Dosáhněte prvotřídní kvality recyklovaných materiálů s naším specializovaným sušicím řešením. Tento systém, navržený pro dosažení vlhkosti **méně než 2%**, eliminuje vady, zvyšuje propustnost a maximalizuje hodnotu recyklovaných vloček a granulí pro následné zpracování.

Vaše konkurenční výhoda

Maximalizujte hodnotu materiálu

Vyrábějte recyklované plasty prémiové kvality, které si vyžádají vyšší ceny. Náš systém zaručuje obsah vlhkosti <2%, který je nezbytný pro bezchybnou peletizaci a lisování.

Zvyšte svou propustnost

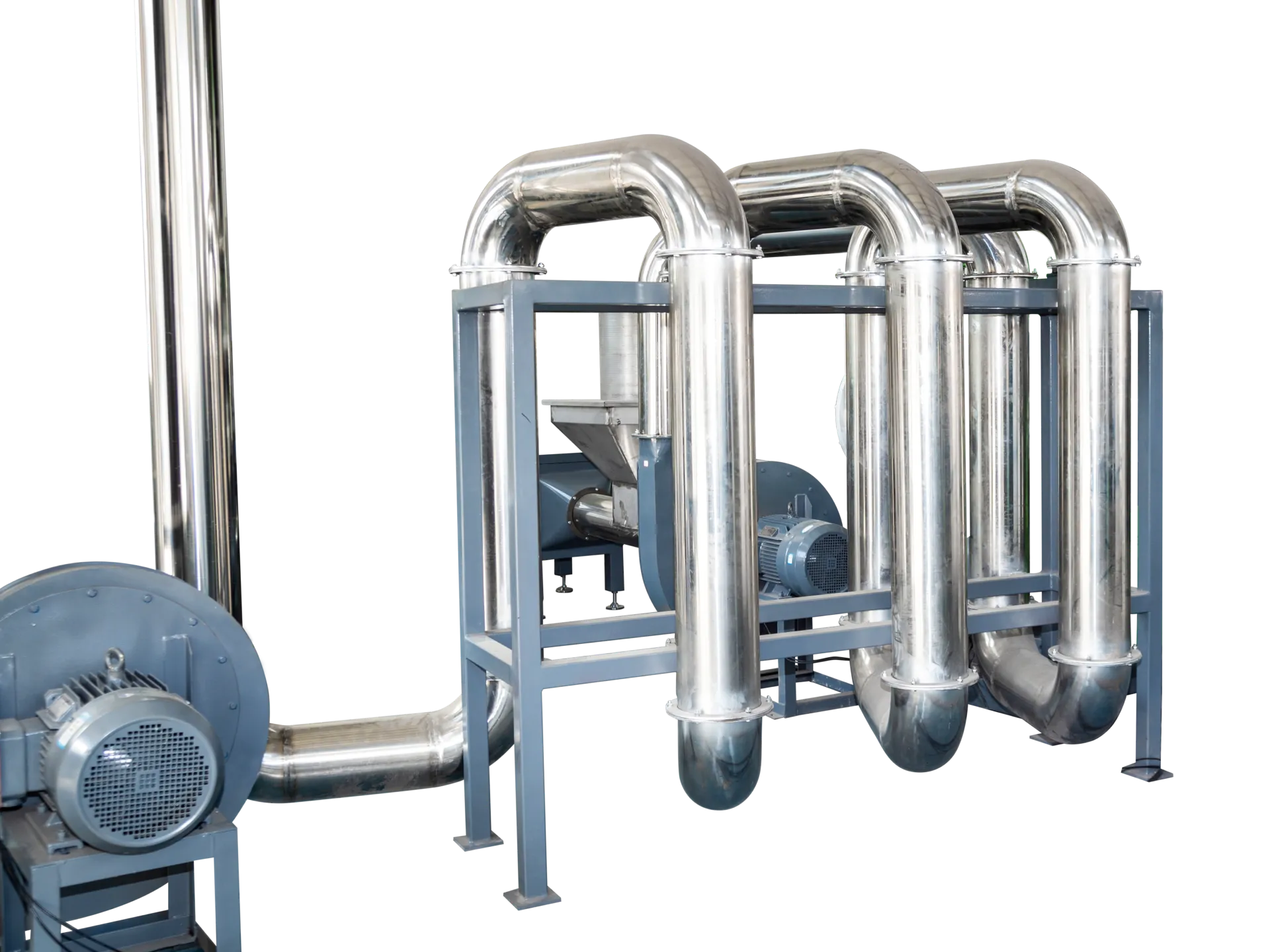

Výkonný ohřev o výkonu 72 kW a 30metrové potrubí umožňují nepřetržité zpracování velkých objemů a minimalizují tak úzká hrdla ve vaší prací lince.

Nižší provozní náklady

Vysoce kvalitní izolace snižuje spotřebu energie až o 20%, zatímco odolná konstrukce z nerezové oceli SU304 minimalizuje údržbu a zajišťuje životnost více než 10 let.

Navrženo pro výkon a spolehlivost

Robustní konstrukce pro nepřetržitý provoz 24 hodin denně, 7 dní v týdnu

Náš systém je navržen tak, aby odolal nejnáročnějším průmyslovým podmínkám, a kombinuje vynikající materiály pro maximální životnost:

- Materiální kontaktní části: Nerezová ocel SU304 odolná proti korozi zabraňuje kontaminaci a zajišťuje čistotu recyklovaných plastů.

- Konstrukční rám: Robustní rám z těžké uhlíkové oceli poskytuje neochvějnou stabilitu pro nepřetržitý provoz.

Tepelný výkon při vysokých rychlostech

Výkonná topná jednotka o výkonu 72 kW a ventilátor o výkonu 11 kW vytvářejí proud přesně řízeného horkého vzduchu. To zajišťuje rovnoměrné a rychlé sušení každé vločky a granule, čímž se zkracuje doba zpracování a zachovává se integrita materiálu.

Ideální aplikace

Tento systém je perfektním řešením pro sušení široké škály praných tuhých plastů, včetně:

Vločky z PET lahví po spotřebě

Postindustriální HDPE drcený materiál

Prané PP granule

Technické specifikace

| Cílové materiály | PET, HDPE, PP (vločky, granule, drť) |

| Konečný obsah vlhkosti | < 2% |

| Topný výkon | 72 kW |

| Výkon ventilátoru | 11 kW |

| Délka potrubí | 30 metrů |

| Průměr potrubí | 219 mm |

| Tloušťka stěny potrubí | 2 mm |

| Materiální kontaktní díly | Nerezová ocel SU304 |

| Materiál rámu | Uhlíková ocel (60x60x3 mm) |

Podívejte se na to v akci

Jste připraveni zvýšit kvalitu recyklovaných plastů?

Přestaňte dovolit, aby vlhkost snižovala váš výkon. Kontaktujte naše specialisty ještě dnes a proberte s nimi vaše specifické potřeby v oblasti sušení, přizpůsobte systém vaší výrobní linky a získejte podrobnou cenovou nabídku.