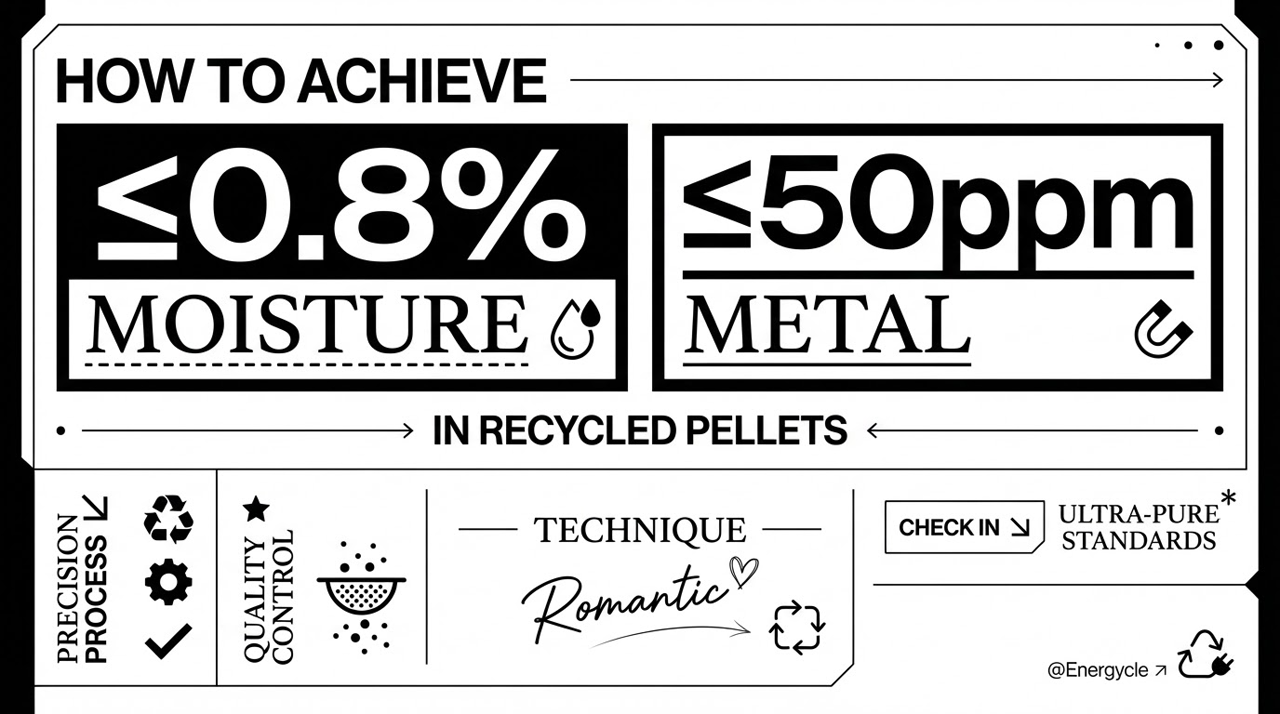

You run a recycling plant. You wash film or flakes, and you need the final pellets to hit two tight targets: moisture at 0.8 percent or lower and metal contamination at 50 parts per million or less. Meet those numbers and your pellets sell for more, run smoothly in customer extruders, and avoid rejects. Miss them and you face bubbles, weak material, screw wear, and lost sales.

At Energycle we build and tune complete lines every week for recyclers who face exactly this challenge. We rely on a proven multi-stage drying approach that handles the heavy lifting on moisture while you add targeted separation steps for metal. Follow the process below and you will reach those specs with consistent, repeatable results.

Why These Exact Targets Matter for Your Pellets

Moisture above 0.8 percent turns into steam the moment material enters a hot extruder. You see voids, surface splay, reduced melt strength, and lower output. For PE and PP film—the most common recycled streams—surface water left after washing causes the biggest headaches.

Metal above 50 ppm does its own damage. Ferrous and non-ferrous particles scratch screws and barrels, create black specks in the final product, and fail buyer audits for food-contact or high-end applications. Industry buyers routinely list metal below 50 ppm as a pass/fail criterion on flake and pellet specs.

Hit both targets and you produce dense, uniform pellets that feed reliably, extrude cleanly, and command premium pricing.

The Multi-Stage Drying Systems That Get You to ≤0.8% Moisture

You cannot reach 0.8 percent moisture with a single piece of equipment. You remove the bulk water mechanically first, then squeeze or press for deeper reduction, and finally polish with controlled hot air. Here is the exact sequence we install for film lines.

Step 1: High-Speed Centrifugal Dewatering Removes the Bulk Water

Feed your washed film flakes straight into a mașină centrifugă de deshidratare a foliei de plastic de mare viteză. The rotor spins at up to 1,500 RPM and generates strong G-force that flings water through a perforated screen. You drop from 10–35 percent incoming moisture down to 3–5 percent in seconds.

This step uses no heat, so you save energy and protect polymer quality. The non-clog rotor design handles lightweight film, woven bags, and even abrasive agricultural mulch without downtime. Choose the model that matches your throughput—400 to 2,000 kg/h capacities cover most plants.

Step 2: Plastic Film Squeezing Machine Handles the Tough Residual Moisture

For PE and PP film and woven material, send the output from the centrifugal dryer into a mașină de stoarcere a foliei de plastic. The high-torque screw presses the flakes through a perforated barrel, mechanically wringing out trapped water while frictional heat gently densifies the fluffy material into small, uniform lumps.

You reach 1–5 percent moisture (often 1–3 percent in practice) and create a stable feed for your pelletizer. The densified lumps prevent bridging and surging in the extruder, which boosts throughput by up to 30 percent in real lines. Models range from 200 kg/h up to 1,000 kg/h.

Step 3: Pipeline Hot Air Drying System Delivers the Final ≤0.8%

Finish the job with a sistem de uscare cu aer cald pentru conducte. High-velocity hot air (typically 60–80 °C for PE/PP) travels through a 30-meter insulated pipeline and contacts every particle. The 72 kW heater and powerful fan ensure uniform drying without hotspots that could degrade the plastic.

You exit at less than 2 percent and, with proper airflow and residence time, consistently hit 0.8 percent or lower. The insulated design cuts energy use by up to 20 percent compared with open systems, and the stainless-steel contact parts stand up to 24/7 operation.

Run these three stages in series—centrifugal first, squeezer for film, hot air last—and you lock in the moisture target every shift.

How to Keep Metal at or Below 50 ppm

Moisture control alone does not solve metal. You remove it at multiple points so nothing reaches the final pellets.

- Place strong magnetic separators right after shredding or granulation to catch ferrous metals from equipment wear or input waste.

- Add eddy current separators downstream of the sink-float tank to pull out aluminum, copper, and other non-ferrous pieces.

- Install inline metal detectors just before the pelletizing extruder. Set sensitivity to reject anything above your 50 ppm threshold; the detector diverts contaminated flow automatically.

- Equip your extruder with automatic screen changers and melt filters (80–120 micron) to catch any microscopic particles that slip through.

Combine these steps with clean input sorting and you stay well under 50 ppm. Many plants we work with report final metal levels of 10–30 ppm when they follow this layered approach.

Your Practical Implementation Checklist

- Measure your current washing-line output moisture and metal levels with a handheld moisture balance and lab samples.

- Size each dryer to your exact throughput so you never bottleneck the line.

- Install the centrifugal dewatering machine immediately after the last washer.

- Add the squeezing machine if you process film or bags.

- Connect the pipeline hot air drying system right before the pelletizer or compactor.

- Place metal separators at the three key points listed above.

- Calibrate temperatures, airflow, and screw speeds during the first week and log results.

- Run daily moisture tests on output pellets and weekly metal lab checks until you confirm stability.

Keep the entire drying section enclosed and ventilated to stop re-absorption from ambient humidity.

How You Verify the Results

Use a calibrated infrared moisture analyzer or Karl Fischer titration unit for quick, accurate checks on pellets—target ≤0.8 percent. For metal, send composite samples to a third-party lab for ICP-OES analysis or rely on your inline detector logs. Record every batch so you can show customers exact data.

What You Gain When You Hit the Targets

Plants that reach these numbers report 15–25 percent higher pellet selling prices, 10–20 percent more stable extruder throughput, and far fewer customer complaints. You also reduce scrap rates and energy costs because the material feeds cleanly and requires less power to melt.

We have installed these exact drying combinations for recyclers processing agricultural film, stretch wrap, and post-consumer bags. In every case, the combination of centrifugal dewatering, squeezing where needed, and pipeline hot air drying delivered the 0.8 percent moisture target while the separation steps kept metal well below 50 ppm.

Start with your current line layout and material type. Tell us your hourly tonnage and incoming moisture range and we will recommend the precise models and layout that will get you there. You focus on running the plant; we make sure the pellets meet the specs your customers demand.

Ready to produce pellets that consistently hit ≤0.8% moisture and ≤50ppm metal? Contact the Energycle team today and let us design the upgrade that pays for itself through higher-value output.