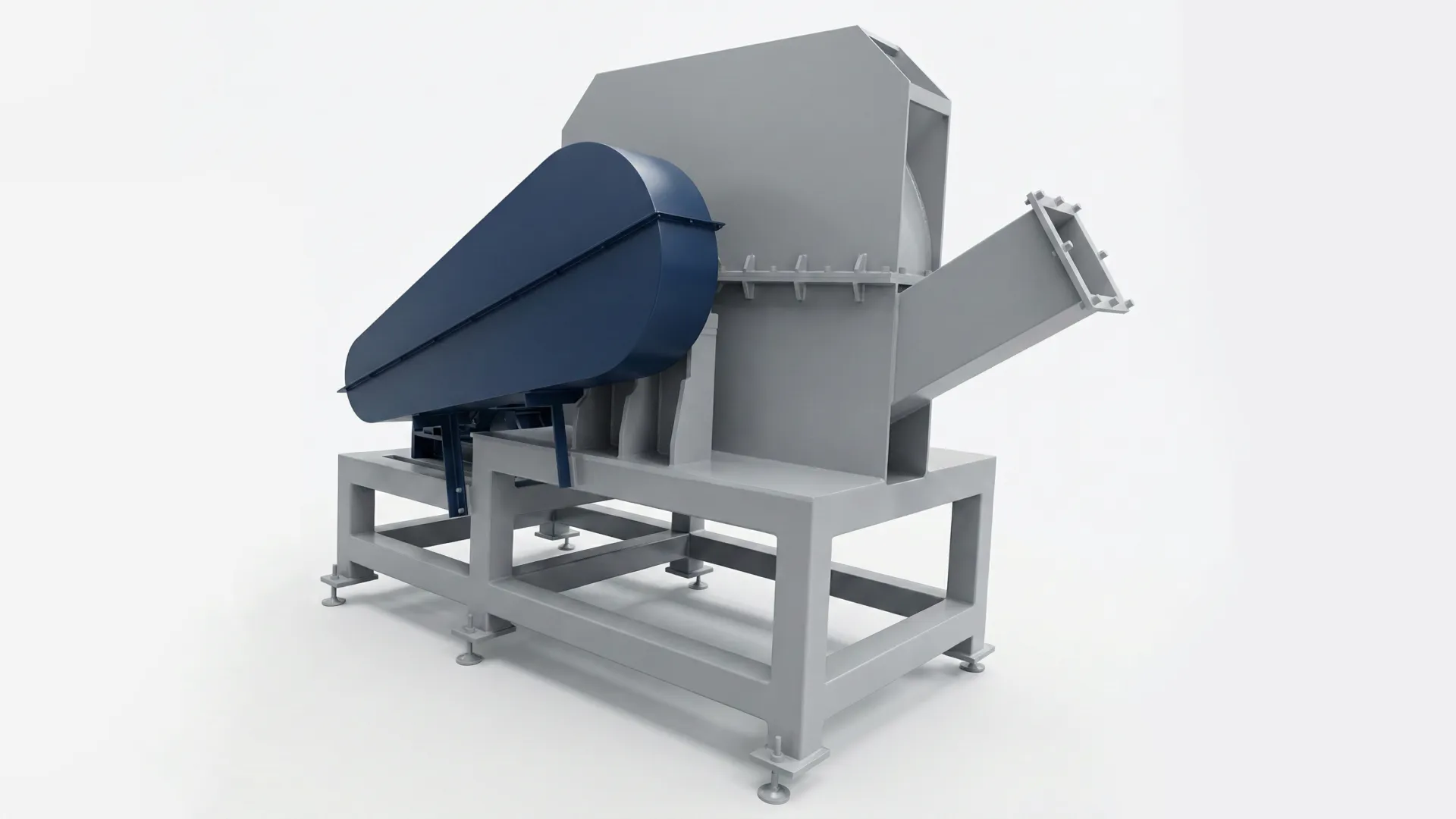

Large Diameter HDPE Pipe Crusher & Quick Tearing Machine

Specially engineered for high-efficiency shredding of large-diameter, thick-walled HDPE pipes (also known as an HDPE pipe quick tearing machine). Handles up to 1200mm diameter pipes directly without pre-cutting, delivering uniform output for recycling lines.

맞춤 견적 받기개요

This machine is purpose-built for recycling oversized HDPE/PE pipes where manual pre-cutting is unsafe and inefficient. With a wide horizontal infeed and PLC-controlled hydraulic pusher, it grips thick-walled pipes reliably and delivers stable, uniform chips for washing and extrusion lines.

Applications & Material Fit

Designed specifically for oversized thermoplastic pipes where conventional shredders struggle with feeding stability and wall thickness.

지원되는 재료

HDPE / PE large-diameter pipes, thick-walled pipe scrap, long pipe sections, and bundled pipe offcuts. PVC can be processed, but for high-throughput PVC recycling we recommend dedicated granulation systems.

Accepted Pipe Forms

Straight pipes, short sections, and loose bundles. Horizontal infeed allows whole pipes to be loaded directly without manual pre-cutting.

Typical Feed Conditions

Handles dirty or slightly contaminated pipe waste. For metal inserts or heavy sand content, upstream inspection or magnetic separation is recommended to extend blade life.

Why Choose Our Pipe Crusher?

No Pre-Cutting Needed

Designed with an extra-wide chamber and horizontal infeed to handle full-length pipes up to 6000mm+ and diameters up to 1200mm directly.

Powerful Tearing Action

Equipped with high-torque rotors and hardened alloy steel blades that effectively tear through thick-walled HDPE pipes with ease.

스마트 자동화

Features a PLC-controlled hydraulic pusher system that automatically adjusts feeding speed to prevent jams and ensure continuous operation.

Engineered for Large Pipes

강화된 안전성

Horizontal loading eliminates the risks associated with manual cutting and vertical feeding of heavy, unstable pipes.

Consistent Granule Size

Screen-controlled discharge ensures uniform particle size, making the material perfect for downstream washing and extrusion.

High Durability

Robust structural design with wear-resistant components ensures a long service life even under heavy-duty continuous operation.

Key Engineering Components

Hydraulic Ram Feeding

A PLC-controlled hydraulic pusher continuously presses pipes into the rotor, preventing material bridging and idle running while maintaining stable cutting load.

High-Torque Rotor & Blades

Low-speed, high-torque rotor geometry combined with hardened alloy steel blades delivers aggressive tearing of thick walls while minimizing current spikes.

Adjustable Counter Knives

Precision-set stationary knives optimize shearing efficiency and can be re-adjusted as blades wear, extending service intervals.

Hydraulic Opening Hopper

The feed box opens hydraulically for fast access during maintenance and blade changes, reducing downtime.

Screen-Controlled Discharge

Interchangeable screens define final chip size and ensure consistent output for downstream washing or extrusion.

Solving Large Pipe Recycling Challenges

Common Issues

- Manual cutting of large diameter pipes is slow, costly, and dangerous.

- Standard shredders struggle to grip and fracture thick-walled HDPE material.

- Uneven shredding leads to jams and poor quality output for pelletizing.

Our Solution

- Large horizontal hopper accepts whole pipes, eliminating manual prep work.

- Specialized rotor geometry provides the aggressive torque needed for quick tearing.

- Automated load sensing prevents overfeeding and ensures uniform chip production.

Processing Flow & Line Integration

1. Whole Pipe Loading

Long or oversized pipes are placed directly into the horizontal feeding trough by forklift or crane.

2. Controlled Hydraulic Feeding

The hydraulic ram advances automatically, adapting feed speed to rotor load and preventing overload or jamming.

3. Shredding / Tearing

High-torque blades tear thick-walled pipes against counter knives, rapidly reducing them into uniform chips.

4. Downstream Processing

Material exits through the screen and can be conveyed to secondary crushing, washing lines, or extrusion pelletizing systems.

Typical recycling lines combine this pipe shredder with conveyors, secondary granulators, washing systems, and pelletizing units to form a complete HDPE pipe recycling solution.

Compare the Efficiency

| 특징 | Conventional Shredders | Our Pipe Tearing Machine |

|---|---|---|

| Large Pipe Handling | Requires Pre-Cutting | Direct Whole Pipe Feed |

| Feeding Mechanism | Gravity / Manual Push | Hydraulic Auto-Push |

| 처리량 | Low / Intermittent | High & Continuous |

| 근로자 안전 | Risk Exposure | Fully Enclosed |

Watch the Machine in Action

머신 갤러리

Typical Project Scenarios

Recycling facility processing long HDPE pipes (600–800mm diameter). Whole pipes are fed directly, eliminating manual cutting and reducing labor while producing consistent chips for washing lines.

Municipal pipe scrap with mixed lengths and thick walls. Horizontal infeed and hydraulic ram maintain stable throughput and prevent bridging inside the hopper.

자주 묻는 질문

이 기계가 처리할 수 있는 최대 파이프 직경은 얼마입니까?

Does this machine work as a Quick Tearing Machine?

출력 입자 크기를 제어할 수 있나요?

Is the machine suitable for PVC pipes as well?

What maintenance is required for the blades?

Do I need a secondary crusher or granulator?

How does the machine prevent material bridging or jamming?

Can the system be supplied as part of a complete recycling line?

What support is included after delivery?

Client Success Stories

We process tons of 800mm HDPE pipes daily. This crusher handles them effortlessly without any pre-cutting, saving us huge labor costs.

재활용 공장 관리자

The quick tearing action is impressive. It's much quieter and more efficient than our old shredders. A solid investment for our line.

Operations Lead

Reliable, robust, and safe. The hydraulic feeding system makes operating this large machine very simple and safe for our team.

Facility Owner

Get a Quote for Your Pipe Crusher

Tell us about your pipe sizes and capacity requirements, and we'll provide a tailored solution.