Recycling-Nachrichten

In der Welt des Recyclings ist Abfall nicht gleich Abfall. Während starre Kunststoffe (wie Flaschen und Rohre) leicht zu zerkleinern sind, Weiche Materialien – insbesondere Kunststofffolien und Textilfasern – sind bekanntermaßen schwer zu verarbeiten.

Sie wickeln sich um Rotoren, verstopfen Siebe und schmelzen unter Reibung. Dennoch stellen sie einen enormen Anteil des Abfallstroms dar.

Um diese problematischen Materialien gewinnbringend zu verwerten, reicht herkömmliches Zerkleinern nicht aus. Sie benötigen eine leistungsstarke, langsam laufende Zerkleinerungstechnologie. Dieser Leitfaden zeigt Ihnen, wie Spezialzerkleinerer die Rückgewinnung von Folien und Fasern revolutionieren und so potenziellen Deponiemüll in wertvollen Rohstoff verwandeln.

Die Herausforderung: Das Problem des "weichen Materials"

Bevor wir die Lösung verstehen können, müssen wir die Herausforderung respektieren.

- Kunststofffolien (LDPE/LLDPE/PP): Leicht und flexibel. In einem Standardgranulator neigen die Folien dazu, eher zu "schwimmen" als transportiert zu werden, oder schlimmer noch, sich eng um die Hauptwelle zu wickeln, was zu Ausfallzeiten führt.

- Fasern (Textilien, Teppiche, PP-Raffia): Extrem hohe Zugfestigkeit. Sie brechen nicht leicht, sondern reißen. Ohne die richtige Schnittgeometrie können sie zu katastrophalen Blockaden und Motorschäden führen.

Die Lösung: Einwellen-Zerkleinerungstechnologie

Der Branchenstandard zur Bewältigung dieser Herausforderungen ist der Einwellenzerkleinerer. Im Gegensatz zu Hochgeschwindigkeitsgranulatoren arbeiten diese Maschinen mit niedrigeren Drehzahlen, jedoch mit einem hohen Drehmoment. Dabei wird ein Hydraulikzylinder eingesetzt, um das Material gegen den Rotor zu pressen.

1. Revolutionierung des Faser- und Textilrecyclings

Textilabfälle – von Altkleidern bis hin zu Industrieteppichen – erfordern eine Maschine, die zähe synthetische Fasern durchtrennen kann, ohne sie zu verheddern.

Ein spezialisierter Einwellenzerkleinerer für Textilabfälle wurde genau für diesen Zweck entwickelt.

- Anti-Verwicklungs-Design: Die Rotormesser sind so angeordnet, dass sich keine langen Fasern um die Welle wickeln können.

- Prozessintegration: Durch das Zerkleinern von Textilmassen in gleichmäßige Stücke bereitet der Shredder das Material für nachfolgende Prozesse vor und gewährleistet so eine reibungslose Materialzufuhr. Kunststoff-Pelletizer ohne Überbrückung oder Blockierung des Extruderhalses.

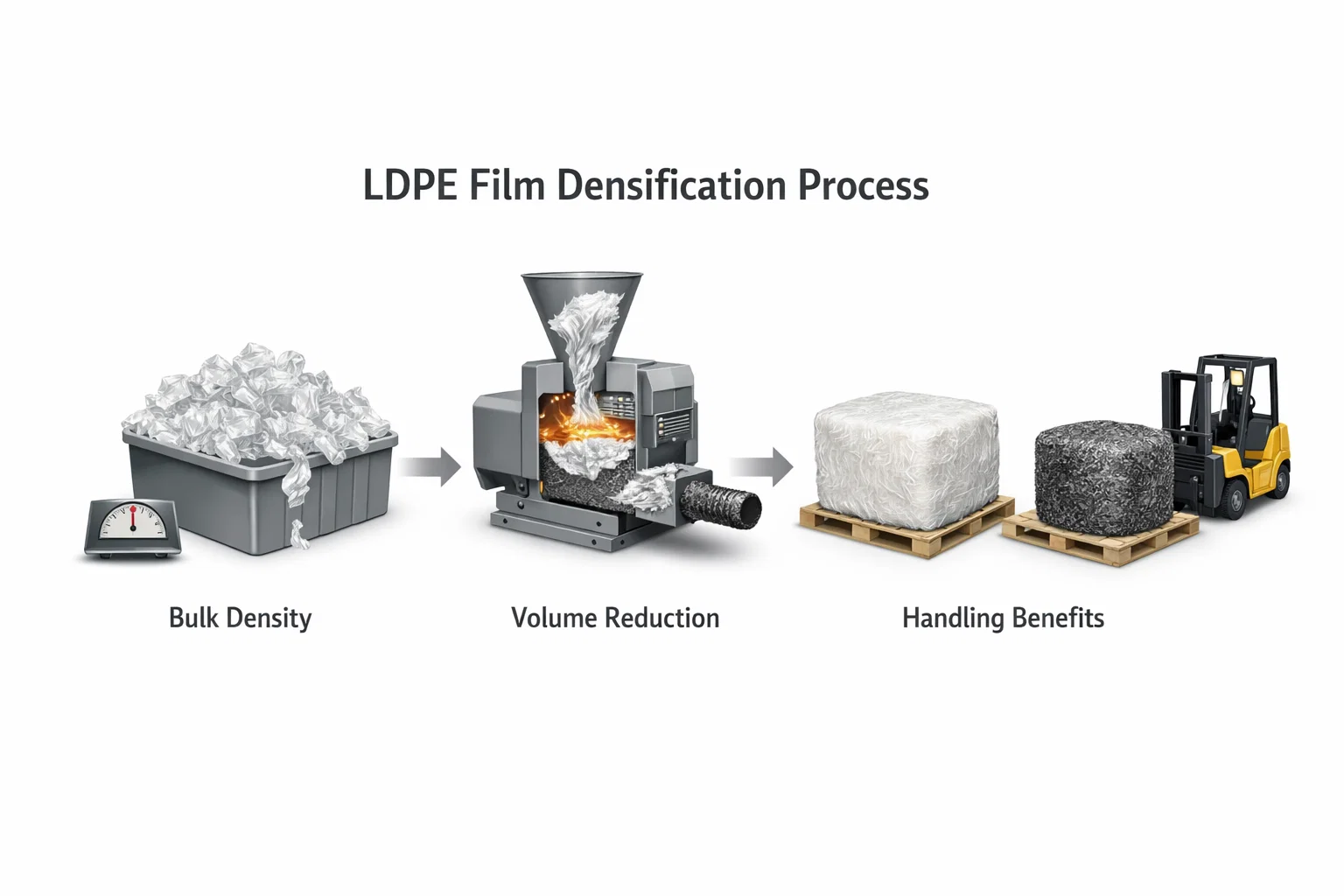

- Volumenreduzierung: Lose Textilien sind voluminös und teuer im Transport. Durch das Zerkleinern wird die Schüttdichte deutlich erhöht, was die Logistik optimiert.

2. Optimierung der Kunststofffolienverarbeitung

Bei Agrarfolien, Schrumpffolien und Post-Consumer-Beuteln fungiert der Schredder als entscheidender "erster Schritt" in der Waschanlage.

- Vorbereitung vor dem Waschen: Man kann einen ganzen Ballen Folie nicht effektiv waschen. Durch das Zerkleinern wird das Material aufgelockert und die Oberfläche vergrößert.

- Tiefenreinigung: Diese Größenreduzierung ist für den nächsten Schritt unerlässlich. Sie gewährleistet, dass Wasser und mechanische Kraft Schmutz, Sand und Verunreinigungen im nachfolgenden Schritt effektiv entfernen können. Reibungsschraubenscheibe.

- Schutz der Ausrüstung: Durch die Reduzierung des Films auf eine einheitliche Größe (z. B. 40-60 mm) wird ein Verstopfen von Pumpen und Förderbändern weiter unten in der Produktionslinie verhindert.

Nachhaltigkeit trifft auf Effizienz

Die Investition in den richtigen Aktenvernichter ist nicht nur eine betriebliche Entscheidung, sondern auch eine Nachhaltigkeitsstrategie.

- Den Kreislauf schließen: Durch die effektive Verarbeitung schwieriger Materialien wie verschmutzter Agrarfolien oder ausrangierter Teppiche können Recyclingunternehmen Ressourcen zurückgewinnen, die zuvor als "zu schwer zu recyceln" galten und auf Mülldeponien landeten.

- Energieeffizienz: Moderne Schredder mit intelligenten Steuerungssystemen (wie z. B. automatischer Rücklauf bei Überlastung) verbrauchen im Vergleich zu veralteten, kraftraubenden Zerkleinerungsmethoden weniger Energie pro Tonne.

- Hochwertigere Recyclingmaterialien: Ein sauberer, gleichmäßiger Schnitt führt zu besseren Waschergebnissen und letztendlich zu einem hochwertigeren Recyclinggranulat, das einen besseren Marktpreis erzielt.

Abschluss

Schredder sind die Torwächter der Recyclinganlage. Für feste Materialien sind sie hilfreich; für Folien und Fasern, Sie sind obligatorisch.

Ob Sie hochfestes PP-Raffia oder verschmutzte Agrarfolien verarbeiten müssen – der Unterschied zwischen einem rentablen Betrieb und einem Wartungsalbtraum liegt oft in der Wahl des richtigen Schredders. Durch den Einsatz moderner Geräte wie dem Einwellenzerkleinerer für Textilabfälle, Sie stellen sicher, dass Ihre Produktionslinie reibungslos läuft – vom ersten Schnitt über die Reibungsscheibe bis hin zur endgültigen Pelletierung.

https://www.energycle.com/plastic-shredders/textile-waste-single-shaft-shredder/

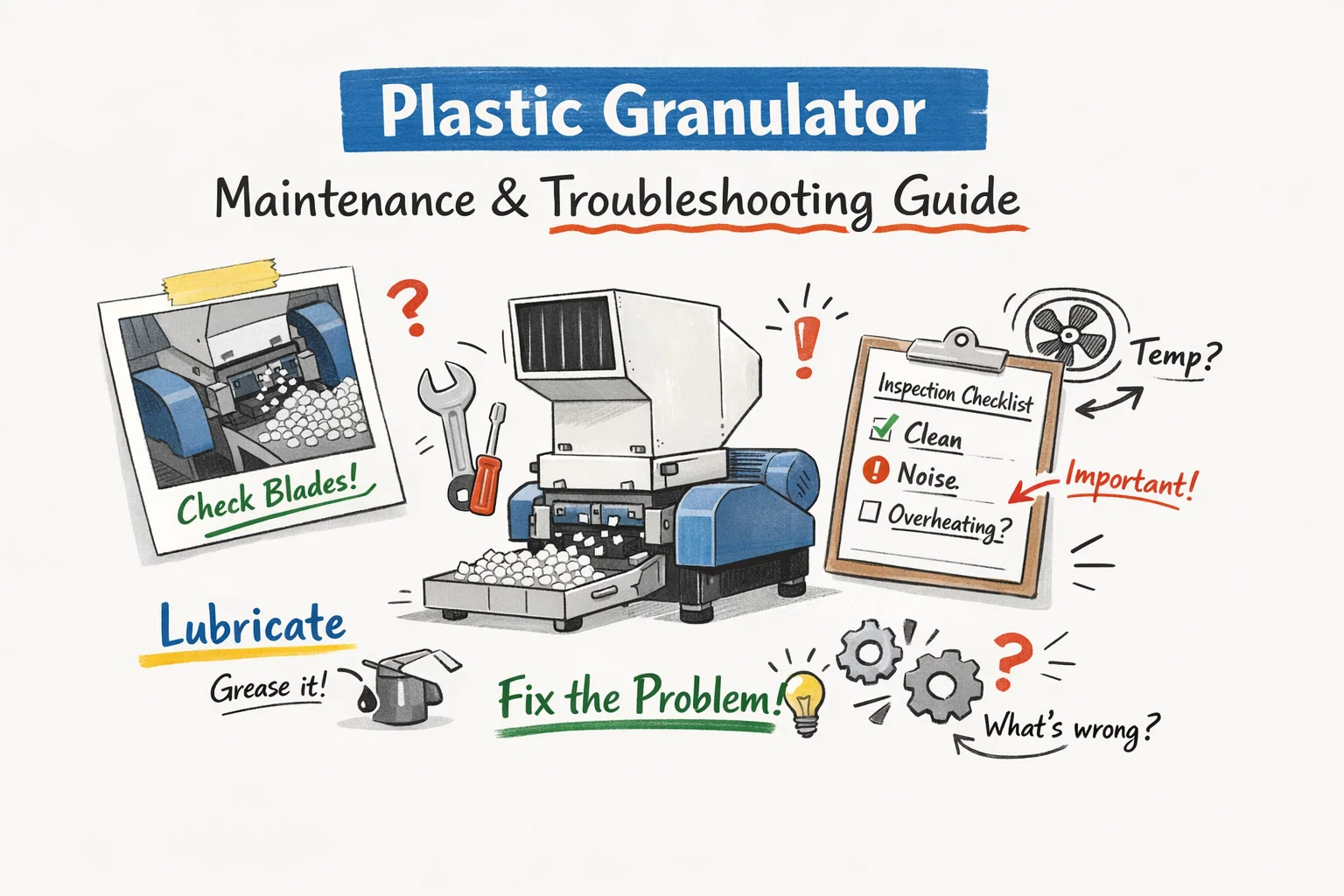

Kunststoffgranulatoren Sie sind ein wesentlicher Bestandteil des täglichen Betriebs in Recyclinganlagen und dafür verantwortlich, Kunststoffabfälle zu einheitlichem Granulat für die Weiterverarbeitung zu zerkleinern. Im Laufe der Zeit können jedoch Verschleiß, Verunreinigungen und unsachgemäße Bedienung die Leistung erheblich beeinträchtigen und Ausfallzeiten verlängern.

Dieser Leitfaden konzentriert sich auf praktische Wartungs-, Fehlerbehebungs- und Betriebsoptimierungsmethoden um Recyclinganlagen dabei zu helfen, die Nutzungsdauer zu verlängern, eine stabile Produktion aufrechtzuerhalten und ungeplante Stillstände zu reduzieren – ohne Überschneidungen mit der Auswahl oder dem Kauf von Anlagen.

Warum die ordnungsgemäße Wartung von Granulatoren in Recyclinganlagen wichtig ist

Im kontinuierlichen Recyclingprozess ist ein Kunststoffgranulator wechselnden Materialien, abrasiven Verunreinigungen und hohen mechanischen Belastungen ausgesetzt. Ohne strukturierte Wartung können selbst gut konstruierte Maschinen vorzeitigen Verschleiß und Leistungseinbußen erleiden.

Eine effektive Wartung trägt dazu bei:

- Gleichbleibende Granulatqualität auch bei langen Produktionsläufen gewährleisten

- Reduzierung unerwarteter Stillstände und Notfallreparaturen

- Verlängerung der Betriebsdauer von Verschleißteilen

- Verbesserung der Gesamteffizienz und Sicherheit der Anlage

Für Recyclinganlagen, die mit geringen Gewinnmargen arbeiten, ist vorbeugende Instandhaltung oft kostengünstiger als reaktive Reparaturen.

Wesentliche Wartungsarbeiten an Kunststoffgranulatoren

Ein strukturierter Wartungsplan gewährleistet einen stabilen Betrieb unter realen Recyclingbedingungen. Für die meisten industriellen Recyclingumgebungen werden die folgenden Maßnahmen empfohlen.

Tägliche Wartung

- Reinigen Sie den Trichter und den Zuführbereich, um Materialansammlungen zu vermeiden.

- Überprüfen Sie die Schneidkammer auf Kunststoffreste oder Verunreinigungen.

- Prüfen Sie Klingen und Siebe auf erste Anzeichen von Verschleiß.

- Schmierstellen entsprechend Betriebsstunden und Belastung prüfen.

Wöchentliche Wartung

- Saubere Luftfilter gewährleisten optimale Kühlung und Luftzirkulation.

- Antriebsriemen und Kupplungen auf Spannung und Ausrichtung prüfen.

- Prüfen Sie die elektrischen Verbindungen auf festen Sitz und Überhitzung.

- Entfernen Sie Staubablagerungen von den Außenflächen

Monatliche Wartung

- Überprüfen Sie die Rotor- und Statorausrichtung unter Betriebsbedingungen.

- Lager auf ungewöhnliche Geräusche oder Temperaturanstieg prüfen.

- Reinigen und schmieren Sie gegebenenfalls das Getriebe.

- Sicherheitssysteme wie Not-Aus-Schalter und Verriegelungen prüfen

Jährliche oder planmäßige Überholung

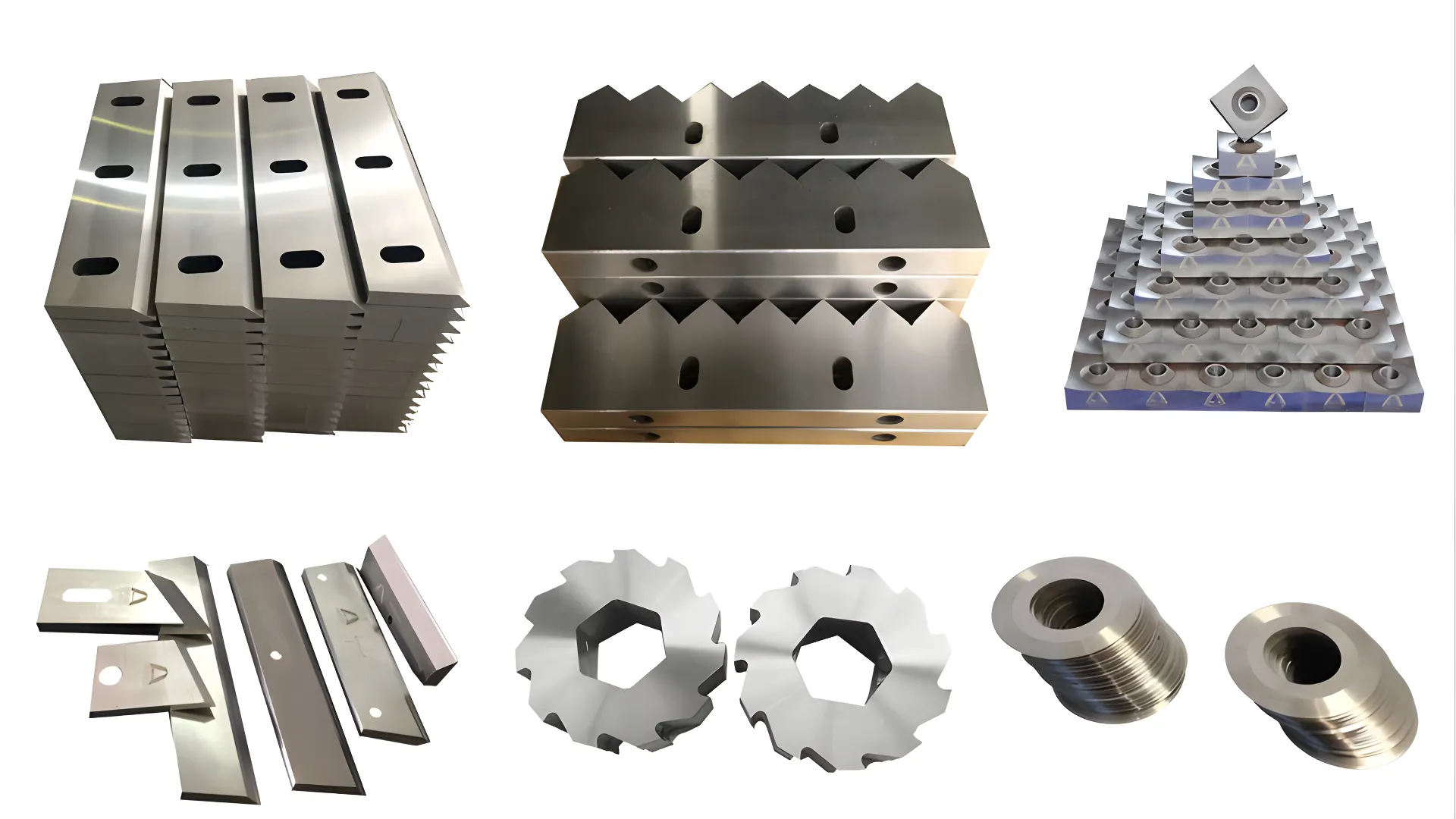

- Verschleißteile wie Klingen, Siebe und Lager sollten ausgetauscht werden.

- Bauteile auf Ermüdung oder Risse prüfen

- Überprüfen Sie die Maschinenkalibrierung, um die Schneidleistung wiederherzustellen.

- Überprüfen Sie die Betriebsprotokolle, um wiederkehrende Probleme zu identifizieren.

Häufige Probleme bei Kunststoffgranulatoren beheben

Selbst bei regelmäßiger Wartung können Betriebsstörungen auftreten. Eine frühzeitige Diagnose kann verhindern, dass kleinere Probleme sich verschlimmern.

Granulator startet nicht

- Stellen Sie sicher, dass die Stromversorgung stabil ist und die Spannung korrekt ist.

- Sicherheitsschalter und Verriegelungen prüfen

- Stellen Sie sicher, dass der Not-Aus-Schaltkreis vollständig zurückgesetzt ist.

Reduzierte Leistung oder Durchsatz

- Prüfen Sie die Schärfe der Klinge und den Schnittspalt.

- Prüfen Sie die Siebe auf Verstopfung oder Verformung.

- Prüfen Sie, ob die Korngröße des Aufgabematerials und die Durchflussrate übereinstimmen.

Uneinheitliche Korngröße

- Prüfen Sie die Klingen und Siebe auf ungleichmäßigen Verschleiß.

- Korrekte Rotor-Stator-Ausrichtung prüfen.

- Bewerten Sie die Konsistenz und den Kontaminationsgrad des Eingangsmaterials.

Übermäßiger Lärm oder Vibrationen

- Lager und Befestigungspunkte prüfen

- Prüfen Sie auf Rotorunwucht, die durch ungleichmäßigen Verschleiß verursacht wird.

- Stellen Sie sicher, dass die Maschine korrekt ausgerichtet und verankert ist.

Bewährte Verfahren zur Verbesserung der Granulatorleistung

Neben der routinemäßigen Wartung spielt die operative Disziplin eine wichtige Rolle für die langfristige Leistungsfähigkeit.

Verwenden Sie anwendungsgerechte Klingen und Siebe.

Die Auswahl von Schneidkomponenten, die auf Materialart, Dicke und Härte abgestimmt sind, reduziert Energieverbrauch und Verschleiß.

Einen stabilen Fütterungsprozess aufrechterhalten

Plötzliche Leistungsspitzen oder ungleichmäßige Zufuhr erhöhen die mechanische Belastung und beschleunigen den Verschleiß der Schaufel.

Energieverbrauchstrends überwachen

Ein allmählicher Anstieg des Stromverbrauchs deutet oft auf Verschleiß der Rotorblätter, Verstopfungen des Siebs oder Lagerprobleme hin, bevor sichtbare Symptome auftreten.

Vorausschauende Wartung anwenden, wo immer möglich

Zustandsüberwachung, Schwingungsanalyse und Temperaturüberwachung helfen, Ausfälle frühzeitig zu erkennen und ungeplante Ausfallzeiten zu reduzieren.

Wenn die Instandhaltung allein nicht mehr ausreicht

Durch Instandhaltung lässt sich die Nutzungsdauer verlängern, Kapazitätsengpässe, Materialermüdung oder sich ändernde Produktionsanforderungen können jedoch nicht auf Dauer kompensiert werden.

Wenn eine Recyclinganlage Folgendes erlebt:

- Anhaltender Durchsatzrückgang

- Zunehmende Vibrationen trotz wiederholter Reparaturen

- Struktureller Verschleiß, der die Sicherheit oder Zuverlässigkeit beeinträchtigt

Es könnte an der Zeit sein, eine Bewertung vorzunehmen. Geräteaustausch oder Systemmodernisierung.

Für Betriebe, die neue Lösungen evaluieren, können Sie hier unsere Optionen für industrielle Kunststoffgranulatoren einsehen:

https://www.energycle.com/plastic-granulators/

(Eine einzige Referenz für Bewertungszwecke; die Wartungshinweise bleiben geräteunabhängig.)

Abschluss

Die Wartung von Kunststoffgranulatoren ist mehr als nur eine Checkliste – sie ist eine Betriebsstrategie, die sich direkt auf Produktivität, Sicherheit und Kostenkontrolle in Recyclinganlagen auswirkt. Durch die Kombination von vorbeugender Wartung, strukturierter Fehlersuche und diszipliniertem Betrieb können Recyclingunternehmen eine zuverlässigere Leistung und eine längere Lebensdauer ihrer Anlagen erreichen.

Eine klare Trennung zwischen Betriebsanleitung Und Geräteauswahl gewährleistet eine bessere Entscheidungsfindung in jeder Phase des Recyclingprozesses.

Häufig gestellte Fragen (FAQ)

Wie oft sollten Granulatormesser gewartet werden?

Die Wartungsintervalle hängen von der Abrasivität des Materials, dem Verschmutzungsgrad und den Betriebsstunden ab. In industriellen Recyclingumgebungen ist eine Inspektion alle 100–300 Stunden üblich.

Sind Ersatzteile aus dem Zubehörhandel für Recyclingprozesse geeignet?

Ersatzteile aus dem Zubehörhandel können zwar kurzfristig Kosten sparen, Kompatibilität und Haltbarkeit können jedoch variieren. Unterschiedliche Teile führen oft zu schnellerem Verschleiß und instabilem Betrieb.

Wie sollten die Bediener für die tägliche Wartung geschult werden?

Die Bediener sollten eine dokumentierte Checkliste für Reinigung, Inspektion und Sicherheitsprüfung befolgen. Praktische Schulung und Aufsicht sind für die Einhaltung der Standards unerlässlich.

Was ist im Falle eines plötzlichen Ausfalls zu tun?

Die Maschine sicher abschalten, die Stromzufuhr unterbrechen und das Problem systematisch analysieren. Wiederholte Ausfälle deuten in der Regel auf tieferliegende mechanische oder betriebliche Probleme hin.

Unser Kunststofffolien-Schraubpresse (Quetsch-/Verdichtungsanlagen) sind vorwiegend für Europa und Nordamerika bestimmt, wo Recyclingunternehmen mit ähnlichen Herausforderungen konfrontiert sind: höhere Lohnkosten, strengere Qualitätsanforderungen und steigende Energiepreise. Käufer in diesen Regionen legen typischerweise Wert auf Anlagen, die folgende Vorteile bieten:

- Stabile Feuchtigkeitsreduzierung für gewaschene Filme (zur Verbesserung der Extrusionsstabilität und der Pelletqualität)

- Geringere Betriebskosten durch effiziente Entwässerung und Wärmenutzung

- Gleichbleibender Durchsatz mit minimalem Bedienereingriff

- Zuverlässige Leistung auch bei anspruchsvollen Rohstoffen (bedruckter Film, Mischfilm, nasser oder verunreinigter Film)

Europa (EU/UK): Die Nachfrage ist am stärksten in Ländern mit ausgereifter Recyclinginfrastruktur und ambitionierten Zielen für das Verpackungsrecycling – insbesondere in Deutschland, Italien, Frankreich, Spanien, den Niederlanden, Polen und Großbritannien. Diese Märkte erfordern oft eine strengere Kontrolle von Verunreinigungen und Feuchtigkeit, um die Qualitätsanforderungen an das Pellet in den nachgelagerten Verarbeitungsbetrieben zu erfüllen.

Nordamerika (USA/Kanada): Viele Anlagen erweitern ihre Kapazitäten, um mehr Altfolien und Industriefolien zu verarbeiten. Zu den wichtigsten Prioritäten gehören Automatisierung, Anlagenverfügbarkeit und die Reduzierung des Energieverbrauchs pro Tonne bei gleichzeitig gleichbleibender Pelletqualität für hochwertige Anwendungen.

Was ist ein Kunststofffolien-Schneckenpresssystem (Quetsch-/Verdichtungssystem)?

Ein Kunststofffolien-Schraubenpresssystem ist ein mechanische Entwässerung + Verdichtungsstufe Wird nach dem Waschen des Films verwendet. Es entfernt überschüssiges Wasser vom gewaschenen Film. Kompression und Scherung, Umwandlung von nassem, flauschigem Film in einen heißer, verdichteter, feuchtigkeitsarmer Output das eine zuverlässigere Zuführung in Extruder und Granulator ermöglicht.

In einer typischen Filmproduktionslinie befindet sich die Schraubenpresse nach:

Sortieren → Zerkleinern → Waschen → (Reibungs-/Schwimmspülung) → mechanische Entwässerung → Schneckenpresse (Quetscher) → Extrusion → Granulieren

Im Vergleich zu einfachen Zentrifugen oder Presswalzen kann eine gut konstruierte Schneckenpresse Folgendes leisten:

- Niedrigere und stabilere Feuchtigkeit

- Heißes, verdichtetes Ausgangsmaterial (verdichteter Film)

- Verringerter Lufteinschluss vor der Extrusion

- Bessere Schnurstabilität unter realen Rohstoffvariationen

Warum die Feuchtigkeitskontrolle Kosten und Pelletqualität direkt beeinflusst

Feuchtigkeit ist nicht einfach nur “Wasser”. Beim Folienrecycling treten Feuchtigkeitsprobleme oft zusammen mit Folgendem auf:

- Waschmittelrückstände, Feinstverunreinigungen und organische Spuren

- flüchtige Bestandteile der Tinte (gedruckter Film)

- ungleichmäßige Trocknung aufgrund von Schichtdickenvariationen

- Wasser, das in Falten und mehrschichtigen Strukturen eingeschlossen ist

Bei instabiler Feuchtigkeit muss der Extruder dagegen ankämpfen. Das Ergebnis ist jedem Folienrecycler bekannt:

- Blasen/Hohlräume in den Pellets

- instabiler Schmelzdruck

- häufige Siebwechsel (Verunreinigungen + Gele)

- geringerer Durchsatz oder erzwungene Verlangsamungen

- höherer Energieverbrauch pro Tonne

- mehr Ausschuss und mehr Eingriffe des Bedieners

Eine Schneckenpresse löst das Problem früher – bevor der Extruder zu einem “Trockner” wird.”

Hauptzielgruppe: Für wen dieses System entwickelt wurde

Dieses System ist für Anlagen konzipiert, die gewaschene Kunststofffolie in ein stabiles, hochwertiges Ausgangsmaterial für Extrusion und Granulierung umwandeln müssen. Zu den typischen Kunden zählen:

1) Anlagen zum Recycling von Kunststofffolien (Verbraucher- und Industrieabfälle)

- Bearbeitung durch Bediener LDPE/LLDPE-Folie, Stretchfolie, Verpackungsfolie, Einkaufstüten, Agrarfolie und gemischte flexible Kunststoffe

- Werke mit vollständiger Produktpalette: Sortieren → Zerkleinern → Waschen → Entwässern/Auspressen → Extrudieren → Granulieren

2) Pelletier-/Granulieranlagen

- Hersteller rüsten von einfacher Entwässerung auf bessere Feuchtigkeitskontrolle um, um die Schmelzstabilität zu verbessern.

- Pflanzen, die auf Folgendes abzielen Höhere Pelletkonsistenz, weniger Blasen/Hohlräume und reduzierter Geruch verursacht durch Restfeuchtigkeit und flüchtige Stoffe

3) Wäschereianlagenintegratoren & EPC-/Schlüsselfertiganlagenbauer

- Ingenieurbüros und Systemintegratoren, die komplette Folienrecyclinganlagen liefern und eine zuverlässige Quetsch-/Verdichtungsstufe benötigen, um den ROI des Gesamtsystems zu optimieren.

4) Abfallwirtschafts- und Sortieranlagenbetreiber expandieren in das Folienrecycling

- Betreiber rüsten ihre Anlagen zum Folienrecycling auf, um mehr Wert aus flexiblen Verpackungsströmen zu gewinnen.

5) Kunststoffverarbeiter und -hersteller mit internem Recycling

- Fabriken, die Filmabfälle aus eigener Produktion wiederverwerten und ihre Entsorgungskosten senken sowie die Wiederaufbereitungseffizienz verbessern wollen.

Typische Entscheidungsträger

In Europa und Nordamerika werden Kaufentscheidungen üblicherweise von folgenden Faktoren bestimmt:

- Anlagenbesitzer / Geschäftsführer (ROI und Kapazität)

- Betriebsleiter (Verfügbarkeit, Personalbesetzung, Stabilität)

- Verfahrenstechniker (Feuchtigkeitsvorgaben, Pelletqualität, Linienintegration)

- Instandhaltungsmanager (Wartungsfähigkeit und Verschleißteile)

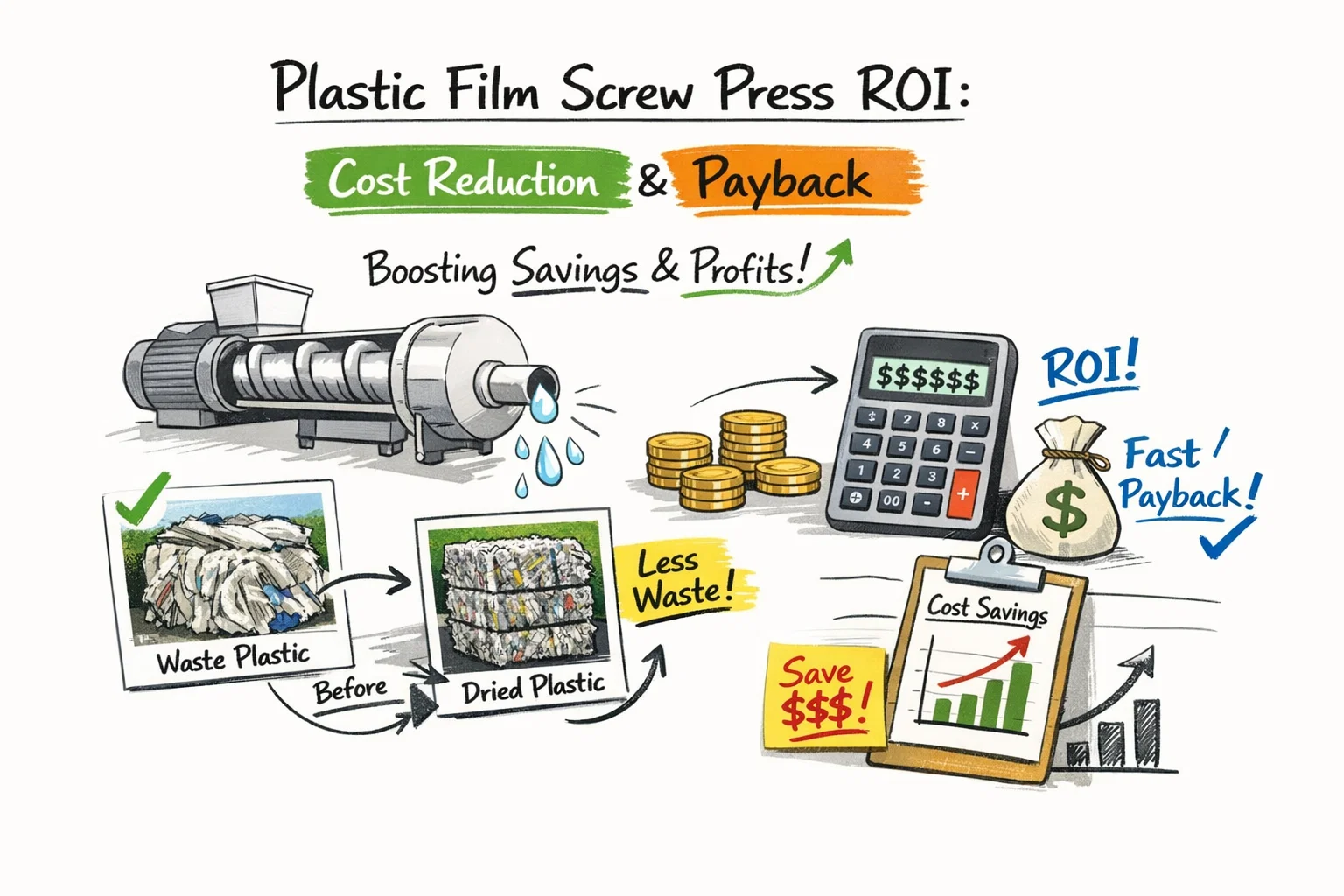

Kostenreduzierung: Wo die Schraubenpresse einen echten ROI liefert

Bei der Bewertung eines Schneckenpressensystems in Produktionsbetrieben ist die wichtigste Frage nicht “Wie funktioniert es?”, sondern wo das Geld gespart wird. Im realen Betrieb ergeben sich Einsparungen typischerweise aus fünf Bereichen:

1) Höherer Durchsatz und weniger Verlangsamungen

Nassfilm verhält sich unbeständig und kann die Zuführungen überlasten, Brückenbildung verursachen oder den Extruder zu einer niedrigeren Drehzahl zwingen. Eine Schneckenpresse gibt Folgendes aus: dichtes, warmes, gleichmäßiges Material, wodurch die Zuführung verbessert und die Extrusion stabilisiert wird.

Praktische Auswirkungen:

- stabilerer Schmelzdruck

- weniger Notstopps

- verbesserte Laufzeit pro Schicht

- Zielvorgabe leichter einhalten

2) Geringerer Energieverbrauch pro Tonne

Wenn Feuchtigkeit in den Extruder eindringt, wird Energie verbraucht für:

- verdunstendes Wasser

- Ausgleich der Schmelzinstabilität

- Vakuumsysteme härter (und länger) betreiben.

Durch die mechanische Wasserentfernung (die im Allgemeinen günstiger ist als die thermische Entfernung) wird der Energieaufwand in den nachgelagerten Bereichen reduziert.

Was sich verbessert:

- niedrigerer kWh/Tonne-Wert für Extrusion

- weniger Temperaturschocks und geringere Temperaturschwankungen

- reduzierter Heizbedarf aufgrund wärmeren, verdichteten Rohstoffs

3) Geringere Arbeitskosten durch reduzierte Interventionen

Viele Filmproduktionslinien setzen auf das Geschick des Bedieners, um “Schwankungen entgegenzuwirken”. Eine Schraubenpresse reduziert die Schwankungen selbst.

Wo die Arbeitskosten sinken:

- Weniger Anpassungen an den Zuführungs- und Extrudereinstellungen erforderlich

- Weniger Stillstände für Reinigung und Fehlerbehebung

- weniger Zeitaufwand für die Handhabung von flockigem, nassem Film (manuelles Entstopfen, Entfernen von Brücken usw.).

4) Bessere Pelletqualität (Höherer Verkaufspreis oder breiterer Käuferkreis)

Feuchtigkeit und flüchtige Bestandteile tragen maßgeblich dazu bei:

- Blasen in Pellets

- Geruchs- und dampfbedingte Defekte

- schlechte Oberflächenbeschaffenheit

- instabiles MFI-Verhalten in der nachgelagerten Verarbeitung

Eine bessere Feuchtigkeitsregulierung ermöglicht Folgendes:

- einheitlicheres Pellet-Erscheinungsbild

- weniger Kundenbeschwerden/Rückgaben

- Zugang zu höherwertigen Anwendungen (abhängig vom Rohstoff und der Gesamtanlagenkonstruktion)

5) Reduzierter Ausschuss, weniger Ausfallzeiten und geringerer Wartungsaufwand

Instabile Nassfütterung erhöht oft:

- Siebpaket-Last- und Änderungsfrequenz

- Kontaminationsübertragung

- Verschleiß an Schrauben, Heizelementen und nachgeschalteten Komponenten

- “Versteckte Ausfallzeiten” aufgrund ständiger Mikrostopps und Neustartzyklen

Eine stabile, verdichtete Zufuhr reduziert die Betriebsbelastung entlang der gesamten Produktionslinie.

ROI-Analyse: So berechnen Sie die Amortisationszeit in einer Folienrecyclinganlage

Ein einfaches und praktisches ROI-Modell umfasst vier messbare Elemente:

- Zusätzliche Produktion (Tonnen/Jahr) von verbesserter Verfügbarkeit und stabilem Durchsatz

- Energieeinsparungen (kWh/Tonne oder $/Tonne) durch geringere Trocknungsbelastung und stabile Extrusion

- Arbeitsersparnis (1 TP8T/Jahr) durch weniger Eingriffe und weniger Betriebsunterbrechungen

- Qualitätssteigerung ($/Tonne) Wenn verbesserte Pellets bessere Preise erzielen oder eine breitere Kundenakzeptanz finden

ROI-Formel (vereinfacht)

Jährlicher Nutzen = (Zusätzliche Tonnen × Marge pro Tonne) + Energieeinsparungen + Arbeitsersparnis + Qualitätssteigerung

Amortisationszeit = Systeminvestition / Jährlicher Nutzen

Hinweis: Bei der “Marge pro Tonne” handelt es sich um Ihre tatsächliche Marge (Verkaufspreis abzüglich variabler Kosten), nicht um den Umsatz.

Beispielhaftes ROI-Szenario (illustrativ)

Um die Mathematik zu verdeutlichen, hier ist ein illustrativ Beispiel (die Zahlen variieren je nach Werk und Region):

Pflanzenbedingungen:

- Anlage zur Aufbereitung von gewaschenem Film mit einer Jahreskapazität von 3.000–6.000 Tonnen.

- Die derzeitigen Feuchtigkeitsschwankungen verursachen häufige Produktionsausfälle und Qualitätsprobleme.

Konservative Verbesserungsannahmen nach der Modernisierung der Schraubenpresse:

- +8% effektive Verbesserung der Verfügbarkeit/des Durchsatzes

- -10% Extrusionsenergieverbrauch pro Tonne

- -1 Bedienerstunde/Tag weniger Eingriffsaufwand (oder gleichwertige Kostenreduzierung)

- reduzierter Ausschuss und Nacharbeit

Selbst unter konservativen Annahmen wird die Rentabilität vieler Anlagen maßgeblich durch Folgendes bestimmt:

- mehr verkaufsfähige Produktion (Tonnen)

- weniger Spielunterbrechungen

- niedrigere Gesamtbetriebskosten pro Tonne

Wenn Sie möchten, können wir eins bauen benutzerdefiniertes ROI-Blatt Verwenden Sie Ihre tatsächlichen Zahlen (Kapazität, kWh-Preis, Lohnsatz und Ausschussquote), damit die Amortisationsberechnung zu Ihrer Zielgruppe passt.

Wichtigste Leistungsziele, die Käufer fordern

Wenn Käufer in der EU/Großbritannien und Nordamerika Schraubpressensysteme bewerten, fragen sie in der Regel:

- Feuchtigkeitskonsistenz (nicht nur die durchschnittliche Feuchtigkeit)

- Durchsatzstabilität unter gemischtem Film und gedrucktem Film

- Kosten der Verschleißteile und Wechselintervalle

- Leichter Zugang für Reinigung und Wartung

- Integrationskompatibilität mit bestehenden Wasch- und Extrusionsanlagen

- Automatisierungsfunktionen (Laststeuerung, Drehmomentschutz, Alarmlogik)

Wie sich das System in eine Wasch- und Pelletieranlage integriert

Ein Schraubenpressensystem ist am effektivsten, wenn es in einen stabilen Produktionsfluss integriert ist:

- Stabile Fütterung von der Wäscheleine (konsequentes Waschen und mechanische Entwässerung im vorgelagerten Bereich)

- Schneckenpressenentwässerung + Verdichtung (mechanische Wasserentfernung und Verdichtung)

- Kontrollierte Entladung (dichter, warmer Ausstoß direkt zum Extruder-Zuführsystem)

- Extrusion optimiert für Schmelzqualität, nicht gezwungen, als Trockner zu fungieren

Bei vielen Upgrades wird die Schneckenpresse zum “Stabilisator”, der es dem Extruder ermöglicht, näher an seine geplante Kapazität heranzufahren.

Häufig gestellte Fragen (FAQ)

Frage 1: Kann die Schraubenpresse bedruckte und gemischte Folien verarbeiten?

Ja. Bedruckte und gemischte Folien weisen typischerweise einen höheren Anteil an flüchtigen Bestandteilen und größere Schwankungen auf. Die Schneckenpresse trägt zur Stabilisierung der Feuchtigkeit und der Materialdichte bei, wodurch Prozessschwankungen in nachgelagerten Prozessschritten reduziert werden.

Frage 2: Ersetzt es einen Wäschetrockner?

In vielen Filmlinien wird die Schraubenpresse verwendet reduziert oder vereinfacht Trocknungsbedarf. Ob es die thermische Trocknung vollständig ersetzen kann, hängt von Folgendem ab:

- Ihr Feuchtigkeitsziel für die Extrusion

- Art des Ausgangsmaterials und Kontamination

- Ihr gesamtes Liniendesign

Frage 3: Ist es für die Bediener schwierig zu handhaben?

Nein. Die meisten Systeme sind für eine unkomplizierte Bedienung ausgelegt mit:

- Lastregelung und Drehmomentschutz

- Alarme und Verriegelungen klarstellen

- stabile Leistung, die den manuellen Eingriff reduziert

Frage 4: Was ist für den ROI wichtiger – Feuchtigkeitsreduzierung oder Verdichtung?

Beides ist wichtig. Die Reduzierung der Feuchtigkeit verbessert die Schmelzstabilität, während die Verdichtung die Materialzufuhr und den Durchsatz verbessert. Die beste Rentabilität wird üblicherweise durch die Kombination beider Faktoren erzielt:

- Stabile Feuchtigkeit + stabile Futterdichte + weniger Stopps

Sind Sie bereit, Kosten zu senken und die Pelletstabilität zu verbessern?

Wenn Ihre Anlage gewaschene Filme verarbeitet und Sie mit folgenden Problemen zu kämpfen haben:

- instabile Extrusion

- Blasen/Hohlräume

- Ausfallzeiten durch Nassfutter

- hohe Betriebskosten pro Tonne

Eine Kunststofffolien-Schneckenpresse ist oft eine der schnellsten Möglichkeiten, den ROI zu verbessern, da sie die teuerste nachgelagerte Stufe – Extrusion und Granulierung – stabilisiert.

Kontaktieren Sie uns Bitte teilen Sie uns Ihre Materialart (LDPE/LLDPE/Mischfolie), die gewünschte Kapazität und den aktuellen Feuchtigkeitsbereich mit. Wir empfehlen Ihnen die passende Konfiguration und helfen Ihnen, die Rentabilität anhand Ihrer lokalen Strom- und Lohnkosten zu berechnen.

Dieser auf Käufer ausgerichtete Leitfaden erklärt, wann ein Kunststoffbrecher nicht eingesetzt werden sollte, wie man anhand der Materiallänge und realistischer Kapazitätsgrenzen zwischen einem Brecher und einem Schredder wählt und welche “Hochleistungs”-Optionen oft unnötig sind.

Dieser Artikel richtet sich an Fachleute im Recyclingbereich und hilft Ihnen, kostspielige Fehler zu vermeiden und die richtige Zerkleinerungslösung für Ihre Recyclinganlage auszuwählen.