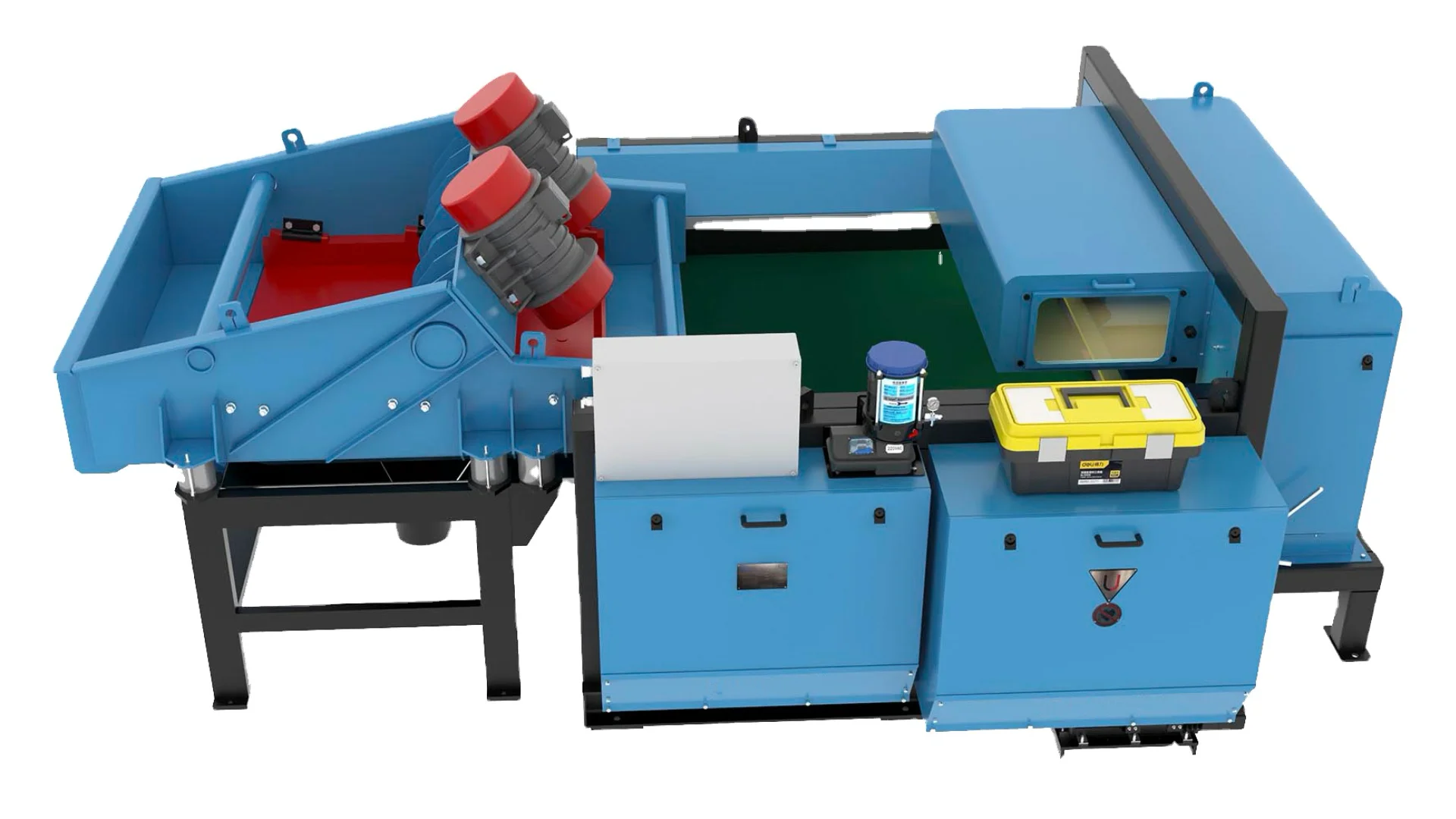

Eddy Current Magnetic Separator

Efficiently recover non-ferrous metals with our advanced Eddy Current Separator. The innovative eccentric pole system ensures maximum recovery for all recycling operations.

Request a Quote

Technical Parameters

- Roller Diameter: 280mm

- Belt Width: 300mm

- Power Supply: 4.5 kW

- Magnetic Field Strength: Adjustable

- Recovery Rate: Up to 96%

- Dimensions: Customizable

Key Features

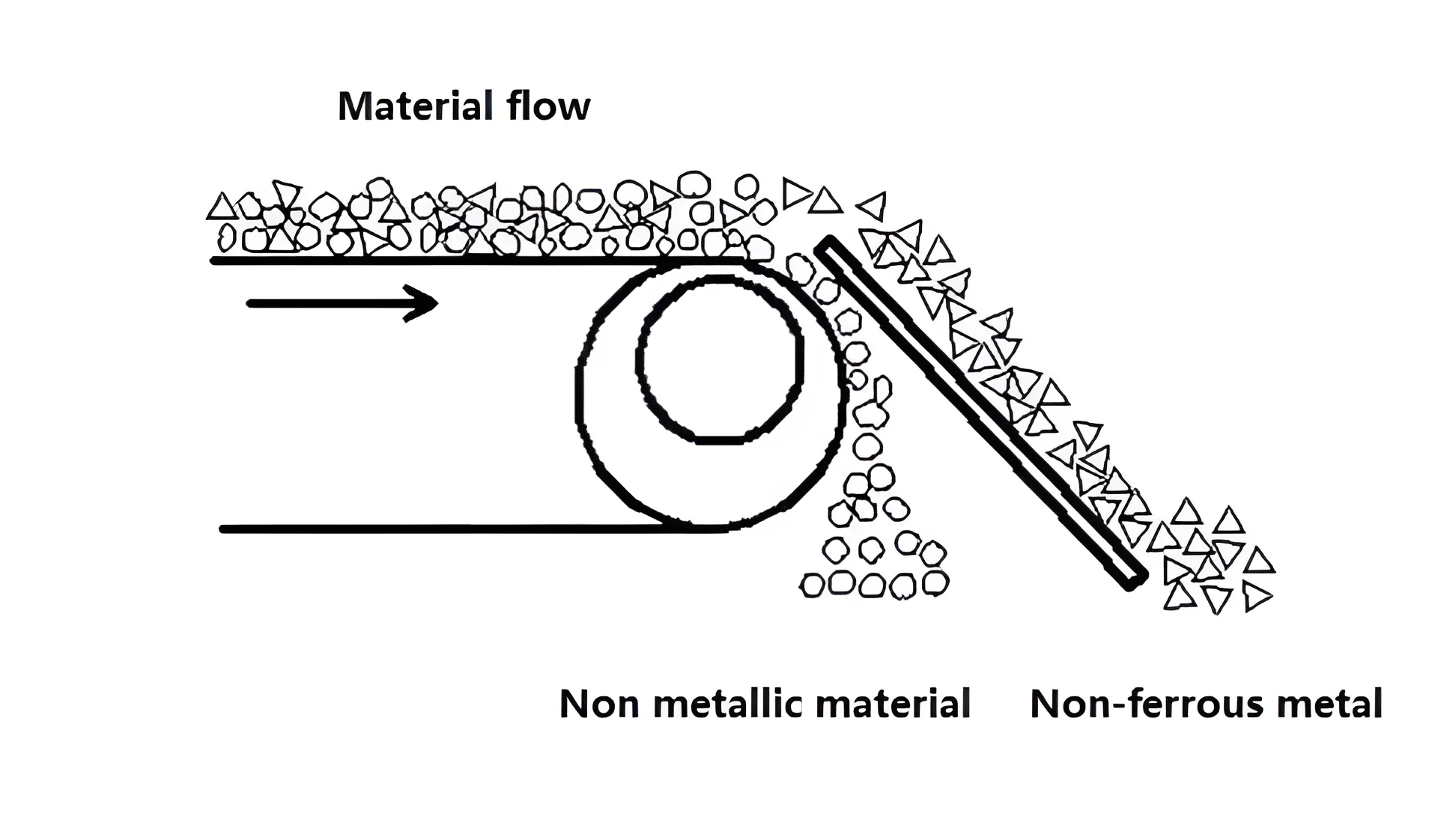

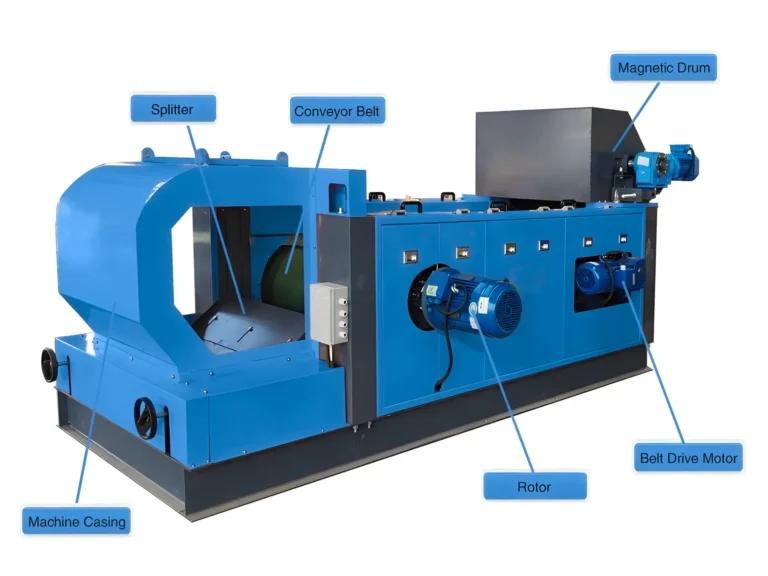

Eccentric & Concentric Systems

Adaptable pole systems to maximize recovery based on material type and size.

High Separation Efficiency

Effectively separates non-ferrous metals with precision for maximum purity.

Low Maintenance Design

Engineered for easy operation and minimal maintenance, saving long-term costs.

Specifications

| Model | Belt Width (mm) | Roller Ø (mm) | Belt Speed (m/s) | Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| SES-300 | 300 | 280 | 0~2.5 | 2.2 + 0.75 | 760 |

Applications

Aluminum Recycling

Separates aluminum cans and fragments from mixed waste streams.

Shredder Material

Processes ASR (Auto Shredder Residue) for valuable metal recovery.

Electronic Scrap (WEEE)

Recovers copper and aluminum from crushed electronic waste.

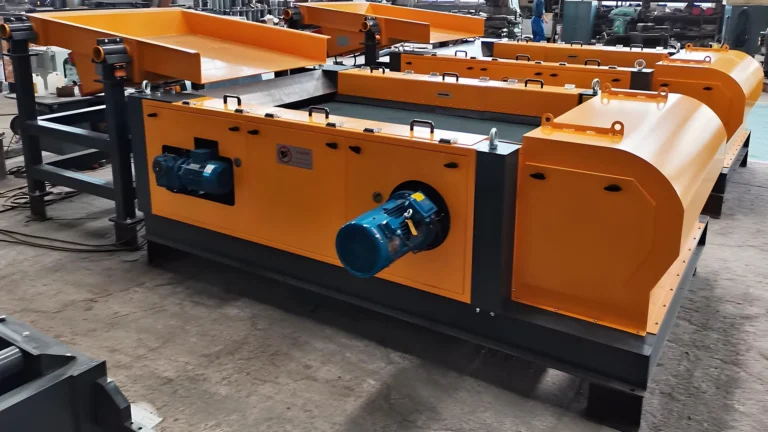

Explore Our Separator Lineup

High-Recovery for Fine Aluminum

Designed for high-efficiency separation of tiny non-ferrous particles from PET flakes, glass scrap, and IBA processing.

Efficient Non-Ferrous Metal Recovery

Essential machinery for separating aluminum and other non-ferrous metals from various mixed process streams.

Advanced Separator for Recycling

A crucial and sophisticated separator for maximizing efficiency in plastic recycling, e-scrap, and shredder residue.

Frequently Asked Questions

What types of non-ferrous metals can this machine separate?

It is highly effective at separating aluminum, copper, brass, magnesium, and other non-ferrous metals from non-metallic materials like plastic, glass, and wood.

What is the typical maintenance schedule?

The machine is designed for low maintenance. Regular checks involve inspecting the conveyor belt for wear and ensuring the magnetic rotor is clean. A detailed schedule is provided in the user manual.

Can the separator be integrated into an existing processing line?

Absolutely. We offer customizable dimensions and configurations to ensure seamless integration with your current conveyor systems and facility layout.