Advanced MSW Sorting Plant & Recycling Systems

Turn municipal solid waste from a costly liability into a valuable asset. Our fully automated sorting plants recover high-purity recyclables and produce alternative fuels, diverting up to 90% of waste from landfills.

Design Your Custom PlantA Smarter Approach to Waste Management

Maximize Resource Recovery

Automatically extract valuable commodities like plastics, metals, paper, and glass with over 95% sorting accuracy.

Create New Revenue Streams

Generate significant income by selling recovered materials and producing high-calorific Refuse-Derived Fuel (RDF).

Drastically Reduce Landfill

Achieve ambitious environmental goals by diverting massive volumes of waste, extending landfill life and reducing pollution.

From Urban Waste Crisis to Sustainable Opportunity

The High Cost of Unsorted Waste

- Valuable, recyclable materials are lost forever in overflowing landfills.

- Rising landfill taxes and transportation costs strain municipal and private budgets.

- Environmental pollution and public pressure demand more sustainable solutions.

The Automated Sorting Solution

- Our system unlocks the hidden value in MSW by segregating it into profitable commodities.

- Turn a major expense into multiple revenue streams from recyclables and alternative fuels.

- Provide a modern, eco-friendly solution that meets regulatory targets and public expectations.

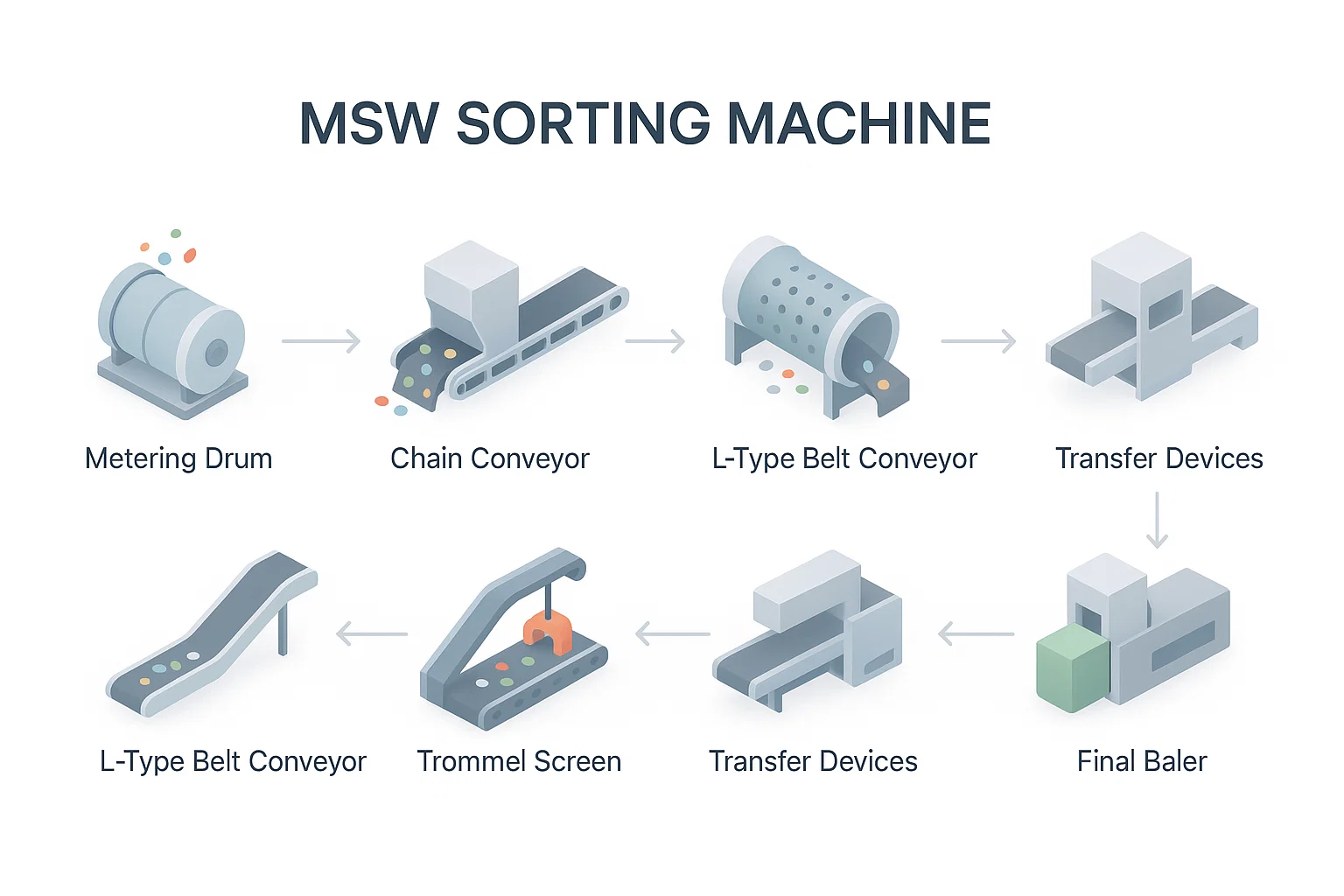

The Automated Sorting Process

1. Infeed & Pre-Sorting

Raw MSW is loaded, and large items and bags are opened to prepare for automated separation.

2. Size & Density Separation

Trommel screens separate organics by size, while ballistic and air separators segregate materials by density and shape.

3. Material Recovery

Magnetic and eddy current separators recover ferrous and non-ferrous metals. Optical sorters purify plastics.

4. Final Processing

Recovered materials are baled for sale, organics are sent for composting, and the rest is processed into RDF.

Landfilling vs. Automated Sorting

| Outcome | Traditional Landfilling | Our MSW Sorting Plant |

|---|---|---|

| Resource Value | 100% Lost | Value Maximized |

| Financial Model | Pure Cost Center | Profit Center |

| Environmental Impact | High Pollution & Land Use | Circular Economy |

| Sustainability | Unsustainable | Long-Term Solution |

Inside a Modern Sorting Facility

Valuable Outputs from Waste

Recyclable Commodities

High-purity streams of PET, HDPE, ferrous metals, aluminum, and paper, baled and ready for sale.

Refuse-Derived Fuel (RDF)

Non-recyclable, high-calorific materials are processed into an alternative fuel for industrial use.

Organic Compost

The organic fraction of waste is separated and can be processed into valuable compost for agriculture.

Core System Technologies

| Processing Capacity | Fully customizable from 50 to 500+ tons per day. |

|---|---|

| Primary Screening | Bag Breakers, Rotary Trommel Screens |

| Density Separation | Ballistic Separators, Air Classifiers (Wind Shifters) |

| Metal Separation | Overband Magnets (Ferrous), Eddy Current Separators (Non-Ferrous) |

| Plastics Purification | Advanced Optical Sorters (NIR technology) |

| Control System | Centralized SIEMENS PLC for full plant automation. |

Frequently Asked Questions

What is the typical resource recovery rate?

What physical footprint is required for a plant?

Can the system be adapted for different types of waste?

What are the primary revenue streams from this plant?

What Our Partners Are Saying

This sorting plant has been a game-changer for our municipality. We've extended our landfill's life by over 15 years and are now meeting national recycling targets ahead of schedule.

Municipal Waste Director

The level of automation is incredible. Our recovery rates for aluminum and PET have increased by over 30%, and the purity of the material is consistently high. It's a reliable, efficient system.

MRF Plant Manager

We transitioned our business model from simple waste hauling to resource recovery. This plant turned a major expense into a profitable enterprise. The ROI has exceeded all our projections.

CEO, Waste Management Services

Design Your Waste-to-Value Facility

Contact our engineers to configure a custom MSW sorting plant that meets your capacity, recovery goals, and budget.