O melhor triturador de eixo único para resíduos de extrusora

Transforme sem esforço resíduos persistentes da cabeça da extrusora em material valioso e reutilizável com nossa solução de trituração robusta e confiável.

Solicite um orçamentoProjetado para desempenho e durabilidade

Trem de força robusto

Possui um redutor série H de alto torque e um eixo principal sólido de uma só peça, garantindo entrega de potência consistente para triturar os materiais mais difíceis.

Lâminas econômicas

Nossas facas móveis exclusivas de quatro ângulos podem ser giradas para usar uma nova lâmina afiada, aumentando significativamente sua vida útil e reduzindo os custos de manutenção.

Proteção Inteligente

O avançado sistema de controle PLC inclui um mecanismo de retorno automático de sobrecarga, prevenindo danos e garantindo confiabilidade operacional a longo prazo.

Do resíduo à matéria-prima em quatro etapas simples

Alimentação de material

Um cilindro hidráulico fornece uma taxa de alimentação constante e controlada, empurrando os resíduos da extrusora de forma consistente para a câmara de trituração.

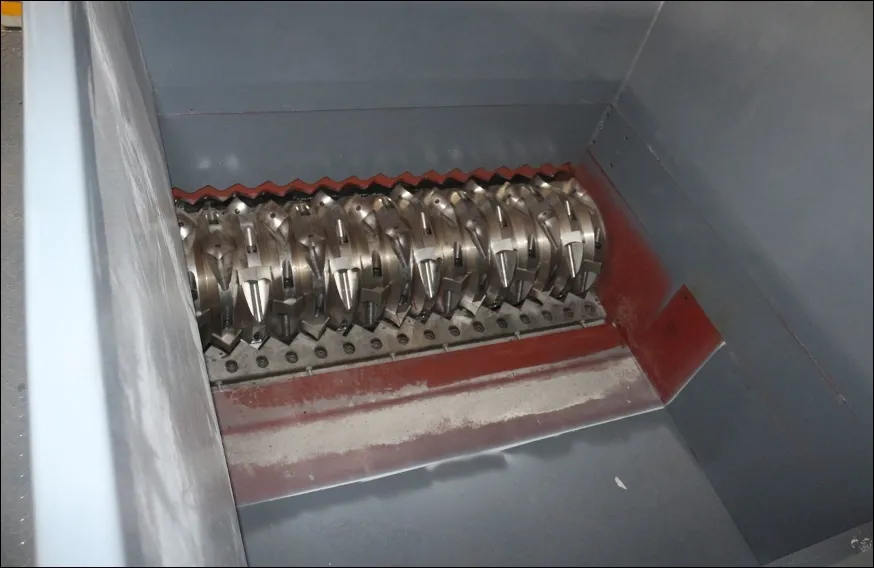

Destruição Eficiente

Facas rotativas de liga de aço de alta resistência trabalham contra facas fixas para cortar o material em pedaços menores e uniformes.

Controle PLC

O sistema monitora a carga do motor. Se uma sobrecarga for detectada, o eixo reverte automaticamente para eliminar o bloqueio antes de continuar.

Saída de material

O material triturado passa por uma peneira (opcional), garantindo um tamanho de partícula consistente, pronto para a próxima etapa da reciclagem.

Assista ao Shredder em ação

Veja você mesmo como nosso triturador de eixo único processa com eficiência plásticos industriais resistentes. Este vídeo demonstra a potência da máquina, a operação suave e a qualidade do produto final triturado.

Características detalhadas e especificações técnicas

Montagem Principal

O núcleo da máquina é construído sobre uma estrutura robusta com um eixo rotativo sólido, processado em CNC. Este é complementado por um assento de rolamento externo da estrutura de uma renomada marca nacional (Wafangdian) para maior estabilidade e facilidade de manutenção.

Poder e Controle

Acionado por um potente motor de 22 kW e um redutor de dentes permanentes da série H, o triturador atinge uma potência estável de 81 rpm. Toda a operação é gerenciada por um sistema Delta PLC com componentes elétricos Siemens e Schneider de alta qualidade para confiabilidade incomparável.

Sistema Hidráulico

O sistema hidráulico de 3 kW aciona o carrinho de alimentação de material, fornecendo até 21 MPa de pressão. Isso garante uma velocidade de alimentação estável e ajustável. O sistema é mantido na temperatura ideal por um eficiente mecanismo de resfriamento a ar.

| Item | Parâmetro | Descrição |

|---|---|---|

| Modelo | RTM-SD2360 | Triturador de eixo único |

| Saída | 200-300 kg/h | Depende do tipo de material e do tamanho da tela. |

| Câmara de trituração | 550 mm x 580 mm | Área de trabalho efetiva para processamento de materiais. |

| Sistema de corte | 30 lâminas móveis e 1 lâmina fixa | Lâminas de liga de aço SKD-11 (40x40 mm) em um eixo de 230 mm de diâmetro. |

| Potência do motor principal | 22 kW | Marca de motores nacionais confiável. |

| Energia Hidráulica | 3 kW | Alimenta o cilindro de alimentação de material. |

Galeria de Máquinas

Obtenha uma solução personalizada e um orçamento

Nossos especialistas estão prontos para ajudar você a configurar o triturador ideal para suas necessidades específicas. Entre em contato conosco hoje mesmo para receber os preços e prazos de entrega mais recentes.