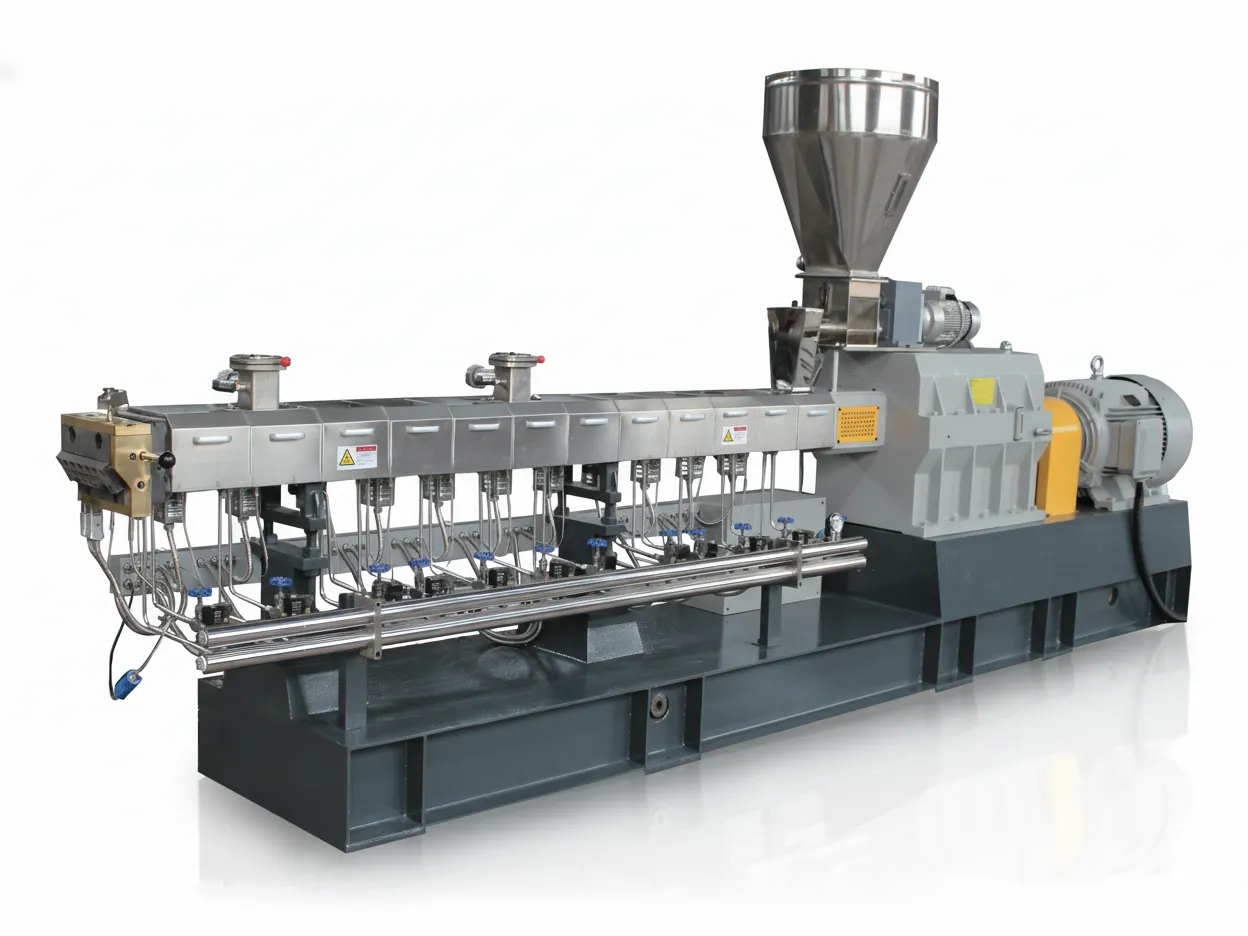

Twin-Screw Plastic Extruder & Pelletizer

Master complex compounding with our high-speed, co-rotating twin-screw extruder. Engineered for superior mixing of fillers, fibers, and additives.

Advanced Compounding Technology

Our extruder is built to handle the most demanding jobs, delivering unparalleled reliability, efficiency, and pellet quality.

Superior Compounding & Mixing

Co-rotating screw shafts provide intense, homogenous blending of plastics, fillers, and additives for a perfect compound.

Precise Temperature Control

Patented Heat Wave Stabilization™ technology ensures even heat distribution for an ideal, stable pelletizing process.

Continuous, Uninterrupted Operation

A hydraulic screen changer allows for filter changes without stopping the machine, maximizing uptime and throughput.

Robust & Wear-Resistant

Constructed from blended steel strengthened with gas nitriding technology for exceptional durability and long service life.

Solve Your Most Complex Compounding Challenges

Standard extruders fail when processing complex material blends. Our twin-screw system is engineered specifically for these demanding tasks.

Problem: Inconsistent Mixing

Single-screw extruders struggle to evenly disperse high levels of fillers, fibers, or masterbatch, leading to inconsistent, low-quality products.

Solution: Homogenous Blending

The intense shearing and mixing action of the co-rotating twin screws guarantees a perfectly homogenous melt, even with high additive content.

Problem: Material Degradation

Poor temperature control and localized overheating in standard extruders can degrade heat-sensitive polymers and additives, ruining the batch.

The Advanced Compounding & Pelletizing Process

A systematic process that ensures superior mixing, stable extrusion, and the creation of high-quality, uniform pellets.

1. Precision Feeding

Plastic resin, along with fillers, reinforcing fibers, and other additives, are accurately dosed into the extruder.

2. Intense Mixing & Melting

The co-rotating screws convey, shear, and intensely mix the materials while our stabilization tech ensures a perfect, even melt.

3. Melt Filtration

The homogenous molten plastic is forced through a hydraulic screen changer to remove any contaminants before pelletizing.

4. Pelletizing & Cooling

The clean melt is extruded and cut into uniform pellets using either a strand or water-ring pelletizing system, then rapidly cooled.

Machine Showcase

The Ultimate Machine for High-Value Applications

Our twin-screw extruder is essential for creating the high-quality compounds and masterbatches required by advanced manufacturing sectors.

Masterbatch Production

Ideal for producing high-concentration color, additive, and filler masterbatches with perfect pigment and additive dispersion.

Polymer Compounding & Alloying

Expertly blends different polymers or compounds plastics with reinforcing agents like glass fiber, talc, and calcium carbonate.

Reactive Extrusion

Provides the controlled environment necessary for polymerization and other chemical reactions to occur directly within the extruder.

Technical Specifications

| Model | Screw Diameter (mm) | L/D Ratio | Driving Motor (KW) | Output (KG/H) |

|---|---|---|---|---|

| SHJ50/RM120 | 50.2 / 120 | 24/48, 7/20 | 37-45 / 30-37 | 150-300 |

| SHJ75/RM150 | 62.4 / 150 | 24/48, 7/20 | 55-75 / 37-45 | 150-300 |

| SHJ75/RM180 | 71 / 180 | 24/48, 7/20 | 90-110 / 45-55 | 300-600 |

| SHJ95/RM200 | 93 / 200 | 24/48, 7/20 | 132-135 / 55-75 | 500-1,000 |

Frequently Asked Questions

What is the main advantage of a twin-screw vs. a single-screw extruder?

A twin-screw extruder provides far superior mixing and compounding capabilities. The interlocking, co-rotating screws create intense shearing and distributive mixing, making it essential for blending different materials, like polymers with fillers, fibers, or colorants. A single-screw extruder is better for simple extrusion of a single, pre-compounded material.

What is “Heat Wave Stabilization™” technology?

It is our patented technology that ensures precise and uniform heat distribution throughout the entire extruder barrel. This prevents hot spots and cold spots, which is critical for processing heat-sensitive materials and ensuring a consistent melt viscosity, leading to higher quality and more uniform pellets.

Can this machine be customized for my specific needs?

Yes. The system is highly modular. You can choose different pelletizing methods like “strand pelletizing” or “melt/water-ring pelletizing.” We can also add components like water tanks, dewatering machines, and product silos to create a fully automated production line tailored to your requirements.

Elevate Your Compounding Capabilities

Stop struggling with inconsistent blends and material degradation. Contact us to learn how our twin-screw extruder can revolutionize your production process. Get a custom quote today.