Recycling News

Introduction to PVC and Its Environmental Footprint

PVC, or Polyvinyl Chloride, is one of the most widely used plastics due to its versatility, durability, and cost-effectiveness. However, its lifecycle—from production to disposal—can have significant environmental implications. This article explores how recycling PVC can mitigate these impacts, focusing on reducing carbon footprints and managing plastic waste effectively.

When it comes to managing plastic waste efficiently, selecting the best rigid plastic recycling machine is crucial. The right machine not only reduces your environmental footprint but also boosts the efficiency and profitability of your recycling operations. In this comprehensive guide, we’ll walk you through all the key factors to help you make an informed decision.

In the rapidly evolving world of recycling, rigid plastic recycling machines have seen groundbreaking advancements. These innovations are helping industries reduce waste, save costs, and improve efficiency. Let’s explore the top five game-changing technologies revolutionizing this field in 2024.

What does 'PVC' stand for?

Polyvinyl chloride. PVC is commonly referred to as vinyl, and the two names can be used interchangeably. Vinyl resin can be combined with a wide range of other materials such as plasticizers, stabilizers, lubricants, and colorants, depending on the requirements of the end product. Not all vinyl products use the same combination of materials.

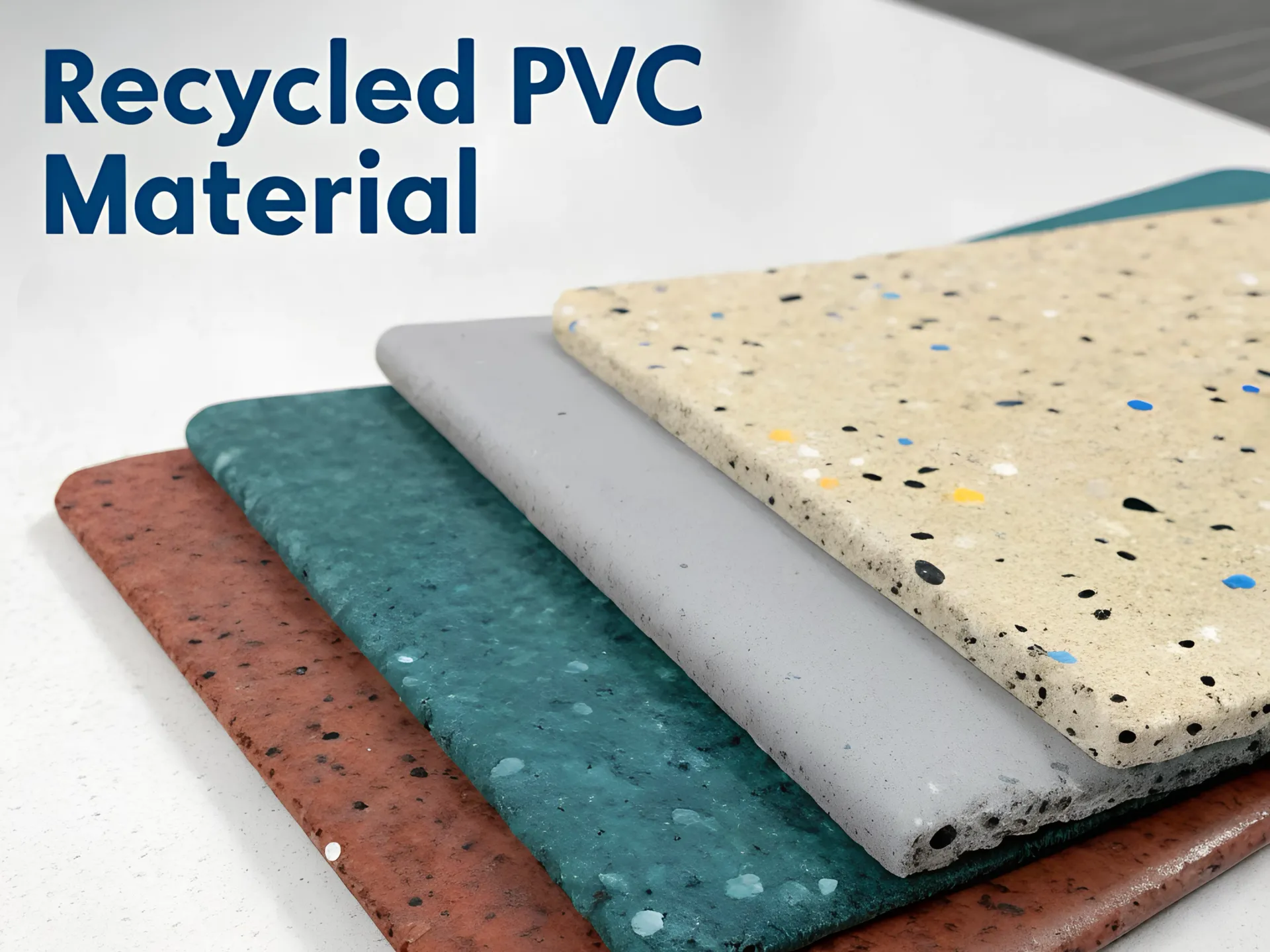

Recycled polyvinyl chloride (PVC) is gaining prominence as industries seek sustainable materials. The global PVC recycling market, valued at USD 3.3 billion in 2023, is projected to reach USD 4.9 billion by 2028, growing at a compound annual growth rate (CAGR) of 8.0%.

Expanded Polystyrene (EPS) foam, commonly used in packaging and insulation, presents significant recycling challenges due to its lightweight and bulky nature. Recent advancements in EPS recycling machinery are addressing these issues, enhancing waste management efficiency and promoting sustainability.

In today’s sustainability-focused landscape, the demand for recycled PVC materials is steadily increasing. This growth is fueled by regulatory mandates and a market shift towards eco-friendly materials across industries such as construction, automotive, and packaging. By understanding these market dynamics and investing in the right tools—specifically PVC recycling machines—businesses can position themselves at the forefront of this green revolution.

Introduction

Polyvinyl Chloride (PVC) is widely used in construction, automotive, and consumer goods due to its durability, versatility, and cost-effectiveness. With increasing environmental awareness and regulatory pressures, recycling PVC has become essential to reducing waste and conserving resources. The two primary recycling methods—mechanical recycling and feedstock recycling—are essential for handling both straightforward and complex PVC waste streams.

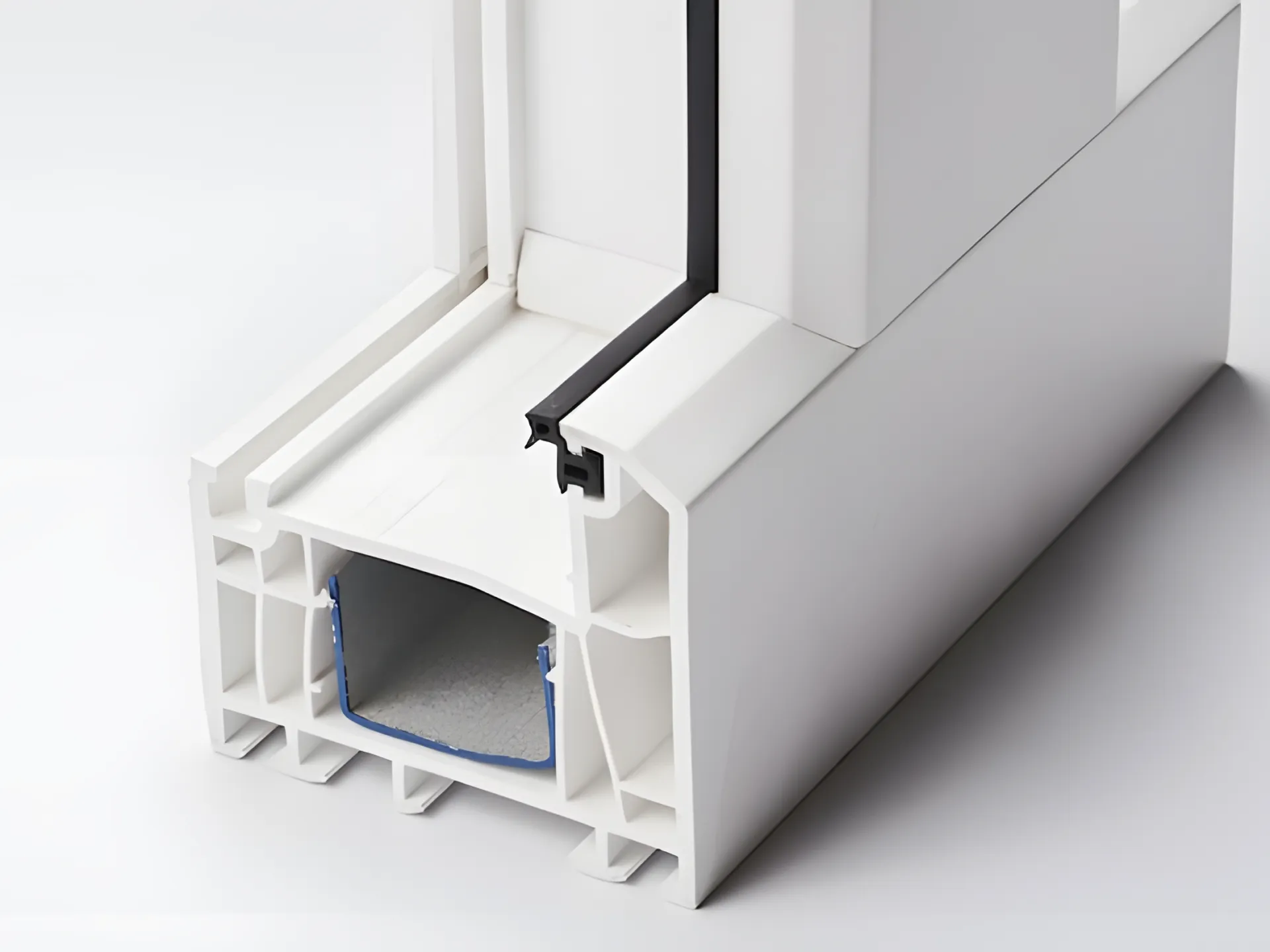

Why PVC Profile Recycling Matters

Recycling PVC profiles, especially through advanced machinery, is essential for reducing waste, saving resources, and supporting a circular economy. PVC, or polyvinyl chloride, is widely used in construction for products like windows and doors. When companies like Deceuninck recycle these profiles, they extend the lifespan of PVC materials, reduce environmental impact, and preserve the quality of the products.

The European Union has introduced new restrictions on lead usage in PVC (polyvinyl chloride) products, aimed at minimizing human exposure to this hazardous substance. The updated regulation, adopted on May 3, 2023, amends Annex XVII of the REACH Regulation (EC No. 1907/2006) and sets clear guidelines for the use and marketability of PVC products containing lead.

In the world of plastic manufacturing, waste management is no small affair, and the introduction of PVC pipe horizontal crushers has been nothing short of a game-changer. Let’s dive deep into how these robust machines are making significant strides in transforming the industry’s approach to waste.