왜 우리의 수직형 탈지기를 선택해야 할까요?

⚡

탁월한 효율성

압축 해제 과정을 자동화하여 수동 작업과 준비 시간을 대폭 줄입니다.

📈

향상된 처리량

연속적이고 대량의 처리를 위해 여러 개의 베일을 동시에 처리합니다.

💲

상당한 비용 절감

노동력 요구 사항을 낮추고 업무 흐름을 간소화하여 운영 비용을 최소화합니다.

4가지 간단한 단계로 베일에서 병까지

짐 묶음

포크리프트를 사용하여 최대 5개의 베일을 공급 컨베이어에 올려놓습니다.

스트랩 자르기

각 베일을 고정하는 전선이나 끈을 빠르고 안전하게 자릅니다.

자동 탈포

두 개의 반대 방향으로 회전하는 로터가 압축된 플라스틱을 정밀하게 분해합니다.

연속 출력

풀린 재료는 재활용을 위해 다음 컨베이어로 흘러갑니다.

성능을 위해 설계됨

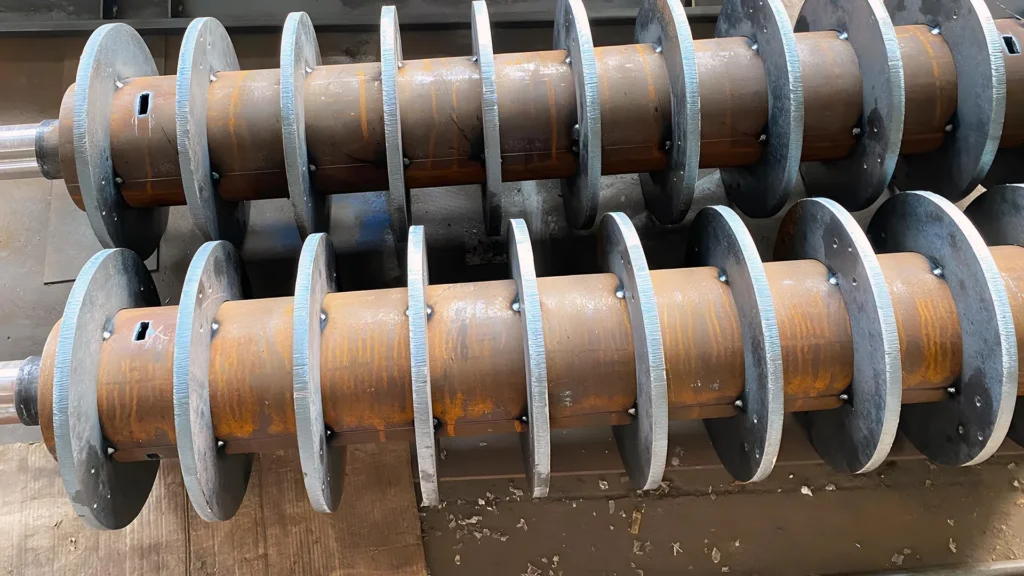

이중 역회전 로터

최대의 파단력과 효율성을 위해 설계된 기계의 핵심입니다.

기술 사양

| 특징 | 사양 |

| 메인 모터 전력 | 7.5kW x 2 (총 15kW) |

| 피더 치수 | 1550mm x 1850mm |

| 적용 가능한 재료 | 압축 HDPE, PET 병 및 기타 경질 플라스틱 |

| 인증 | CE 인증 |

| 사용자 정의 | 요청 시 더 높은 전력과 더 큰 모델 제공 가능 |

다양한 응용 분야 및 고품질 출력

맞춤형 솔루션 및 견적 받기

재활용 운영에 혁신을 가져올 준비가 되셨나요? 아래 양식을 작성해 주시면 저희 전문가가 연락드려 구체적인 요구 사항을 상담해 드리겠습니다.

자주 묻는 질문

수직 탈지기의 주요 기능은 무엇입니까?

주요 기능은 PET 및 HDPE 병과 같은 단단한 플라스틱의 압축된 베일을 자동으로 분해하여 분류, 세척 또는 분쇄와 같은 재활용 과정의 다음 단계를 준비하는 것입니다.

이 기계가 플라스틱 필름 베일을 처리할 수 있나요?

아니요, 이 기계는 경질 플라스틱용으로 특별히 설계되었습니다. 플라스틱 필름이 로터를 감싸 손상을 유발할 수 있습니다. 플라스틱 필름 베일의 경우, 특수 필름 파쇄기 또는 베일 분쇄기를 권장합니다.

처리량은 얼마입니까?

처리량은 모델과 베일 밀도에 따라 달라집니다. 저희 표준 모델은 시간당 수 톤을 처리할 수 있습니다. 고객님의 자재 및 베일 크기에 따라 정확한 수치를 제공해 드릴 수 있습니다.

얼마나 많은 수작업이 필요합니까?

수작업은 최소화됩니다. 작업자는 지게차로 베일을 적재하고 기계에 들어가기 전에 베일 와이어/스트랩을 절단해야 합니다. 베일 제거 과정 자체는 완전 자동화되어 있습니다.