Floating Separation Tank (Sink Float Tank) for PP/PE Recycling

Esse Tanque de separação flutuante (sink‑float tank) uses water density to recover floating PP/PE while removing heavy plastics (PET, PVC, ABS) and debris. The water‑saving two‑zone design helps improve output purity and stabilize downstream washing, dewatering, and extrusion.

Why This Floating Separation Tank Works

Reliable density separation, integrated washing, and a water‑saving tank layout to stabilize PP/PE recovery.

Clean PP/PE Fraction

Separates light plastics that float (PP/PE) from heavy polymers and contaminants that sink.

Remoção de Contaminação

Helps remove dirt, stones, glass, and metal fragments—reducing load on downstream equipment.

Pre‑Washing Effect

Agitation in water supports preliminary washing to improve output quality and consistency.

Two‑Zone Water Saving

Primary + polishing zones help maintain higher cleanliness while reducing overall water replacement.

Adjustable Paddle Control

Frequency‑controlled paddle motors guide floating material steadily to discharge.

Industrial Build

304 stainless steel interior with heavy‑duty carbon steel frame supports long‑term reliability.

How the Floating Separation Tank Works

A proven method: water density creates a clear split between floating PP/PE and sinking heavy fractions and contaminants.

Step 1

Alimentação

Mixed plastic flakes enter the tank via a screw conveyor and disperse into the water.

Step 2

Separação por flutuação

Heavy materials (PET, PVC, ABS) and debris sink; light plastics (PP, PE) float to the surface.

Step 3

Collection & Discharge

Surface paddles move floating PP/PE to discharge while bottom conveyance removes sinking fractions.

Design Innovations

Better separation, cleaner output, and lower operating cost—driven by a practical two‑stage tank layout.

W‑Shaped Sedimentation Bottom

A “W” bottom promotes faster settling of heavy dirt and debris, improving cleanliness and separation stability.

Primary + Polishing Zones

Handles the dirty infeed in the first zone, then “polishes” floating plastic in cleaner water for higher purity and reduced water use.

Customization for Your Line

Share the details below so we can size the tank correctly and quote the right configuration.

Material & Contamination

- Input stream: PP/PE flakes, mixed rigid plastics, or PET flakes with cap/label contamination

- Contaminants: sand, stones, glass, metal fragments

- Target output purity and acceptable carry‑over

Capacity & Residence Time

- Throughput (kg/h) and flake size distribution

- Tank length/width for stable separation at your feed rate

- Paddle speed control to prevent clumping and overflow

Water & Discharge Design

- Water circulation, filtration, and make‑up water plan

- Bottom discharge method for sinking fractions

- Two‑zone layout if you need lower water consumption

Need a quick recommendation? Send your material, throughput, and layout space—our engineers will propose a configuration.

Especificações técnicas

Standard configuration ranges. We can engineer custom sizes based on your line layout and throughput target.

| Interior width | 1000–1800 mm |

|---|---|

| Total length | 4–7 meters |

| Interior material | Type 304 stainless steel (corrosion resistance) |

| Exterior frame | Heavy‑duty carbon steel (structural integrity) |

| Paddle motors | 1.5 kW × 2 (frequency control for adjustable speed) |

| Certificação | Certificação CE disponível |

Observação: Larger or higher‑throughput models can be built upon request.

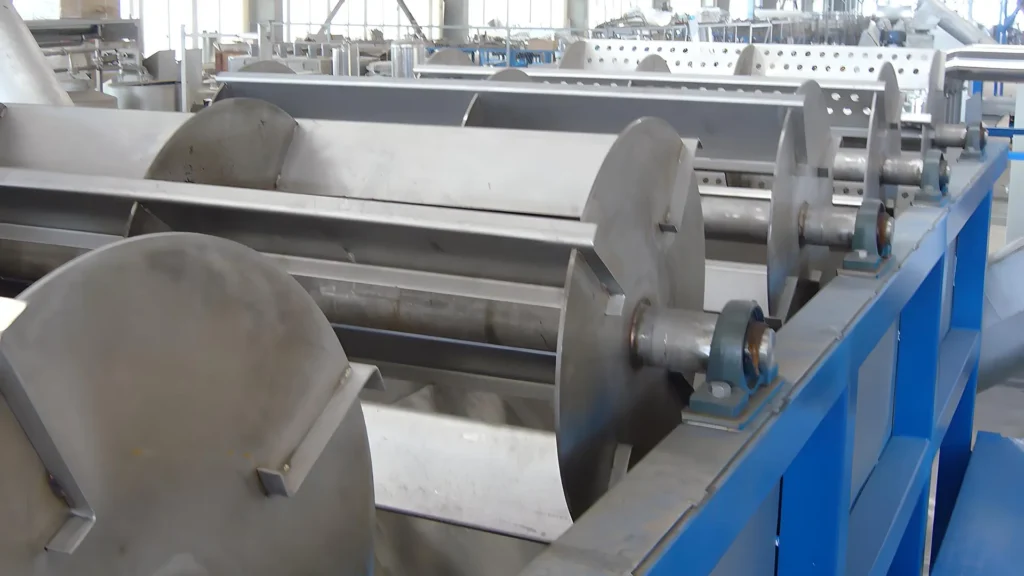

Floating Separation Tank Photos

A reference view of typical build and installation.

Perguntas frequentes

What is a Floating Separation Tank used for?

It is used for sink‑float separation to recover light plastics (PP/PE) while removing heavy plastics (PET/PVC/ABS) and debris. It also provides a preliminary washing step.

Can it separate PP from PE?

PP and PE are both light plastics that typically float in water, so the tank separates them together from heavier fractions. For PP vs PE separation, additional processes may be required.

How do I choose the right tank size?

Key inputs are throughput (kg/h), flake size, contamination level, and available layout space. Share these details and we can recommend width/length and paddle configuration.

Do you offer CE certification?

Yes. CE certification is available, and we provide installation guidance and after‑sales support.

How do I get the right configuration and price?

Send your material list, contamination level, throughput target, and available layout space. We’ll recommend a tank width/length and discharge configuration, then provide a quotation.

Garantia e instalação

Desde o comissionamento até o serviço pós-venda, ajudamos a garantir uma produção estável e confiabilidade a longo prazo.

Garantia limitada de 1 ano

Oferecemos uma garantia limitada de um ano que cobre os componentes principais em condições normais de operação e manutenção.

Apoio à contratação

We provide installation guidance, parameter suggestions, and after‑sales support to keep your washing line running smoothly.

Solicite um orçamento

Tell us your input material, contamination level, and required capacity. We’ll recommend the right Floating Separation Tank configuration and quote.

Prefer email? Use our contact page for faster routing.