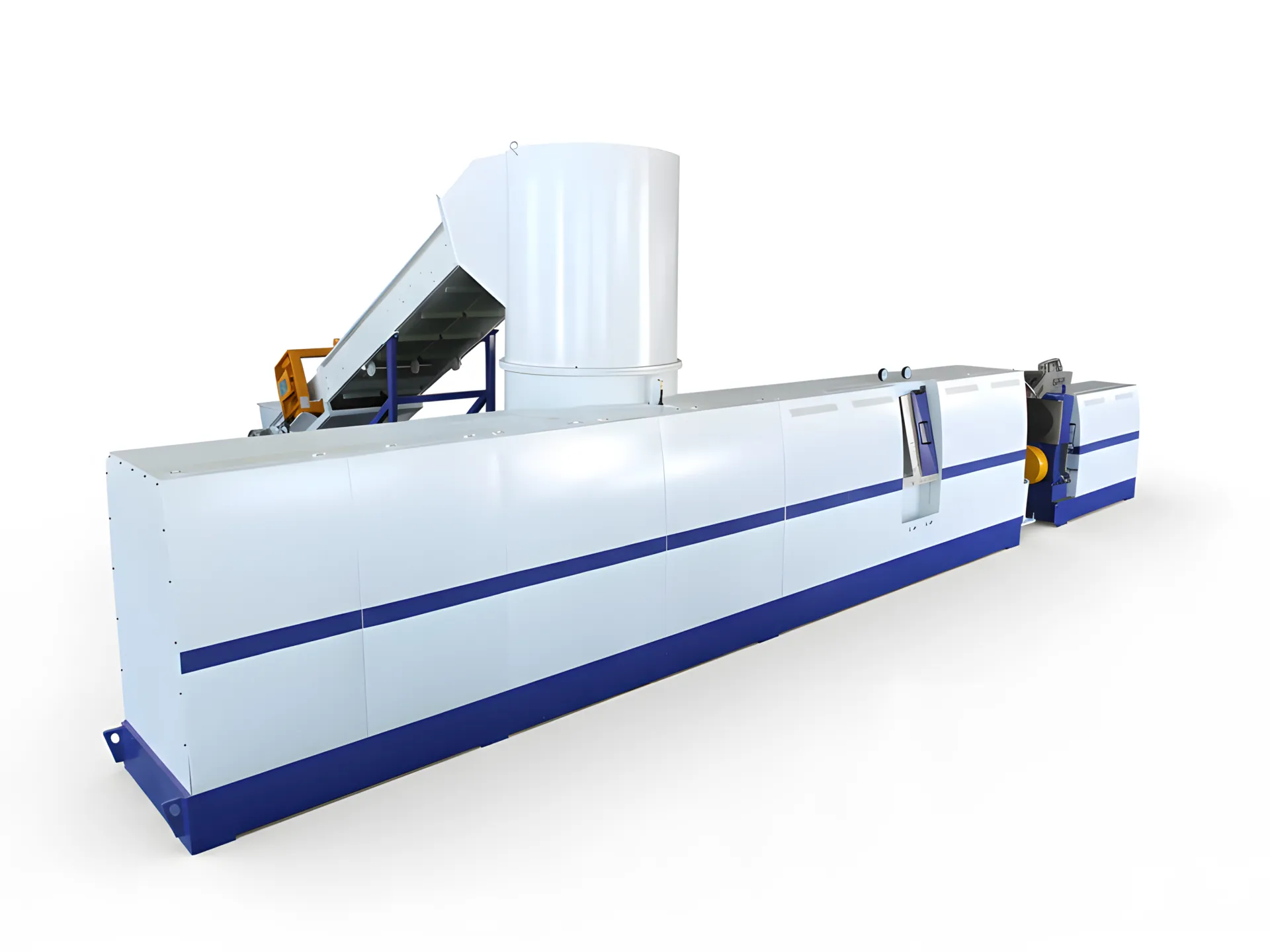

EPS Foam Pelletizing Line

Transform bulky Styrofoam waste into valuable, dense plastic pellets. Drastically reduce storage and transport costs while creating a new revenue stream.

Request a QuoteCore Operational Advantages

Our complete pelletizing line is a highly efficient, automated solution for converting problematic EPS foam into a valuable commodity.

Extreme Volume Reduction

Compacts bulky foam waste by up to 90:1 ratio, slashing your storage space requirements and hazardous transportation fees.

Create a Revenue Stream

The dense, recycled EPS pellets (PS) are a valuable commodity that can be sold directly to manufacturers of new plastic products.

Boost Sustainability

Divert thousands of cubic meters of non-biodegradable foam from landfills, enhancing your company's environmental compliance.

High-Efficiency Output

Designed for continuous, 24/7 operation with automated temperature control, ensuring maximum productivity and rapid ROI.

Extrusion Process Flow

A complete, automated system that transforms bulky foam blocks into uniform, high-quality plastic pellets.

1. Crushing & Feeding

Large EPS blocks and boxes are fed into a heavy-duty crusher, breaking them down into small, uniform flakes suitable for screw extrusion.

2. Melting & Degassing

The flakes enter a specialized single-screw extruder where they are melted. Vacuum degassing strips out trapped air and volatiles.

3. Filtration & Screening

A hydraulic screen changer continuously filters out contaminants (labels, tape, dirt), ensuring the purity of the final PS pellet.

4. Strand Pelletizing

Molten strands are extruded into a cooling water bath and then cut by a high-speed rotary cutter into uniform, dry pellets.

Machine Specifications

| Model | Capacity (kg/h) | Crusher Power (kW) | Main Extruder Power (kW) | Total Power (kW) |

|---|---|---|---|---|

| EPS-150 | 120 - 150 | 7.5 | 22 | ~45 |

| EPS-200 | 180 - 220 | 11 | 37 | ~65 |

| EPS-300 | 250 - 300 | 15 | 55 | ~90 |

Equipment Operation Showcase

See the robust construction and high-quality output of our EPS recycling line.

Warranty & Satisfaction Guarantee

Get clear warranty terms and responsive after-sales support. We ensure your machine keeps running profitably.

Standard Warranty

12 months for major components (screw, barrel, motor). Extended warranty options available.

Remote Support

Lifetime technical support via video call, email, and phone for troubleshooting and parameter settings.

Spare Parts

We stock critical spare parts (heaters, blades, screens) for fast dispatch to minimize downtime.

Installation & Training

Optional on-site commissioning and operator training to ensure your team can run the line at peak efficiency.

Technical Support & FAQ

How does the machine maximize pellet density?

By fully melting and degassing the foam in a single-screw extruder with a high L/D ratio, we remove all air pockets. The result is solid PS pellets with density comparable to virgin material (>1.0 g/cm³), ideal for injection molding.

Can it handle wet or dirty material (e.g., fish boxes)?

The system has venting zones to handle some moisture (up to 3-5%). However, for heavily soiled fish boxes, we recommend our optional washing module or pre-drying to ensure machine longevity and pellet purity.

What is the typical maintenance schedule?

Routine maintenance involves checking hydraulic fluid, changing screen filters (depending on contamination), and sharpening pelletizer blades. The robust gearbox and screw are designed for years of low-maintenance operation.

What is the ROI for this line?

ROI is typically 6-12 months. By converting waste that costs money to dispose of into pellets that sell for $500-800/ton, the machine pays for itself very quickly given sufficient feedstock volume.

Start Profiting From Your Foam Waste

Stop paying disposal fees. Contact us for a custom quote and layout drawing for your facility.

Comments are closed.