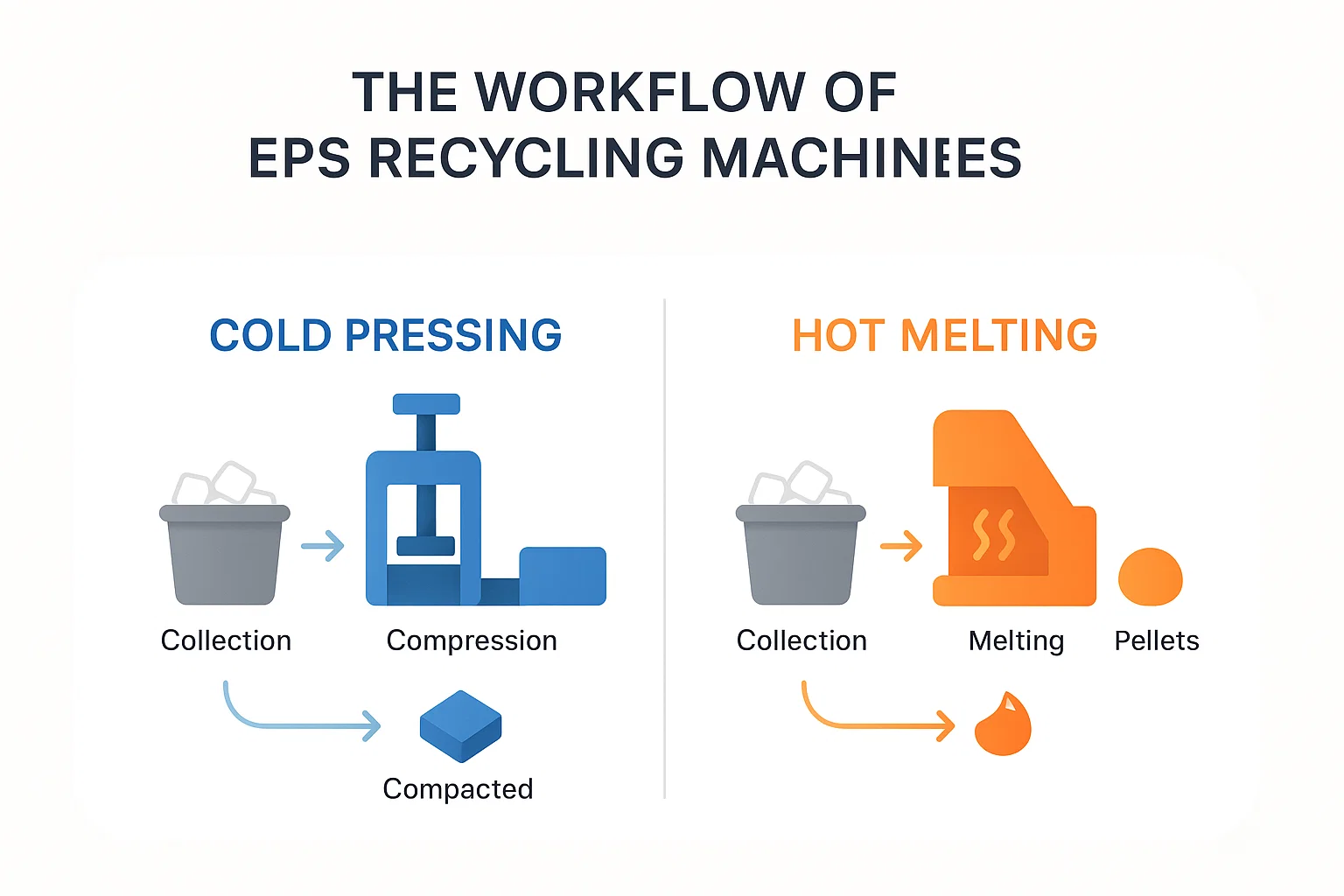

포장재, 단열재, 일회용 식품 용기 등에 널리 사용되는 발포 폴리스티렌(EPS)은 가볍고 부피가 커서 재활용이 매우 어렵습니다. 그러나 EPS 재활용 기계와 같은 최신 재활용 장비는 EPS 폐기물 처리 및 재활용에 효율적인 솔루션을 제공합니다. 이 글에서는 EPS 재활용 기계의 두 가지 주요 유형인 냉간 압착 및 열 용융의 작업 흐름을 자세히 살펴보고 재활용 작업에 가장 적합한 장비를 선택하는 데 도움을 드리겠습니다.

콜드프레싱 EPS 재활용 기계 작업 흐름

콜드 프레싱 기계는 EPS 농축기라고도 불리며, 열을 가하지 않고 EPS 폐기물을 기계적으로 압축하여 부피를 크게 줄입니다.

- 수집 및 분류

초기 단계에는 EPS 폐기물을 수거하고 테이프, 라벨, 먼지 등의 오염 물질을 제거하는 작업이 포함됩니다. - 파쇄

깨끗한 EPS 폐기물은 파쇄기에 넣어 더 작고 관리하기 쉬운 조각으로 분해됩니다. - 압축

파쇄된 EPS 소재는 냉간 압착 챔버로 이송되어 고압으로 기계적으로 압축됩니다. 이렇게 하면 부피가 최대 50:1까지 줄어듭니다. - 블록으로 압출

압축된 EPS는 밀도가 높고 단단한 블록이나 통나무 형태로 압출되어 효율적인 운송과 보관이 가능합니다.

장점:

- 에너지 소비 감소.

- 열 관련 배출이 없습니다.

- 단순성과 비용 효율성을 추구하는 작업에 적합합니다.

냉간 압착 기계에 대한 자세한 정보는 다음을 참조하세요. EPS 폼 콜드 프레스 기계 페이지.

핫멜팅 EPS 재활용 기계 작업 흐름

핫멜팅 머신은 EPS 소재를 작고 재사용 가능한 형태로 녹여 재활용 효율성을 크게 높입니다.

- 수집 및 사전 처리

콜드 프레싱과 유사하게 EPS 폐기물은 수거되어 세척되어 오염물질이 제거됩니다. - 공급 및 분쇄

EPS 소재는 기계의 호퍼에 투입되고 통합된 분쇄기를 통해 가공되어 더 작은 조각으로 분해됩니다. - 용융 공정

분쇄된 EPS는 가열실로 들어가 140°C~200°C의 온도에서 녹아 액체 상태가 됩니다. - 압출 및 냉각

녹은 EPS는 노즐을 통해 압출되어 냉각되고 응고되면서 밀도가 높은 잉곳이나 블록을 형성합니다.

장점:

- 높은 감속비(최대 90:1).

- 새로운 제품으로 재활용하기에 적합한 균일하고 밀도가 높은 잉곳을 생산합니다.

- 대량의 EPS 폐기물을 효율적으로 처리합니다.

자세한 내용을 방문하세요 EPS 폼 용융기 고온 용융 공정에 대해 더 자세히 알아볼 수 있는 가이드입니다.

비교 분석: 콜드 프레싱 vs 핫 멜팅

콜드 프레싱과 핫 멜팅 기계 중 하나를 선택하는 것은 여러 가지 운영 요인에 따라 달라집니다.

| 특징 | 콜드 프레싱 | 핫멜팅 |

|---|---|---|

| 볼륨 감소 비율 | 중간(최대 50:1) | 높음(최대 90:1) |

| 에너지 소비 | 낮추다 | 더 높은 |

| 최종 제품의 품질 | 압축된 고체 블록 | 재사용에 적합한 균일한 잉곳 |

| 환경 영향 | 최소한의 열 방출 | 가열 과정으로 인해 더 높아짐 |

귀사에 적합한 EPS 재활용 장비 선택

EPS 재활용 장비를 선택할 때는 운영 규모, 가용 예산, 재활용 목표를 고려해야 합니다. 콜드프레싱은 간편하고 운영 비용이 낮아 소규모 사업장이나 EPS 폐기물이 적은 사업장에 적합합니다. 반면, 핫멜팅은 고밀도 출력과 높은 재활용 효율을 요구하는 사업장에 적합합니다.

결론

Energycle의 EPS 재활용 기계(냉간 압착 및 열 용융)는 고객의 산업 재활용 요구에 맞춰 지속 가능하고 실용적인 솔루션을 제공합니다. 기업은 적절한 장비에 투자함으로써 상당한 환경적, 경제적 이점을 얻는 동시에 지속가능성에 대한 의지를 강화할 수 있습니다.

귀하의 요구 사항에 맞는 가장 적합한 EPS 재활용 솔루션에 대해 논의하려면 오늘 당사 전문가 팀에 문의하세요!