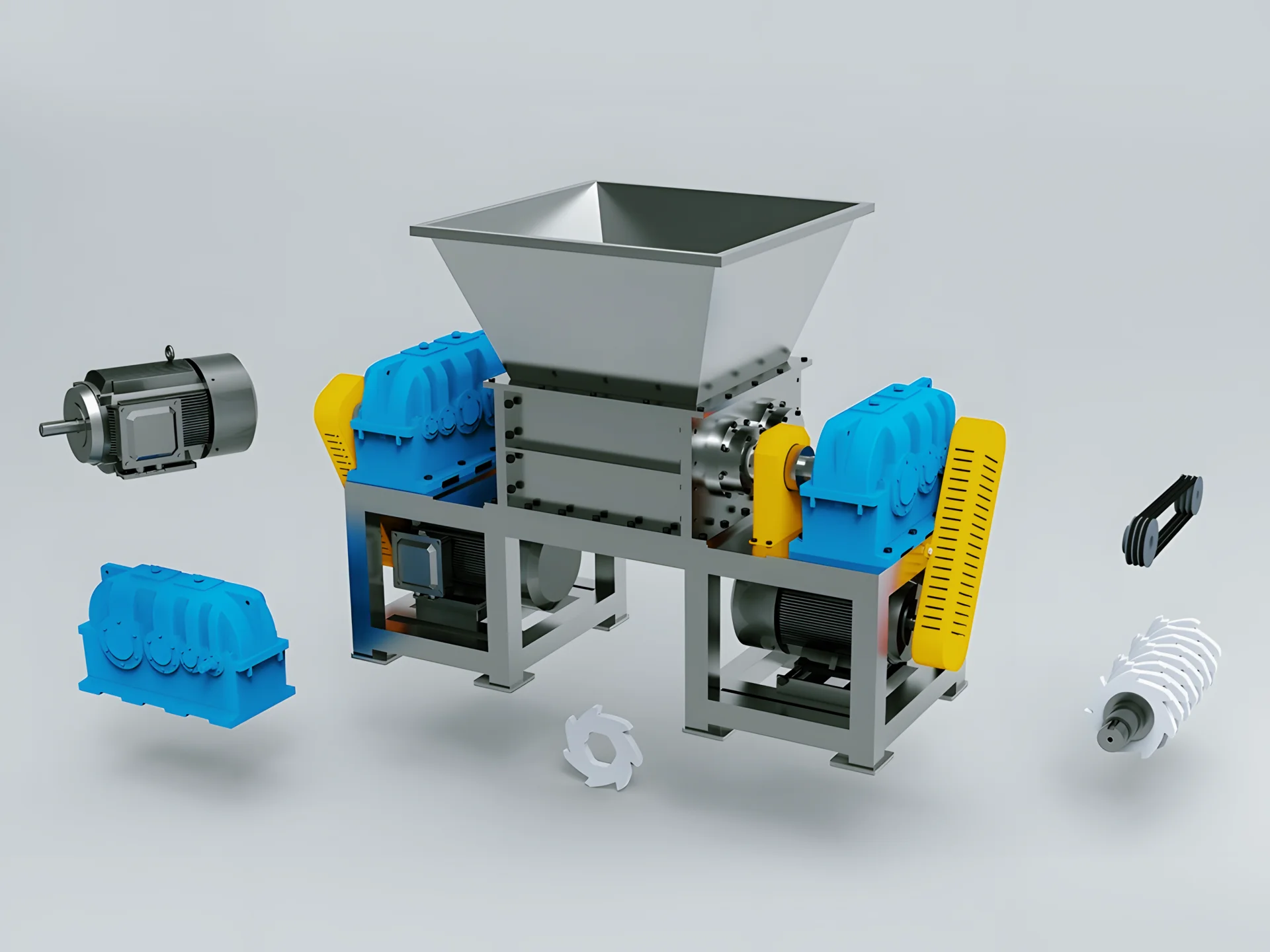

Shear Type Double Shaft Shredder

High‑capacity shredding for plastics, metals and complex industrial waste. Shear cutting delivers efficient, precise reduction with low downtime.

Key Benefits

Engineered for uptime, safety, and versatility.

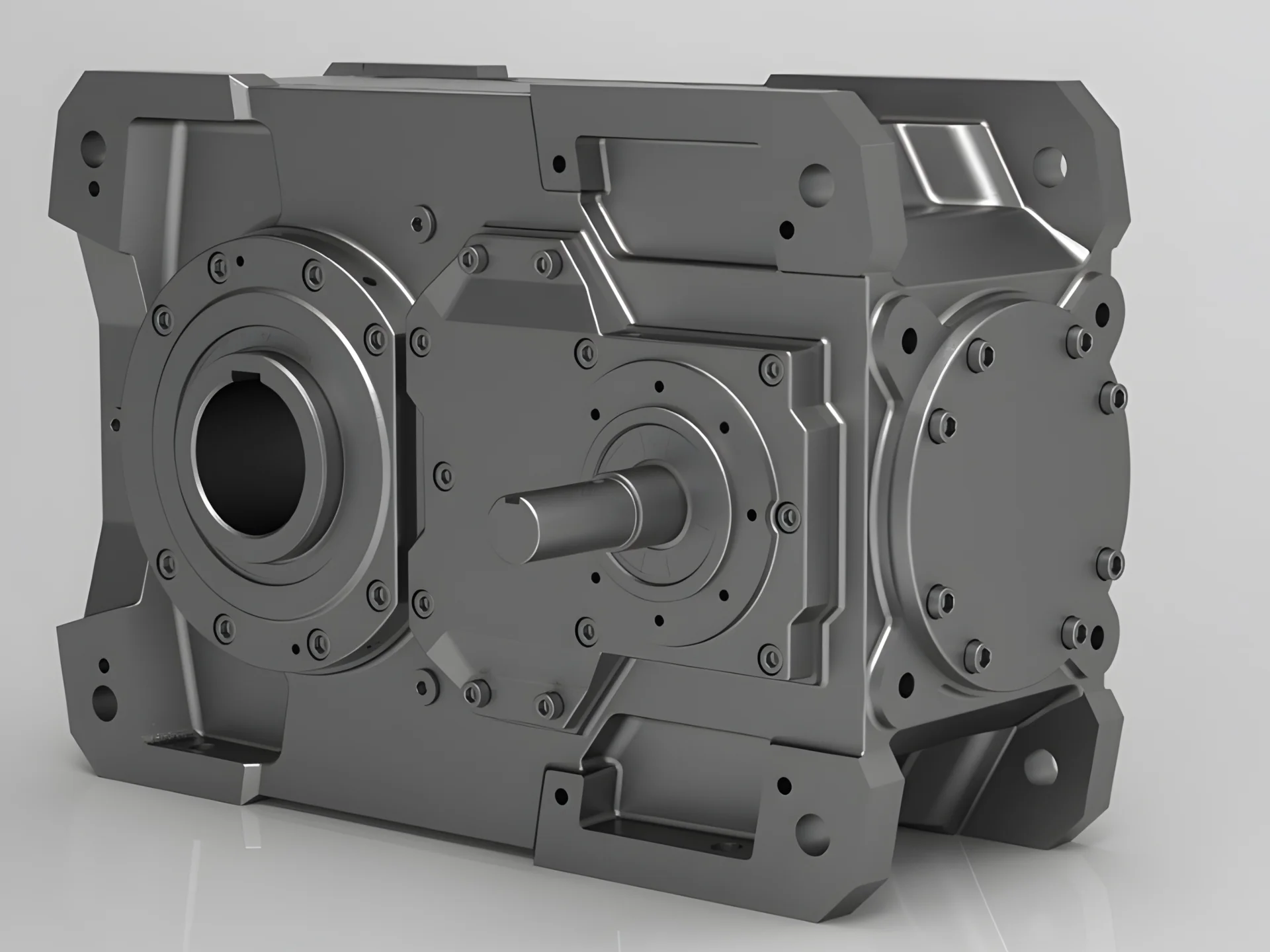

Smooth Speed Reduction

Belt‑pulley drivetrain protects motors and reducers from shock.

Advanced Coupling

Adjustable reverse force ensures stability under heavy loads.

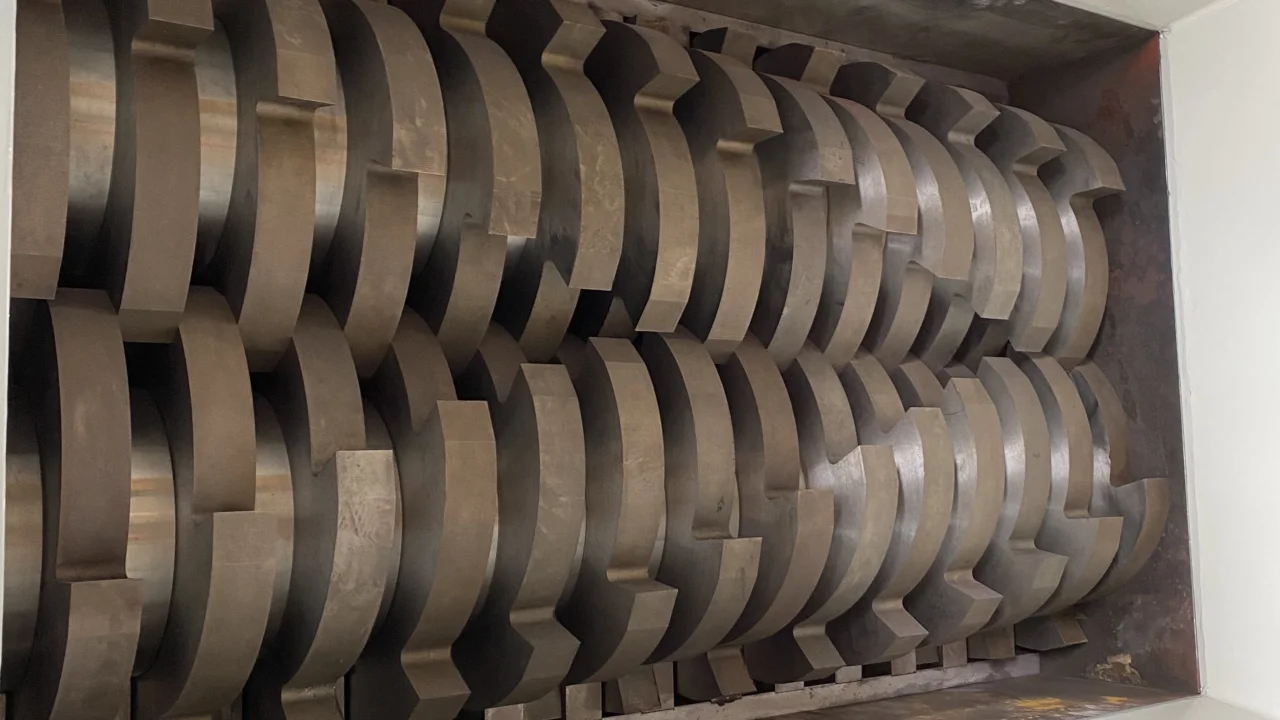

Custom Knife Sets

Blade thickness options from 25–100 mm for different materials.

PLC Control

Siemens PLC for safe, reliable automation and diagnostics.

Ideal for Processing

Plastic/Metal Drums

Reduces large containers into uniform pieces ready for recycling.

Tires & Bumpers

Handles rubber products like tires, bumpers and road blocks.

Wood & Bulky Waste

Shreds mixed bulky waste streams with consistent performance.

Technical Parameters

| Model | Unit | ERMDS800 | ERMDS1000 | ERMDS1200 | ERMDS1400 | ERMDS2000 |

|---|---|---|---|---|---|---|

| Motor Power | kW | 22×2 | 30×2 | 45×2 | 55×2 | 75×2 |

| Spindle Rotary Diameter | mm | Φ460 | Φ460 | Φ520 | Φ520 | Φ520 |

| Blade Thickness | mm | 25/30/40/50/60/80/100 | 25/30/40/50/60/80/100 | 25/30/40/50/60/80/100 | 25/30/40/50/60/80/100 | 25/30/40/50/60/80/100 |

| Speed | rpm | 20 | 20 | 18 | 18 | 18 |

| Shredding Chamber | mm | 800×980 | 1000×980 | 1200×1250 | 1400×1250 | 2000×1250 |

| Production Capacity | kg/h | 800–1200 | 1000–1500 | 1200–2000 | 2000–3000 | 2500–4000 |

| Weight | kg | 6500 | 7500 | 9200 | 11800 | 14700 |

Device Showcase

Gallery and a short operation demo.

Get a Custom Quote

Share your materials, target capacity and site constraints. We’ll reply with a tailored solution and pricing.

Contact Sales