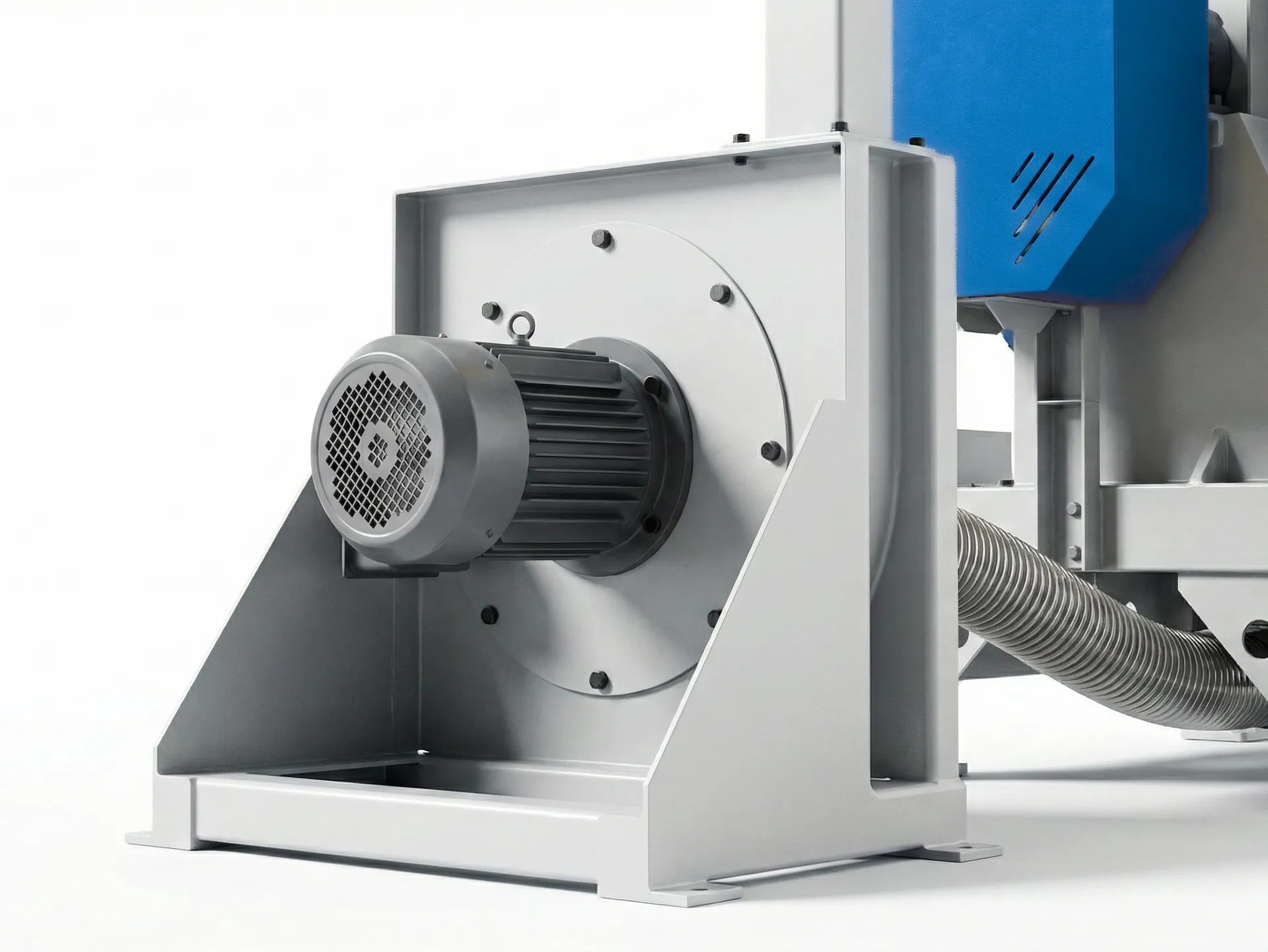

Specialized Horizontal Granulator for Pipes & Window Profiles

Designed specifically for recycling PVC pipes and window profiles. Our horizontal granulator feeds long, awkward materials directly, eliminating the need for pre-cutting and maximizing your operational throughput.

Request a Custom QuoteCore Advantages

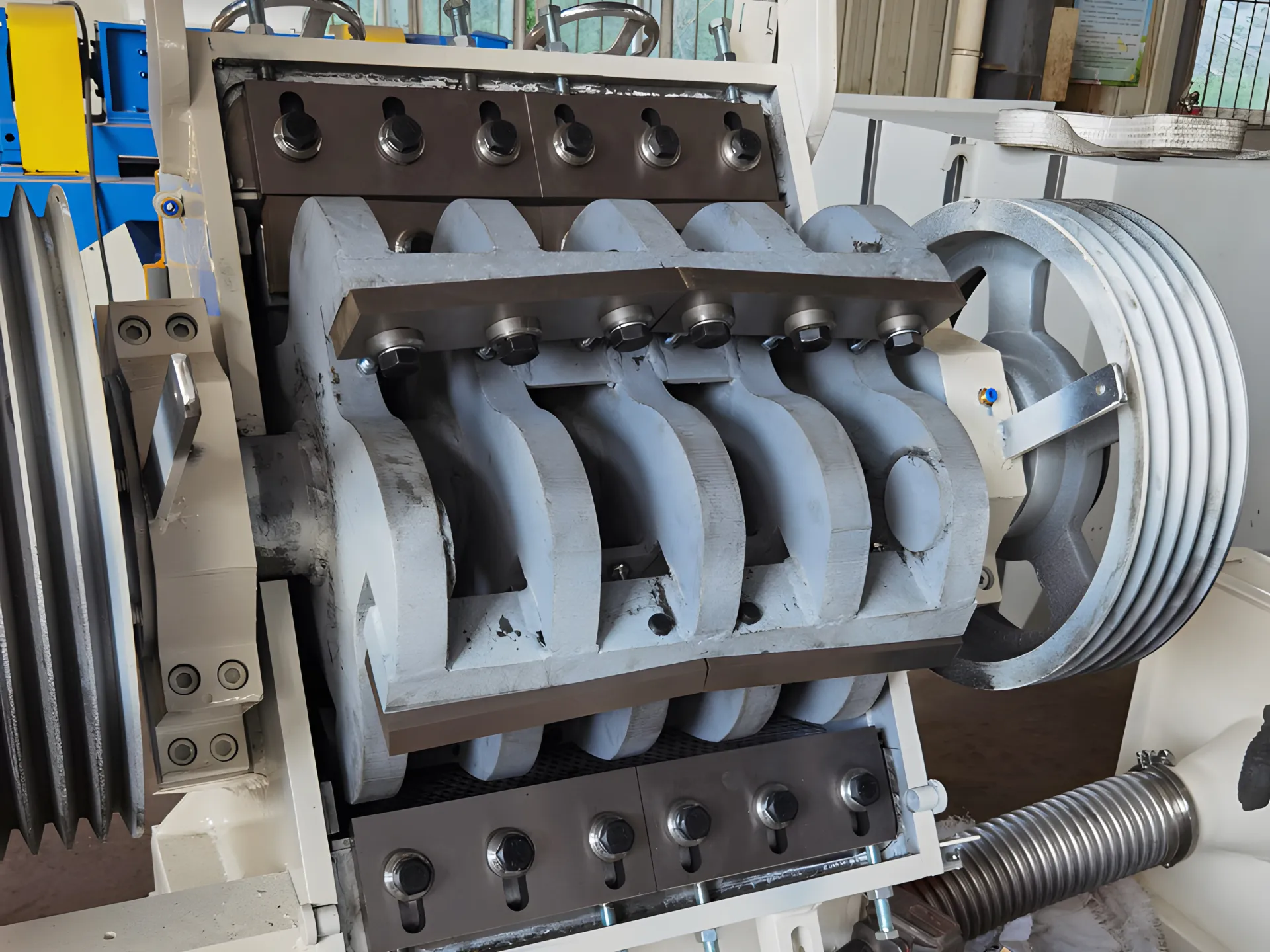

High-Efficiency V-Cut Rotor

Engineered to deliver a clean, uniform cut with lower energy consumption, ideal for rigid PVC.

Direct Horizontal Infeed

Allows full-length pipes and profiles to be fed directly, saving labor and preventing jams.

Durable D2 Alloy Blades

Provides exceptional wear resistance against abrasive materials, ensuring a longer service life.

Turn Your Recycling Challenges Into Profit

Common Industry Headaches

- Time-consuming manual cutting of long PVC pipes and window frames creates a major bottleneck.

- Standard granulators constantly jam when processing awkward or bulky profiles.

- Frequent downtime for maintenance and cleaning reduces overall plant productivity.

The Horizontal Granulator Solution

- The horizontal feed hopper is purpose-built to accept long materials, streamlining your workflow.

- A hydraulic ram ensures a steady, controlled feed rate for smooth, non-stop operation.

- Quick-access hydraulics open the chamber swiftly for fast, easy maintenance and screen changes.

A Smarter Workflow: How It Works

1. Direct Infeed

Full-length pipes or profiles are placed directly into the horizontal feeding hopper. No pre-cutting required.

2. Hydraulic Feeding

A hydraulic pusher ram automatically senses rotor load and feeds the material forward at an optimal, consistent rate.

3. High-Torque Granulation

The material is efficiently granulated between the high-speed V-cut rotor and stationary bed knives.

4. Uniform Output

Consistently sized regrind passes through a heavy-duty screen and is discharged, ready for reprocessing.

The Horizontal Advantage

| Feature | Traditional Granulator | Our Horizontal Granulator |

|---|---|---|

| Material Infeed | Requires pre-cutting | Direct Feed |

| Jamming Risk | High risk with long parts | Near-Zero Risk |

| Labor Requirement | High (for cutting/feeding) | Minimal |

| Operational Safety | Exposed cutting process | Enclosed & Automated |

See It In Action

Purpose-Built for Your Industry

PVC & PE Pipe Recycling

The premier solution for granulating scrap pipes of all sizes into high-quality, reusable material.

Vinyl Window & Door Profiles

Efficiently reclaims waste from the production of vinyl window frames, sills, and door components.

Other Extruded Profiles

Also effective for recycling other long extruded products, such as siding, decking, and plastic lumber.

Technical Specifications

| Model | Rotor Diameter (mm) | Fixed Blades | Rotating Blades | Capacity (kg/h) | Motor Power (kW) |

|---|---|---|---|---|---|

| SWP400 | 400 | 2 | 5 | 250-350 | 15 |

| SWP500 | 500 | 2 | 5 | 450-500 | 22 |

| SWP560 | 550 | 4 | 10 | 550-650 | 30 |

| SWP630 | 630 | 4 | 10 | 650-750 | 37 |

| SWP730 | 730 | 4 | 10 | 700-800 | 55 |

| SWP830 | 830 | 4 | 14 | 800-900 | 75 |

| SWP900 | 900 | 4 | 14 | 1100-1200 | 110 |

Frequently Asked Questions

What material types is this machine best for?

What does blade maintenance involve?

Can the machine be customized?

What Our Clients Are Saying

This machine was a game-changer. We eliminated the pre-cutting step for our PVC pipes entirely, which saved us over 20 man-hours a week. The ROI was faster than we ever expected.

Operations Manager

We used to struggle with constant jams in our old granulator when feeding window profiles. The hydraulic feed on this horizontal unit is incredibly reliable. It just runs and runs with no issues.

Plant Supervisor

The build quality is impressive, and the ease of maintenance is a huge plus. Being able to access the chamber so quickly for cleaning has significantly reduced our downtime between material runs.

Business Owner

Eliminate Pre-Cutting. Maximize Profit.

Contact our specialists today for a personalized consultation and a detailed quote for your pipe and profile recycling operation.