EPS (Expanded Polystyrene) recycling machines are specialized equipment designed to process and recycle foam plastic waste. As global environmental awareness increases, EPS recycling technology has become a crucial solution for addressing packaging and construction waste challenges. This article provides a comprehensive analysis of the complete operational workflow of EPS recycling machines.

The Importance of EPS Recycling

EPS materials are widely used in packaging, insulation, and construction applications, but their composition of 98% air and only 2% polystyrene makes them bulky and expensive to transport. Traditional landfill disposal not only occupies substantial space but also causes long-term environmental pollution. Professional recycling can reduce foam waste volume by over 90%, significantly lowering transportation costs while converting it into high-quality reusable raw materials. EPS strojevi za recikliranje Main Types of EPS Recycling Equipment

The market offers three primary types of EPS recycling equipment, each suited for different application scenarios:

- Cold Press Compactors

- Hot Melt Densifiers

- Pelletizing Recycling Systems

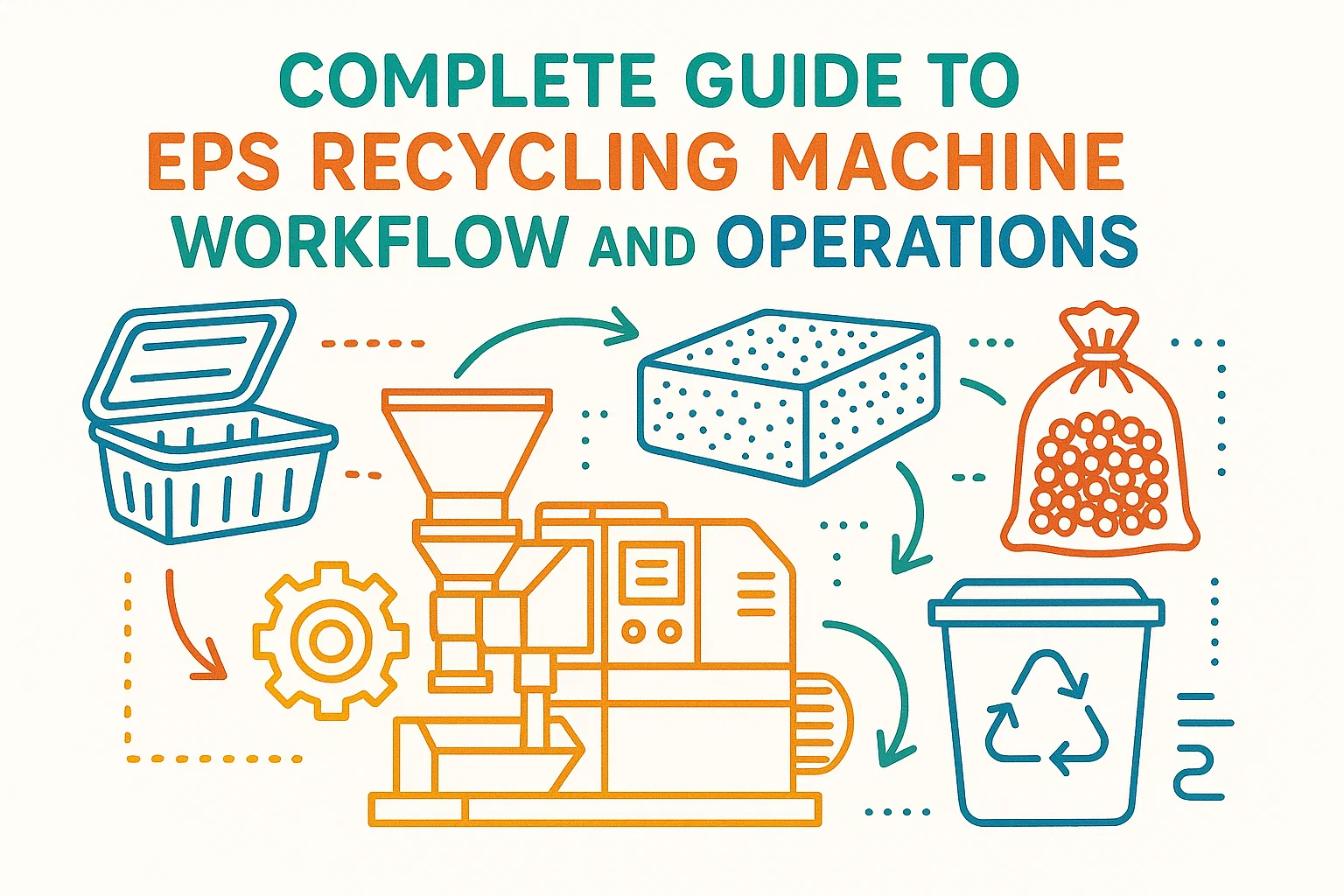

Complete EPS Recycling Operational Workflow

Step One: Waste Collection and Sorting

The recycling process begins with collecting EPS waste from various sources, including packaging facilities, retail stores, construction sites, and manufacturing plants. After collection, waste must be sorted and cleaned to remove potential contaminants. Before feeding, it is essential to ensure removal of tape, plastic films, metals, and stones, as these materials can block filter screens or damage equipment crushers, screws, and cutters.

Step Two: Crushing Process

Sorted EPS waste is fed into specialized crushers for shredding. Crushers cut large foam materials into smaller fragments, typically 10-20mm in size. This step is crucial for subsequent melting and compaction processes, as smaller fragments are easier to handle in equipment and prevent long strips from tangling and blocking conveyor systems.

Step Three: Melting and Compaction

Crushed EPS fragments are fed into the core processing unit of the recycling machine. During this stage, equipment employs different processing methods based on type:

- Cold press equipment uses high-speed rotating screws (approximately 1000 RPM) to compress foam, forcibly expelling air and gradually compacting the material.

- Hot melt equipment heats EPS through heating chambers to temperatures of approximately 200-210 degrees Celsius, causing it to melt and compress.

Step Four: Cooling and Solidification

After melting or compaction, extruded EPS material requires cooling and solidification through cooling systems. For thermally processed materials, molten foam is extruded into thin strips, then cooled through water tanks. Cooling systems ensure materials maintain stable shape and consistency, preparing them for subsequent cutting or storage.

Step Five: Cutting and Pelletizing

When using complete pelletizing systems, cooled EPS strips are fed into cutting machines for pellet formation. Cutters typically feature 19 blades, enabling material cutting into uniform pellets. Cut pellets pass through vibration screens for screening, with unqualified pellets automatically rejected to ensure final product quality.

Step Six: Storage and Reuse

Final products are stored in silos as dense blocks or pellets, conveniently transported to manufacturers. These recycled materials can be used to produce new building insulation materials, picture frames, plastic products, and other items, achieving resource circulation. Recycled EPS materials enjoy high market acceptance, creating additional revenue streams for enterprises.

Core Components of EPS Recycling Machines

Complete EPS recycling systems typically include the following key components:

- Feeding System

- Melting Chamber or Compaction Chamber

- Screw Extrusion System

Sustav hranjenja - Cooling Device - Cutting System - Control System Critical Operational Considerations - Temperature Control is the core of hot melt equipment operation. The first extruder temperature is typically set to 210 degrees Celsius, the second extruder to 197 degrees, and the die head temperature to 200 degrees. Operators must observe material melting degree, raising temperature if material is too hard and lowering it if too thin. - Maintenance is crucial for extending equipment lifespan. After daily production, residual materials in screws must completely flow out to avoid cooling and solidification. If materials are not completely melted during second-day startup, screw wear increases, potentially damaging equipment components in severe cases. Blowtorches can be used to accelerate temperature rise, rapidly melting solidified materials. Regular addition of lubricating oil and component cleaning are also important measures for maintaining equipment in good condition. Safety Operating Procedures require operators to ensure waste contains no hard impurities such as metals or stones, which can damage crushers, screws, and cutters. Equipment is equipped with hydraulic stations, electrical control panels, and movable plates as safety devices. All systems must be carefully checked for normal operation before starting. Economic and Environmental Benefits of EPS Recycling Kontrolni sustav manifest in multiple aspects. By reducing EPS volume by up to 90%, enterprises can substantially lower transportation and storage costs. Recycled foam materials can be sold as raw materials or internally reused, creating additional revenue. Meanwhile, recycling processing is more economical than landfill disposal, reducing waste handling expenses.

value is significant. EPS materials are not biodegradable, causing long-term environmental harm if not properly handled. Converting waste into reusable resources through

Kontrola temperature substantially reduces waste entering landfills, supporting circular economy development. Many countries and regions are implementing stricter environmental regulations. Using recycling equipment helps enterprises comply with regulatory requirements, avoiding potential fines.

Svakodnevno održavanje improvements are notable. Recycled EPS materials can serve as raw materials for manufacturing new products, including insulation boards, picture frames, and construction materials, forming complete circular economy chains. On average, 56% of post-use EPS is utilized as recycled content in new packaging, demonstrating material durability and sustainability.

Application Cases Across Industries EPS recycling machines have been widely applied across multiple industries globally.

- EPS Manufacturers

Ušteda troškova - Recycling Companies

Zaštita okoliša - Packaging Industry strojevi za recikliranje - Construction Industry

Učinkovitost resursa Key Factors in Selecting EPS Recycling Machines

Enterprises must consider multiple factors when purchasing EPS recycling equipment.

- Processing Capacity - Technology Type - Space and Configuration

Recycling Companies employ professional EPS recycling equipment to process foam waste collected from various channels. An Italian recycling company operating Energycle equipment demonstrates exceptional efficiency, substantially streamlining recycling logistics. American recycling companies also utilize similar equipment, significantly reducing EPS volume to enhance operational efficiency, making materials easier to handle, transport, and further process.

Ambalažna industrija generates substantial EPS waste, particularly in electronics, appliances, and fragile goods packaging sectors. These enterprises solve waste disposal problems by installing on-site recycling equipment while reinvesting recycled materials into production, reducing raw material procurement costs.

Construction Industry generates substantial cutting waste when using EPS insulation board materials. Through recycling equipment, this waste can be compressed into blocks or converted into pellets, reused for producing new insulation materials or other construction products. Australian EPS factories successfully utilize recycling machines to compact EPS insulation board waste, achieving zero-waste production processes.

Key Factors in Selecting EPS Recycling Machines

Enterprises must consider multiple factors when purchasing EPS recycling equipment. Kapacitet obrade is the primary consideration, with equipment processing capacities ranging from 100 to 300 kilograms per hour. Enterprises need to select appropriately sized equipment based on their waste generation volume, from compact models suitable for small operations to high-capacity systems designed for large recycling centers.

Technology Type selection depends on specific application requirements. For relatively clean EPS waste processing, cold press equipment is ideal due to low energy consumption and simple operation. For processing mixed waste containing certain impurities, hot melt equipment offers higher tolerance. For enterprises seeking ready-to-use plastic pellets, complete pelletizing systems, though requiring higher investment, provide maximum added value.

Space and Configuration require advance planning. Complete recycling production lines span 15-25 meters in length and approximately 6 meters in height. Enterprises must ensure adequate plant space. Equipment electrical configuration is also important. Depending on processing capacity, installed power ranges from 37.5 kilowatts to over 100 kilowatts, requiring corresponding electrical infrastructure support.

Retorno sobre Investimento É um importante critério de tomada de decisão para empresas. Embora o investimento inicial em equipamentos seja significativo, a maioria das empresas pode recuperar o investimento em 2-3 anos através de economia de custos de transporte, redução de taxas de descarte de resíduos e venda de materiais reciclados. Além disso, o uso de equipamentos ajuda as empresas a estabelecer imagens ambientais verdes, aumentando o valor da marca.

Inovação Tecnológica e Desenvolvimento Futuro

A tecnologia de reciclagem de EPS continua evoluindo. Aplicações de Inteligência Artificial já começaram a integrar-se ao design de equipamentos, com a Energycle aplicando tecnologia de inteligência artificial aos touchscreens e sistemas de controle de equipamentos. O modo de tempo e o modo de energia do equipamento de prensa fria são realizados através da inteligência artificial, com muitos controles de equipamentos utilizando sistemas de controle central para alcançar a gestão inteligente.

Otimização da Eficiência Energética é uma direção de desenvolvimento tecnológico crucial. Os novos equipamentos empregam sistemas de aquecimento econômicos, designs de espiral otimizados e tecnologia de controle de temperatura inteligente, reduzindo significativamente o consumo de energia enquanto garantem a eficácia do processamento. Alguns equipamentos também estão equipados com sistemas de recuperação de calor, utilizando o calor desperdiçado durante o processamento para pré-aquecer materiais brutos ou fornecer aquecimento para a fábrica.

Grau de Automatização continua a crescer. As máquinas modernas de reciclagem de EPS possuem sistemas de alimentação automáticos, ajuste de temperatura automático, corte automático e funções de deteção de qualidade automática, reduzindo significativamente a intervenção manual e facilitando a operação e os custos de mão-de-obra. Uma linha de produção de 500 kg/hora requer apenas 2-3 operadores para operação.

Kompatibilnost s više materijala é uma tendência emergente no desenvolvimento de equipamentos de reciclagem. Novos máquinas de reciclagem podem processar não apenas EPS, mas também acomodar XPS (polistireno extrudado), EPP (polipropileno expandido), EPE (polietileno expandido) e outros materiais de espuma, aumentando a flexibilidade de uso dos equipamentos e o valor do investimento.

Padrões Industriais e Melhores Práticas

Para garantir uma reciclagem eficiente e segura de EPS, as empresas devem seguir as melhores práticas da indústria. Gestão da Qualidade de Materiais-Prima é fundamental. Estabelecer sistemas de triagem de resíduos rigorosos, garantindo que o resíduo de EPS que entra no equipamento não contenha impurezas nocivas, como metais, pedras ou fitas excessivas. Considere instalar detectores de metais ou dispositivos de separação magnética nas entradas de alimentação para maior proteção do equipamento.

Obuka operatera não pode ser ignorado. Os operadores precisam de treinamento profissional para entender os princípios de funcionamento do equipamento, procedimentos de operação segura, problemas comuns de diagnóstico e pontos de manutenção diária. Os fabricantes geralmente fornecem manuais de operação detalhados e serviços de treinamento no local. As empresas devem aproveitar plenamente esses recursos.

Preventivno održavanje pode prolongar significativamente a vida útil do equipamento. Desenvolva planos de manutenção detalhados, incluindo inspeções diárias (limpeza de entradas de alimentação, verificação de lubrificação), manutenção semanal (limpeza de filtros, verificação do desgaste das lâminas) e serviços mensais (inspeção elétrica completa, substituição de peças de desgaste). Manter registros detalhados de manutenção ajuda a identificar problemas potenciais rapidamente.

Kontrola kvalitete permeia todo o processo de reciclagem. Teste regularmente os indicadores de qualidade dos grânulos ou blocos de saída, incluindo densidade, cor e conteúdo de impurezas. Estabeleça sistemas de rastreamento de qualidade, garantindo que os materiais reciclados atendam aos requisitos dos clientes downstream, criando condições favoráveis para a venda de materiais reciclados.

Zaključak

As máquinas de reciclagem de EPS representam direções tecnológicas avançadas na gestão moderna de resíduos plásticos. Através de workflows operacionais científicos e equipamentos profissionais, problemas de resíduos de espuma anteriormente complicados podem ser transformados em oportunidades de circulação de recursos valiosos. Desde coleta e triagem, processamento de trituração, derretimento e compactação até a pelotização final e armazenamento, cada etapa reflete a contribuição da inovação tecnológica para a proteção ambiental.

À medida que a atenção global ao meio ambiente continua a crescer, a tecnologia de reciclagem de EPS inevitavelmente receberá um espaço de desenvolvimento mais amplo. Seja para empresas de manufatura, empresas de reciclagem ou indústrias da construção, investir em equipamentos de reciclagem de EPS não apenas traz benefícios econômicos, mas também cumpre responsabilidades ambientais, contribuindo significativamente para o desenvolvimento sustentável. A seleção de equipamentos de reciclagem apropriados, o cumprimento de procedimentos operacionais corretos e a manutenção de uma gestão de manutenção padronizada plenamente realizam o valor da tecnologia de reciclagem de EPS, encontrando o equilíbrio ótimo entre proteção ambiental e lucratividade.