Introducere

Alegerea sistemului de peletizare potrivit pentru linia dvs. de producție PET este o decizie crucială care poate avea un impact semnificativ asupra eficienței operaționale, calității produsului și costurilor pe termen lung. Printre cele mai utilizate metode se numără peletizare cu inel de apă şi peletizare a firelor răcite cu apăFiecare sistem are avantajele sale și este adaptat la diferite obiective de producție și constrângeri ale instalațiilor.

La Mașină Energycle, ne specializăm în a ajuta producătorii din SUA și Europa să își optimizeze liniile de reciclare și procesare a polimerilor. Dacă explorați sisteme concepute pentru fulgi de PET, vizitați pagina noastră Peletizator cu șurub unic din fulgi de plastic PET pagină pentru a afla mai multe despre soluțiile de înaltă eficiență cu șurub unic.

Acest ghid detaliat vă va prezenta o comparație echilibrată a ambelor tehnologii de peletizare, ajutându-vă să determinați cea mai potrivită pentru nevoile dumneavoastră specifice.

Înțelegerea elementelor de bază ale peletizării PET

Peletizarea PET-ului (polietilen tereftalat) este un proces ulterioar în linia de reciclare a plasticului sau a polimerilor virgini, unde PET-ul topit este transformat în pelete solide. Aceste pelete sunt mai ușor de manipulat, transportat și reutilizat în procesele de fabricație.

Cele două sisteme dominante sunt:

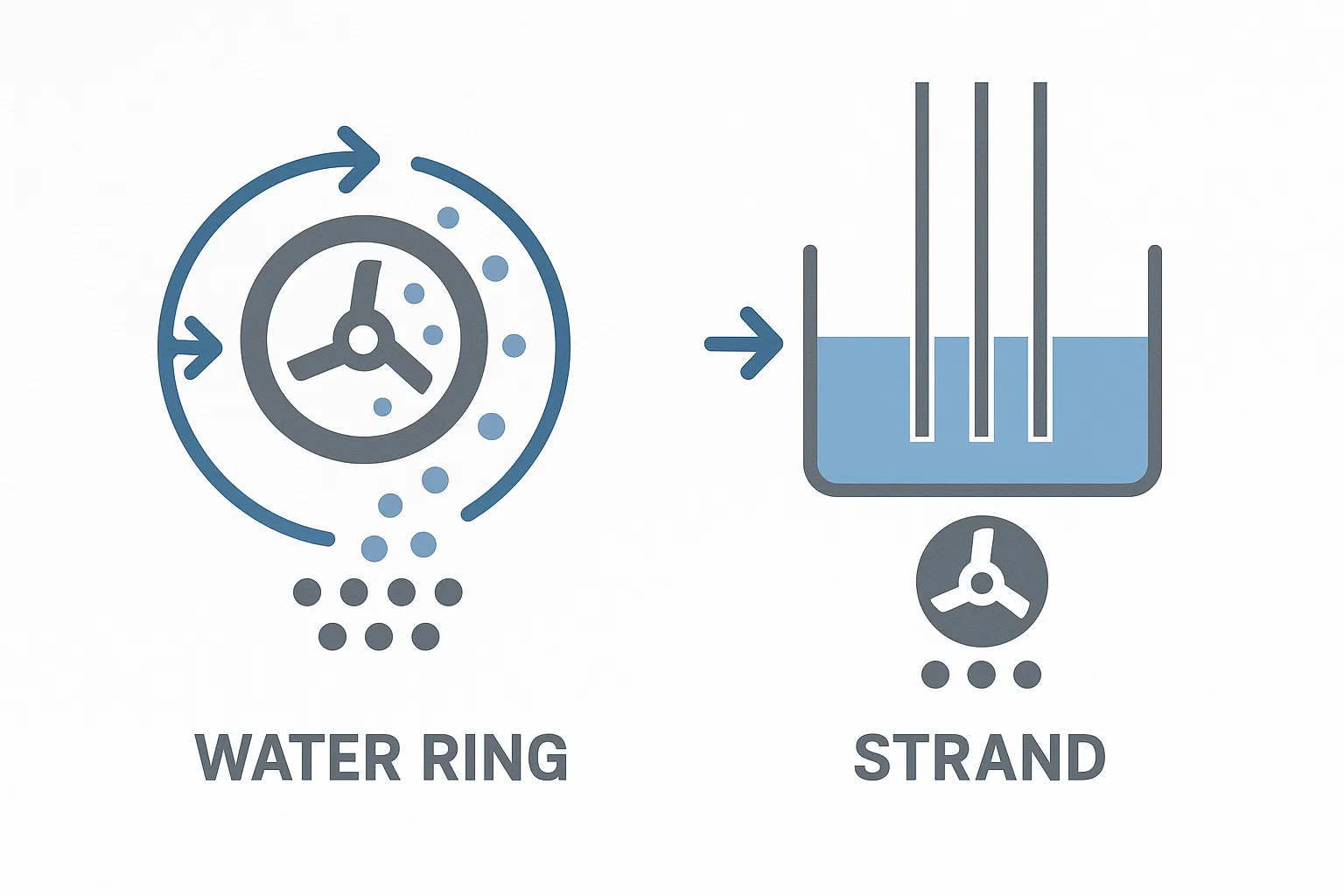

- Peletizarea cu inel de apăPET-ul topit este extrudat printr-o matriță și tăiat imediat în pelete prin lame rotative. Peletele sunt apoi răcite într-un inel de apă circulantă.

- Peletizarea firelor răcite cu apăPET-ul topit este extrudat sub formă de fire continue, răcit într-o baie de apă și apoi tăiat în pelete.

Pentru fulgi de sticle PET, Mașină Energycle oferă, de asemenea sisteme specializate de peletizare Proiectat pentru un randament stabil și o calitate constantă a peleților.

Amprentă și cerințe de spațiu

Peletizarea cu inel de apă

Sistemele cu inel de apă sunt compacte și extrem de integrate. Acestea ocupă mai puțin spațiu pe podea, ceea ce le face ideale pentru instalațiile unde spațiul este prețios. Toate componentele majore, inclusiv tăietorul, inelul de apă și uscătorul, sunt de obicei asamblate ca o singură unitate.

Peletizarea firelor răcite cu apă

Sistemele cu fire de oțel necesită o suprafață mai mare din cauza jgheaburilor de apă de răcire și a amplasării firelor de oțel. Această configurație poate reprezenta limitări pentru fabricile mai mici sau pentru instalațiile de modernizare. Cu toate acestea, poate oferi mai multă flexibilitate în gestionarea diferitelor vâscozități ale materialelor.

Mașină Energycle recomandă evaluarea configurației instalației dumneavoastră pentru a înțelege ce sistem se potrivește cel mai bine amprentei dumneavoastră operaționale.

Automatizare și ușurință în utilizare

Peletizarea cu inel de apă

Sistemele cu inele de apă sunt în general mai automatizate și necesită mai puțină intervenție din partea operatorului. Presiunea lamei este adesea autoreglabilă, iar uscarea peleților este integrată, reducând necesitatea manipulării manuale.

Peletizarea firelor răcite cu apă

Sistemele de peletizare a firelor necesită mai multă forță de muncă. Operatorii trebuie să asigure o aliniere corectă a firelor și un debit constant de apă. Pornirea și oprirea necesită mai multă atenție și îndemânare.

Pentru producătorii care doresc să reducă costurile cu forța de muncă și să îmbunătățească consecvența, Mașină Energycle sugerează luarea în considerare a peletizării cu inel de apă pentru beneficiile sale de automatizare.

Forma și calitatea peleților

Peletizarea cu inel de apă

Produce peleți rotunjiți și uniformi, cu un finisaj lucios. Aceștia sunt deosebit de benefici pentru aplicații de înaltă calitate, unde estetica și fluiditatea peleților contează.

Peletizarea firelor răcite cu apă

Peleții sunt de obicei cilindrici cu capete ușor neregulate. Deși sunt funcționali pentru majoritatea utilizărilor din aval, este posibil să nu îndeplinească standardele estetice sau de procesare premium.

Dacă uniformitatea și aspectul peleților sunt esențiale pentru aplicația dumneavoastră, Mașină Energycle recomandă sistemele cu inele de apă.

Tabel comparativ rezumativ

| Caracteristică | Peletizarea cu inel de apă | Peletizarea firelor răcite cu apă |

|---|---|---|

| Amprentă | Compact | Este nevoie de spațiu mai mare |

| Automatizare | Ridicat | Mediu spre scăzut |

| Forma peletei | Rotund, uniform | Cilindrică, variabilă |

| Întreţinere | Moderat | Risc mai mic de uzură |

| Cost inițial | Superior | Inferior |

| Costuri de operare | Pe termen lung mai mic | Costul mai mare al forței de muncă |

| Randament | Ridicat | Mediu |

| Flexibilitatea materialelor | Mediu | Ridicat |

Întrebări frecvente

Î1: Pot să adaptez un peletizator cu inel de apă la linia mea PET existentă?

Da, mulți dintre Mașină EnergycleModelele sunt proiectate pentru modernizare, dar parametrii de amplasare și extrudare trebuie evaluați.

Î2: Ce peletizator este mai potrivit pentru PET reciclat?

Peletizarea cu inel de apă este adesea mai bună pentru PET-ul reciclat datorită randamentului mai mare și integrării superioare a uscării.

Î3: Există sisteme hibride disponibile?

Unele sisteme oferă opțiuni modulare care combină caracteristicile ambelor tipuri de peletizare. Mașină Energycle poate oferi consultanță pentru soluții personalizate.

Î4: Care este perioada de recuperare obișnuită pentru modernizarea la un sistem cu inele de apă?

În funcție de producție și de costurile cu forța de muncă, perioada de recuperare a investiției poate varia între 1 și 3 ani.

Faceți alegerea potrivită pentru linia dvs. de producție

Alegerea sistemului de peletizare potrivit poate modela viitorul liniei dumneavoastră de producție PET. Permiteți-ne Mașină Energycle te ajută să faci o investiție informată și pregătită pentru viitor.

Vizitați-ne Peletizator cu șurub unic din fulgi de plastic PET sau contactați-ne astăzi pentru a discuta despre nevoile dumneavoastră.

Solicitați o ofertă personalizată