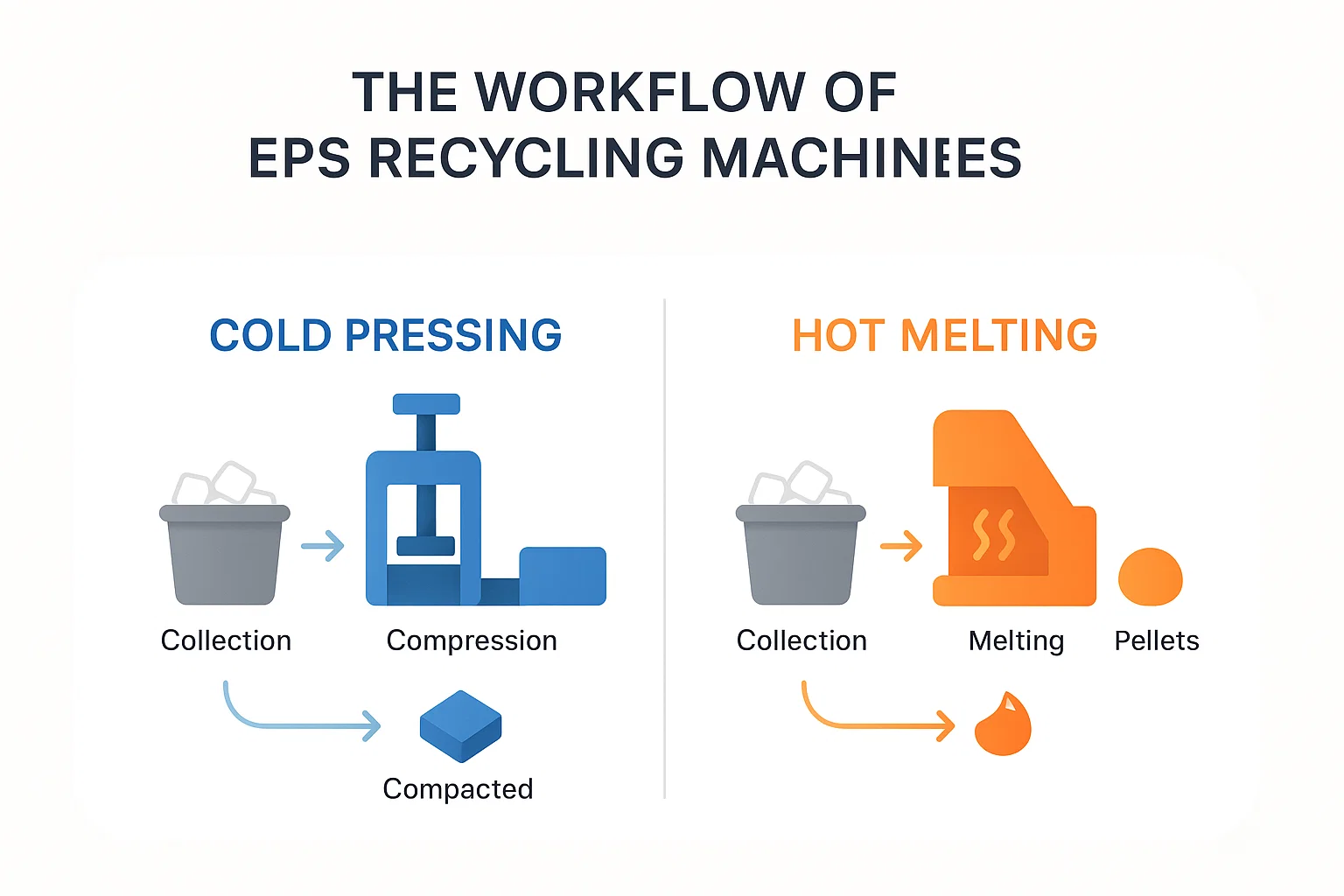

Polistirenul expandat (EPS), utilizat pe scară largă pentru ambalaje, izolații și recipiente alimentare de unică folosință, este notoriu de dificil de reciclat datorită naturii sale ușoare și voluminoase. Cu toate acestea, utilajele moderne de reciclare, cum ar fi mașinile de reciclare EPS, oferă soluții eficiente pentru manipularea și reutilizarea deșeurilor EPS. Acest articol analizează fluxurile de lucru ale celor două tipuri principale de mașini de reciclare EPS - presarea la rece și topirea la cald - pentru a vă ajuta să alegeți cel mai potrivit echipament pentru operațiunile dvs. de reciclare.

Flux de lucru pentru mașina de reciclare EPS prin presare la rece

Mașinile de presare la rece, cunoscute și sub denumirea de densificatoare EPS, compactează mecanic deșeurile de EPS fără aplicarea de căldură, reducându-le semnificativ volumul.

- Colectare și sortare

Etapa inițială implică colectarea deșeurilor de EPS și asigurarea îndepărtării contaminanților precum banda adezivă, etichetele și murdăria. - Mărunțire

Deșeurile curate de EPS sunt introduse într-un tocător, fiind descompuse în bucăți mai mici, ușor de gestionat. - Comprimare

Materialul EPS mărunțit este apoi introdus în camera de presare la rece, unde este comprimat mecanic sub presiune ridicată. Acest lucru îi reduce volumul cu până la 50:1. - Extrudare în blocuri

EPS-ul comprimat este extrudat în blocuri sau bușteni denși și solizi, gata pentru transport și depozitare eficiente.

Avantaje:

- Consum redus de energie.

- Fără emisii legate de căldură.

- Potrivit pentru operațiuni care caută simplitate și rentabilitate.

Pentru informații detaliate despre utilajele de presare la rece, explorați Mașină de presat la rece din spumă EPS pagină.

Flux de lucru al mașinii de reciclare EPS cu topire la cald

Mașinile de topire la cald funcționează prin topirea materialelor EPS într-o formă compactă și reutilizabilă, crescând semnificativ eficiența reciclării.

- Colectare și preprocesare

Similar presării la rece, deșeurile de EPS sunt colectate și curățate pentru a îndepărta contaminanții. - Hrănire și Zdrobire

Materialele EPS sunt introduse în pâlnia mașinii și procesate printr-un concasor integrat, reducându-le în fragmente mai mici. - Procesul de topire

EPS-ul zdrobit intră într-o cameră de încălzire unde este topit la temperaturi între 140°C și 200°C, transformându-l în stare lichidă. - Extrudare și răcire

EPS-ul topit este extrudat printr-o duză, formând lingouri sau blocuri dense pe măsură ce se răcește și se solidifică.

Avantaje:

- Raport de reducere ridicat (până la 90:1).

- Produce lingouri uniforme și dense, potrivite pentru reciclare în produse noi.

- Manipularea eficientă a volumelor mari de deșeuri de EPS.

Vizitați detaliile noastre Mașină de topire a spumei EPS ghid pentru a înțelege mai multe despre procesele de topire la cald.

Analiză comparativă: Presare la rece vs. Topire la cald

Alegerea între mașinile de presare la rece și cele de topire la cald depinde de mai mulți factori operaționali:

| Caracteristică | Presare la rece | Topire la cald |

|---|---|---|

| Raport de reducere a volumului | Moderat (până la 50:1) | Înalt (până la 90:1) |

| Consum de energie | Inferior | Superior |

| Calitatea produsului finit | Blocuri comprimate solide | Lingouri uniforme potrivite pentru reutilizare |

| Impactul asupra mediului | Emisii minime de căldură | Mai mare datorită procesului de încălzire |

Alegerea mașinii de reciclare EPS potrivite pentru afacerea dvs.

Luați în considerare amploarea operațională, bugetul disponibil și obiectivele de reciclare atunci când selectați utilajele de reciclare a EPS. Presarea la rece oferă simplitate și costuri de operare mai mici, fiind ideală pentru întreprinderile mai mici sau operațiunile cu deșeuri moderate de EPS. În schimb, topirea la cald se potrivește afacerilor care necesită randamente cu densitate mai mare și o eficiență mai mare a reciclării.

Concluzie

Mașinile de reciclare EPS de la Energycle, atât pentru presare la rece, cât și pentru topire la cald, oferă soluții practice și sustenabile, adaptate nevoilor dumneavoastră industriale de reciclare. Investind în echipamente adecvate, companiile pot obține beneficii semnificative de mediu și economice, consolidându-și în același timp angajamentul față de sustenabilitate.

Pentru a discuta despre cele mai potrivite soluții de reciclare a EPS adaptate cerințelor dumneavoastră, contactați echipa noastră de experți astăzi!