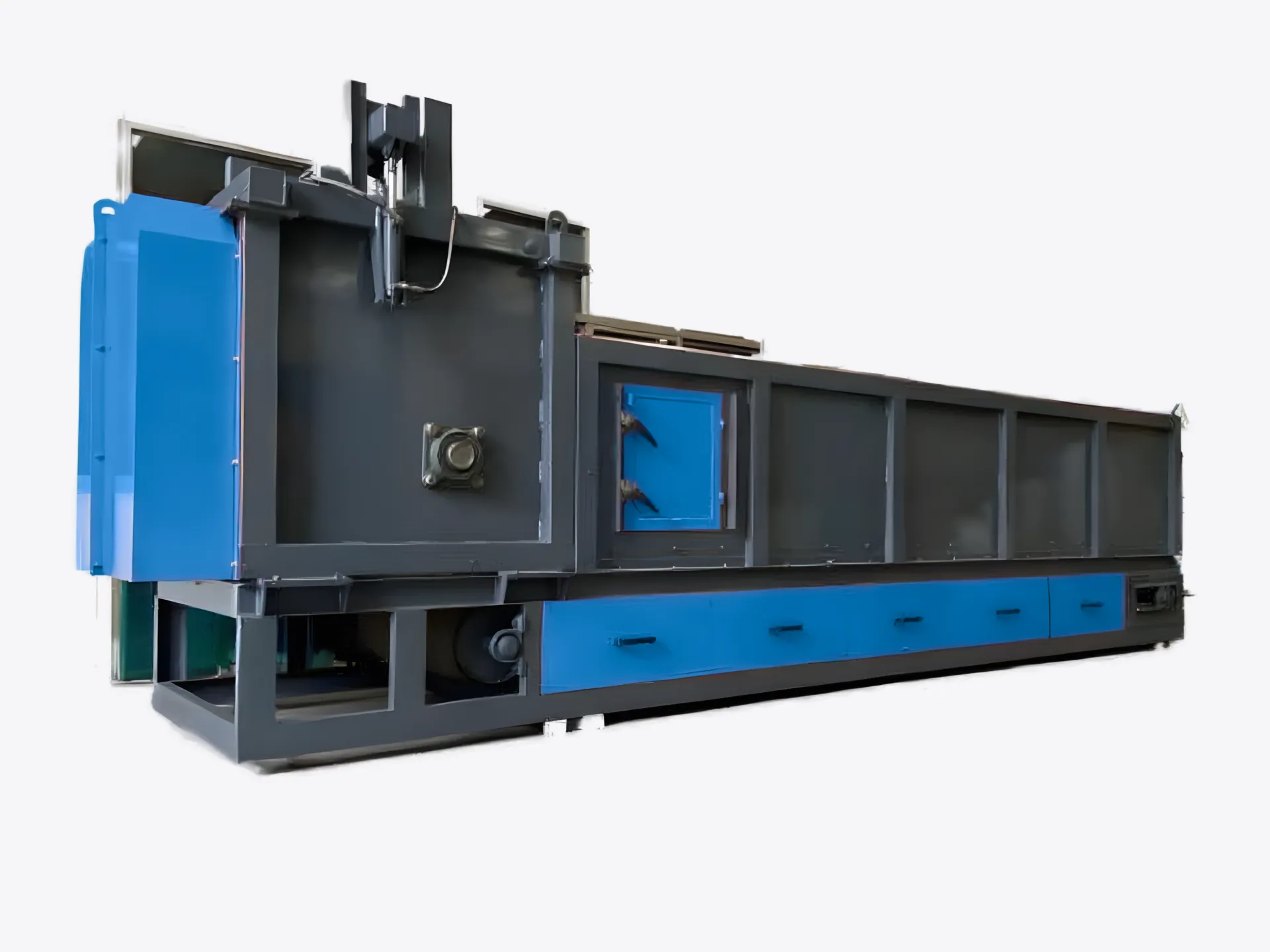

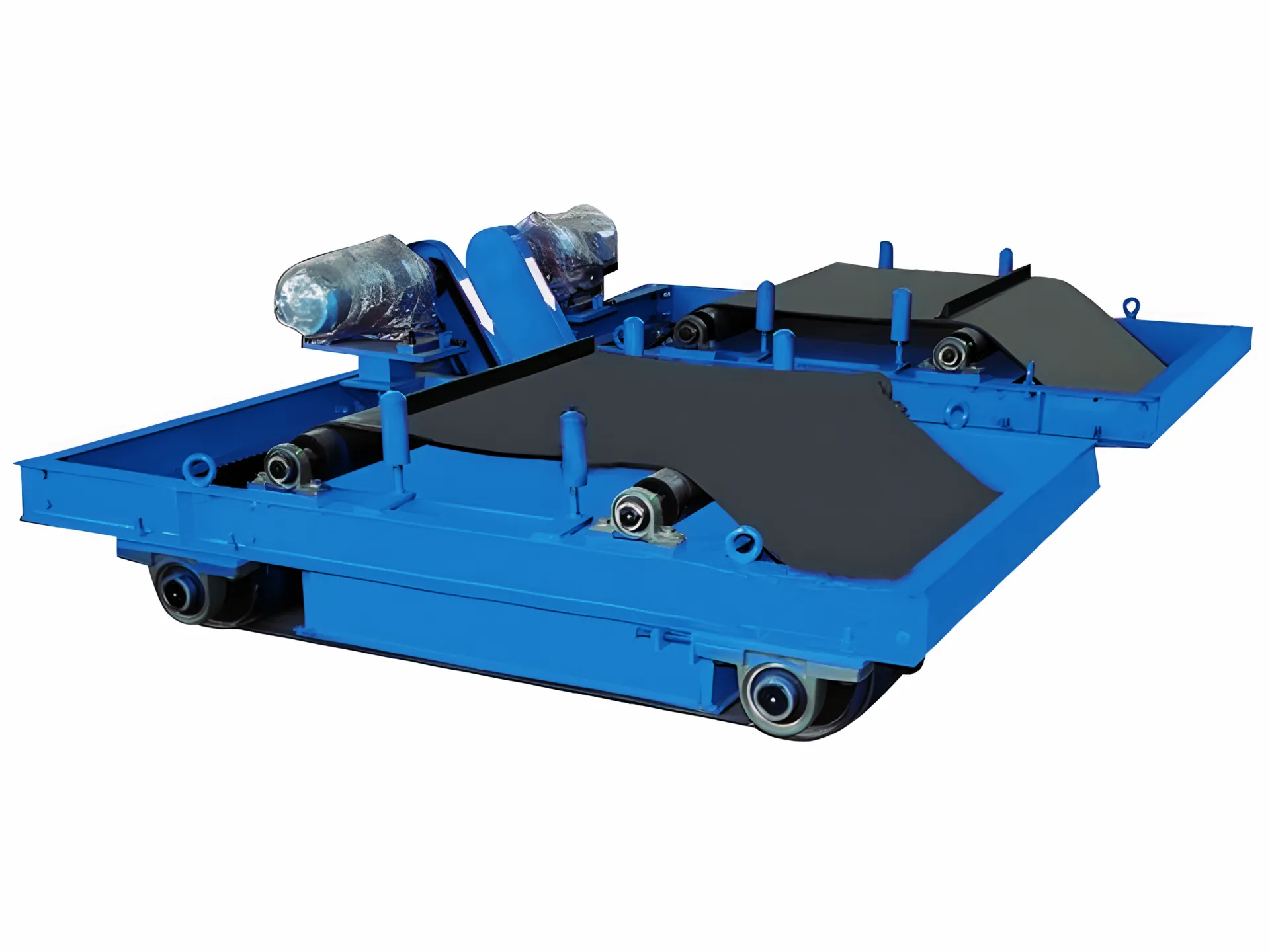

Self‑Discharging Magnetic Separator

Over‑belt magnet with automatic cleated belt to remove ferrous metals — protects grinders & extruders.

800 mm Belt Width

Suitable for conveyors up to 0.8 m.

Self‑Cleaning Belt

No manual scrap removal, maximises uptime.

Vertical Mixing Dryer

Fast blend‑and‑dry in one drum — dual‑layer insulation and 0‑30 min timer keep colour uniform and moisture low.

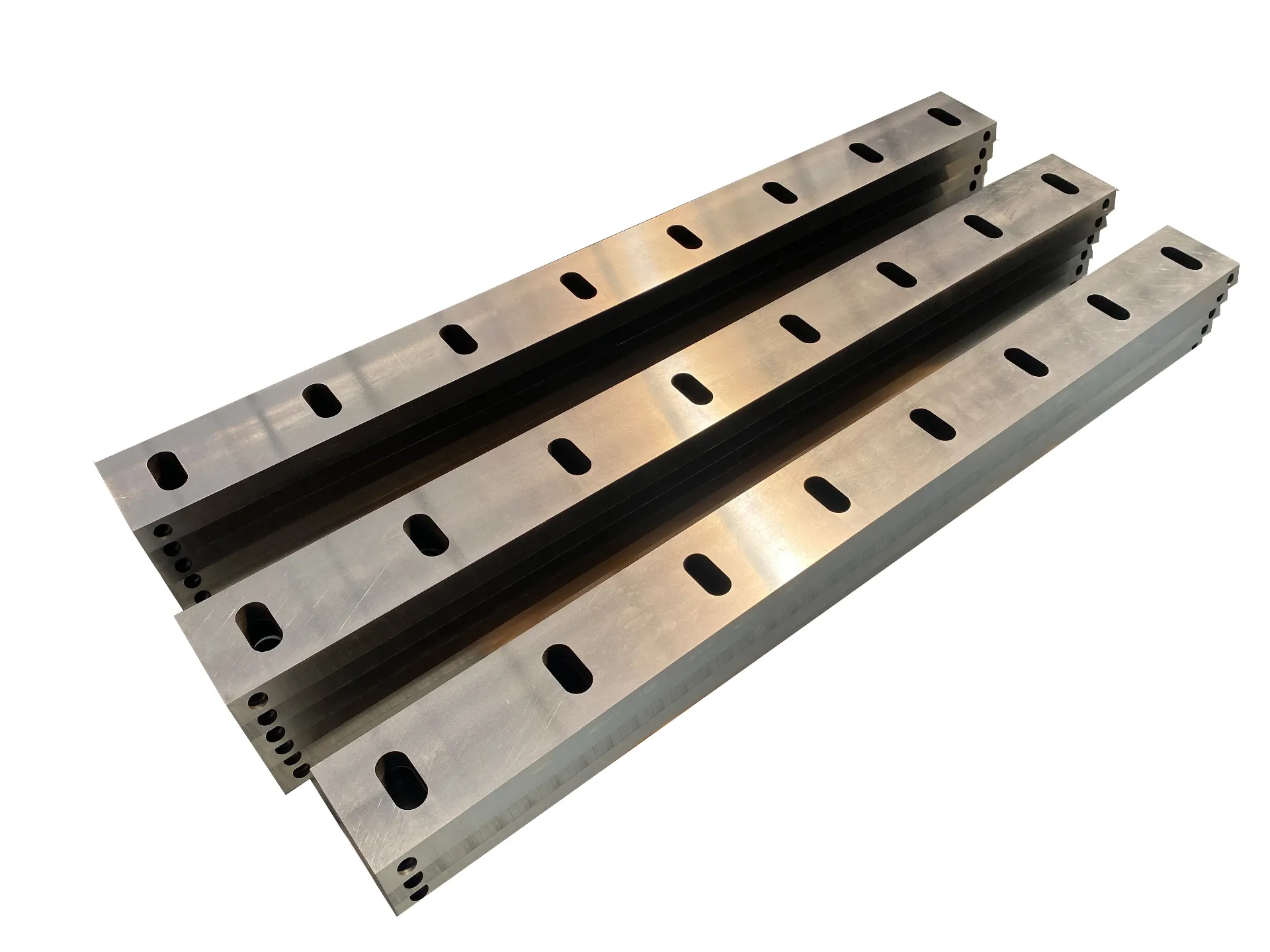

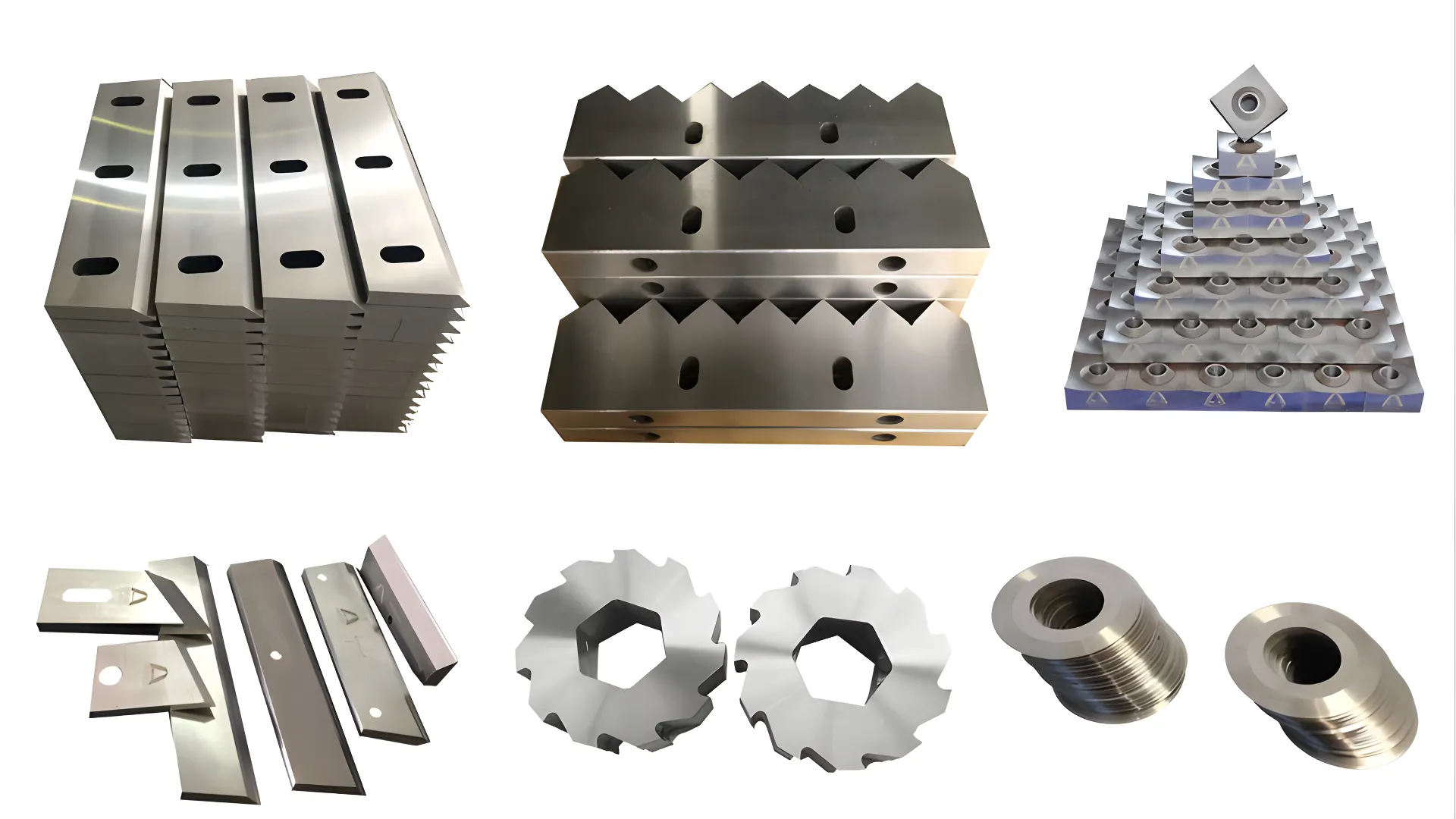

Granulator Replacement Blades

SKD‑11 knives in stock — quick swap keeps throughput high.

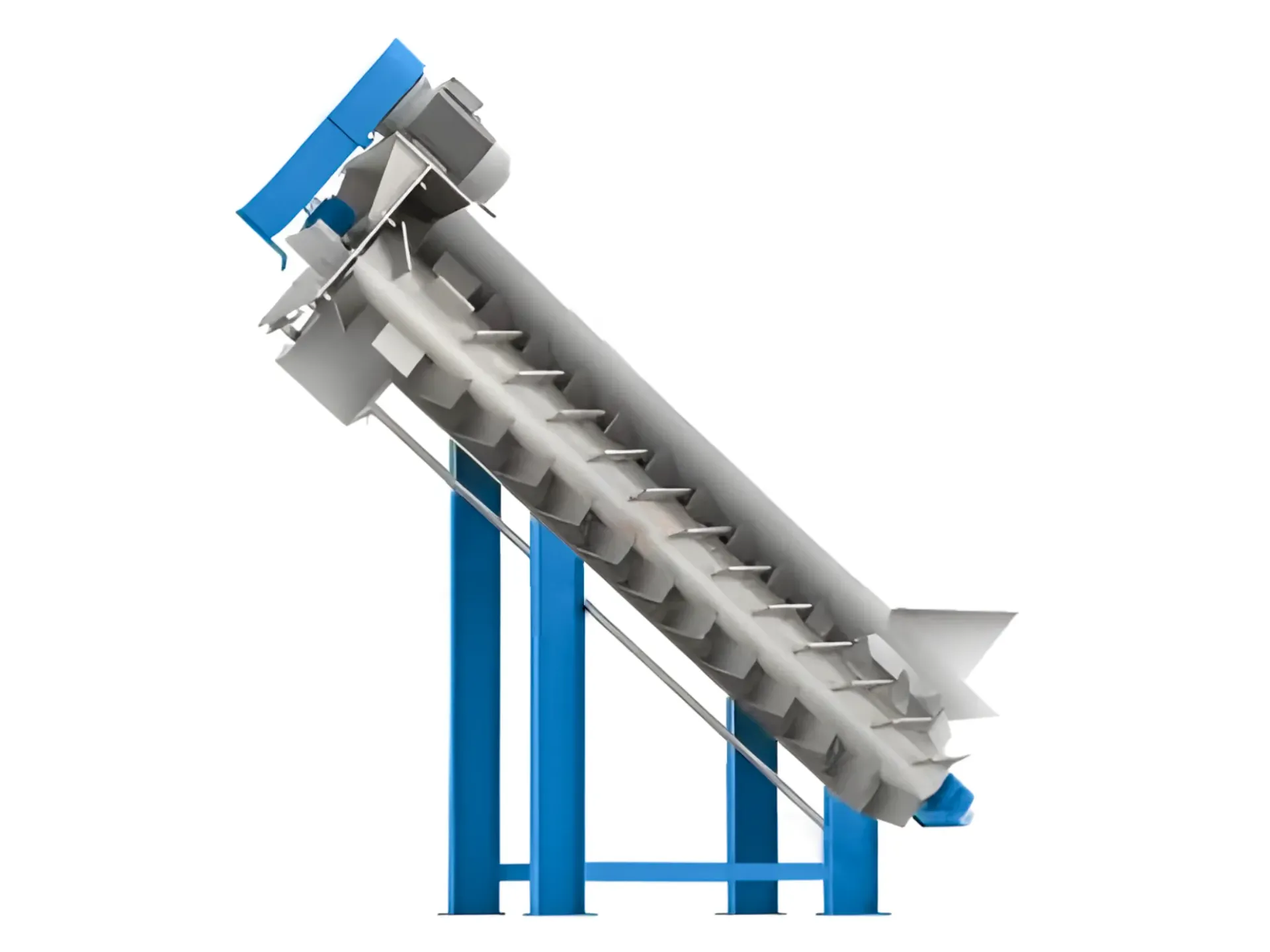

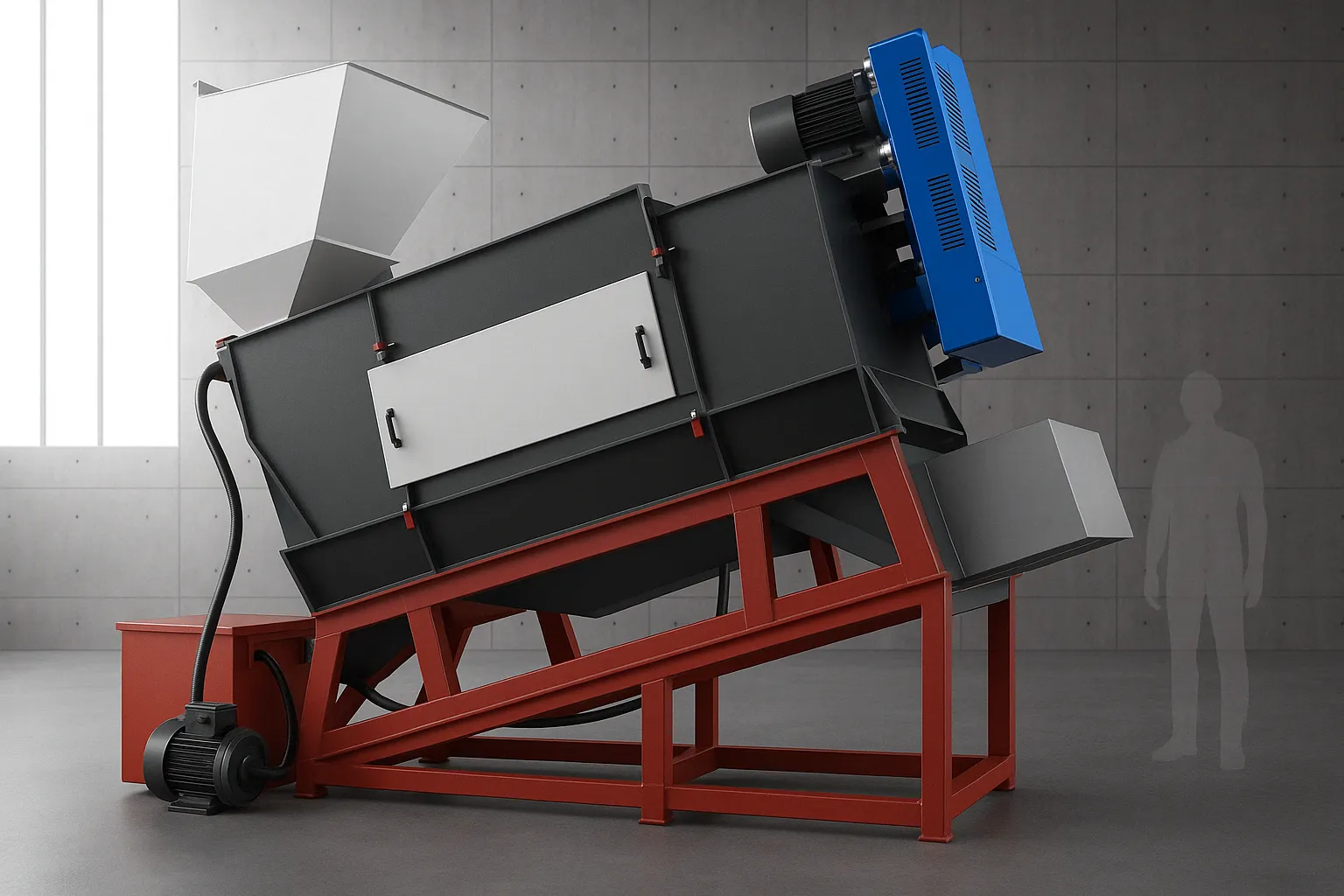

Wet Bottle Label Remover

Strips & rinses PET bottle labels in one step, >95 % efficiency.

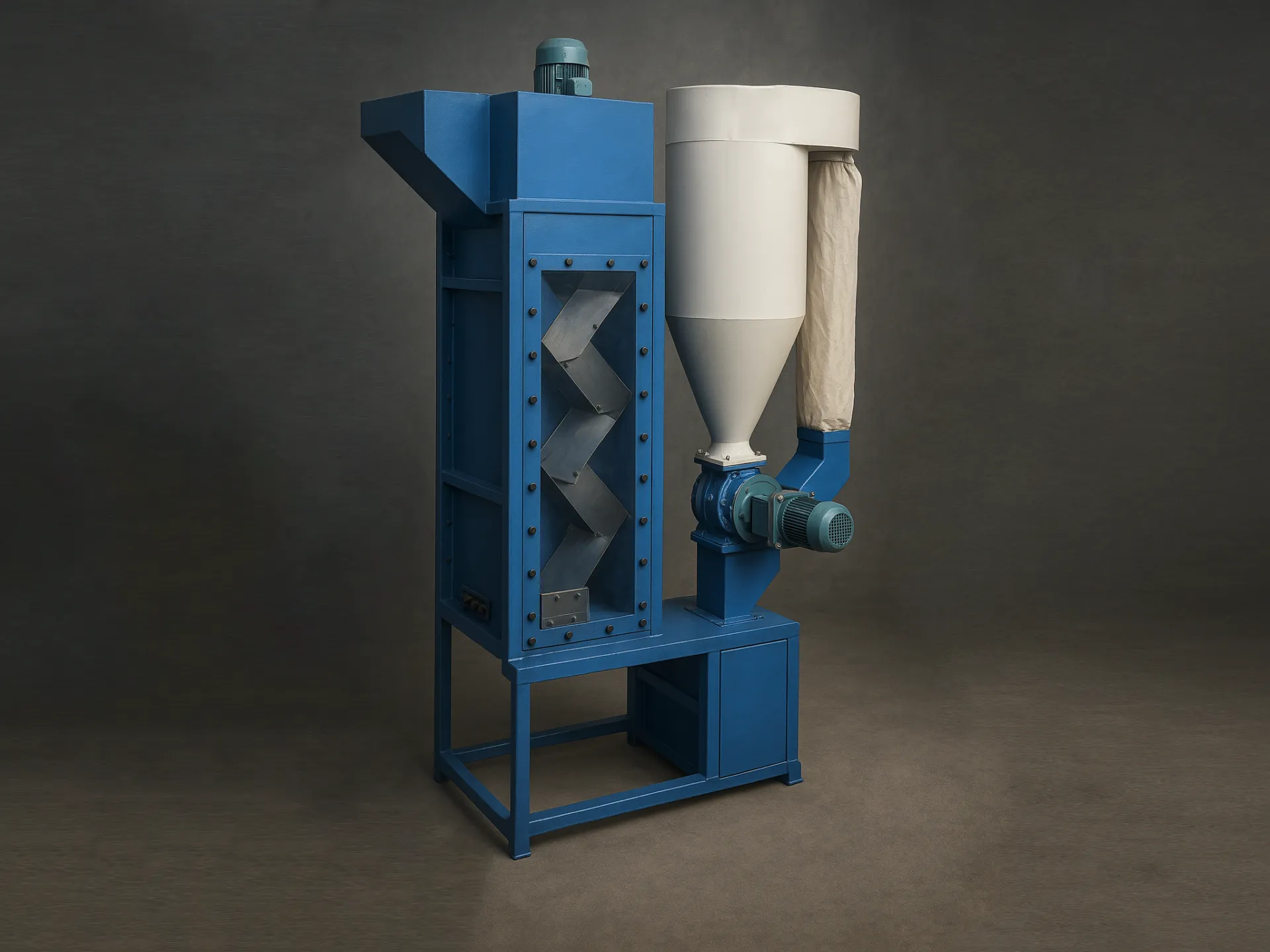

Zig‑Zag Air Classifier

Density‑based air column separates light films & dust from heavy regrind.

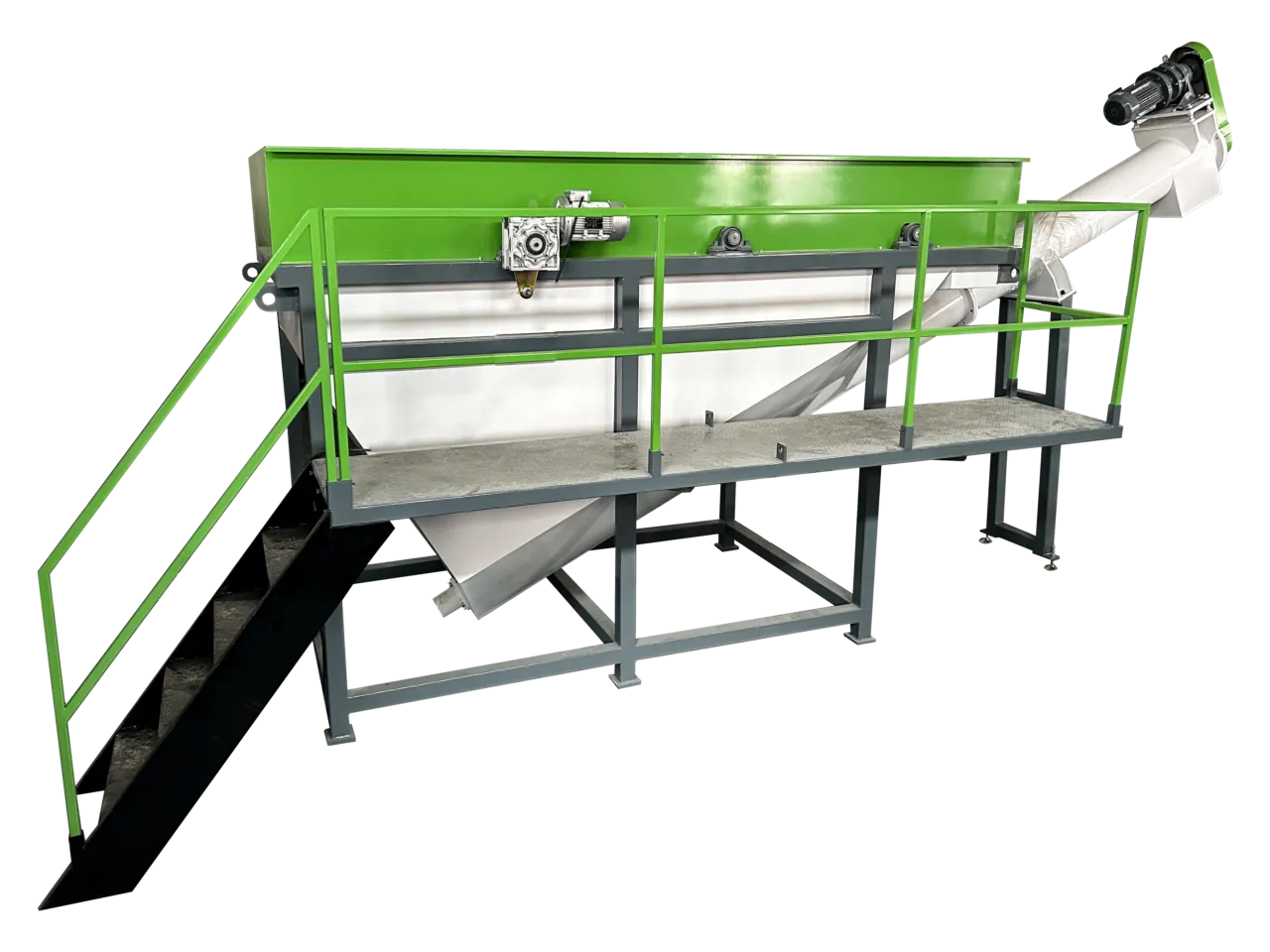

Sink‑Float Separation Tank

Rinse, separate & de‑sand heavier plastics like PET / PVC in a single unit.

Industrial Air‑Cooled Chiller

Energy‑efficient cooling (up to 30 % power savings) for moulding & washing lines.

Ready to Upgrade Your Line?

Chat with our engineers to choose the right assistive package — we’ll tailor a modular solution for your plant.

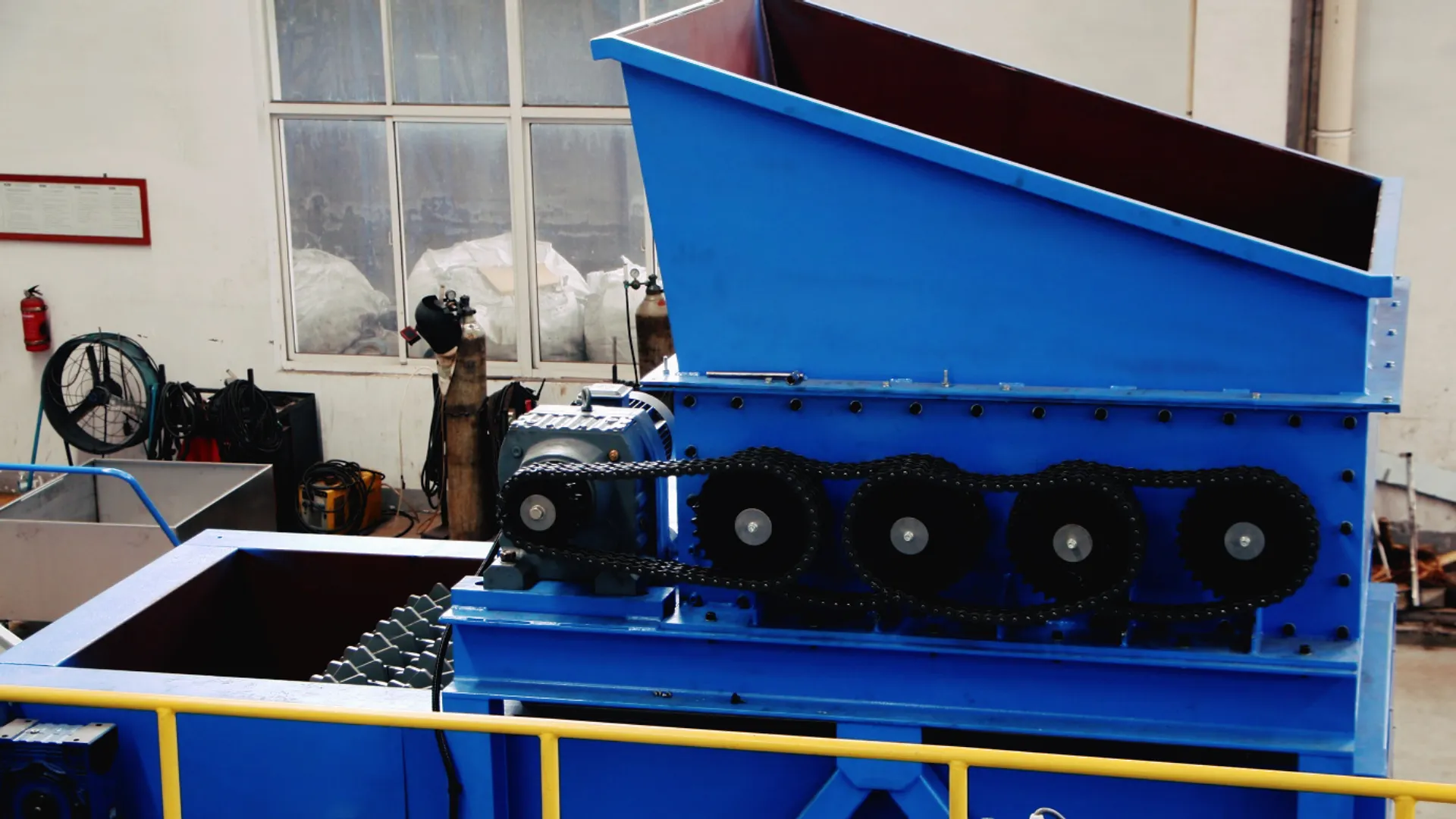

Request a Quick QuoteMaintaining the efficiency and performance of your plastic recycling machines requires timely replacement of shredder blades. Our plastic shredder replacement blades are engineered to ensure maximum durability and precision cutting, enhancing your recycling operations.

Plastic recycling is a dynamic industry that requires precision, efficiency, and the right equipment to ensure optimal results. One crucial tool that enhances the recycling process is the suspension magnetic separator. These machines are designed to recover valuable ferrous metals and remove harmful tramp ferrous metals, thereby protecting downstream equipment and improving the quality of recycled products.

Air separators play a crucial role in plastic recycling, particularly in removing lightweight contaminants like paper and cardboard from HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate) bottles. These machines are an integral part of recycling lines, ensuring that the recycled plastic is free from impurities, thus improving the quality of the final product.

Our Disk Separator is a highly efficient machine designed to separate material streams based on size. Whether you're dealing with plastics, paper, metals, or other mixed materials, this machine ensures precise separation tailored to your needs. Its customizable features and robust construction make it a top choice for various industrial applications.

Our wet plastic bottle label remover is an innovative recycling machine capable of removing more than 95% of the labels from intact plastic bottles. As this machine utilizes water to detach the labels, the bottles are cleaned simultaneously, making this an excellent option to enhance your current or new PET bottle recycling operation.