Vuoi massimizzare l'efficienza e la qualità nelle tue operazioni di lavorazione dei polimeri? Energia fornisce all'avanguardia estrusori bivite corotanti Progettati per la miscelazione, la compoundazione e la lavorazione di precisione nei settori della plastica, dei prodotti chimici, della produzione alimentare e dei materiali avanzati. Grazie alla comprovata esperienza nella tecnologia di estrusione e a un approccio incentrato sul cliente, aiutiamo i produttori di tutto il mondo a raggiungere risultati di produzione superiori.

Che cosa è un estrusore bivite corotante?

Un estrusore bivite corotante è dotato di due viti interconnesse che ruotano nella stessa direzione all'interno di un cilindro riscaldato. Questo design a stretto contatto crea un'eccezionale azione autopulente e una distribuzione uniforme del materiale, rendendolo lo standard del settore per applicazioni di compounding complesse.

I principali vantaggi includono:

- Capacità di miscelazione superiore – Sia la miscelazione distributiva che quella dispersiva garantiscono una miscelazione omogenea di polimeri, additivi, riempitivi e rinforzi

- Ottima autopulizia – Le viti interconnesse co-rotanti prevengono l’accumulo di materiale e riducono il rischio di degradazione

- Elaborazione flessibile – Il design modulare della vite si adatta a diversi materiali e formulazioni

- Devolatilizzazione efficiente – Le molteplici zone di ventilazione rimuovono efficacemente l’umidità e le sostanze volatili

Perché scegliere gli estrusori bivite corotanti Energycle?

1. Applicazioni versatili in più settori

I nostri estrusori bivite eccellono negli ambienti di produzione più esigenti:

- Compounding di materie plastiche – Produzione di masterbatch, miscele di polimeri, composti riempiti

- Elaborazione chimica – Estrusione reattiva, modifica dei polimeri, dispersione degli additivi

- Rivestimenti in polvere – Miscelazione uniforme di pigmenti e resine

- Lavorazione alimentare – Snack, cibo per animali, proteine testurizzate

- Compositi legno-plastica (WPC) – Decking, profili, materiali da costruzione

- Applicazioni farmaceutiche – Estrusione hot melt per sistemi di somministrazione di farmaci

2. Ingegneria avanzata e progettazione modulare

Configurazione modulare delle viti "Building Block"

Gli estrusori Energycle sono dotati di elementi vite intercambiabili, personalizzabili in base alle specifiche esigenze di processo. Questa flessibilità si traduce in:

- Facile adattamento a nuove formulazioni senza sostituzione delle attrezzature

- Manutenzione semplificata e cambi più rapidi

- Elaborazione ottimizzata per ogni applicazione unica

- Sviluppo e ridimensionamento dei processi a costi contenuti

Gamma di prestazioni della serie RTM

La nostra linea completa di prodotti comprende diametri delle viti da 20 mm a 200 mm, con configurazioni su misura per le vostre esigenze di produttività:

- Scala da laboratorio (20-35 mm) – R&S, test pilota, produzione in piccoli lotti

- Scala di produzione (50-200 mm) – Produzione industriale con produzioni fino a diverse tonnellate all’ora

- Classi di coppia personalizzate – Adattare la potenza del motore e la progettazione del riduttore alla viscosità del materiale e all’intensità di lavorazione

3. Prestazioni superiori di plastificazione e compoundazione

La geometria delle viti strettamente interconnesse garantisce:

- Azione autopulente completa – Le viti si puliscono continuamente a vicenda, evitando il ristagno del materiale

- Trasmissione positiva – Flusso di materiale costante indipendentemente dalle variazioni di viscosità

- Zone di miscelazione intensiva – I blocchi impastatori e gli elementi di miscelazione garantiscono una dispersione completa

- Controllo preciso del tempo di residenza – La distribuzione ristretta del tempo di residenza protegge i materiali sensibili al calore

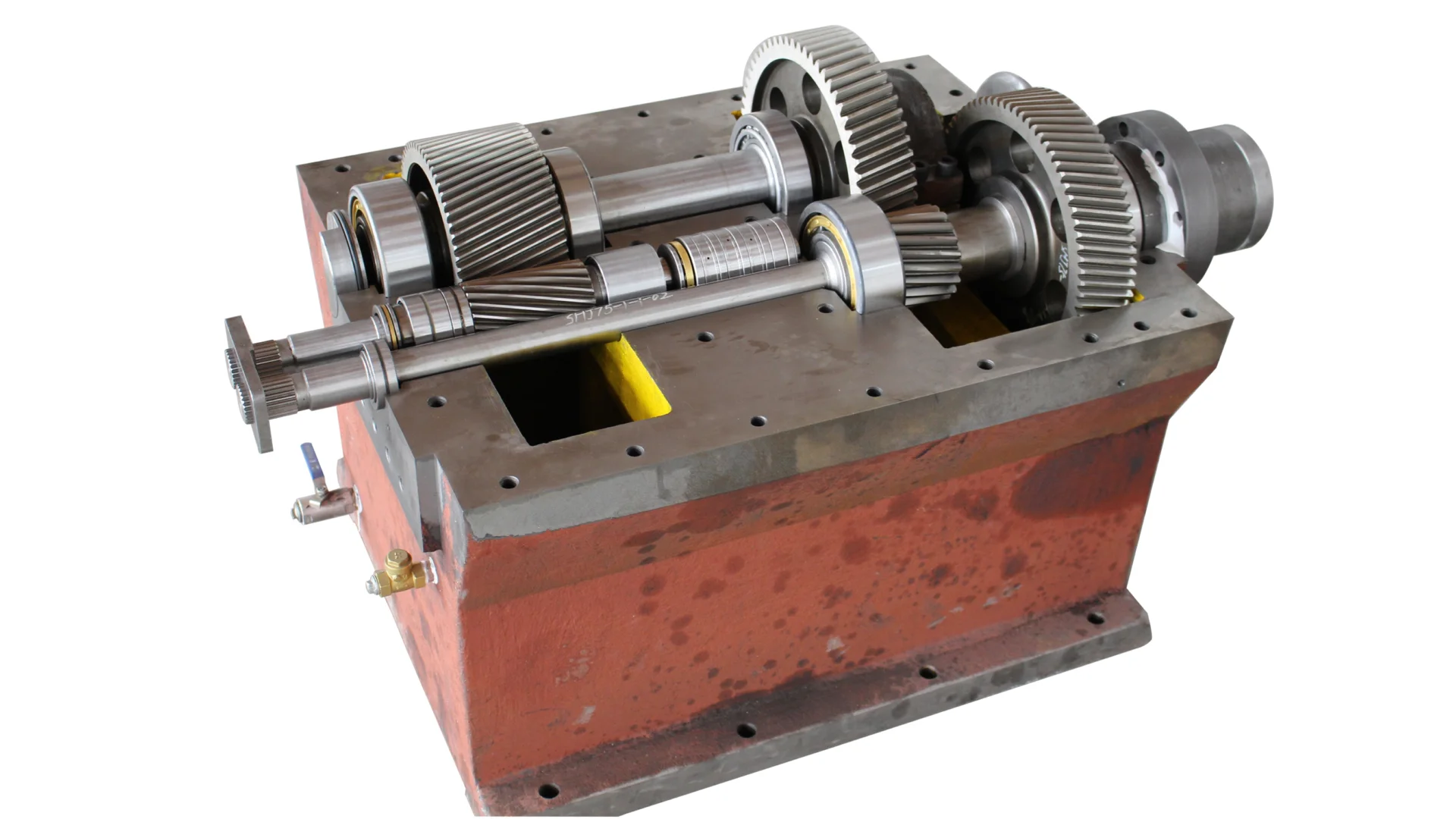

4. Sistema di trasmissione di potenza robusto

L'affidabilità inizia con componenti di alta qualità. Gli estrusori Energycle sono caratterizzati da:

- Cambio per impieghi gravosi con denti degli ingranaggi temprati e rettificati con precisione per una distribuzione uniforme della coppia

- Cuscinetti importati di alta qualità classificato per funzionamento continuo sotto carichi impegnativi

- Sistema di lubrificazione integrato con monitoraggio della temperatura per una maggiore durata dei componenti

- Protezione da sovraccarico per salvaguardare il tuo investimento durante condizioni di elaborazione impreviste

5. Materiali e costruzione di alta qualità

Ogni componente è costruito per durare:

- Sezioni della canna temprate e nitrurate resistere all'usura causata da riempitivi abrasivi

- Rivestimenti bimetallici per canne (facoltativo) per un'estrema resistenza all'usura con fibra di vetro o composti minerali

- Robusta base in acciaio saldato con cuscinetti di regolazione di precisione garantisce un allineamento corretto

- Coperture isolanti per barili in acciaio inossidabile mantenere l'efficienza termica e la sicurezza dell'operatore

6. Tecnologia avanzata di cambio schermo

Mantieni una produzione continua con i nostri innovativi sistemi di filtrazione della massa fusa:

- Cambiafiltri idraulici a piastra scorrevole – Cambi di schermo rapidi e continui senza interruzione della produzione

- Cambiafiltri a nastro continuo – Filtrazione automatica per un output ultra-pulito in applicazioni critiche

- Cambiafiltri a cestello – Soluzione conveniente per esigenze di filtrazione standard

Ogni sistema si integra perfettamente con le apparecchiature di pellettizzazione, profilatura o estrusione di fogli a valle.

Componenti interni del cambio ad alta precisione progettati per una distribuzione affidabile della coppia e una maggiore durata

Co-rotazione vs. controrotazione: comprendere la differenza

Sebbene entrambe le configurazioni soddisfino le esigenze di estrusione, gli estrusori bivite corotanti offrono vantaggi distinti:

| Caratteristica | Co-rotazione | Controrotante |

|---|---|---|

| Autopulente | Ottimo: le viti si puliscono completamente a vicenda | Limitato: il materiale può accumularsi nella zona intermesh |

| Intensità di miscelazione | Superiore sia per la miscelazione distributiva che dispersiva | Più adatto per una miscelazione delicata |

| Flessibilità modulare | Altamente modulare: facile riconfigurazione delle viti | Modularità limitata |

| Applicazioni | Compounding, estrusione reattiva, devolatilizzazione | Estrusione di profili, produzione di tubi |

| Versatilità dei materiali | Gestisce un'ampia gamma di viscosità | Ideale per materiali con viscosità costante |

Per la miscelazione di polimeri, la produzione di masterbatch e le formulazioni complesse, i progetti co-rotanti garantiscono prestazioni ineguagliabili.

Il tuo partner di fiducia nella tecnologia di estrusione

Oltre 20 anni di competenza specialistica posiziona Energycle come il vostro partner di produzione affidabile. Sappiamo che ogni applicazione presenta sfide uniche, dal raggiungimento di tolleranze di colore ristrette nella produzione di masterbatch all'ottimizzazione della produttività nella miscelazione di resine riciclate.

Il nostro team di ingegneri lavora a stretto contatto con voi per:

- Seleziona le configurazioni delle viti ottimali per i tuoi materiali

- Progettare zone di lavorazione che bilancino la qualità della miscelazione e l'efficienza energetica

- Processi di scala dal laboratorio alla produzione completa

- Fornire supporto tecnico continuo e ottimizzazione dei processi

Che tu stia elaborando materie plastiche tecniche, creando masterbatch colorati, componendo polimeri caricati a vetro o sviluppando materiali innovativi di origine biologica, Energycle estrusori bivite corotanti forniamo la precisione e l'affidabilità richieste dalle vostre attività.

Pronti a potenziare le vostre operazioni di compounding?

Parleremo di come la tecnologia Energycle può risolvere le vostre specifiche sfide di lavorazione. I nostri ingegneri applicativi sono pronti a valutare i vostri requisiti di materiali, gli obiettivi di produzione e le specifiche tecniche.

Contatta oggi stesso il team Energycle per esplorare configurazioni di estrusori su misura per le tue esigenze. Ci impegniamo ad aiutarti a raggiungere:

- Maggiore qualità del prodotto con una migliore consistenza

- Maggiore efficienza produttiva e riduzione degli sprechi

- Minore costo totale di proprietà grazie a un design durevole

- Tempi di commercializzazione più rapidi per le nuove formulazioni

Trasforma le tue capacità di lavorazione dei polimeri con Energycle, dove l'eccellenza ingegneristica incontra l'affidabilità produttiva.