Energycle: zwevende zelfontladende magnetische scheider

Hangende zelfontladende magnetische scheiders, een hoeksteen van Energycle's geavanceerde oplossingen voor materiaalverwerking, spelen een cruciale rol in diverse industriële sectoren, met name recycling en mijnbouw. Deze systemen zijn zorgvuldig ontworpen voor de efficiënte extractie van ferrometalen uit niet-magnetische bulkstromen. Hun functie is cruciaal voor de zuivering van materialen en een essentieel onderdeel bij het optimaliseren van grondstoffenwinning en het stimuleren van initiatieven voor duurzame recycling.

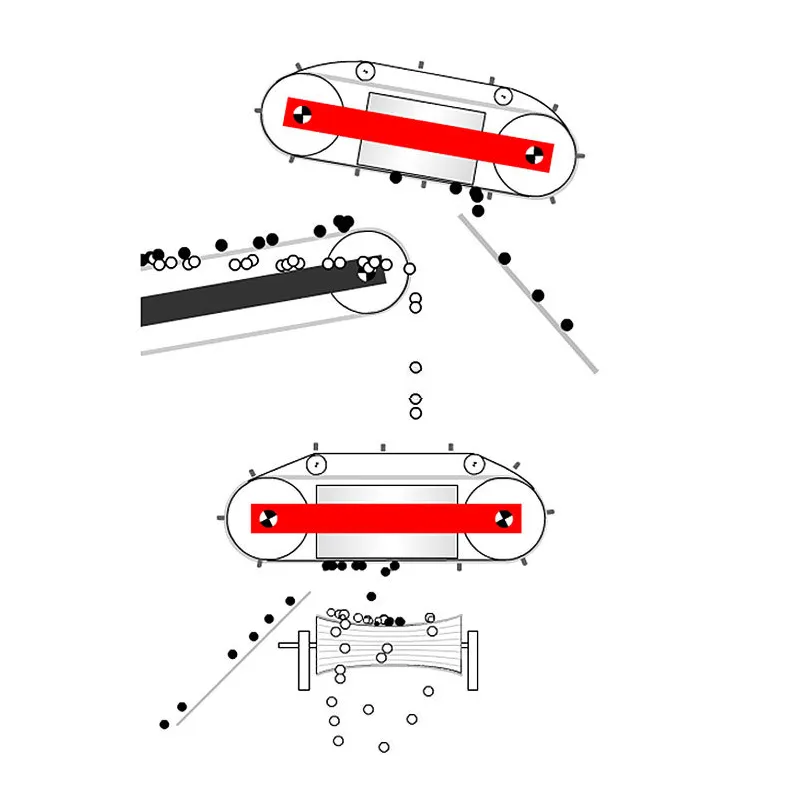

Werkingsprincipe

De operationele effectiviteit van deze scheiders is afhankelijk van een krachtig magnetisch veld dat is ontworpen om ferrometalen in een getransporteerd materiaalmengsel aan te trekken en te isoleren. Wanneer het mengsel door dit nauwkeurig gekalibreerde veld stroomt, worden magnetische deeltjes selectief onttrokken en automatisch afgevoerd, waardoor een zuivere scheiding van niet-magnetische bestanddelen wordt bereikt. De scheidingsefficiëntie is intrinsiek gekoppeld aan de magnetische gevoeligheid van de doelmaterialen en de intensiteit van het door het apparaat gegenereerde magnetische veld.

Het landschap begrijpen: soorten magnetische scheiders

- » Overband magnetische scheiders: Strategisch geplaatst boven transportbanden om effectief grote ijzerhoudende verontreinigingen uit de productstroom te verwijderen.

- » Trommelmagneten: Maak gebruik van een roterende trommel met een stationaire magnetische kern om continu ijzerhoudende stoffen te scheiden van bulkmaterialen.

- » Magnetische katrollen: Geïntegreerd aan de uitvoerzijde van transportsystemen, dienend als koprollen om ononderbroken magnetische scheiding te garanderen.

- » Wervelstroomscheiders: Maak gebruik van krachtige magnetische velden om wervelstromen op te wekken, waardoor non-ferrometalen (bijv. aluminium, koper) van niet-metalen materialen gescheiden kunnen worden.

Belangrijkste industriële toepassingen

- Afvalbeheer en recycling: Stroomlijnt de scheiding van ferrometalen uit vast stedelijk afval (MSW) en industrieel afval, waardoor de zuiverheid en waarde van gerecyclede grondstoffen aanzienlijk worden verbeterd.

- Mijnbouw- en steengroevenactiviteiten: Maakt de verwerking van ijzerertsen en de zuivering van niet-metalen mineralen, zoals kwarts, mogelijk door het verwijderen van zwerfijzer.

- Voedselverwerkende en farmaceutische industrie: Zorgt voor productintegriteit en veiligheid voor de consument door uiterst nauwkeurige verwijdering van kleine metaalverontreinigingen uit productlijnen.

- Productie- en fabricagefaciliteiten: Zuivert grondstoffen en beschermt kritische verwerkingsmachines tegen schade door metaalresten.

Belangrijkste voordelen en voordelen

- Superieure scheidingsefficiëntie: Ontworpen voor verwerking met een hoge doorvoersnelheid, waardoor volledige extractie van ferrometalen uit uiteenlopende materiaalstromen wordt gegarandeerd.

- Verbeterde kosteneffectiviteit: Optimaliseert verwerkingstijden en verhoogt de commerciële waarde van teruggewonnen materialen aanzienlijk.

- Bescherming van downstream-apparatuur: Voorkomt kostbare schade en stilstand van de nabewerkingsmachines door het effectief verwijderen van verontreinigingen door losse metalen.

- Bevordering van ecologische duurzaamheid: Vermindert de hoeveelheid afval die gestort wordt aanzienlijk en ondersteunt de doelstellingen van de circulaire economie door robuuste recyclingprogramma's mogelijk te maken.

Onderhoud en operationele uitmuntendheid

Om blijvende topprestaties en een lange levensduur te garanderen, is een proactief onderhoudsschema essentieel. Dit omvat routinematige controle van de magnetische veldsterkte, zorgvuldige reiniging van magnetische oppervlakken en grondige inspectie van alle mechanische componenten. Strategische operationele parameters, zoals optimale plaatsing van de separator, kalibratie van de transportbandsnelheid en de juiste materiaalbelasting, zijn cruciaal voor het maximaliseren van de scheidingseffectiviteit.

Conclusie: samenwerken voor zuiverheid en prestaties

De zwevende zelfontladende magnetische scheiders van Energycle vormen een essentiële technologie in de hedendaagse materiaalverwerking, met name binnen recycling- en bulkverwerkingsprocessen. Hun bewezen bekwaamheid in het scheiden en extraheren van ferrometalen uit diverse productstromen maakt ze onmisbaar voor het bereiken van superieure productzuiverheid, het beschermen van downstream apparatuur en het bevorderen van milieubewustzijn. Naarmate de industriële vraag evolueert, blijft Energycle zich inzetten voor de ontwikkeling van deze scheidingstechnologieën, zodat ze wereldwijd nog efficiënter en waardevoller worden in materiaalwinningsprocessen.

Vragen en overleg

Neem vandaag nog contact op met een specialist van Energycle voor gedetailleerde specificaties, oplossingen op maat of om uw specifieke toepassingsvereisten voor onze zwevende zelfontladende magnetische scheiders te bespreken.