Recycling News

How to Recycle 3D Printing Waste with a Mini Desktop Shredder

If you own a 3D printer, you already know the “hidden cost” of making things. For every clean prototype, there is a pile of supports, brims, purge lines, and failed parts that can fill a bin fast.

A 3D print shredder is one of the simplest ways to take control of that waste. Instead of tossing bulky scraps, you can reduce them into consistent flakes that are easier to store, easier to transport, and in many workflows, ready for the next step in recycling.

This guide explains how to recycle common 3D printing plastics using a mini desktop shredder, with a focus on real world constraints like noise, safety, contamination, and flake quality.

Why shred 3D printing waste instead of throwing it away?

Shredding does not magically “recycle” plastic by itself, but it unlocks options that are hard to achieve with whole prints.

- Lower volume, easier handling: Supports and failed prints are awkward shapes. Shredded flakes pack tightly and store better.

- More consistent processing: If you plan to reprocess material, uniform flakes feed better into small extruders.

- Better sorting: You can sort by plastic type and color before shredding, which improves the quality of any recycled output.

- Cleaner shop habits: Waste piles attract dust and mix materials. A simple collection and shredding routine keeps your workspace manageable.

Step 1: Sort your prints by plastic type first

Before you shred anything, separate waste by polymer. Mixing plastics is the fastest way to ruin recycled material.

Common 3D printing plastics you may see:

- PLA: Easiest to work with for small scale recycling. Low odor in normal conditions, but still treat dust seriously.

- ABS: More temperature resistant, but can be more sensitive to contamination. Some users notice stronger odor if scraps are heated later.

- PETG: Often recyclable in principle, but it is still important to keep it separate from PET bottles and other PET streams.

- TPU: Flexible. Shredding may require more attention to feeding and blade condition.

- Nylon and fiber filled filaments: These can be abrasive or behave unpredictably. If you are not sure, do not shred them in a small desktop unit.

Rule of thumb: If you cannot confidently identify the filament type, keep it out of your recycling batch.

Step 2: Remove contamination that causes weak recycled filament

A mini shredder can handle plastic. It should not be your dustbin.

Before shredding, remove:

- Adhesive residue from tape, glue sticks, or build plate adhesives.

- Metal parts such as embedded nuts, heat set inserts, magnets, screws.

- Labels and paper from storage bins.

- Non matching plastics like silicone pads, rubber feet, foam, or mixed material prints.

If parts are dirty with oils or heavy dust, wipe them down and let them fully dry. Moisture and debris can show up later as bubbles, weak layers, or inconsistent extrusion.

Step 3: Prepare pieces for smooth feeding

Desktop shredders work best when the feed is reasonable.

- Break very large parts into smaller chunks using hand tools.

- Avoid forcing long, thin pieces that can bridge in the hopper.

- Keep a steady feeding rhythm instead of dumping a full bin at once.

Step 4: Shred into consistent flakes

Your goal is not “as small as possible.” Your goal is consistent.

A practical target for small scale reprocessing is flakes that:

- Flow without clumping.

- Are not so fine that they turn into dust.

- Fit the intake requirements of your next step, whether that is an extruder or a recycler.

If your next step is filament extrusion, consistency matters because uneven chunks can cause:

- Surging feed rate.

- Temperature swings.

- Poor diameter control.

Step 5: Keep flakes clean, dry, and labeled

Once shredded, treat flakes like raw material.

- Store in sealed containers.

- Label by polymer, brand, and color.

- If you live in a humid area, use desiccant packs or dry the material before extrusion.

A small habit here saves hours later.

What a mini desktop shredder needs to do well for 3D printing waste

Industrial shredders are overkill for maker spaces. A desktop workflow is different.

1) Compact footprint for real workbenches

A desktop unit should sit near your printer or post processing area without rearranging the room. That is the difference between a system you use weekly and a machine that collects dust.

2) Low noise, because you work around it

Many users want to shred in a small studio, classroom, or office style lab. Noise matters.

When evaluating any 3D print shredder, look for:

- Enclosed cutting chamber.

- Stable frame and vibration control.

- A feeding approach that does not require constant force.

3) Practical safety features

Small machines still have serious cutting force. Good desktop safety design typically includes:

- A guarded feed opening.

- Clear jam clearing procedure.

- Easy access for cleaning without putting hands near blades.

Wear PPE. Eye protection is non negotiable. If you generate fine fragments, add a dust mask and clean the area after each session.

4) Easy cleaning between materials and colors

If you plan to recycle into filament, cleaning matters. Small leftovers from black ABS can ruin a batch of white PLA.

Look for quick access panels and a layout that lets you:

- Brush out the chamber.

- Remove trapped flakes.

- Wipe contact surfaces.

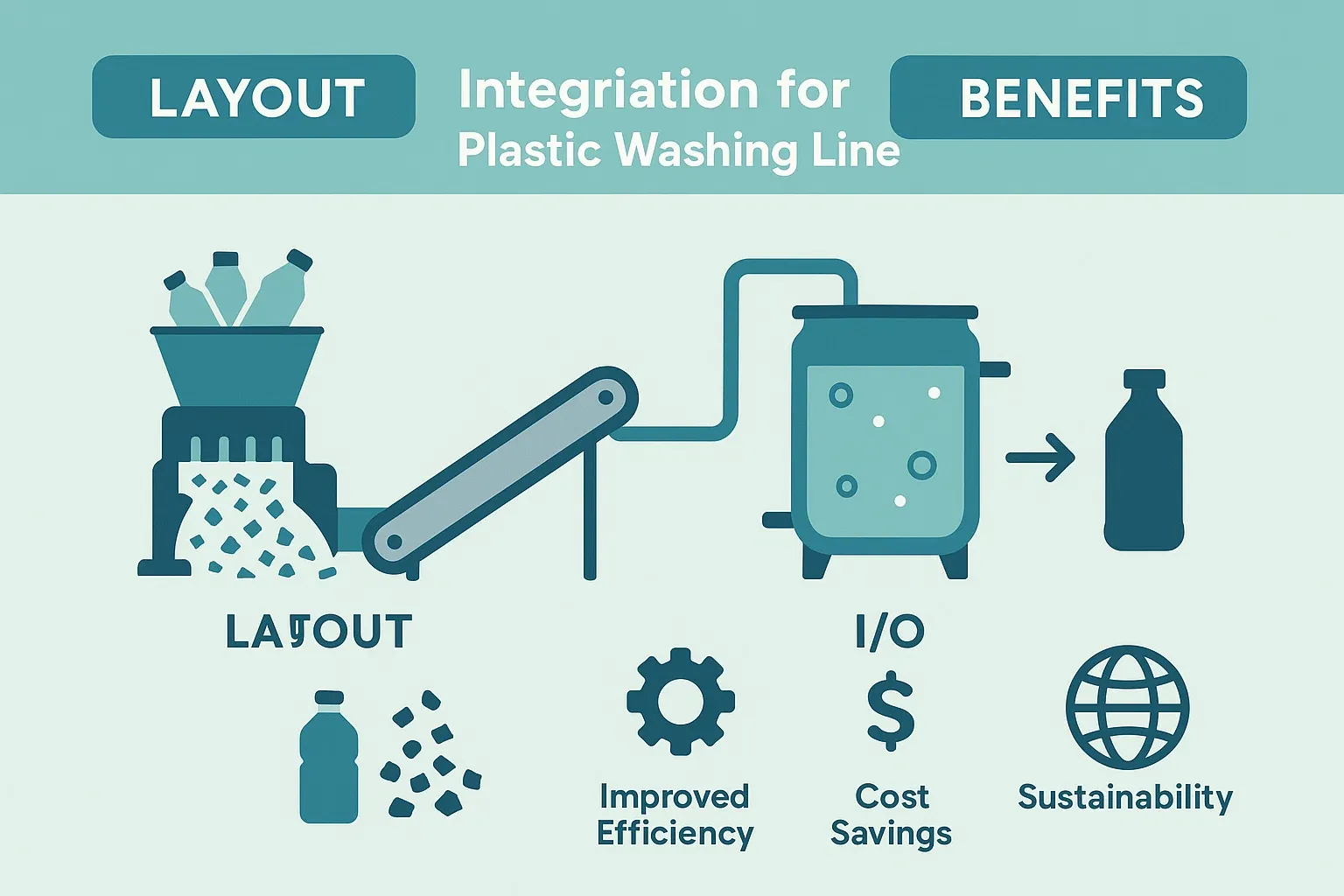

A simple closed loop workflow for maker scale recycling

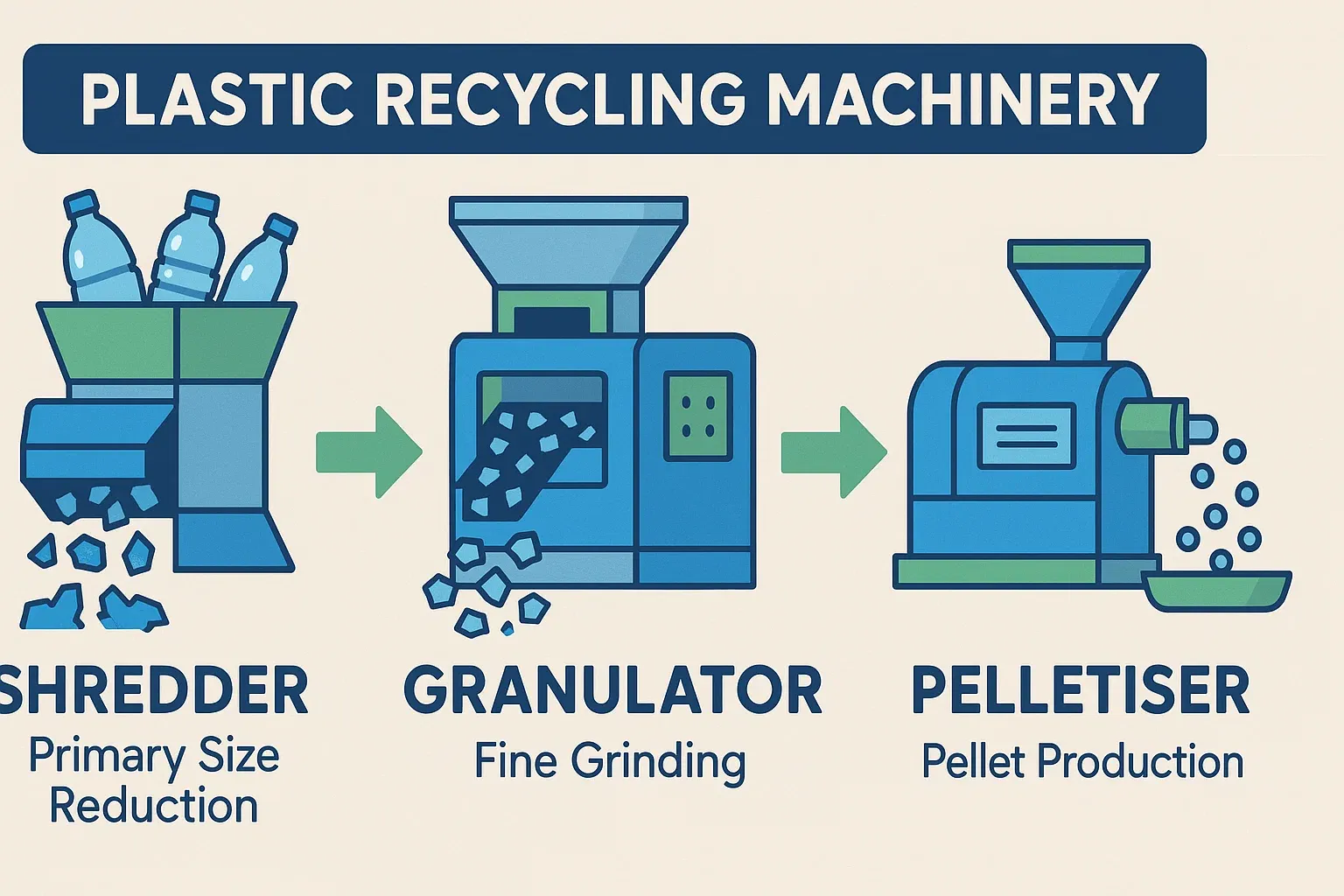

A 3D print shredder is the “front end” of a loop. Here is what a realistic loop looks like.

- Collect: Keep a dedicated bin for each material.

- Inspect and sort: Remove inserts and mixed materials.

- Shred: Turn scraps into uniform flakes.

- Condition: Dry and store properly.

- Reprocess:

- Option A: Feed into a filament extruder.

- Option B: Ship flakes to a recycler that accepts your polymer.

- Print again: Use recycled filament for prototypes, test prints, and non critical parts.

Not every shop needs to extrude filament. Even if you only shred and ship, you reduce storage pain and make the material easier to handle.

Where our Mini Desktop Small Shredder fits

If you are building a quiet, clean, and repeatable recycling corner, the Mini Desktop Small Shredder is designed for exactly that desktop environment.

- Desktop friendly size: Fits next to printers and post processing stations.

- Quiet focused operation: Better suited for classrooms and studios than industrial machines.

- Strong cutting system: Built for common plastics and steady reduction into flakes.

- Maintenance oriented design: Faster cleaning to help prevent color and material cross contamination.

Product page: Mini Desktop Small Shredder

https://www.energycle.com/plastic-shredders/mini-desktop-small-shredder/

Troubleshooting: common issues when shredding 3D printing waste

Problem: flakes are inconsistent

- Feed at a steady pace.

- Pre break large parts.

- Avoid mixing flexible materials with rigid ones.

Problem: material jams

- Reduce piece size.

- Do not force long thin scraps.

- Stop the machine before clearing any jam.

Problem: too much dust

- Avoid over shredding.

- Clean the chamber and area after use.

- Consider a basic dust control routine for your workspace.

Problem: recycled filament prints poorly

- Confirm you did not mix polymers.

- Dry flakes before extrusion.

- Keep contamination low.

Safety checklist for desktop shredding

- Wear eye protection.

- Keep hands away from the feed opening.

- Never clear a jam while the machine is running.

- Do not shred unknown materials.

- Keep the area clean to avoid slipping on flakes.

FAQ

Can I recycle 3D printing waste at home?

Yes, at a small scale, you can set up a workflow to collect, sort, and shred waste. Whether you re extrude filament at home or send flakes to a recycler depends on your equipment and local options.

Do I need to wash prints before shredding?

If prints have adhesive, oils, or visible dirt, clean them. The goal is to prevent contamination that later shows up as weak parts or ugly filament.

What plastics from 3D printing are easiest to recycle?

PLA is often the easiest for small scale projects because it is widely used and behaves predictably in basic recycling workflows. Regardless of material, keep polymers separate.

What flake size is best?

Choose a size that fits the requirements of your next step. For extrusion, consistency matters more than absolute size.

A "Jack of all trades" shredder is a master of downtime. While it is tempting to buy one machine to process "everything" (Purging, Film, Pipe, Pallets), the physics of material reduction dictate that you will lose 30-40% efficiency on every ton. This guide explains why specialization is the only path to profitability.

Related equipment: PE/PP film shredder, rigid plastic shredder.

1. The RPM Mismatch

- Film/Fiber (Soft): Requires High Torque + High Speed (80-100 RPM). You need momentum to shear the material before it stretches.

- Hard Plastic (Lumps): Requires High Torque + Low Speed (40-60 RPM). High speed causes the rotor to bounce off the block, creating shock loads.

- The "Universal" Compromise: A machine running at 70 RPM is too fast for lumps (shock) and too slow for film (jamming).

2. Rotor Geometry: Spline vs. Smooth

- Film/Fiber: Often uses an Anti-Winding Spline Rotor. The raised surfaces prevent the material from lying flat and wrapping.

- Rigid Plastic: Uses a Smooth Rotor. Splines would create stress concentration points that could crack when hitting a solid block of PP.

- Result: Running film on a smooth rotor often leads to wrapping. Running dense lumps on a spline rotor can increase stress concentrations and risk mechanical damage, depending on rotor design and control settings.

3. Ram Logic (Hydraulics)

- Film: Light and fluffy. Requires a Turbo Ram (fast approach, low pressure) to constantly force material into the blades.

- Pipe/Purging: Dense and solid. Requires a Load Sensing Ram (slow approach, high pressure) that "nibbles" the material to prevent stalling.

- Conflict: A universal ram logic will either overfeed the lumps (stall) or underfeed the film (throughput drop).

4. Screen Design

- Film: 40mm screen with 50% Open Area.

- Rigid: 40mm screen with 35% Open Area (stronger web thickness).

- Failure: Running lumps on a film screen will bend or break the screen due to lack of structural rigidity.

Conclusion

Buying two specialized machines (one for film, one for rigid) often has a lower Total Cost of Ownership (TCO) than buying one "Universal" machine that runs at 60% efficiency and requires constant maintenance.

References

[1] "Efficiency in Plastic Recycling," Waste Management World. Efficiency in Plastic Recycling

[2] "Design Principles of Industrial Shredders," Journal of Engineering. Design Principles of Industrial Shredders

Shredding textile waste is mechanically different from shredding plastic. A plastic bottle cracks; a cotton shirt stretches. In many textile applications, the machine performs best when configured to Shear rather than Tear. This guide explains the rotor geometries required for high-volume textile recovery.

Related equipment: textile waste single shaft shredder.

1. The Enemy: Winding (Wrapping)

Textiles are high-tensile materials. If the knife dulls or the gap is too wide, the fabric will not cut—it will wrap around the rotor shaft, eventually stalling the motor or burning out the bearings.

The Solution: The "Splined" Anti-Winding Rotor

Standard rotors are smooth cylinders. Textile rotors typically use Raised Splines or Wear Strips welded between the knife holders.

* Function: These raised areas prevent long strips of fabric from lying flat against the shaft, breaking the surface tension and preventing tight wrapping.

* Protection: Bolt-on Winding Discs at the rotor ends protect the bearing housing seals from fiber ingress.

2. Cutting Geometry: The "Double Scissor"

Straight cut knives act like a guillotine—high impact, high noise.

* V-Rotor (Chevron): Knives are arranged in a "V" shape.

* Effect: Pulls material toward the center of the rotor, preventing it from jamming against the side walls.

* F-Rotor (Fillet): Knives are arranged in a continuous spiral.

* Effect: Only 1 knife cuts at a time. Constant load, lower amperage spikes, smoother operation on heavy carpets.

3. Throughput Calculation Logic

Textile waste has incredibly low bulk density (60 - 100 kg/m³).

* Formula: $Capacity (kg/h) = Volume (m³) \times RPM \times Efficiency \times Density$.

* Implication: You need a physically larger machine to achieve the same tonnage as plastic.

* Example: A 1200mm shredder does 2 tons/hr of plastic. It will only do 600 kg/hr of loose textile.

* Fix: Hydraulic Ram Assist. A customized "High Speed" ram is required to force the fluffy material into the rotor to artificially increase density at the cutting point.

4. Application-Specific Output

- Rag Production (Wiping): 100mm - 150mm strips. Requires a large screen (100mm).

- Fiber Opening (Recycling): <40mm chips. Requires a small screen (40mm) and high rotor speed (120 RPM) to "open" the weave.

References

[1] "Mechanics of Fiber Cutting," Textile Research Journal. Mechanics of Fiber Cutting

[2] "Design of Industrial Shredders," Waste Management. Design of Industrial Shredders

The textile recycling industry is shifting from "downcycling" (insulation/rags) to "circularity" (fiber-to-fiber). This shift demands a radical change in shredding technology. A machine that makes rags cannot prepare feedstock for a chemical depolymerization reactor. This guide explores the pre-processing innovations required for modern textile recovery.

Related equipment: textile waste single shaft shredder.

1. The Feedstock Gap: Fluff vs. Chips

Mechanical Recycling (Spinning)

- Goal: Retain max fiber length (>15mm).

- Technology: Garnett-style single-shaft shredders with tearing pins.

- Innovation: Soft-Start High-Torque Drives that gently pull fabrics apart at low speeds (<60 RPM) to minimize fiber breakage and friction heat (which melts Polyester).

Chemical Recycling (Depolymerization)

- Goal: Maximize surface area for chemical reaction.

- Requirement: Uniform, dense "chips" (e.g., 10mm x 10mm). Fluff causes "bridging" in hoppers and floats in solvents.

- Technology: Double-Cut Granulators. A secondary granulator with a "guillotine" rotor cuts the pre-shredded textile into precise squares, increasing bulk density from 40kg/m³ to 150kg/m³.

2. Automated Sorting (NIR)

You cannot rely on garment labels (they are often wrong).

* Innovation: Hyperspectral NIR Cameras mounted over the shredder infeed conveyor.

* Function: Detects the precise Polyester/Cotton ratio (e.g., 60/40 vs 50/50) in milliseconds.

* Action: Air jets divert non-compliant items (e.g., all-nylon items in a cotton line) before they enter the shredder.

3. The "Hard Part" Problem: Zippers & Buttons

Zippers (Brass/Alu) and Buttons (Thermoset Plastic) destroy fine shredder blades.

* Old Method: Manual removal (too expensive).

* New Method: Hammer Mill Liberation.

* After pre-shredding to 50mm, the textile is passed through a high-speed Hammer Mill.

* The impact shatters buttons and detaches zippers from the fabric.

* A downstream Eddy Current Separator and Zig-Zag Air Classifier then remove the heavy metal/plastic fragments, leaving pure fiber.

4. Dust Control: The Microfiber Threat

Polyester microfibers are explosive (Kst > 0) and a respiratory hazard.

* Innovation: Negative Pressure Cutting Chambers.

* The shredder rotor is enclosed in a vacuum-sealed housing.

* Dust is extracted at the source (the cutting point) rather than allowing it to float into the room.

* This improves sensor reliability (no dust on optical lenses) and prevents cross-contamination of colors.

Conclusion

The future of textile recycling is not just "shredding"—it is fractionation. Buying a general-purpose shredder for sophisticated textile recovery often produces inconsistent feedstock and poor downstream yields. You should engineer the line for your specific end-product: Fiber (Mechanical) or Monomer (Chemical).

References

[1] "Guide to Recycled Materials (GRS-202)," Textile Exchange. Guide to Recycled Materials (GRS-202)

[2] "Automated Sorting Technologies," Recycling International. Automated Sorting Technologies