Single-Shaft Shredder for Hard & Rigid Plastics

Engineered for the toughest rigid plastics—turn bulky scraps into consistent, high‑value regrind with stable throughput and low operating cost.

Key Benefits

Why leading recyclers choose this shredder.

Operational Efficiency

Continuous feeding and a large‑diameter rotor maximize throughput and reduce labor.

Superior Durability

Vibration‑damping couplers and robust blades extend service life and cut maintenance.

Powerful Performance

Purpose‑built to shred lumps, purges, and thick‑walled parts without jamming.

Enhanced Safety

PLC automation with overload protection ensures stable, safe operation.

Ideal for Processing

Lumps & Extruder Purges

Break down dense blocks from line startups/shutdowns (PE, PP, PC).

Pipes, Profiles & Sheets

Shred PVC/HDPE pipes, window profiles, and sheet rolls into uniform pieces.

Large Molded Products

Pallets, crates, and automotive parts such as bumpers and dashboards.

Advanced Engineering Features

Continuous Feeding System

Steady material flow maximizes throughput and prevents interruptions.

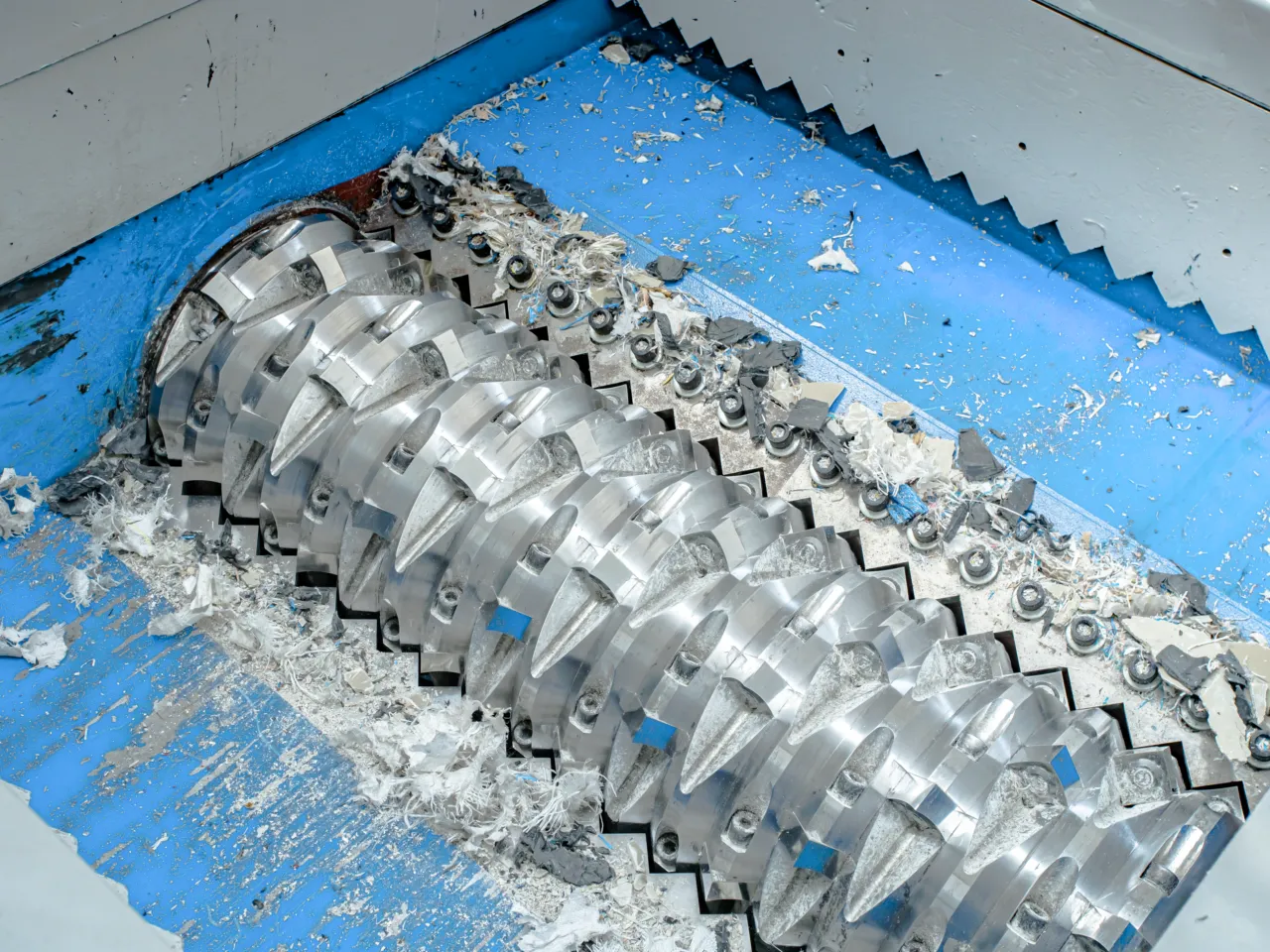

Customized Large‑Diameter Rotor

Greater cutting contact per cycle delivers higher productivity.

Coupler‑Connected Transmission

Reduces vibration and protects spindle and gearbox from shock loads.

Strategic Fixed Blade Placement

Top and bottom fixed blades optimize cutting and reduce spindle stress.

PLC Self‑Programming Control

Start/stop/reverse and automatic overload protection for safe autonomy.

Technical Specifications

| Feature | ERM-800-SHD | ERM-1000-SHD | ERM-1200-SHD | ERM-1500-SHD |

|---|---|---|---|---|

| Number of Rotary Blades | 30 pcs | 39 pcs | 48 pcs | 57 pcs |

| Motor Power | 30 kW | 37 kW | 55 kW | 75 kW |

| Rotor Diameter (mm) | Φ275 | Φ315 | Φ375 | Φ400 |

| Approx. Output (kg/hr) | 450 | 800 | 1200 | 1500 |

| Rotating Speed (rpm) | 82 | 82 | 82 | 82 |

| Knife Material | SKD11 (High‑carbon, high‑chromium tool steel) | |||

Device Showcase

Photos and a short walkthrough of the system in action.

Get a Custom Quote

Tell us your materials, target capacity, and site constraints. We’ll respond with a tailored solution and pricing.