Recycling News

The global challenge of plastic waste has necessitated innovative solutions in recycling technology. One of the most groundbreaking advancements is the integration of Artificial Intelligence (AI) into the sorting and processing of plastics. AI technologies are transforming the recycling industry by enhancing efficiency, accuracy, and the overall quality of recycled materials.

The total shipment value of primary plastics machinery in North America reached an estimated $319.0 million in Q3 2024, marking a 41.9% rise compared to the previous quarter.

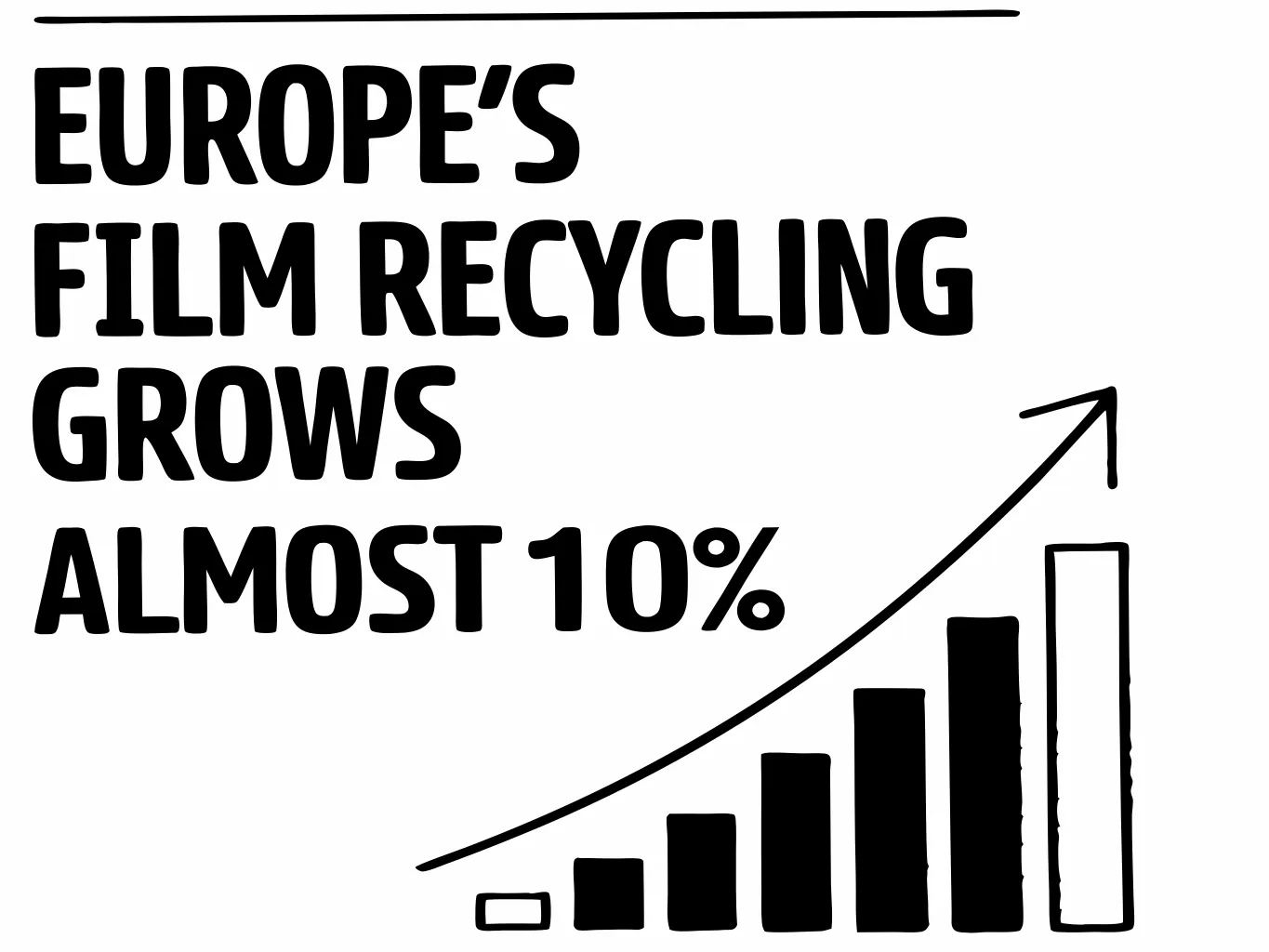

Despite the significant disruptions in waste management due to the COVID-19 pandemic, Europe's recycling capacity for flexible film surged by nearly 10% in 2020. According to Plastics Recyclers Europe, this growth highlights the region's leadership in mechanical film recycling and its commitment to advancing a circular economy.

Rigid plastics, encompassing materials like HDPE, LDPE, PET, and PVC, are integral to various industrial applications, from consumer packaging to automotive parts. Recycling these materials not only helps in conserving resources but also significantly reduces landfill waste and environmental pollution. This guide aims to explore the high-performance recycling equipment designed specifically for processing rigid plastics, providing insights into how these machines work, why they are essential, and what to consider when selecting the right equipment for your operation.

Maintaining PVC recycling machinery is vital for ensuring optimal performance, extending equipment longevity, and producing high-quality recycled products. Below is a detailed guide on best practices for maintaining PVC recycling machinery effectively.

Vinyl siding is widely used for its durability and low maintenance, but what happens when it reaches the end of its life? Recycling is a sustainable solution, and with the aid of vinyl recycling machines, the process becomes even more efficient. This guide will walk you through the essentials of vinyl siding recycling, including the role of specialized machines in making the process easier and more environmentally friendly.

PVC (polyvinyl chloride) is a widely used plastic in construction, packaging, and consumer goods. Recycling PVC can mitigate environmental harm and provide economic benefits, but it requires specialized equipment. Below is a structured cost-benefit analysis to help evaluate the investment.

What is Automotive Plastic Parts Recycling?

Automotive plastic parts recycling involves the process of reclaiming and reusing plastic components from vehicles. With the increasing emphasis on sustainability, recycling automotive plastics not only helps in managing waste but also in conserving resources.

Maximizing efficiency in PET (polyethylene terephthalate) recycling is essential for reducing environmental impact and enhancing operational productivity. To achieve this, consider the following strategies:

Rigid plastic recycling machines are pivotal in transforming waste plastics into valuable raw materials for manufacturing, contributing to both environmental sustainability and economic efficiency. Below is an in-depth look at the key components, functionalities, and benefits of these machines, along with guidance on selecting the right equipment for your business.

Rigid plastics, including items like containers, bottles, and durable goods, form a significant part of plastic waste. Recycling these materials not only conserves resources but also reduces environmental impact. Here's how you can select the best machine for recycling rigid plastics:

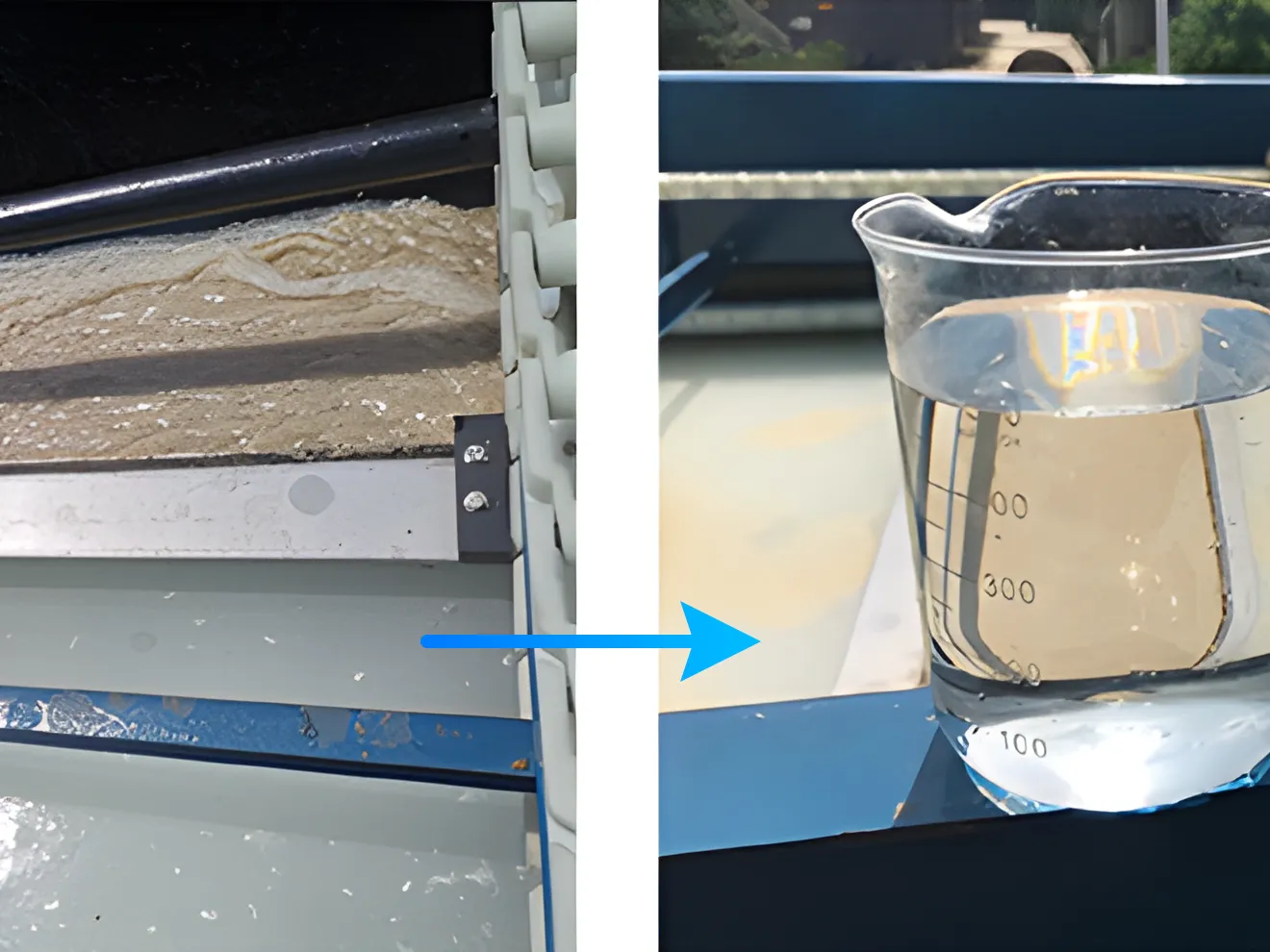

Wastewater from plastic recycling and washing is a major source of pollution in the plastic recycling and regeneration process, primarily originating from the cleaning, separation, and wet crushing of waste plastics. The concentration of pollutants in the wastewater is closely related to the characteristics of the raw waste plastics. For mixed, low-grade materials containing significant amounts of impurities such as paper and soil particles, the wastewater generation can reach up to 10 tons per ton of waste plastic. The wastewater produced during the cleaning and crushing stages contains high levels of organic matter and suspended solids, with chemical oxygen demand (COD) reaching up to 2000 mg/L and suspended solids (SS) up to 500 mg/L.